Documente Academic

Documente Profesional

Documente Cultură

Chapter 11.en - Es

Încărcat de

Cristian RemacheTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Chapter 11.en - Es

Încărcat de

Cristian RemacheDrepturi de autor:

Formate disponibile

08.09.98 AC 43.

13-1B

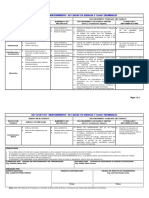

Artículo 8. Requisitos del cableado de instalación Inspección

11-96. GENERAL. Alambres y cables e. Clamp retaining screws are properly secured so that

deben ser inspeccionados para verificar su adecuación de apoyo, la the movement of wires and ca- bles is restricted to the

protección y el estado general en todas partes. Las características span between the points of support and not on soldered or

deseables y no deseables en instalaciones de cableado embarcaciones mechanical connections at terminal posts or connectors.

con aire se enumeran a continuación e indican condiciones que pueden

o no pueden existir. En consecuencia, el cableado de la aeronave debe

ser inspeccionado visualmente para los siguientes requisitos: f. Wire and cables are properly supported and bound so

that there is no interference with other wires, cables, and

equipment.

PRECAUCIÓN: Para su seguridad personal y para

evitar la posibilidad de incendio, apague toda la g. Wires and cables are adequately sup- ported to

energía eléctrica antes de iniciar una inspección del prevent excessive movement in areas of high vibration.

sistema eléctrico de la aeronave o realizar el

mantenimiento.

h. Insulating tubing is secured by tying, tie straps

a. Alambres y cables are supported by suitable or with clamps.

clamps, grommets, or other devices at intervals of not

more than 24 inches, except when contained in troughs, i. Continuous lacing ( spaced 6 inches apart) is not

ducts, or conduits. The supporting devices should be of a used, except in panels and junc- tion boxes where this

suitable size and type, with the wires and cables held practice is optional. When lacing is installed in this

securely in place without damage to the insu- lation. manner, out- side junction boxes should be removed and

re- placed with individual loops.

b. Metal stand-offs must be used to maintain j. Do not use tapes ( such as friction or plastic tape)

clearance between wires and struc- ture. Employing which will dry out in service, pro- duce chemical reactions

tape or tubing is not accept- able as an alternative to with wire or cable in- sulation, or absorb moisture.

stand-offs for main- taining clearance.

k. Insulating tubing must be kept at a minimum

c. Phenolic blocks, plastic liners, or rubber and must be used to protect wire and cable from

grommets are installed in holes, bulk- heads, floors, or abrasion, chafing, exposure to fluid, and other conditions

structural members where it is impossible to install which could affect the cable insulation. However; the

off-angle clamps to maintain wiring separation. In such use of in- sulating tubing for support of wires and cable

cases, ad- ditional protection in the form of plastic or in- in lieu of stand-offs is prohibited.

sulating tape may be used.

l. Do not use moisture-absorbent material as “fill” for

d. Wires and cables in junction boxes, panels, and clamps or adapters.

bundles are properly supported and laced to provide

proper grouping and routing. m. Ensure that wires and cables are not tied or

fastened together in conduit or insulat- ing tubing.

par 11-96 página 11-43

AC 43.13-1B CHG 1 9/27/01

n. Ensure cable supports do not restrict the wires or combustible, u oxígeno línea, de la pared del depósito de combustible,

cables in such a manner as to in- terfere with operation o de otro cableado de baja tensión que entra en un depósito de

of equipment shock mounts. combustible y requiere el aislamiento eléctrico para evitar un peligro

ción igni-. Cuando no puede prácticamente ser proporcionado 6

espaciamiento pulgadas, un mínimo de 2 pulgadas debe mantenerse

o. Do not use tape, tie straps, or cord for primary entre el cableado y tales líneas, equipo relacionado, las paredes del

support. tanque de combustible y el cableado de baja tensión que entra en un

depósito de combustible. Tal cableado debe estar estrechamente

p. Make sure that drain holes are pres- ent in drip sujeta y con soporte rígido y atado a intervalos de tal manera que no

loops or in the lowest portion of tubing placed over the ocurriría de contacto betwe4en tales líneas, sobre Equipos

wiring. relacionados, las paredes del tanque de combustible u otros cables,,

suponiendo un cable roto y un lazo de alambre que falta o abrazadera.

q. Ensure that wires and cables are routed in such

a manner that chafing will not occur against the

airframe or other compo- nents.

X. Asegúrese de que un bucle de trampa o goteo se

proporciona para evitar que los fluidos o hume- dad condensada se

r. Ensure that wires and cables are po- sitioned in ejecute en alambres y cables vestidos hacia abajo a un conector,

such a manner that they are not likely to be used as bloque de terminales, el panel, o caja de conexiones.

handholds or as support for personal belongings and

equipment.

y. Hilos y cables instalados en las sentinas y otros lugares

s. Ensure that wires and cables are routed, insofar donde los fluidos pueden ser atrapados son encaminadas en la

as practicable, so that they are not exposed to damage medida desde el punto más bajo posible o proporcionado de otro

by personnel moving within the aircraft. modo con una cubierta a prueba de humedad.

t. Ensure that wires and cables are lo- cated so as not z. cables separados de equipos de alta temperatura, tales como

to be susceptible to damage by the storage or shifting of resistencias, pilas de escape, los conductos de calefacción, etc., para

cargo. prevenir un aislamiento averiado.

Aislar los cables que se deben ejecutar a través de

u. Ensure that wires and cables are routed so that áreas calientes con un material de aislamiento de alta temperatura,

there is not a possibility of dam- age from battery tales como fibra de vidrio o PTFE. Evitar las zonas de alta

electrolytes or other corrosive fluids. temperatura cuando se utilizan cables que tienen aislamiento de

plástico blando tal como ileno polyeth-, debido a que estos

materiales están sujetos a deterioro y deformación a tem- peraturas

v. Ensure that wires and cables are ade- quately elevadas. Muchos cables coaxiales tienen este tipo de aislamiento.

protected in wheel wells and other ar- eas where they

may be exposed to damage from impact of rocks, ice,

mud, etc. (If re-

routing of wires or cables is not practical, pro- tective Automóvil club británico. El radio mínimo de curvas en grupos

jacketing may be installed). This type of installation must de cables o haces no debe ser inferior a 10 veces el diámetro exterior

be held to a minimum. del alambre o de cable más grande, a excepción de que en las

regletas de terminales donde los cables estallan en las terminaciones

w. Where practical, route electrical wires and cables o RE-

above fluid lines and provide a 6 inch separation from

any flammable liquid,

Page 11-44 Par 11-96

09.27.01 AC 43.13-1B CHG 1

dirección verso en un paquete. Cuando el alambre se (4) Permitir el cambio de equipo, según sea necesario, para

apoya adecuadamente, el radio puede ser de 3 veces el llevar a cabo la alineación, mantenimiento, puesta a punto, la

diámetro del alambre o cable. Cuando no sea práctico eliminación de las tapas de polvo, y el cambio de los componentes

instalar el cableado o los cables dentro de los requisitos internos mientras está instalado en aire oficio.

de radio, la curva debe ser encerrado en tubos aislantes.

El radio de cable del termopar debe hacerse en ajustan

ción recomendación del fabricante y deberá ser suficiente ff. Asegúrese de que los cables no utilizados son

para evitar pérdidas excesivas o daños en el cable. individualmente-muerto composición, atado en un haz, y asegurada a

una estructura permanente. Cada alambre debería haber hebras

cortar incluso con el aisla- miento y un conector de extremo cerrado

pre-aislado o una pieza de 1 pulgada de tubo colocado sobre el

cama y desayuno. Asegurarse de que los cables de RF, por ejemplo,alambre

coaxial con su extremo doblado hacia atrás y atado aislante.

y triaxial están dobladas en un radio de no menos de 6 veces

el diámetro exterior del cable.

gg. Asegúrese de que todos los cables se identifican

cc. Asegúrese de que los alambres y cables, que están adecuadamente a intervalos de no más de 15 pulgadas. Los cables

unidos a los conjuntos cuando se produce un movimiento relativo coaxiales se identifican en ambos extremos del equipo.

(como en las bisagras y piezas Tating ro-; en particular las

puertas, palancas de control, ruedas de control, columnas, y

superficies de control de vuelo), se instalan o protegidas de una 11-97. SUSTITUCIÓN DE CABLEADO. ING Wir- debe ser

manera tal como para evitar el deterioro de los alambres y cables reemplazado con el alambre equivalente (ver párrafo 11-78) cuando

causadas por el movimiento relativo de las piezas montadas. se encuentran a tener cualquiera de los siguientes defectos:

a. Alambrado que ha sido sometido a desgaste por fricción y el

dd. Asegúrese de que los cables y bles ca- eléctricas están deshilachado, que ha sido severamente DAÑAR, o que el

separados de bles de control de ca- mecánicas. aislamiento primario es sospechoso de ser penetrado.

En ningún caso debe cablear ser capaz de llegar más

cerca de 1/2 pulgada a dichos controles cuando se aplica una ligera

presión manual a los alambres o controles. En los casos donde el segundo. Alambrado en el que el aislamiento exterior es frágil

espacio es menor que este, el apoyo adecuado se debe hasta el punto que una ligera flexión hace que se agriete.

proporcionar para evitar rozaduras.

do. Alambrado que tiene aislamiento exterior tiempo-agrietado.

ee. Asegúrese de que los alambres y cables se proporcionan

con suficiente holgura para cumplir con los requisitos siguien- tes:

re. Alambrado que se sabe que se han expuesto al

electrólito o en el que el aislamiento parece ser, o es

(1) Permitir la facilidad de mantenimiento. sospechoso de ser, en una etapa inicial de deterioro

debido a los efectos de electrolito.

(2) Evitar la tensión mecánica sobre los alambres,

cables, empalmes, y soportes.

(3) Permitir el movimiento libre de shock y equipo

montado vibración.

par 11-96 página 11-45

AC 43.13-1B CHG 1 09.27.01

mi. Compruebe el cableado que muestra evidencia de específico para el modo de degradación del Reglamento de insu-. Si

sobrecalentamiento (aunque sólo sea en un grado menor) para la las muestras fallan cualquiera de los ensayos de integridad eléctricos

causa del sobrecalentamiento. o químicos, entonces el cableado en el área que rodea el área de

muestreo es un candidato para la sustitución.

F. Alambrado en el que el aislamiento tiene BE- llegado

saturado con aceite de motor, fluido hidráulico, u otro lubricante.

11-98. TERMINALES Y bloques de terminales. Inspeccionar

para asegurar que se cumplen los requisitos de instalación

gramo. Alambrado ése da evidencias de haber sido si- guiente:

aplastado o muy retorcido.

a. tubos aislantes se coloca sobre termina- Nals

h. cableado blindado en el que el blindaje metálico está (excepto tipos preaislados) para proporcionar protección

deshilachado y / o corroído. Los agentes de limpieza o conservantes eléctrica y soporte mecánico y está asegurado para evitar el

no deben ser utilizados para reducir al mínimo los efectos de la deslizamiento de la tubería de la terminal.

corrosión o deterioro de los escudos de alambre.

segundo. bloques del módulo de terminales están montados de

yo. Alambrado que muestra evidencia de roturas, grietas, suciedad forma segura y provisto de distancias eléctricas adecuadas o

o humedad en las fundas de plástico colocados sobre empalmes de tiras de aislamiento entre

cables o terminales de cable. hardware de montaje y las partes conductoras, CEPT ex cuando se

utiliza el bloque de terminales para los propósitos de puesta a tierra.

j. Las secciones de alambre en el que empalmes ocurrir a

intervalos de menos de 10 pies, a menos Específicamente autorizado,

debido a las conexiones en paralelo, ubicaciones o inaccesibilidad. do. Las conexiones de terminales al terminal

espárragos y tuercas en los pernos utilizados en bloque del módulo

están apretados.

k. Al sustituir el cableado o ca- coaxial bles, identificarlos

correctamente en ambos equipos y fuente de alimentación termina. re. La evidencia de sobrecalentamiento y Sion corrosión no está

presente en las conexiones a los pernos prisioneros módulo de bloque

de terminales.

l. substitution- hilo En la reparación y modificación de

aeronaves existentes, cuando se requiere la colocación de un mi. Daño físico a los postes, roscas de los espárragos, y

alambre re-, el manual de mantenimiento para que las los bloques de módulo terminal no es evidente. Reemplazar

aeronaves deben primero ser re-vista para determinar si el regletas de bornes agrietados y los pernos con roscas.

fabricante original de la aeronave (OAM) ha aprobado ningún

titución sub.

Si no, entonces el OAM debe ser F. El número de conexiones de terminales

contactado para un reemplazo aceptable. a un perno bloque de terminales no exceda de cuatro, a menos que

específicamente autorizado.

metro. Prueba de la integridad cal eléctrica y químicamente del

aislamiento de los hilos de muestra tomados de áreas de la aeronave gramo. blindaje debería estar muerta de composición con

que tiene problemas de cableado con conocimientos avanzados en el terminales aislados adecuados.

pasado, se puede utilizar para complementar el examen visual del

alambre. La prueba para la integridad química debe ser h. Todos los cables, bloques de terminales, y clavos viduales

indi- están claramente identificados para los corresponden con

manuales de circuitos aviones.

página 11-46 par 11-97

09.27.01 AC 43.13-1B CHG 1

yo. terminaciones debe hacerse utilizando terminales del tamaño de modo que el apriete de la tapa del adaptador abrazadera de cable

adecuado y las herramientas que prensan terminales apropiados. proporciona un agarre suficiente en los cables para mantener la

tensión de ser aplicada a los pasadores Nector con-.

11-99. FUSIBLES Y portafusibles.

Inspeccionar la siguiente manera: re. Hacer tapones no utilizados seguro y receptáculos están

cubiertos para evitar la inclusión de polvo y humedad. Los

a. revisión de seguridad de conexiones a los portafusibles. recipientes deben tener tapas para el polvo de material compuesto

unidos por su método mal apareamiento nor- metal o. Plugs

pueden tener una tapa contra el polvo similar al anterior, o tener

Inspeccionar la presencia de la corrosión

segundo. una pieza de enfundado retráctil de poliolefina encogido sobre el

y la evidencia de sobrecalentamiento de fusibles y portafusibles. conector, a partir de los hilos nueva carcasa, con una cola

Cambiar los fusibles y portafusibles corroídos limpias. suficientemente el tiempo suficiente para hacer doble hacia atrás

Si la evidencia de sobrecalentamiento es sobre el conector y ser atado con cinta éster poli- cordón detrás de

encontrado, comprobar si hay valor correcto del fusible. la tuerca de acoplamiento. La etiqueta de identificación cable debe

ser visible almacenado detrás el conector o una etiqueta debe

do. Comprobar la seguridad de montaje del portafusibles. estar unido identificar el circuito asociado o equipo de fijación. El

conector debe estar unido a la estructura por sus medios de

montaje normales o por el uso de abrazaderas apropiadas.

re. Inspeccionar para la reposición de piezas de fusibles

utilizados en vuelo. Reemplazar con fusibles de AP- única valoración

actual apro-.

mi. Controlar por fusibles expuestos susceptibles a mi. Asegúrese de que los conectores están totalmente acoplada

cortocircuito. Instalar la cubierta de no conductor por la posición y la estanqueidad de anillo de acoplamiento o de su

el material si es necesario. alineación con la línea de indicador totalmente acoplada en el

receptáculo de cheques, si es aplicable.

11-100. Conectores. Asegurar la fiabilidad de los conectores mediante

la verificación de que las condiciones siguientes se cumplen o que las F. Asegúrese de que la tuerca de acoplamiento de conectores

reparaciones se efectúan según se requiera. MS está safetied, por hilo o por otros medios me- chanical de bloqueo,

como es requerido por los manuales de instrucción de aeronaves cable

muy favorable.

a. inspeccione los conectores para la seguridad y la

evidencia de sobrecalentamiento (causa del sobrecalentamiento debe gramo. Asegúrese de que mate- rial absorbente de humedad No

ser corregido), y los exteriores de la corrosión y grietas. También, los se utiliza como “relleno” para las abrazaderas MS3057 o adaptadores.

cables que conducen a los conectores deben ser inspeccionados por el

deterioro debido al sobrecalentamiento. Reemplazar las conexiones

corroídas y conectores sobrecalentados. h. Asegúrese de que no hay ninguna evidencia de deterioro tales

como agrietamiento, falta, o la desintegración del material de

encapsulamiento.

segundo. asegurar una instalación de la abrazadera del cable

(referencia MIL-C-85049) adaptadores en aplica- conectores MS ble, yo. conectores idénticos en ciones PAR- adyacentes puede

excepto los que son a prueba de humedad. conducir a conexiones incorrectas. Cuando este tipo de instalaciones

son inevitables, el documento adjunto

do. Ver que la cinta de silicona se envuelve alrededor de los

cables en MS3057 adaptadores de sujeción cable

par 11-98 página 11-47

AC 43.13-1B CHG 1 09.27.01

el cableado debe ser claramente identificada y debe ser enrutado y Metálica flexible y no metálicos rígidos. Inspección de

se sujeta de manera que no puede ser igualada mis-. conducto ensamblajes de la articulación debe cerciorarse

de que:

j. Conectores en áreas no presurizadas a. Conduit es aliviado de tensión y ing flexi- de férulas.

deben colocar de manera que la humedad se drene fuera de ellos

cuando no acoplamiento. Salida- cables conectores ing deben

colocarse de forma que drena la humedad lejos de ellos. segundo. El conducto no se derrumbó o aplanada de una

flexión excesiva.

11-101. Cajas de conexiones, paneles, pantallas, y el do. Conductos no será fluidos trampa o con- humedad

microinterruptor HOUS- Ings. Examinar conjuntos de condensada. orificios de drenaje adecuados deben ser proporcionados

alojamiento a ascer- tain lo siguiente: en los puntos bajos.

re. abrazaderas de unión no causar daños en el conducto.

a. Verificar que uno o más adecuados agujeros, sobre 3

diámetro / 8 pulgadas, pero no menos de 1/8 pulgadas de

diámetro, están dispuestos en el punto más bajo de la caja, mi. escudos resistentes a la atmósfera en duits con- flexibles del

excepto las cajas de vapor-apretado, para permitir el drenaje con tren delantero y el aterrizaje principal y en huecos de las ruedas no

la aeronave en el suelo o en el nivel de vuelo. están rotas; que trenza metálica del conducto resistente a la intemperie

no está expuesto; y que las tuercas de conducto, férulas, y accesorios

de conducto se instalan de forma segura.

segundo. Verificar que el vapor de cajas cerradas o prueba de

explosiones están etiquetados externamente Al vapor PRUEBA

APRETADO o explosión. F. Acaba de conductos abiertos se acampanado o enrutado para

evitar bordes afilados que podrían rozar los cables que salen desde el

do. Verificar que las cajas están montados de forma segura. conducto.

11-103. Bifurcaciones. Asegúrese de que sólo aire fabricante

re. Verificar que las cajas están limpios internamente y libre de embarcaciones dispositivos aprobados, tales como terminales de tipo

objetos extraños. sin soldadura, bloques de terminales, conectores, empalmes de

desconexión, empalmes permanentes, y casquillos pasantes se

mi. Verificar que el cableado de seguridad está instalado en todos utilizan para uniones de cables.

los sujetadores tapa en J-cajas, paneles, pantallas, o alojamientos Controlar por las disposiciones

microinterruptor que se instalan en zonas no accesibles para la se describe a continuación:

inspección en vuelo, a menos que los elementos de fijación incorporan

dispositivos de autobloqueo. a. uniones eléctricas should be pro- tected from

short circuits resulting from movement of personnel,

cargo, cases, and other loose or stored materials.

F. Verificar que la caja de cableado está alineado correctamente. Protection should be provided by covering the junction,

installing them in junction boxes, or by locat- ing them

in such a manner that additional pro- tection

gramo. Verificar que no hay agujeros, desenchufados no se utilice

(con excepción de los agujeros de drenaje) en cajas. is not required, etc.

11-102. CONDUCTO - metálico rígido,

página 11-48 par 11-100

9/27/01 AC 43.13-1B CHG 1

b. Exposed junctions and buses should be protected

with insulating materials. Junc- tions and buses located 11-106. ELECTROMAGNETIC INTER- FERENCE

within enclosed areas containing only electrical and (EMI). Wiring of sensitive cir- cuits that may be affected

electronic equipment are not considered as exposed. by EMI must be routed away from other wiring

interference, or provided with sufficient shielding to

avoid system malfunctions under operating condi- tions.

c. Electrical junctions should be me- chanically and EMI between susceptible wiring and wiring which is a

electrically secure. They should not be subject to source of EMI increases in proportion to the length of

mechanical strain or used as a support for insulating parallel runs and decreases with greater separation.

materials, except for in- sulation on terminals. EMI should be limited to negligible levels in wiring

related to critical systems, that is, the function of the

critical system should not be affected by the EMI

11-104. CIRCUIT BREAKERS. Note generated by the adjacent wire. Use of shielding with

those circuit breakers which have a tendency to open 85 percent coverage or greater is recommended.

circuits frequently, require resetting more than normal, or Coaxial, triaxial, twinaxial, or quadraxial cables should

are subject to nuisance trip- ping. Before considering their be used, wherever appropriate, with their shields

replacement, investigate the reason. connected to ground at a single point or multiple points,

de- pending upon the purpose of the shielding. The

airframe grounded structure may also be used as an

11-105. SYSTEM SEPARATION. Wires of redundant EMI shield.

aircraft systems should be routed in separate bundles

and through separate con- nectors to prevent a single

fault from disabling multiple systems. Wires not

protected by a circuit-protective device, such as a circuit

breaker or fuse, should be routed separately from all 11-107. INTERFERENCE TESTS. Per-

other wiring. Power feeders from separate sources form an interference test for installed equip- ment and

should be routed in separate bundles from each other electrical connections as follow:

and from other air- craft wiring, in order to prevent a

single fault from disabling more than one power source. a. The equipment must be installed in ac- cordance

The ground wires from aircraft power sources should be with manufacturer’s installation in- structions. Visually

attached to the airframe at separate points so that a inspect all the installed equipment to determine that

single failure will not disable multiple sources. Wiring industry standard workmanship and engineering practices

that is part of elec- tro-explosive subsystems, such as were used. Verify that all mechanical and electrical

cartridge- actuated fire extinguishers, rescue hoist shear, connections have been properly made and that the

and emergency jettison devices, should be routed in equipment has been located and installed in accordance

shielded and jacketed twisted-pair cables, shielded with the manufacturer’s recom- mendations. The wire

without discontinuities, and kept separate from other insulation temperature rating should also be considered.

wiring at connectors. To facilitate identification of specific

separated system bundles, use of colored plastic cable

ties or lacing tape is allowed. During aircraft

maintenance, colored plastic cable straps or lacing tape b. Power input tests must be conducted with the

should be replaced with the same type and color of tying equipment powered by the airplane’s electrical power

materials. generating system, unless oth- erwise specified.

Par 11-103 Page 11-49

AC 43.13-1B CHG 1 9/27/01

c. All associated electrically operated equipment and the equipment manufacturer should design for

systems en el avión debe estar encendido y funcionamiento antes all installation environ- ments. The installing

de realizar las pruebas de interferencia, a menos que se especifique facility will be responsible for resolving any

lo contrario. incom- patibility between this equipment and

previously installed equipment in the airplane.

re. Los efectos en la interferencia debe ser evaluado como The various factors con- tributing to the

sigue: incompatibility should be considered.

(1) El equipo no debe ser la fuente de interferencia

perjudicial conducción o radiación o afectar

negativamente a otros equipos o sistemas instalados en NOTE: Ground EMI test have consis- tently

el avión. been found adequate for fol- low-on approvals

of like or identical equipment types,

(2) Con el equipo energizado en el suelo, operar irrespective of the airplane model used for the

individualmente otros equipos y sistemas eléctricamente

initial ap- proval. Radio frequency

camente operado en el avión para determinar que no existe

transmission devices, such as wireless

interferencia por conductos o radiada con- significativo.

telephones, must also be tested with respect

Evaluation comió todas las combinaciones razonables de Tings

to their transmission frequencies and

de control conjunto- y modos de operación. Operar comu-

nicación y el equipo de navegación de al menos una baja alta y harmonics. 11-108.

media-banda de frecuencia,. Tome nota de los sistemas o

modos de operación que también debe ser evaluado durante el IDENTIFICATION STENCILS AND

vuelo. PLACARDS ON ELECTRICAL EQUIPMENT. Replace

worn stencils and missing placards.

(3) For airplane equipment and systems that can be

checked only in flight, determine that no operationally 11-109. • • 11-114. [RESERVED.]

significant conducted or radiated interference exists.

Evaluate all rea- sonable combinations of control settings

and operating modes. Operate communications and

navigation equipment on at least one low, high and

mid-band frequency.

NOTE: Electromagnetic compatibil- ity

problems which develop after in- stallation of

this equipment may result from such factors

as design charac- teristics of previously

installed systems or equipment, and the

physical in- stallation itself. It is not intended

that

Page 11-50 Par 11-107

9/27/01 AC 43.13-1B CHG 1

SECCIÓN 9. PROTECCIÓN AMBIENTAL E INSPECCIÓN

11-115. MANTENIMIENTO Y OPERA- CIONES. Wire

bundles must be routed in ac- cessible areas that are

protected from damage from personnel, cargo, and

maintenance activ- ity. They should not be routed in

areas in where they are likely to be used as handholds

or as support for personal equipment or where they

F IGURE 11-7. Group and bundle ties.

could become damaged during removal of aircraft

equipment. Wiring must be clamped so that contact with

equipment and structure is avoided. Where this cannot

be accomplished, extra protection, in the form of

grommets, chafe strips, etc., should be provided.

Protec- tive grommets must be used, wherever wires

cannot be clamped, in a way that ensures at least a

3/8-inch clearance from structure at penetrations. Wire

must not have a preload against the corners or edges of

chafing strips or grommets. Wiring must be routed away

from high-temperature equipment and lines to pre- vent

deterioration of insulation. Protective flexible conduits

should be made of a material and design that eliminates

the potential of chafing between their internal wiring and

the conduit internal walls. Wiring that must be routed

across hinged panels, must be routed and clamped so

that the bundle will twist, rather than bend, when the

panel is moved.

F IGURE 11-8. Comb for straightening wires in bundles.

11-116. GROUP AND BUNDLE TIES. A wire bundle ensure all edges are rounded to protect the wire insulation.

consists of a quantity of wires fastened or secured

together and all traveling in the same direction. Wire

bundles may con- sist of two or more groups of wires. It 11-117. MINIMUM WIRE BEND RADII.

is often advantageous to have a number of wire groups The minimum radii for bends in wire groups or bundles

individually tied within the wire bundle for ease of must not be less than 10 times the out- side diameter of

identification at a later date. (See fig- ure 11-7.) Comb their largest wire. They may be bent at six times their

the wire groups and bundles so that the wires will lie outside diameters at breakouts or six times the diameter

parallel to each other and minimize the possibility of where they must reverse direction in a bundle, provided

insulation abrasion. A combing tool, similar to that that they are suitably supported.

shown in figure 11-8, may be made from any suitable

insulating material, taking care to

a. RF cables should not bend on a radius of less than

six times the outside diameter of the cable.

Par 11-115 Page 11-51

AC 43.13-1B CHG 1 9/27/01

b. Care should be taken to avoid sharp bends in wires

that have been marked with the hot stamping process. 11-119. POWER FEEDERS. The power feeder wires

should be routed so that they can be easily inspected or

replaced. They must be given special protection to

11-118. SLACK. Wiring should be installed with sufficient prevent potential chafing against other wiring, aircraft

slack so that bundles and indi- vidual wires are not structure, or components.

under tension. Wires con- nected to movable or

shock-mounted equip- ment should have sufficient

length to allow full travel without tension on the bundle. 11-120. RF CABLE. All wiring needs to be protected

Wiring at terminal lugs or connectors should have from damage. However, coaxial and triaxial cables are

sufficient slack to allow two retermina- tions without particularly vulnerable to certain types of damage.

replacement of wires. This slack should be in addition to Personnel should ex- ercise care while handling or

the drip loop and the allowance for movable equipment. working around coaxial. Coaxial damage can occur

Normally, wire groups or bundles should not exceed when clamped too tightly, or when they are bent sharply

1/2-inch deflection between support points, as shown in (normally at or near connectors). Damage can also be

figure 11-9a. This measurement may be exceeded incurred during unrelated maintenance actions around

provided there is no possibility of the wire group or the coaxial cable. Coaxial can be severely damaged on

bundle touching a surface that may cause abrasion. the inside without any evidence of damage on the out-

side. Coaxial cables with solid center con- ductors

should not be used. Stranded center coaxial cables can

Sufficient slack be used as a direct replace- ment for solid center coaxial.

should be provided at each end to:

a. Permit replacement of terminals.

b. Prevent mechanical strain on wires. 11-121. PRECAUTIONS.

c. Permit shifting of equipment for main- tenance a. Never kink coaxial cable.

purposes.

b. Never drop anything on coaxial cable.

11-118A. DRIP LOOP IN WIRE BUNDLE.

A drip loop is an area where wire is dressed c. Never step on coaxial cable.

downward to a connector, terminal block, panel, or

junction bo. In additional to the d. Never bend coaxial cable sharply.

service termination and strain relief, a trap or drip loop

shall be provided in the wiring to prevent fluid or e. Never loop cable coaxial más apretado que el radio de

condensate from running into the above devices. (see curvatura permisible.

Figure 11-9b) Wires or groups of wires should enter a

junction box or piece of equipment in an upward direction F. Nunca tire en cable coaxial, excepto en una línea recta.

where practicable. Where wires must be routed

downwards to a junction box or unit of electric

equipment, the entry should be sealed or adequate slack gramo. Nunca usar cable coaxial para un mango, se apoyan en

should be provided to form a trap or drip loop to ella, o colgar cosas en él (o cualquier otro cable).

prevent liquid from running down the wires in the box

or electric unit.

Page 11-52 Par 11-117

09.27.01 AC 43.13-1B CHG 1

F RÁFICO 11-9a. Holgura entre apoyos

11-9b figura. agujero de drenaje en bajo punto de tubo.

par 11-115 11-52a página (y 11-52b)

08.09.98 AC 43.13-1B

11-122. Protección contra la humedad, pozos del sunlight when aircraft are parked for extended periods

tren y tren de aterrizaje áreas. should also be taken into account. Wires such as in fire

detection, fire extin- guishing, fuel shutoff, and

fly-by-wire flight control systems that must operate

a. Cables situados en el tren de aterrizaje y en el área de cavidad during and after a fire, must be selected from types that

de la rueda puede ser expuesto a muchas condiciones peligrosas si no are qualified to provide circuit integrity after exposure to

se protege adecuadamente. Donde haces de cables pasan puntos de fire for a specified period. Wire insulation deteriorates

flexión, no debe haber ninguna presión sobre los archivos adjuntos o rapidly when subjected to high temperatures. Do not

ex holgura cesiva cuando las piezas están completamente extendida o use wire with soft polyethylene insulation in areas

retraída. El cableado y tubos de protección deben ser inspeccionados subject to high temperatures. Use only wires or cables

con frecuencia y se sustituyen en la primera señal de desgaste. with heat resistance shielding or insulation.

segundo. Los cables deben ser encaminados so that 11-125. MOVABLE CONTROLS WIR- ING

fluids drain away from the connectors. When this is not PRECAUTIONS. Clamping of wires routed near

practicable, connectors must be potted. Wiring which must movable flight controls must be attached with steel

be routed in wheel wells or other external areas must be hardware and must be spaced so that failure of a single

given extra pro- tection in the form of harness jacketing attachment point can not result in interference with con-

and connector strain relief. Conduits or flexible sleeving trols. The minimum separation between wir- ing and

used to protect wiring must be equipped with drain holes to movable controls must be at least 1/2 inch when the

prevent entrap- ment of moisture. bundle is displaced by light hand pressure in the

direction of the controls.

11-123. PROTECTION AGAINST PER- SONNEL AND 11-126. FLAMMABLE FLUIDS AND GASES. An arcing

CARGO. Wiring must be in- stalled so the structure fault between an electrical wire and a metallic

affords protection against its use as a handhold and flammable fluid line may puncture the line and result in

damage from cargo. Where the structure does not afford a fire. Every ef- fort must be made to avoid this hazard

adequate protection, conduit must be used, or a suitable by physical separation of the wire from lines and

mechanical guard must be provided. equipment containing oxygen, oil, fuel, hy- draulic fluid,

or alcohol. Wiring must be routed above these lines

and equipment with a minimum separation of 6 inches

11-124. HEAT PRECAUTIONS. Wiring must be routed or more whenever possible. When such an arrange-

away from high-temperature equipment and lines to ment is not practicable, wiring must be routed so that it

prevent deterioration of insulation. Wires must be rated does not run parallel to the fluid lines. A minimum of 2

(reference paragraph 11-66 and 11-67) so that the con- inches must be main- tained between wiring and such

ductor temperature remains within the wire specification lines and equipment, except when the wiring is posi-

maximum when the ambient temperature, and heat rise, tively clamped to maintain at least 1/2-inch separation,

related to current carrying capacity are taken into or when it must be connected

account. The residual heating effects caused by

exposure to

par 11-115 página 11-53

AC 43.13-1B 9/8/98

directly to the fluid-carrying equipment. In-

stall clamps as shown in figure 11-10. These clamps

should not be used as a means of sup- porting the wire

bundle. Additional clamps should be installed to support

the wire bundle and the clamps fastened to the same

structure used to support the fluid line(s) to prevent

relative motion.

F IGURE 11-10. Separation of wires from plumbing lines.

11-127. • • 11-134. [RESERVED.]

Page 11-54 Par 11-126

9/8/98 AC 43.13-1B

SECTION 10. SERVICE LOOP HARNESSES (Plastic Tie Strips)

11-135. GENERAL. The primary function of a service heat-shrinkable boot, or a length of heat- shrinkable

loop harness is to provide ease of maintenance. The tubing should be installed. The heat-shrinkable boots

components, mounted in the instrument panel and on the will provide preselected angles of wire harness

lower console and other equipment that must be moved termination when heat is applied. Heat-shrinkable

to access electrical connectors, are connected to aircraft tubing should be held at the desired angle until cool.

wiring through service loops. Chafing in service loop

harnesses is controlled using the following techniques.

11-139. “SERVICE LOOP.” Primary sup- port for service

loop harness(es) should be a cushion clamp and a

connector at the harness termination. Service loop

11-136. SUPPORT. Only string ties or plastic cable harnesses should be inspected for the following:

straps in accordance with para- graph 11-158 should be

used on service loop harnesses. A 90 ° or “Y” type spot

tie should be installed at the harness breakout point on a. Adequate Length. Components

the harness bundle. Ties should be installed on service should extend out from their mounting posi- tion a

loop harnesses at 4 to 6-inch inter- vals. distance that permits rotating and un- locking (or

locking) the electrical connector. Usually a distance of 3

to 6 inches, with all other components installed, should

be suffi- cient.

11-137. ANTI-CHAFING MATERIAL.

When service loops are likely to be in contact with each

other, expandable sleeving or equivalent chafe b. Bundle BreakOut Point.

protection jacket material must be installed over service

loop harnesses to prevent harness-to-harness chafing. (1) Bundle breakout point should be adequately

The sleeve should be held in place with string ties at 6 supported with string tie.

to 8-inch intervals. Harness identification labels should

be installed, with string tie, within 3 inches of the service (2) Service loop must maintain a mini- mum bend

loop harness in- stallation. radius of 3 times the harness di- ameter.

(3) The breakout point should be lo- cated directly

11-138. STRAIN RELIEF. The strain re- lief behind, beside, below, or above the component so that

components may be installed to control routing where the service loop harness does not bind other components.

close clearance exists between termination and other

components or bulk- heads. Strain relief components

provide sup- port of the service loop harness at the (4) Plastic ties should not be used be- tween the

termina- tion point. Connector strain relief adapters, service loop breakout and the elec- trical connector when

they are likely to chafe against adjacent wire.

Par 11-135 Page 11-55

AC 43.13-1B 9/8/98

c. Service Loop Routing. The service loop harness

should be routed directly from the breakout point to the

component. The harness should not contact moving

mechanical compo- nents or linkage, and should not be

wrapped or tangled with other service loop harnesses.

d. Service Loop Harness Termination.

Strain relief should be provided at the service loop

harness termination, and is normally pro- vided by the

connector manufacturer’s back- shell, heat-shrinkable

boot, or tubing.

11-140. • • 11-145. [RESERVED.]

Page 11-56 Par 11-139

9/27/01 AC 43.13-1B CHG 1

SECTION 11. CLAMPING

11-146. GENERAL. Wires and wire bun- dles must be b. Clamps lined with nonmetallic mate- rial should be

supported by using clamps meet- ing Specification used to support the wire bundle along the run. Tying may

MS-21919, or plastic cable straps in accessible areas if be used between clamps, but should not be considered as

correctly applied within the restrictions of paragraph a sub- stitute for adequate clamping. Adhesive tapes are

11-158. Clamps and other primary support devices must subject to age deterioration and, therefore, are not

be constructed of materials that are com- patible with acceptable as a clamping means.

their installation and environment, in terms of

temperature, fluid resistance, expo- sure to ultraviolet

(UV) light, and wire bundle mechanical loads. They c. The back of the clamp, whenever practical, should

should be spaced at intervals not exceeding 24 inches. be rested against a structural member. Stand-offs should

Clamps on wire bundles should be selected so that they be used to main- tain clearance between the wires and

have a snug fit without pinching wires, as shown in figure the structure. Clamps must be installed in such a

11-11 through figure 11-13. manner that the electrical wires do not come in contact

with other parts of the aircraft when subjected to

vibration. Sufficient slack should be left between the last

clamp and the electri- cal equipment to prevent strain at

CAUTION: The use of metal clamps on coaxial the terminal and to minimize adverse effects on shock-

RF cables may cause prob- lems if clamp fit is mounted equipment. Where wires or wire bundles pass

such that RF ca- ble’s original cross-section is through bulkheads or other structural members, a

distorted. grommet or suitable clamp should be provided to

prevent abrasion.

a. Clamps on wire bundles should not allow the

bundle to move through the clamp when a slight axial

pull is applied. Clamps on RF cables must fit without

crushing and must be snug enough to prevent the cable d. When wire bundle is clamped into position, if there

from moving freely through the clamp, but may al- low is less than 3/8-inch clearance between the bulkhead

the cable to slide through the clamp when a light axial cutout and the wire bun- dle, a suitable grommet should

pull is applied. The cable or wire bundle may be be installed as indicated in figure 11-14. The grommet

wrapped with one or more turns of electrical tape when may be cut at a 45 degree angle to facilitate instal- lation,

required to achieve this fit. Plastic clamps or cable ties provided it is cemented in place and the slot is located at

must not be used where their failure could result in inter- the top of the cutout.

ference with movable controls, wire bundle contact with

movable equipment, or chafing damage to essential or

unprotected wiring. They must not be used on vertical 11-147. WIRE AND CABLE CLAMPS INSPECTION.

runs where inadvertent slack migration could result in Inspect wire and cable

chafing or other damage. Clamps must be in- stalled clamps for proper tightness. Where cables pass

with their attachment hardware posi- tioned above them, through structure or bulkheads, inspect for proper

wherever practicable, so that they are unlikely to rotate clamping and grommets. Inspect

as the result of wire bundle weight or wire bundle for sufficient slack between the last clamp and the

chafing. (See figure 11-11.). electronic equipment to prevent strain at the cable

terminals and to minimize adverse effects on

shock-mounted equipment.

Par 11-146 Page 11-57

AC 43.13-1B CHG 1 9/27/01

F IGURE 11-11. Safe angle for cable clamps.

F IGURE 11-12. Typical mounting hardware for MS-21919 cable clamps.

Page 11-58 Par 11-49

9/8/98 AC 43.13-1B

F IGURE 11-13. Installing cable clamp to structure.

Par 11-147 Page 11-59

AC 43.13-1B 9/8/98

F IGURE 11-14. Clamping at a bulkhead hole.

11-148. • • 11-154. [RESERVED.]

Page 11-60 Par 11-147

9/8/98 AC 43.13-1B

SECTION 12. WIRE INSULATION AND LACING STRING TIE

11-155. GENERAL. Insulation of wires m. Special properties unique to the aircraft.

should be appropriately chosen in accordance with the

environmental characteristics of wire routing areas.

Routing of wires with dissimilar insulation, within the n. For a more complete selection of in- sulated wires

same bundle, is not rec- ommended, particularly when refer to SAE AS 4372 Aerospace Wire Performance

relative motion and abrasion between wires having Requirement and SAE AS 4373 Test Methods for

dissimilar insulation can occur. Soft insulating tubing Aerospace Wire.

(spaghetti) cannot be considered as mechanical

protection against external abrasion of wire; since at best, 11-157. STRIPPING INSULATION.

it provides only a delaying ac- tion. Conduit or ducting Attachment of wire, to connectors or termi- nals,

should be used when mechanical protection is needed. requires the removal of insulation to ex- pose the

conductors. This practice is com- monly known as

stripping. Stripping may be accomplished in many

ways; however, the following basic principles should be

11-156. INSULATION MATERIALS. In- sulating practiced.

materials should be selected for the best combination of

characteristics in the fol- lowing categories: a. Make sure all cutting tools used for stripping are

sharp.

a. Abrasion resistance. b. When using special wire stripping tools, adjust the

tool to avoid nicking, cutting, or otherwise damaging the

b. Arc resistance ( noncarbon tracking). strands.

c. Corrosion resistance. c. Damage to wires should not exceed the limits

specified in table 11-13.

d. Cut-through strength.

d. When performing the stripping op- eration, remove

e. Dielectric strength. no more insulation than is necessary.

f. Flame resistance.

11-158. LACING AND TIES. Ties, lacing, and straps are

g. Heat distortion temperature. used to secure wire groups or bundles to provide ease

of maintenance, in- spection, and installation. Braided

h. Impact strength. lacing tape per MIL-T-43435 is suitable for lacing and

tying wires.

i. Mechanical strength. In lieu of applying ties, straps

meeting Specification MS17821 or MS17822 may be

j. Resistance to fluids. used in areas where the temperature does not exceed

120 C. Straps may not be used in areas of SWAMP such

k. Resistance to notch propagation. as wheel wells, near wing flaps or wing folds. They may

not be used in high vibration areas, where failure

l. Smoke emission.

Par 11-155 Page 11-61

AC 43.13-1B 9/8/98

T ABLE 11-13. Allowable nicked or broken strands.

Maximum allowable nicked and broken strands

Wire Size Conductor material Number of strands per Total allowable nicked and

conductor broken strands

24-14 Copper 19 37 2 nicked, none broken 4

12-10 or Copper 133 nicked, none broken 6

8-4 2-1 Alloy 665-817 nicked, 6 broken 6 nicked,

6 broken 6 nicked, 6

0-00

1,045-1,330 broken 6 nicked, 6 broken

000

1,665- 6 nicked, 6 broken

0000 2,109-

8-000

Aluminum All numbers of strands None, None

of the strap would permit wiring to move against parts 12 inches apart. A tie consists of a clove hitch, around the

which could damage the insula- tion and foul wire group or bundle, secured by a square knot as shown

mechanical linkages or other moving mechanical parts. in figure 11-17.

They also may not be used where they could be

exposed to UV light, unless the straps are resistant to c. Plastic Ties. Refer to Para-

such ex- posure. graph 11-220 and table 11-21.

11-159. INSULATION TAPE. Insulation

a. Lacing. Lace wire groups or bundles inside tape should be of a type suitable for the appli- cation, or

junction boxes or other enclosures. Single cord-lacing as specified for that particular use. Insulation tape should

method, shown in fig- ure 11-15, and tying tape, be used primarily as a filler under clamps and as

meeting specifica- tion MIL-T-43435, may be used for secondary support. Nonadhesive tape may be used to

wire groups of bundles 1-inch in diameter or less. The wrap around wiring for additional protection, such as in

recommended knot for starting the single cord-lacing wheel wells. All tape should have the ends tied or

method is a clove hitch secured by a double-looped otherwise suitably secured to prevent unwinding. Tape

overhand knot as shown in figure 11-15, step a. Use used for protection should be applied so that overlapping

the double cord- lacing method on wire bundles 1-inch layers shed liquids. Drainage holes should be provided at

in di- ameter or larger as shown in figure 11-16. When all trap points and at each low point between clamps.

using the double cord-lacing method, employ a bowline Plastic tapes, that absorb moisture or have volatile

on a bight as the starting knot. plasticizers that produce chemical re- actions with other

wiring, should not be used. (Reference MIL-W-5088.)

b. Tying. Use wire group or bundle ties where the

supports for the wire are more than

Page 11-62 Par 11-158

9/8/98 AC 43.13-1B

F IGURE 11-15. Single cord lacing.

F IGURE 11-16. Double cord lacing.

Par 11-159 Page 11-63

AC 43.13-1B 9/8/98

F IGURE 11-17. Making ties.

11-160. • • 11-166. [RESERVED.]

Page 11-64 Par 11-159

9/8/98 AC 43.13-1B

SECTION 13. SPLICING.

11-167. GENERAL. Splicing is permitted on wiring as c. There should not be more than one splice in any

long as it does not affect the reli- ability and the one wire segment between any two connectors or other

electromechanical characteris- tics of the wiring. Splicing disconnect points, ex- cept; when attaching to the spare

of power wires, coaxial cables, multiplex bus, and large pigtail lead of a potted connector, to splice multiple wires

gauge wire must have approved data. to a single wire, to adjust wire size to fit connec- tor

contact crimp barrel size, and to make an approved

repair.

a. Splicing of electrical wire should be kept to a (Reference MIL-W-5088,

minimum and avoided entirely in locations subject now AS50881A, and NAVAIR 01-1A-505.)

to extreme vibrations.

Splicing of individual wires in a group or bun- dle should d. Splices in bundles must be staggered so as to

have engineering approval and the splice(s) should be minimize any increase in the size of the bundle,

located to allow periodic inspection. preventing the bundle from fitting into its designated

space, or cause congestion that will adversely affect

maintenance. (See

b. Many types of aircraft splice connec- tors are figure 11-18.)

available for use when splicing indi- vidual wires. Use of

a self-insulated splice connector is preferred; however, a e. Splices should not be used within 12 inches of a

noninsu- lated splice connector may be used provided termination device, except for paragraph f below.

the splice is covered with plastic sleeving that is secured

at both ends.

Environmentally f. Splices may be used within 12 inches of a

sealed splices, that conform to MIL-T-7928, provide a termination device when attaching to the pigtail spare

reliable means of splicing in SWAMP areas. lead of a potted termination de- vice, or to splice multiple

However, a noninsulated wires to a single wire, or to adjust the wire sizes so that

splice connector may be used, provided the splice is they are compatible with the contact crimp barrel sizes.

covered with dual wall shrink sleeving of a suitable

material.

g. Selection of proper crimping tool, re- fer to

paragraph 11-178.

F IGURE 11-18. Staggered splices in wire bundle.

11-168. • • 11-173. [RESERVED.]

Par 11-167 Page 11-65 (and 11-66)

9/27/01 AC 43.13-1B CHG 1

SECTION 16. WIRE MARKING

11-205. GENERAL. The proper identifica- tion of electrical 11-208. PLACEMENT OF IDENTIFI- CATION

wires and cables with their circuits and voltages is MARKINGS. Identification

necessary to provide safety of operation, safety to markings should be placed at each end of the wire and

maintenance per- sonnel, and ease of maintenance. at 15-inch maximum intervals along the length of the

wire. Wires less than 3 inches long need not be

identified. Wires 3 to 7 inches in length should be

a. Each wire and cable should be marked with a part

identified ap- proximately at the center. Added

number. It is common practice for wire manufacturers to

identification marker sleeves should be so located that

follow the wire material part number with the five

ties, clamps, or supporting devices need not be re-

digit/letter C.A.G.E. code identifying the wire

moved in order to read the identification. The wire

manufacturer. Ex- isting installed wire that needs

identification code must be printed to read horizontally

replacement can thereby be identified as to its

performance ca- pabilities, and the inadvertent use of a (from left to right) or verti- cally (from top to bottom). The

lower performance and unsuitable replacement wire two methods of marking wire or cable are as follows:

avoided.

b. The method of identification should not impair the a. Direct marking is accomplished by printing the

characteristics of the wiring. cable’s outer covering. (See fig- ure 11-23.)

CAUTION: Do not use metallic bands in place of

insulating sleeves. Exercise care when marking b. Indirect marking is accomplished by printing a

coaxial or data bus cable, as deforming the cable heat-shrinkable sleeve and installing the printed sleeve on

may change its electrical characteristics. 11-206. WIRE the wire or cables outer covering.

IDENTIFICATION. To fa- cilitate installation and

Indirect-marked wire or cable

should be identified with printed sleeves at each end and

maintenance, original wire-marking identification is to be

at intervals not longer than 6 feet. The individual wires

retained. The wire identification marks should consist of

inside a cable should be identified within 3 inches of their

a combination of letters and numbers that identify the

termination. (See figure 11-24.)

wire, the circuit it belongs to, its gauge size, and any

other information to relate the wire to a wiring diagram.

All markings should be legible in size, type, and color. 11-209. TYPES OF WIRE MARKINGS.

The preferred method is to mark directly on the wire. A

successful requirement qualifica- tion should produce

markings that meet the marking characteristics specified

in MIL-W- 5088 or AS50881A without causing insulation

11-207. IDENTIFICATION AND IN- FORMATION degradation.

RELATED TO THE WIRE AND WIRING Teflon coated wires, shielded

DIAGRAMS. The wire wiring, multi-conductor cable, and thermocou- ple wires

identification marking should consist of simi- lar usually require special sleeves to carry identification

information to relate the wire to a wiring diagram. marks. There are some wire marking machines in the

market that can be used to stamp directly on the type

wires mentioned above. Whatever method of mark- ing

is used, the marking should be legible and

Par 11-205 Page 11-83

AC 43.13-1B CHG 1 9/27/01

the color should contrast with the wire insula- tion or sleeve.

3” 15” 15” 3”

H215A20 H215A20 H215A20

(b) Single wire without sleeve

F IGURE 11-23. Spacing of printed identification marks (direct marking).

a. Extreme care must, therefore, be taken during

circuit identification by a hot stamp machine on insulation

wall 10 mils or thinner.

b. Alternative identification methods

such as “Laser Printing”, “Ink Jet”, and “Dot Matrix” are

preferred. When such modern equipment is not

available, the use of stamped identification sleeving

should be considered on insulation wall thickness of 10

mils or less.

11-210. HOT STAMP MARKING. Due to widespread

use of hot stamp wire marking, personnel should refer

to SAE ARP5369, Guidelines for Wire Identification

Marking using the Hot Stamp Process, for guidance on

minimizing insulation damage. Hot stamp process uses

a heated typeface to transfer pig- ment from a ribbon or

foil to the surface of wires or cables. The traditional

method im- prints hot ink marks onto the wire. Exercise

caution when using this method, as it has been shown

to damage insulation when incorrectly applied. Typeset

characters, similar to that used in printing presses but

F IGURE 11-24. Spacing of printed identification marks (indirect shaped to the

marking).

Page 11-84 Par 11-209

9/27/01 AC 43.13-1B CHG 1

contour of the wire, are heated to the desired temperature. pending on equipment configuration, dot ma- trix can

Wire is pulled through a channel directly underneath the mark wire from 0.037 to 0.5-inch out- side diameter.

characters. The heat of the type set characters transfers Multi-conductor cable can also be marked.

the ink from the marking foil onto the wire.

11-212. INK JET MARKING. This is a

a. Good marking is obtained only by the proper “non-impact” marking method wherein ink droplets are

combination of temperature, pressure, and dwelling. Hot electrically charged and then di- rected onto the

stamp will mark wire with an outside diameter of 0.038 to moving wire to form the char- acters. Two basic ink

0.25-inch. types are available: thermal cure and UV cure.

b. Before producing hot stamp wire, it must be

a. Thermal cure inks must generally be heated in an

assured that the marking machine is properly adjusted

oven for a length of time after marking to obtain their

to provide the best wire marking with the least wire

durability. UV cure inks are cured in line much like dot

insulation deterio- ration. The marking should never

matrix.

create an indent greater than 10 percent of the

insulation wall.

b. Ink jet marks the wire on the fly and makes a

reasonably durable and legible mark without

damaging the insulation.

Ink jets

CAUTION: The traditional Hot

normally mark wire from 0.030 to 0.25-inch outside

Stamp method is not recommended for use on

diameter. Multiconductor cable can also be marked.

wire with outside diameters of

less than 0.035. (REF. SAE

ARP5369). Stamping dies may cause fracture of

11-213. LASER MARKING. Of the variety of laser

the insulation wall and penetration to the

marking machines, UV lasers are proving to be the best.

conductor of these materials. When various fluids

This method marks into the surface of the wire’s

wet these opening in service, arcing and surface

insulation without degradation to its performance. One

tracking damage wire bun- dles. Later in service,

common type of UV laser is referred to as an excimer

when various fluids have wet these openings,

laser marker. UV laser produces the most du- rable

serious arcing and surface tracking will have

marks because it marks into the insula- tion instead of on

damaged wire bundles. 11-211. DOT MATRIX the surface. However, exci- mer laser will only mark

MARKING. The dot matrix marking is imprinted onto insulation that con- tain appropriate percentages of

the wire or cable very similar to that of a dot matrix titanium diox- ide (TiO 2). The wire can be marked on the

computer printer. The wire must go through a cleaning fly. UV can mark from 0.030 to 0.25-inch outside

process to make sure it is clean and dry for the ink to diameter. The UV laser makes only gray marks and they

adhere. Wires marked with dot matrix equipment appear more legible on white or pastel-colored

require a cure consisting of an UV curing process, insulation.

which is normally applied by the marking equipment.

This cure should normally be complete 16 to 24 hours

after marking. Dot matrix makes a legible mark without

damaging the insulation. De 11-214. IDENTIFICATION SLEEVES.

Flexible sleeving, either clear or opaque, is satisfactory for

general use. When color-coded or striped component

wire is used as part of a cable, the identification sleeve

should

Par 11-221 Pages 11-85

AC 43.13-1B CHG 1 9/27/01

specify which color is associated with each wire 11-216. OPERATING CONDITIONS. For sleeving

identification code. Identification sleeves are normally exposed to high temperatures (over 400 ° F), materials

used for identifying the following types of wire or cable: such as silicone fiberglass should be used.

a. Unjacketed shielded wire. 11-217. INSTALLATION OF PRINTED

SLEEVES. Polyolefin sleeving should be

b. Thermocouple wire identification is normally used in areas where resistance to solvent and synthetic

accomplished by means of identifi- cation sleeves. As hydraulic fluids is necessary. Sleeves may be secured in

the thermocouple wire is usually of the duplex type (two place with cable ties or by heat shrinking. The

insulated wires within the same casing), each wire at the identification sleeving for various sizes of wire is shown in

ter- mination point bears the full name of the con- ductor. table 11-17.

Thermocouple conductors are alumel, chromel,

Table 11-17. Recommended size of identification

iron, constantan, and copper sleeving.

constantan. Wire Size Sleeving Size

AN AL No. Nominal ID

c. Coaxial cable should not be hot stamped directly. (inches)

When marking coaxial ca- ble, care should be taken not # 24 12 . 085

to deform the ca- ble as this may change the electrical # 22 11 . 095

charac- teristics of the cable. When cables cannot be # 20 10 . 106

# 18 9876420 . 118

printed directly, they should be identified by printing the

# 16 . 113

identification code (and individual wire color, where # 14 . 148

applicable) on a nonmetallic material placed externally to # 12 . 166

the outer covering at the terminating end and at each # 10 . 208

#8 #8 . 263

junction or pressure bulkhead. Cables not enclosed in

#6 #6 . 330

conduit or a common jacket should be identi- fied with #4 #4 3/8 inch 1/2 . 375

printed sleeves at each end and at intervals not longer #2 #2 inch 1/2 . 500

than 3 feet. #1 #1 inch 5/8 . 500

#0 #0 inch 5/8 . 625

# 00 # 00 inch 3/4 . 625

Individual # 000 # 000 inch . 750

wires within a cable should be identified within 3 # 0000 # 0000 3/4 inch . 750

inches from their termination.

11-218. IDENTIFICATION OF WIRE BUNDLES

d. Multiconductor cable normally use identification AND HARNESSES. The identi- fication of wire bundles

sleeves for identifying un- and harnesses is be- coming a common practice and

shielded, unjacketed cable. may be ac- complished by the use of a marked sleeve

tied in place or by the use of pressure-sensitive tape as

e. High-temperature wire with insulation is difficult to indicated in figure 11-25.

mark (such as Teflon and fiber- glass).

11-215. IDENTIFICATION TAPE. Identi- fication

tape can be used in place of sleeving, in most cases (i.e.

polyvinylfluoride).

Page 11-86 Par 11-220

9/27/01 AC 43.13-1B CHG 1

F IGURE 11-25. Identification of wire bundles and har- nesses.

a. Wires for which identifications are reassigned F IGURE 11-26. Standard sleeves (135 ºC).

after installation, may be remarked on sleeves at the

termination of each wire segment. It may be necessary

to reidentify such wires throughout their lengths to facili-

tate ease of maintenance.

b. For high-density harnessed, shielded, and

jacketed multiconductor cables and when using

nonsignificant wire identification, color coding or its

alphanumeric equivalent may be interchanged within the

same harnesses. The alphanumeric equivalent of the

color code should be as set forth in MIL-STD-681.

F IGURE 11-27. Installation of heat-shrinkable insula- tion sleeves.

11-219. TERMINAL MARKING SLEEVE AND TAGS. Typical

cable mark- ers are flat, nonheat-shrinkable tags. Heat-

shrinkable marking sleeves are available for marking 11-220. SLEEVES AND CABLE

wires and cables, and should be in- serted over the MARKERS SELECTION. Sleeves and ca- ble markers

proper wire or cable and heat- shrunk using the proper must be selected by cable size and operating conditions.

manufacturer recom- mended heating tool. (See tables 11-18

through 11-21).

(See figures 11-26

and 11-27.) a. Markers are printed using a typewriter with a

modified roller. Blank markers on a bandolier are fed

into the typewriter, where they are marked in any

desired combination of characters. The typed markers,

still on ban-

Par 11-221 Pages 11-87

AC 43.13-1B CHG 1 9/27/01

doliers, are heated in an infrared heating tool that

processes the markers for permanency. The typed and (2) Cut the marking plate from the bandolier.

heat-treated markers remain on the bandolier until ready (See figure 11-28.)

for installation.

(3) Thread the tie-down straps through holes in

b. Markers are normally installed using the following marking plate and around cable. Thread tip of tie-down

procedure: strap through slot in head. (See figure 11-29.) Pull tip

until strap is snug around cable.

F IGURE 11-29. Tie-down strap installation.

F IGURE 11-28. Cable markers.

(1) Select the smallest tie-down strap that will

accommodate the outside diameter of the cable. (See

table 11-22.)

T ABLE 11-18. Selecti o n table for standard sleeves .

Wire or Cable Markable Installed Installed Wall As-supplied

Diameter Range. Sleeve Thickness Inside

Length *

(inches) Length (max inches) Diameter (min

Min Max (inches) (nom) inches)

(inches)

0.050 0.080 18 1.5 0.026 0.093

0.075 0.110 18 1.5 0.026 0.125

0.100 0.150 18 1.5 0.028 0.187

0.135 0.215 18 1.5 0.028 0.250

0.200 0.300 18 1.5 0.028 0.375

0.135 0.300 18 1.5 0.028 0.375

0.260 0.450 18 1.5 0.028 0.475

* Based on 12 characters per inch

Page 11-88 Par 11-220

9/27/01 AC 43.13-1B CHG 1

T ABLE 11-19. Selection table for thin-wall sleeves.

Wire or Cable Markable Installed Installed Wall As-supplied

Diameter Range Length * Sleeve Length Thickness (max Inside

(inches) (inches) (nom) inches) Diameter (min

Min. Max. (inches) inches)

0.035 0.080 22 1.75 0.020 0.093

0.075 0.110 22 1.75 0.020 0.125

0.100 0.150 21 1.75 0.021 0.187

0.135 0.225 21 1.75 0.021 0.250

* Based on 12 characters per inch

T ABLE 11-20. Selection table for high-temperature sleeves.

Wire or Cable Markable Installed Installed Wall As-supplied

Diameter Range Sleeve Thickness Inside

Length *

(inches) Length (max inches) Diameter (min

Min. Max. (inches) (nom) inches)

(inches)

0.035 0.080 18 1.5 0.019 0.093

0.075 0.110 18 1.5 0.016 0.125

0.100 0.150 18 1.5 0.018 0.187

0.135 0.215 18 1.5 0.018 0.250

0.200 0.300 18 1.5 0.018 0.375

0.260 0.450 18 1.5 0.018 0.475

* Based on 12 characters per inch

T ABLE 11-21. Selection table for cable markers.

Cable Diameter Type of Cable Marker Number of Number of Marker

Range Attachment Lines of Thickness

(inches) Holes Type (nom)

(inches)

0.25-0.50 Standard, 135 °C High 44 22 0.025

0.25-0.50 Temperature, 200 °C 0.020

Nuclear, 135 °C

0.25-0.50 Standard, 135 °C 4464 2333 0.025

0.50-up Standard, 135 °C High 0.025

0.50-up Temperature, 200 °C 0.025

0.50-up High Temperature, 200 0.020

°C Nuclear, 135 °C

0.50-up Nuclear, 135 °C 6 3 0.020

0.50-up 46 33 0.025

0.50-up 0.025

T ABLE 11-22. Plastic tie-down straps (MS3367, Type I, Class 1).

Cable Diameter Tie-down Strap Strap Identification * Installation Tool Tension Setting

(inches) MS3367-

Min Max

1/16 5/8 4-9 Miniature (MIN) MS90387-1 2466

1/16 1¼ 5-9 Intermediate (INT) MS90387-1

1/16 4 2-9 Standard (STD) MS90387-1

3/16 8 6-9 Heavy (HVY) MS90387-2

* The specified tool tension settings are for typical cable application. Settings less than or greater than those specified may be required for special applications.

Par 11-221 Pages 11-89

AC 43.13-1B CHG 1 9/27/01

(4) Select the applicable installation tool and move

the tension setting to the cor- rect position. (See figure

11-30.)

(5) Slide tip of strap into opening in the

installation tool nose piece. (See fig-

ure 11-30.)

(6) Keeping tool against head of tie- down strap,

ensure gripper engages tie-down strap, and squeeze F IGURE 11-32. Temporary wire identification marker.

trigger of installation tool until strap installation is

completed as shown in figure 11-31. a. With a pen or a typewriter, write wire number on

good quality white split in- sulation sleeve.

b. Trim excess white insulation sleeve,

leaving just enough for one wrap around wire to be

marked, with number fully visible.

c. Position marked white insulation sleeve on wire

so that shielding, ties, clamps, or supporting devices

need not be removed to read the number.

d. Obtain clear plastic sleeve that is long enough to

F IGURE 11-30. Tie-down strap installation tool. extend 1/4 inch past white in- sulation sleeve marker

edges and wide enough to overlap itself when wrapped

around white insulation and wire.

e. Slit clear sleeve lengthwise and place around marker

and wire.

F IGURE 11-31. Completed installation.

f. Secure each end of clear sleeve with lacing tape

spot tie to prevent loosening of sleeve.

11-222. MARKER SLEEVE INSTLA- TION AFTER

11-221. TEMPORARY WIRE AND CABLE PRINTING. The following general procedures apply:

MARKING PROCEDURE. A

temporary wire marking procedure follows but should

be used only with caution and with plans for future a. Hold marker, printed side up, and press end of

permanence. (See fig- wire on lip of sleeve to open sleeve. (See figure

ure 11-32.) 11-33.)

Page 11-90 Par 11-220

9/27/01 AC 43.13-1B CHG 1

F IGURE 11-33. Inserting wire into marker.

b. If wire has been stripped, use a scrap piece of

unstripped wire to open the end of the marker.

c. Push sleeve onto wire with a gentle twisting

motion.

d. Shrink marker sleeve, using heat gun with shrink

tubing attachment. (See fig-

ure 11-34.)

F IGURE 11-34. Shrinking marker on wire.

11-223. • • 11-229. [RESERVED.]

Par 11-221 Pages 11-90a (and 11-90b)

9/27/01 AC 43.13-1B CHG 1

SECTION 17. CONNECTORS

11-230. GENERAL. There is a multitude of types of intentional grounding. Connectors that are

connectors. Crimped contacts are generally used. susceptible to corrosion difficulties may be treated

Some of the more common are the round cannon type, with a chemically inert waterproof jelly.

the rectangular, and the module blocks. Environmental-

resistant connectors should be used in appli- cations

subject to fluids, vibration, thermal, mechanical shock, 11-232. TYPES OF CONNECTORS.

and/or corrosive elements. When HIRF/Lightning Connectors must be identified by an original

protection is required, special attention should be given identification number derived from MIL Specification

to the termi- nations of individual or overall shields. (MS) or OAM specification. Figure 11-35 provides

The number and complexity of wiring systems have some examples of MS connector types. Several

resulted in an increased use of electrical connectors. different types are shown in figures 11-36 and 11-37.

The proper choice and applica- tion of connectors is a

significant part of the aircraft wiring system.

Connectors must be kept to a minimum, selected, and a. Environmental Classes. Environ-

installed to provide the maximum degree of safety and ment-resistant connectors are used in applica- tions

reliability to the aircraft. For the installation of any where they will probably be subjected to fluids,

particular connector assembly, the specification of the vibration, thermal, mechanical shock, corrosive

manufacturer or the ap- propriate governing agency elements, etc. Firewall class con- nectors incorporating

must be followed. these same features should, in addition, be able to

prevent the penetration of the fire through the aircraft

firewall connector opening and continue to function

without failure for a specified period of time when

exposed to fire. Hermetic con- nectors provide a

11-231. SELECTION. . Connectors pressure seal for maintain- ing pressurized areas.

should be selected to provide the maximum degree of When EMI/RFI pro- tection is required, special attention

safety and reliability considering electrical and should be given to the termination of individual and

environmental requirements. Consider the size, weight, overall shields. Backshell adapters designed for shield

tooling, logistic, maintenance support, and compatibility termination, connectors with con- ductive finishes, and

with standardization programs. For ease of assem- bly EMI grounding fingers are available for this purpose.

and maintenance, connectors using crimped contacts

are generally chosen for all applications except those

requiring an her- metic seal. (Reference SAE ARP

1308, Pre- ferred Electrical Connectors For Aerospace

Vehicles and Associated Equipment.) A re- placement b. Rectangular Connectors. The rec- tangular

connector of the same basic type and design as the connectors are typically used in ap- plications where a

connector it replaces should be used. With a crimp type very large number of cir- cuits are accommodated in a

connector for any electrical connection, the proper single mated pair. They are available with a great

insertion, or extraction tool must be used to install or re- variety of contacts, which can include a mix of stan-

move wires from such a connector. Refer to dard, coaxial, and large power types. Cou- pling is

manufacturer or aircraft instruction manual. After the accomplished by various means. Smaller types are

connector is disconnected, inspect it for loose soldered secured with screws which hold their flanges together.

connections to prevent un- Larger ones have integral guide pins that ensure correct