Documente Academic

Documente Profesional

Documente Cultură

Phasetester VX

Încărcat de

Hassan ManzarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Phasetester VX

Încărcat de

Hassan ManzarDrepturi de autor:

Formate disponibile

PhaseTester Multiphase Flowmeter

Well testing service for repeatable, highly accurate

measurements and reduced field development costs

APPLICATIONS A MULTIPHASE FLOWMETER FOR

■ Exploration, appraisal, and IMPROVED WELL DIAGNOSTICS

production well testing Designed for easy deployment,

■ Well cleanup optimization the PhaseTester* portable multi-

phase periodic well testing equip-

■ Production and fiscal allocation ment provides solutions-oriented

on land, platform, and services that cover the entire

subsea wells well testing process, from design

■ Production trending to reservoir interpretation.

Schlumberger offers service

■ Artificial lift system optimization

components to match the needs

■ Flow measurements in slugs, of each job, including site-specific

foams, and emulsions safety analysis, wellsite opera-

tions, well test reporting, well

BENEFITS data analysis, and production

diagnosis. With minimal footprint

■ Improved fluid characterization

and onsite installation needs, the

services

PhaseTester service reduces

■ Enhanced response time the cost per well tested through PhaseTester portable multiphase flowmeter.

■ Reduced field development efficiency and simplified logistics.

costs The PhaseTester units with Vx†

Combining the PhaseTester unit with the InterACT* real-time monitoring

■ Improved well diagnostics multiphase well testing tech-

and data delivery system enables stakeholders of well testing operations

and early water detection nology have excellent dynamic

to participate in the entire decision-making process.

response to fluctuating flows,

■ Eliminated test lines

require little or no stabilization

■ Enhanced installation and time, and are not affected by WHAT IS Vx TECHNOLOGY?

operation safety complex flow regimes such as Vx technology is at the core of the PhaseTester multiphase flowmeters,

■ Reduced gas flaring slug flow, foam, or emulsion providing enhancements and major performance improvements over

environments. The PhaseTester traditional testing methods. Functioning without the need for separation

system requires no process or an upstream mixing device, Vx technology minimizes the size and

FEATURES control because it is insensitive weight of the equipment.

■ Repeatable, highly accurate to changes in flow rate, phase Key to this superior measurement system is the venturi section with a

measurements holdup, and pressure regime. dual-energy gamma ray holdup meter. The system’s source and detector

■ Exceptional dynamic response Because the PhaseTester system elements are contained within pressure housings that provide an

■ Separation and flow calibration takes accurate and repeatable excellent barrier to well fluids.

not required measurements with little or no The PhaseTester flowmeter measures the total mass flow rate and the

stabilization time, as many as holdups of gas, oil, and water, which in turn are used to determine gas,

three wells can be tested per day oil, and water flow rates. Because no moving parts are required, the

on a typical production station. risk of erroneous measurements is reduced.

PhaseTester Multiphase Flowmeter

Flow

computer

Nuclear

detector

Venturi Nuclear

source

Differential-

pressure

transmitter

Pressure

transmitter

Flow

The design of the venturi section ensures accurate measurements of individual

flow rates under a wide range of conditions.

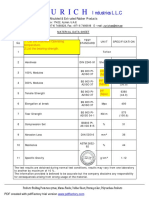

PhaseTester Specifications

Venturi size, mm [in] 52 [2.1] 29 [1.1]

Service H2S (wetted parts) H2S (wetted parts)

Max. working pressure, kPa [psi] 34,474 [5,000] 34,474 [5,000]

Temperature rating, degC [degF] –20 to 150 [–4 to 302] –20 to 150 [–4 to 302]

Ambient working, degC [degF] –20 to 85 [–4 to 185] –20 to 85 [–4 to 185]

Ambient storage, degC [degF] –40 to 85 [–40 to 185] –40 to 85 [–40 to 185]

Water/liquid ratio, % 0 to 100 0 to 100

Liquid viscosity at line conditions, Pa.s [cP] 0.0001 to 2 [0.1 to 2,000] 0.0001 to 2 [0.1 to 2,000]

Max. flow capacity

Liquid flow rate, m3/d [bbl/d] 6,300 [39,500] 2,050 [12,900]

Gas flow rate, MMm3/d [MMcf/d] 3.2 [116] 1 [36.3]

Repeatability (total mass rate at line conditions) Better than ±1% Better than ±1%

Resolution (total mass rate at line conditions) Better than ± 0.1% Better than ± 0.1%

Dimensions (W × D × H), m [ft] 1.50 × 1.65 × 1.77 1.50 × 1.65 × 1.77

[4.92 × 5.41 × 1.77] [4.92 × 5.41 × 1.77]

Weight, kg [lbm] 1,696 [3,740] 1,696 [3,740]

Connections

Inlet Blind tee with 5-in GRAYLOC® hub Blind tee with 5-in GRAYLOC hub

Outlet 5-in GRAYLOC hub 5-in GRAYLOC hub

Power consumption, W 22 continuous 22 continuous

Hazardous area classification ATEX EEx de II B T4 IP 66 ATEX EEx de II B T4 IP 66

Client PVT data usable in PhaseTester processing Yes Yes

Sampling ports Liquid and gas sampling facilities Liquid and gas sampling facilities

www.slb.com/welltesting

06-WT-124 April 2007

*Mark of Schlumberger †Joint mark of Schlumberger and Framo

Other company products and service names are the properties of their respective owners.

Copyright © 2007 Schlumberger. All rights reserved.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5795)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1091)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Lubrication of Cameron ValvesDocument10 paginiLubrication of Cameron ValvesHassan Manzar100% (2)

- TetraSentry SIL Verification Report PDFDocument19 paginiTetraSentry SIL Verification Report PDFHassan ManzarÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldDocument27 paginiSaudi Aramco Inspection Checklist: Review WPS & Process Control Procedure (Plant Piping) SAIC-W-2001 15-Dec-09 WeldIrshad IqbalÎncă nu există evaluări

- Demoversion IWE 2011Document47 paginiDemoversion IWE 2011Burag HamparyanÎncă nu există evaluări

- Learning Activity Sheets: Ganilyn D. Ponciano. Stem 12 - A General Chemistry 2Document7 paginiLearning Activity Sheets: Ganilyn D. Ponciano. Stem 12 - A General Chemistry 2Ganilyn Ponciano0% (3)

- Plant Design For The Production of Sodium CarbonateDocument29 paginiPlant Design For The Production of Sodium CarbonateMuhammad Adeel KhalidÎncă nu există evaluări

- Ion Exchange Process Problems SolutionsDocument73 paginiIon Exchange Process Problems Solutionsanup_nairÎncă nu există evaluări

- Directive 056Document339 paginiDirective 056Hassan ManzarÎncă nu există evaluări

- Front Burner: UpdateDocument3 paginiFront Burner: UpdateHassan ManzarÎncă nu există evaluări

- Heat Protection Measures at ZZ2Document1 paginăHeat Protection Measures at ZZ2Hassan ManzarÎncă nu există evaluări

- VX Multi Phasse TesterDocument8 paginiVX Multi Phasse TesterHassan ManzarÎncă nu există evaluări

- Examen de Evaluación API 571Document18 paginiExamen de Evaluación API 571berray2007100% (2)

- Flame Retardant Finish: Submitted By:-Ravi Bhushan Ritesh RamanDocument11 paginiFlame Retardant Finish: Submitted By:-Ravi Bhushan Ritesh RamanRitesh Raman50% (2)

- R Series Regulators: HPC Single and Two Stage RegulatorsDocument2 paginiR Series Regulators: HPC Single and Two Stage RegulatorspcatruongÎncă nu există evaluări

- Sensors and Actuators B: Chemical: Mariajose Gonzalez-Guerrero, Frank A. Gomez TDocument8 paginiSensors and Actuators B: Chemical: Mariajose Gonzalez-Guerrero, Frank A. Gomez TAllen PrasadÎncă nu există evaluări

- CF1FR v2.0 OnlineDocument2 paginiCF1FR v2.0 OnlineAnonymous 3VAQ9SNxl7Încă nu există evaluări

- Creatinine: Kinetic MethodDocument2 paginiCreatinine: Kinetic MethodVenura VishwajithÎncă nu există evaluări

- Impression Materials Techniques Procedures For Complete Dentures ProsthoDocument30 paginiImpression Materials Techniques Procedures For Complete Dentures ProsthoMaha Lakshmi100% (1)

- Fluidum R11Document2 paginiFluidum R11عبدالعزيز مقيطوفÎncă nu există evaluări

- Basic Electronics1Document27 paginiBasic Electronics1api-291159108Încă nu există evaluări

- Chapter 22 Problems 1,, Straightforward, IntermediateDocument12 paginiChapter 22 Problems 1,, Straightforward, Intermediatecobalt boronÎncă nu există evaluări

- DSGHRTHDDocument12 paginiDSGHRTHDMary Grace VelitarioÎncă nu există evaluări

- Irjet V6i6747Document5 paginiIrjet V6i6747Felipe FurtadoÎncă nu există evaluări

- Presentation - Present Status of Building Materials - G-3Document6 paginiPresentation - Present Status of Building Materials - G-3Tanvir AhmadÎncă nu există evaluări

- Chem01 - Matter Concept MapDocument1 paginăChem01 - Matter Concept MapKerzona Harriet CababasadaÎncă nu există evaluări

- Soil Stabilisation Using Flyash: Civil EngineeringDocument28 paginiSoil Stabilisation Using Flyash: Civil EngineeringNeeraj GuptaÎncă nu există evaluări

- Me8391 Engineering ThermodynamicsDocument1 paginăMe8391 Engineering ThermodynamicsAiam PandianÎncă nu există evaluări

- Chapter-6 Life Processes MCQsDocument13 paginiChapter-6 Life Processes MCQsfagstdjdÎncă nu există evaluări

- Cannabis ManufacturingDocument6 paginiCannabis ManufacturingSebastián RamirezÎncă nu există evaluări

- MAT 2640 MCGB - Data Sheet For Suppliers Old MAT No.: 308Document3 paginiMAT 2640 MCGB - Data Sheet For Suppliers Old MAT No.: 308pkjenaleoÎncă nu există evaluări

- Paschotta2010 - Derivation of The Schawlow - Townes Linewidth of LasersDocument6 paginiPaschotta2010 - Derivation of The Schawlow - Townes Linewidth of LasersHiso JokeyÎncă nu există evaluări

- Teflon MDSDocument1 paginăTeflon MDSSajir ThiyamÎncă nu există evaluări

- NEA Office IAQ GuidelinesDocument47 paginiNEA Office IAQ GuidelinesAndy AnxietyÎncă nu există evaluări

- By DR Ananya MandalDocument4 paginiBy DR Ananya MandalhasimÎncă nu există evaluări

- Compound CylindersDocument20 paginiCompound CylindersEbeda BenardÎncă nu există evaluări

- Presentasi IKOM Handover Gas Metering Services PHE Jambi Merang (20jan2022)Document47 paginiPresentasi IKOM Handover Gas Metering Services PHE Jambi Merang (20jan2022)irwanypcÎncă nu există evaluări