Documente Academic

Documente Profesional

Documente Cultură

WPQ WeldCanada PDF

Încărcat de

Ahmad DanielTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

WPQ WeldCanada PDF

Încărcat de

Ahmad DanielDrepturi de autor:

Formate disponibile

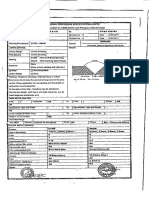

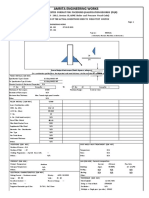

Welder Performance Qualification (WPQ)

ASME Boiler and Pressure Vessel Code, Section IX, QW-301

Company Name: WeldCanada.com

Company Address: info@WeldCanada.com, 1 (877) WPS-WELD

Welder Performance Qualification WPQ No. DEMO-WPQ Test Date: 12,12, 2005

Welding Procedure Specification WPS No. DEMO-WPS Rev. 0

Welder’s Name: Elvis Tom Jones Identification No: ETJ-2005 Stamp No: ETJ-05

BASE METALS (QW-403)

P-No: 1 Group No: 1 Material Specification: SA-36 Type or Grade: UNS No. K02600

Welded to

P-No: 1 Group No: 1 Material Specification: SA-36 Type or Grade: UNS No. K02600

Thickness in (mm): 1/2 in. (13 mm)

Test Coupon Production Weld Plate Pipe

Base Metals Thickness Qualified: No Limit

Welding Variables (QW-350) Actual Values Range Qualified

Diameter, if pipe or tube, in (mm) Plate tested 2-7/8 in. (73 mm) OD and over

Backing Without backing With or without backing

Base Metals P-Number to P-Number 1 to 1 P-No. 1 thru 15F, 34, 41 thru 49

1st Process 2nd Process 1st Process 2nd Process

Welding Process GMAW SMAW GMAW SMAW

Process Type Semi-Automatic Manual Semi-Automatic Manual

Testing Position 3G 3G

Vertical Progression Uphill Uphill Uphill Uphill

Welding Positions Qualified:

(A) Groove, Plate and Pipe over 24 in. (610 mm) OD F, V F, V

(B) Groove, Pipe 2-7/8 in. (73 mm)* to 24 in. (610 mm) OD, incl. [*or Min. qualified diameter, if testing small pipe] F F

(C) Fillet, Plate and Pipe for all thicknesses, fillet sizes, and diameters [when testing Groove] OR

(C) Fillet, Plate and Pipe 2-7/8 in. (73 mm) OD and over [when testing Plate Fillet] OR F, H, V F, H, V

(C) Fillet, Plate and Pipe within qualified diameter range [when testing Pipe Fillet]

Filler Metal Specification (SFA) SFA 5.18 SFA 5.1

Filler Metal Classification ER70S-6 E7018

Filler Metal F-Number 6 4 6 1 to 4

Filler Metal Product Type (GTAW, PAW) n/a n/a n/a n/a

Deposited Weld Thickness, in (mm) 1/8 in. (3 mm) 3/8 in. (10 mm) 1/4 in. (6 mm) 3/4 in. (20 mm)

Consumable Insert (GTAW, PAW) n/a n/a

GMAW Transfer Mode Short Circuit n/a Short Circuit n/a

GTAW Current Type/Polarity n/a n/a n/a n/a

Inert Gas Backing (GTAW, PAW, GMAW) none n/a with or without n/a

Type of Fuel Gas (OFW) n/a n/a n/a n/a

Results

Visual Examination of Completed Weld Result (QW-302.4): Acceptable criteria as per ASME QW-194

Guided-Bend Tests Type (QW-160): Transverse Side Bend Specimens (QW-462.2)

Alternative Volumetric Examination Results (QW-191): n/a RT or UT :

Result and Comments: Two side bend tests were examined as per ASME QW-462.2. Acceptable criteria as per ASME QW-163

Fillet-Weld Tests (QW-180): Plate [QW-462.4(b)]; Pipe-to-Plate or Pipe-to-Pipe [QW-462.4(c)]

Fracture Test (QW-182): n/a Length and Percent of Defects:

Macro-Examination (QW-184): n/a Fillet Size in (mm): X Concavity/Convexity in (mm):

Result and Comments: Groove weld test qualifies fillet weld test as well

Other tests and examinations: This Demo WPQ form has been prepared by WeldCanada.com Online Welding Software

Film or specimens evaluated by: Tom Jones Company: Testing Lab Data, Inc.

Mechanical tests conducted by: Mechanical Group, Ltd. Laboratory Test No. 1012-MIG

Welding supervised by: WeldCanada.com Certified Welding Inspector (CWI)

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and tested in accordance with the requirements of

Section IX of the ASME Boiler and Pressure Vessel Code.

Manufacturer/ Contractor

Authorized By:

Welding Engineer

Name: James Bond

Name: Joe Smith

Title: QA Manager

Title: Welding Engineer

Signature: J. B.

Signature: J. S.

Date: 14, 12, 2005

Date: 14, 12, 2005

S-ar putea să vă placă și

- Industrial radiography A Complete Guide - 2019 EditionDe la EverandIndustrial radiography A Complete Guide - 2019 EditionÎncă nu există evaluări

- WPQ Certificates Klis14Document8 paginiWPQ Certificates Klis14AdhicharanÎncă nu există evaluări

- Cert Piping W54.5Document2 paginiCert Piping W54.5SANU0% (1)

- 170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQDocument4 pagini170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionDocument1 paginăPt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionHaryanto RÎncă nu există evaluări

- Format WPQDocument2 paginiFormat WPQAkash Singh TomarÎncă nu există evaluări

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 paginiWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniÎncă nu există evaluări

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQDocument4 pagini163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Name:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWDocument2 paginiName:Murat First Name (S) : WPQ N°: TUR-18-A-931: Essential Variables (QW - 350) Actual Values Qualified Ranges QWSabit CirdiÎncă nu există evaluări

- WPS - 023Document10 paginiWPS - 023MAT-LION0% (1)

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 paginiQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.Încă nu există evaluări

- Surface Tension Transfer (STT) Pipe WeldingDocument3 paginiSurface Tension Transfer (STT) Pipe WeldingahmedÎncă nu există evaluări

- Welding Book Revised 2012 07 14Document15 paginiWelding Book Revised 2012 07 14surya1960Încă nu există evaluări

- Welding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDDocument5 paginiWelding Procedure Specification (WPS) (ASME SEC-IX QW-482) : Company Techno Weighsystems Pvt. LTDIskak TabriÎncă nu există evaluări

- SMAW DuniDocument4 paginiSMAW DuniMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- Welding Variable Calculator AS1554.1Document2 paginiWelding Variable Calculator AS1554.1Alin TomozeiÎncă nu există evaluări

- Qualified Welder List Valid Until - 03-12-2019Document2 paginiQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- QW-484A (WPQ) GTAW 4MM FilletDocument2 paginiQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- PQR TipsDocument4 paginiPQR TipsWaqas WaqasÎncă nu există evaluări

- 1035 03Document2 pagini1035 03Anuj ShahiÎncă nu există evaluări

- NSH-DALM-JERP-WPS-11-P2 Rev.00Document10 paginiNSH-DALM-JERP-WPS-11-P2 Rev.00Alam MD SazidÎncă nu există evaluări

- Ilcs-Smaw-D1.3-Deck (G) WPSDocument3 paginiIlcs-Smaw-D1.3-Deck (G) WPSRoss100% (1)

- Joints (Qw-402) DetailsDocument3 paginiJoints (Qw-402) DetailsNaqqash SajidÎncă nu există evaluări

- Asme PQR DemoDocument3 paginiAsme PQR DemoMuthusamy AyyanapillaiÎncă nu există evaluări

- Gta+sma PQRDocument3 paginiGta+sma PQRRahul MoottolikandyÎncă nu există evaluări

- Welder Qualification Test Certificate: Weld Test Details Range of ApprovalDocument1 paginăWelder Qualification Test Certificate: Weld Test Details Range of ApprovalRamkunwar YadavÎncă nu există evaluări

- API Welding Procedure Specification PDFDocument3 paginiAPI Welding Procedure Specification PDFBob LeeÎncă nu există evaluări

- Weldspec ASME PQRDocument2 paginiWeldspec ASME PQRSunil KumarÎncă nu există evaluări

- Welding Procedure Qualification Record: Shipyard LogoDocument4 paginiWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pagini2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanÎncă nu există evaluări

- Wps Mma PipeDocument2 paginiWps Mma PipeDimitris NikouÎncă nu există evaluări

- Acceptable Grade of Plate Material (API 650)Document1 paginăAcceptable Grade of Plate Material (API 650)juantamad02Încă nu există evaluări

- WPS RegisterDocument2 paginiWPS RegisterdaveswinburneÎncă nu există evaluări

- 004 Gtaw P5aDocument16 pagini004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- WPS SampleDocument182 paginiWPS Sampleaymenfr23Încă nu există evaluări

- WPS-43 - Gtaw & Smaw Tig + SmawDocument19 paginiWPS-43 - Gtaw & Smaw Tig + SmawAvinash ShrivastavaÎncă nu există evaluări

- WPS Format For Asme Ix - Wps - Gtaw - OverlayDocument1 paginăWPS Format For Asme Ix - Wps - Gtaw - OverlayThe Welding Inspections Community100% (1)

- Qw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )Document2 paginiQw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )essnelsonÎncă nu există evaluări

- HHHHHHHHJJJJJJ: O O O ODocument1 paginăHHHHHHHHJJJJJJ: O O O OAli MoosaviÎncă nu există evaluări

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 paginiHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnÎncă nu există evaluări

- ASMEDocument38 paginiASMEshazanÎncă nu există evaluări

- EFR-190719-PQR-01 - Shell Vertical-Horizontal PDFDocument11 paginiEFR-190719-PQR-01 - Shell Vertical-Horizontal PDFIonut FloricaÎncă nu există evaluări

- WPS PQR PDFDocument23 paginiWPS PQR PDFtomj9104Încă nu există evaluări

- Is 7310 RequirementsDocument4 paginiIs 7310 RequirementsRavichandran Tirupattur SubramaniamÎncă nu există evaluări

- Welding Procedure Specification For GTAW & GMAWDocument4 paginiWelding Procedure Specification For GTAW & GMAWanh thoÎncă nu există evaluări

- Tubular Butt Joint Configurations For Welder Qualification (With and Without Backing)Document21 paginiTubular Butt Joint Configurations For Welder Qualification (With and Without Backing)attaulla100% (1)

- QW-482 201.1Document2 paginiQW-482 201.1Barwin CruzÎncă nu există evaluări

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsDocument11 paginiCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONÎncă nu există evaluări

- WPS Resrvoire Sous Pression Smaw SawDocument6 paginiWPS Resrvoire Sous Pression Smaw SawDanem HalasÎncă nu există evaluări

- WPS & PQRDocument24 paginiWPS & PQRtulasirao.nammiÎncă nu există evaluări

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Document4 paginiProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabÎncă nu există evaluări

- Welder Job Clearance Card: Nesma/TanmiaDocument8 paginiWelder Job Clearance Card: Nesma/TanmiaMohamed Reda Hussein SengarÎncă nu există evaluări

- Registro de Calificacion Del Procedimiento (PQR) : JOINTS (QW-402)Document2 paginiRegistro de Calificacion Del Procedimiento (PQR) : JOINTS (QW-402)Anonymous Xa5rkMZm9ZÎncă nu există evaluări

- Amrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Document3 paginiAmrita Engineering Works: QW 483 Suggested Format For Pocedure Qualification Records (PQR)Balkishan DyavanapellyÎncă nu există evaluări

- 1 5 1Document5 pagini1 5 1daemsalÎncă nu există evaluări

- Welder Performance Qualification (WPQ)Document1 paginăWelder Performance Qualification (WPQ)JBStringerÎncă nu există evaluări

- SampleDocument5 paginiSample이훈Încă nu există evaluări

- Welder Certificate Akilesh YadavDocument1 paginăWelder Certificate Akilesh Yadavtripatipankaj023Încă nu există evaluări

- WPQ Sunil Yadav W-13 PQR 003 Smaw - PipeDocument1 paginăWPQ Sunil Yadav W-13 PQR 003 Smaw - Pipeharshileng3992100% (1)

- LP Formulation MITDocument27 paginiLP Formulation MITAhmad DanielÎncă nu există evaluări

- API Exams CalculationsDocument20 paginiAPI Exams CalculationssyedsayeediÎncă nu există evaluări

- MT 10 Om 02 LDocument20 paginiMT 10 Om 02 LAhmad DanielÎncă nu există evaluări

- WPS PQR PDFDocument23 paginiWPS PQR PDFAhmad Daniel100% (1)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 paginiWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielÎncă nu există evaluări

- UgCalculator V1.1Document1 paginăUgCalculator V1.1Ahmad DanielÎncă nu există evaluări

- BLOB AnalysisDocument9 paginiBLOB AnalysisAhmad DanielÎncă nu există evaluări

- Periodic Table IsotopesDocument1 paginăPeriodic Table IsotopeslamantreveurÎncă nu există evaluări

- NRC - 10 CFR Part 34-Licenses For Industrial Radiography and Radiation Safety Requirements For Industrial Radiographic OperationsDocument24 paginiNRC - 10 CFR Part 34-Licenses For Industrial Radiography and Radiation Safety Requirements For Industrial Radiographic OperationsAhmad DanielÎncă nu există evaluări

- NRC - 10 CFR Part 20-Standards For Protection Against RadiationDocument81 paginiNRC - 10 CFR Part 20-Standards For Protection Against RadiationAhmad DanielÎncă nu există evaluări

- Target Band 7 Trial Listening Edition4Document3 paginiTarget Band 7 Trial Listening Edition4Ahmad DanielÎncă nu există evaluări

- Playing Arpeggios Over Changes Ex in DmajDocument4 paginiPlaying Arpeggios Over Changes Ex in DmajMiguel PereiraÎncă nu există evaluări

- NRC - 10 CFR Part 71-Packaging and Transportation of Radioactive MaterialDocument70 paginiNRC - 10 CFR Part 71-Packaging and Transportation of Radioactive MaterialAhmad DanielÎncă nu există evaluări

- CEng Pink BookDocument46 paginiCEng Pink BookAhmad DanielÎncă nu există evaluări

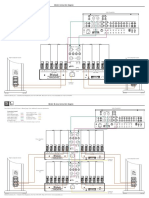

- MC452 Connection DiagramDocument2 paginiMC452 Connection DiagramAhmad DanielÎncă nu există evaluări

- Blues Scale W/tapping: 3-Notes Per Strings Mayones School #5Document1 paginăBlues Scale W/tapping: 3-Notes Per Strings Mayones School #5Ahmad DanielÎncă nu există evaluări

- Alessandro Amp ArticleDocument1 paginăAlessandro Amp ArticleAhmad DanielÎncă nu există evaluări

- XLogic X-Desk Install GuideDocument48 paginiXLogic X-Desk Install GuideAhmad DanielÎncă nu există evaluări

- MT 10 Om 02 LDocument20 paginiMT 10 Om 02 LAhmad DanielÎncă nu există evaluări

- X-Desk X-Panded Recall SheetDocument1 paginăX-Desk X-Panded Recall SheetAhmad DanielÎncă nu există evaluări

- WA Sabrina Hi Fi News 08-15Document3 paginiWA Sabrina Hi Fi News 08-15Ahmad DanielÎncă nu există evaluări

- Funk Guitar Rhythms Pt1 PDFDocument2 paginiFunk Guitar Rhythms Pt1 PDFAlvaro RodriguesÎncă nu există evaluări

- Audeze LCD-X PathosDocument3 paginiAudeze LCD-X PathosAhmad DanielÎncă nu există evaluări

- Bigsby Parts 2010Document85 paginiBigsby Parts 2010Ahmad DanielÎncă nu există evaluări

- HFN Pro-JectClassic LowresDocument3 paginiHFN Pro-JectClassic LowresAhmad DanielÎncă nu există evaluări

- Hamka Dibawah Lindungan KabahDocument1 paginăHamka Dibawah Lindungan KabahAhmad DanielÎncă nu există evaluări

- WA Sabrina Hi Fi News 08-15Document3 paginiWA Sabrina Hi Fi News 08-15Ahmad DanielÎncă nu există evaluări

- API 570 FormulasDocument2 paginiAPI 570 FormulasArif Mokhtar89% (9)

- HFN Pro-JectClassic LowresDocument3 paginiHFN Pro-JectClassic LowresAhmad DanielÎncă nu există evaluări

- Design of Purlins: Try 75mm X 100mm: Case 1Document12 paginiDesign of Purlins: Try 75mm X 100mm: Case 1Pamela Joanne Falo AndradeÎncă nu există evaluări

- Democracy or Aristocracy?: Yasir MasoodDocument4 paginiDemocracy or Aristocracy?: Yasir MasoodAjmal KhanÎncă nu există evaluări

- Introduction To Microelectronic Fabrication PDFDocument332 paginiIntroduction To Microelectronic Fabrication PDFChristy Moore92% (13)

- Unit 3: Theories and Principles in The Use and Design of Technology Driven Learning LessonsDocument5 paginiUnit 3: Theories and Principles in The Use and Design of Technology Driven Learning Lessons서재배Încă nu există evaluări

- 2396510-14-8EN - r1 - Service Information and Procedures Class MDocument2.072 pagini2396510-14-8EN - r1 - Service Information and Procedures Class MJuan Bautista PradoÎncă nu există evaluări

- Support Vector Machine Master ThesisDocument7 paginiSupport Vector Machine Master Thesistammymajorsclarksville100% (2)

- 8 Adam AmuraroDocument28 pagini8 Adam Amurarokmeena73Încă nu există evaluări

- PretestDocument8 paginiPretestAlmonte Aira LynÎncă nu există evaluări

- WD Support Warranty Services Business Return Material Authorization RMA Pre Mailer For ResellerDocument3 paginiWD Support Warranty Services Business Return Material Authorization RMA Pre Mailer For ResellerZowl SaidinÎncă nu există evaluări

- What Is Urban PlanningDocument33 paginiWhat Is Urban PlanningDivine Grace FernandoÎncă nu există evaluări

- Amerex Ansul Badger Ul Catalogo Por PartesDocument37 paginiAmerex Ansul Badger Ul Catalogo Por PartesPuma De La Torre ExtintoresÎncă nu există evaluări

- Ishrana Studenata I Nastavnika Visoke Škole U Subotici Tokom Pandemije COVID-19Document4 paginiIshrana Studenata I Nastavnika Visoke Škole U Subotici Tokom Pandemije COVID-19DejanÎncă nu există evaluări

- 2nd Second Sun of Advent (B)Document4 pagini2nd Second Sun of Advent (B)Max PolakÎncă nu există evaluări

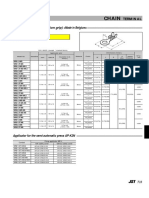

- Chain: SRB Series (With Insulation Grip)Document1 paginăChain: SRB Series (With Insulation Grip)shankarÎncă nu există evaluări

- Yu ZbornikDocument511 paginiYu ZbornikВладимирРакоњацÎncă nu există evaluări

- Technical Rockwell Automation FactoryTalk HistorianDocument6 paginiTechnical Rockwell Automation FactoryTalk HistorianAmit MishraÎncă nu există evaluări

- PedagogicalDocument94 paginiPedagogicalEdson MorenoÎncă nu există evaluări

- NauseaDocument12 paginiNauseakazakom100% (2)

- Bhavesh ProjectDocument14 paginiBhavesh ProjectRahul LimbaniÎncă nu există evaluări

- STW 44 3 2 Model Course Leadership and Teamwork SecretariatDocument49 paginiSTW 44 3 2 Model Course Leadership and Teamwork Secretariatwaranchai83% (6)

- Carbohydrates StainsDocument43 paginiCarbohydrates StainssupahvyÎncă nu există evaluări

- Present Perfect and Present Perfect ProgressiveDocument5 paginiPresent Perfect and Present Perfect ProgressiveKiara Fajardo matusÎncă nu există evaluări

- Module 5Document14 paginiModule 5shin roseÎncă nu există evaluări

- Class InsectaDocument4 paginiClass InsectaLittle Miss CeeÎncă nu există evaluări

- Ass AsDocument23 paginiAss AsMukesh BishtÎncă nu există evaluări

- Zillah P. Curato: ObjectiveDocument1 paginăZillah P. Curato: ObjectiveZillah CuratoÎncă nu există evaluări

- Icc Esr-2302 Kb3 ConcreteDocument11 paginiIcc Esr-2302 Kb3 ConcretexpertsteelÎncă nu există evaluări

- Using Your Digital Assets On Q-GlobalDocument3 paginiUsing Your Digital Assets On Q-GlobalRemik BuczekÎncă nu există evaluări

- LP Pe 3Q - ShaynevillafuerteDocument3 paginiLP Pe 3Q - ShaynevillafuerteMa. Shayne Rose VillafuerteÎncă nu există evaluări

- IPC PL 11 006 MS Auditors Issue 7.05Document32 paginiIPC PL 11 006 MS Auditors Issue 7.05saladinÎncă nu există evaluări