Documente Academic

Documente Profesional

Documente Cultură

Astm A2 08

Încărcat de

Thiago Ribeiro da SilvaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Astm A2 08

Încărcat de

Thiago Ribeiro da SilvaDrepturi de autor:

Formate disponibile

Designation: A2 − 02 (Reapproved 2008)

Standard Specification for

Carbon Steel Girder Rails of Plain, Grooved, and Guard

Types1

This standard is issued under the fixed designation A2; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* 4. Ordering Information

2 4.1 Orders for girder rails under this specification shall

1.1 This specification covers carbon steel girder rails of

three classes based on type or type and weight, and chemistry include the following information as appropriate:

defined as follows and in Table 1. 4.1.1 ASTM designation and date of issue;

1.1.1 Unless otherwise specified by the purchaser, girder- 4.1.2 Quantity (tons or pieces as appropriate);

guard rails shall be Class A. 4.1.3 Complete identification of section with dimensional

1.1.2 Plain and grooved-girder rails under 135 lb/yd (67.1 drawing if required;

kg/m) in weight shall be specified by the purchaser as either 4.1.4 Arrangement of bolt holes, bond holes, and tie rod

Class A or Class B. holes with dimensional drawings, if required;

1.1.3 Plain and grooved-girder rails of 135 lb/yd in weight 4.1.5 Class (in accordance with 1.1 and Table 1); and

and heavier shall be Class C, unless otherwise specified. 4.1.6 Certification and Test Report (see 12.1).

1.2 The values states in inch-pound units are to be regarded 5. Manufacture

as the standard. The values given in parentheses are for 5.1 Melting Practice—The steel shall be made by any of the

information only. following processes: open-hearth, basic-oxygen, or electric-

furnace.

2. Referenced Documents 5.1.1 The steel may be cast by a continuous process or in

2.1 ASTM Standards:3 ingots.

A700 Practices for Packaging, Marking, and Loading Meth- 5.2 Discard—Sufficient discard shall be made to secure

ods for Steel Products for Shipment freedom from injurious segregation and piping.

E10 Test Method for Brinell Hardness of Metallic Materials

6. Chemical Composition

3. Classification of Rails 6.1 Heat or Cast Analysis—An analysis for each heat or cast

3.1 No. 1 Rails—Rails that are free of injurious imperfec- of steel shall be made by the manufacturer to determine the

tions and flaws of all kinds. percentage of the elements specified in Table 1. The analysis

shall be made from a test sample representing the heat or cast

3.2 No. 2 Rails—Rails that contain surface imperfections in and shall conform to the requirements in Table 1.

such number or of such character that shall not, in the judgment

6.2 Upon request by the purchaser, similar samples shall be

of the inspector, render them unfit for recognized uses.

provided to verify the heat or cast analysis as determined in

6.1.

1

6.3 Product Analysis—When ladle tests are not available,

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee finished material representing the heat may be product tested.

A01.01 on Steel Rails and Accessories. The product analysis allowance beyond the limits of the

Current edition approved March 1, 2008. Published March 2008. Originally specified ladle analysis shall be within the limits for product

approved in 1912. Last previous edition approved in 2002 as A2 – 02. DOI:

10.1520/A0002-02R08.

analyses specified in Table 2.

2

Design details for carbon steel girder rails are indicated in the girder rail

catalogs of individual manufacturers. 7. Hardness Properties

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

7.1 Test Specimens:

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 7.1.1 Three representative sections of rail from each heat

the ASTM website. shall be selected as test specimens.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

Copyright by ASTM Int'l (all rights reserved); 1

A2 − 02 (2008)

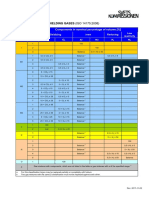

TABLE 1 Chemical Requirements, % 8.2 Weight—The weight of the rails per yard as calculated,

Class A Class B Class C shall be maintained as nearly as possible after conforming to

Carbon 0.60–0.75 0.70–0.85 0.75–0.90 the requirements specified in 8.1.

Manganese 0.60–0.90 0.60–0.90 0.60–0.90

Phosphorus, max 0.04 0.04 0.04 8.3 Length:

Silicon 0.10–0.40 0.10–0.40 0.10–0.40 8.3.1 Unless otherwise specified, the standard length of rail

shall be 39 ft (11.9 m) where measured at a temperature of

60°F (15°C).

TABLE 2 Product Analysis—Allowance Beyond Limits of 8.3.2 All standard 39-ft lengths may be specified; or

Specified Chemical Analysis

8.3.3 Standard 39-ft lengths with up to 11 % of the entire

Allowance Under Minumum Allowance Over Maximum

Limit, % Limit, %

order in lengths shorter than standard, varying by 1 ft (0.3 m)

Carbon 0.04 0.04

from 38 to 24 ft (11.6 to 7.3 m) may be specified; or

Manganese 0.06 0.06 8.3.4 Length variations other than those described in 8.3.3

Phosphorus ... 0.008 may be established by agreement between the purchaser and

Silicon 0.02 0.02A

manufacturer.

A

Continuously cast allowances shall be 0.05 % over maximum for silicon. 8.3.5 A variation of 7⁄16 in. (11 mm) from the specified

length of individual rails will be permitted.

8.4 End Finish:

7.1.2 Excess scale and decarburization shall be removed 8.4.1 Rails shall be milled, abrasive wheel cut, or ground to

from the test area of the head or web of the selected specimens. length, with a variation in end squareness of not more than 1⁄32

7.2 Procedure: in. (0.8 mm) allowed.

7.2.1 The test shall be conducted in accordance with Test 8.4.2 Harmful burrs on the ends shall be removed.

Method E10. 8.5 Drilling:

7.3 Requirements: 8.5.1 Circular holes for joint bar bolts, bonds, and tie rods

7.3.1 Class A rail shall have a Brinell hardness of 248 to shall be drilled to conform to the drawings and dimensions

293, and Classes B and C shall have hardnesses of 269 to 321. furnished by the purchaser and within the following permis-

sible variations:

7.4 Retests—If the average depth of the impressions ob- 8.5.2 The diameter of bolt holes shall not vary more than 1⁄16

tained on the head of the three specimens from any heat fails in. (1.6 mm) over and 0 in. under that specified. The diameter

to conform to the requirements specified in 7.3, the manufac- of bond holes shall not be over the size specified, but may be

turer may at his option retest the specimens, or each rail from 1⁄32 in. (0.8 mm) under. The diameter of the tie rod holes shall

that heat. Rails represented by retests which conform to the not be less than that specified but may be 1⁄16 in. (1.6 mm) over.

requirements of 7.3 shall be accepted. 8.5.3 The location of bolt and bond holes shall not vary

more than 1⁄16 in. (1.6 mm), either longitudinally or vertically

8. Permissible Variations of Dimension, Weight, and

from that specified. The location of the tie rod holes shall not

Other Physical Attributes

vary more than 1⁄4 in. (6.35 mm) vertically and not more than

8.1 Section: 1⁄2 in. (12.7 mm) longitudinally from that specified.

8.1.1 The section of the rail shall conform to the design 8.5.4 Bond holes shall be truly cylindrical and not conical.

specified by the purchaser. 8.5.5 Harmful fins and burrs at the edges of holes shall be

8.1.2 A variation of 1⁄64 in. (0.4 mm) less or 1⁄32 in. (0.8 mm) removed.

greater than the specified height will be permitted.

8.6 Punching—Unless otherwise specified by the purchaser,

8.1.3 A variation of 1⁄8 in. (3.2 mm) from the specified

the tie rod holes in Class A rails may be punched, and, when so

overall width of the head and tram will be permitted, but any

made, they shall be free of burrs, fins, and so forth. Punched tie

variation that would affect the gage line more than 1⁄32 in. (0.8

rod holes shall not be less in diameter than specified, but may

mm) will not be permitted.

be not more than 1⁄8 in. (3.2 mm) over size.

8.1.4 The overall width of the base shall not vary under that

specified more than 1⁄8 in. (3.2 mm) for widths less than 61⁄2 in.

(165 mm), 3⁄16 in. (4.8 mm) for a width of 61⁄2 in., and 1⁄4 in. 9. Workmanship, Finish, and Appearance

(6.35 mm) for a width of 7 in. (178 mm). 9.1 Rails shall be straightened cold in a press or roller

8.1.5 No variation will be permitted in dimensions affecting machine to remove twists, waves, and kinks.

the fit of the joint bars, except that the fishing template 9.2 Deviations in the vertical and horizontal alignment

approved by the purchaser may stand out laterally not more throughout the length of the rail shall be uniform. Sharp

than 3⁄32 in. (2.4 mm). deviations in either direction shall not be acceptable.

8.1.6 The base of the rail shall be at right angles to the web,

and the convexity shall not exceed 1⁄32 in. (0.8 mm). 9.3 Straightness shall be assessed by visual inspection.

8.1.7 When necessary, because of the type of track construc-

tion, and notice to that effect has been given to the manufac- 10. Inspection

turer, the position of the gage line with respect to the outer edge 10.1 The manufacturer shall afford the purchaser’s inspector

of the base shall not vary more than 3⁄64 in. (1.2 mm). all reasonable facilities necessary to satisfy him that the

Copyright by ASTM Int'l (all rights reserved); 2

A2 − 02 (2008)

material is being produced and furnished in accordance with 14. Product Marking

this specification. Mill inspection by the purchaser shall not 14.1 Branding and Stamping:

interfere unnecessarily with the manufacturer’s operations. All 14.1.1 The name or brand of the manufacturer, the year and

tests and inspections shall be made at the place of manufacture, month of manufacture, the weight of the rail, and the section

unless otherwise agreed to. number, shall be legibly rolled in raised letters and figures on

11. Rejection and Rehearing the web.

14.1.2 The heat number shall be legibly stamped on each

11.1 Material that fails to conform to the requirements of rail where it will not be covered subsequently by the joint bars.

this specification may be rejected. Rejections shall be reported

to the manufacturer or supplier promptly and in writing. In case 14.2 Paint Marking:

of dissatisfaction with the test results, the manufacturer or 14.2.1 No. 2 rails shall be paint-marked white.

supplier may make claim for a rehearing. 14.2.2 No. 1 rails less than 39 ft (11.9 m) long shall be

paint-marked green.

12. Certification 14.2.3 Paint-marking shall be located on the top of the head

12.1 When specified in the purchase order or contract, a at one end only, at least 3 ft (0.9 m) from the end.

manufacturer’s certification shall be furnished to the purchaser 14.3 Bar Coding:

that the material was produced and tested in accordance with 14.3.1 The Automotive Industry Action Group (AIAG) Bar

this specification and has been found to meet the requirements. Code Standard for Primary Metals for Steel Products4 may be

12.2 When specified in the purchase order or contract, a considered as a possible auxiliary method of identification. Use

report of the chemical and mechanical test results shall be of this method shall be by agreement between purchaser and

furnished. supplier.

12.3 A Material Test Report, Certificate of Inspection, or 15. Loading

similar document printed from or used in electronic form from

and electronic data interchange (EDI) transmission shall be 15.1 Rails shall be handled carefully to avoid damage.

regarded as having the same validity as a counterpart printed in 15.2 Rails shall be placed together according to class in

the certifier’s facility. The content of the EDI transmitted loading.

document must meet the requirements of the invoked ASTM

15.3 Rails shall be paired as to length before shipment.

standard(s) and conform to any existing EDI agreement be-

tween the purchaser and the supplier. 16. U.S. Government Procurement

12.4 Notwithstanding the absence of a signature, the orga- 16.1 When specified in the contract or purchase order,

nization submitting either a printed document (Material Test material shall be prepared for shipment and storage in accor-

Report, Certificate of Inspection, or similar document) or and dance with the requirements of Practices A700.

EDI transmission is responsible for the content of the report.

13. Acceptance 17. Keywords

13.1 In order to be accepted, the rails offered shall fulfill all 17.1 girder rails; rails; railway applications; steel rails

the requirements of this specification.

13.2 No. 2 rails to the extent of 10 % of the whole order will 4

Available from Automotive Industry Action Group (AIAG), 26200 Lahser Rd.,

be accepted. Suite 200, Southfield, MI 48033, http://www.aiag.org.

SUMMARY OF CHANGES

(1) Deleted military standard reference in Section 2. (4) Added EDI language in Section 12.

(2) Edited footnotes on page 1. (5) Added bar coding language in Section 14.

(3) Changed hardness specification to an ASTM specification (6) Deleted reference to military standard in Section 16.

in Section 7.

Copyright by ASTM Int'l (all rights reserved); 3

A2 − 02 (2008)

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org). Permission rights to photocopy the standard may also be secured from the ASTM website (www.astm.org/

COPYRIGHT/).

Copyright by ASTM Int'l (all rights reserved); 4

S-ar putea să vă placă și

- 60 A 54 C 0 A 0 e 34 e 93 F 99 A 747 D 4Document4 pagini60 A 54 C 0 A 0 e 34 e 93 F 99 A 747 D 4Thiago Ribeiro da SilvaÎncă nu există evaluări

- Nordstrom 2010 Annual ReportDocument88 paginiNordstrom 2010 Annual ReportThiago Ribeiro da SilvaÎncă nu există evaluări

- ACFrOgAVzx Qln0MuOYZ3PbigJ Z5Fw4woeM 6aMd2SpH3LYdbjGwWqs4GFmrqeVn2ITvw9gEuKYqgPY2ssrE95sPIt0lvI2DYs5iDxZSYARdJaa3NvSvLmChWb8xvCkgyN45tx-uMBXxw9KPwADDocument29 paginiACFrOgAVzx Qln0MuOYZ3PbigJ Z5Fw4woeM 6aMd2SpH3LYdbjGwWqs4GFmrqeVn2ITvw9gEuKYqgPY2ssrE95sPIt0lvI2DYs5iDxZSYARdJaa3NvSvLmChWb8xvCkgyN45tx-uMBXxw9KPwADThiago Ribeiro da SilvaÎncă nu există evaluări

- Technipfmc q1 2023 Earnings SlidesDocument18 paginiTechnipfmc q1 2023 Earnings SlidesThiago Ribeiro da SilvaÎncă nu există evaluări

- Keyhole GTAW & GTAW Variants ExplainedDocument2 paginiKeyhole GTAW & GTAW Variants ExplainedThiago Ribeiro da SilvaÎncă nu există evaluări

- Ansi Isa 18.1 2004 PDFDocument54 paginiAnsi Isa 18.1 2004 PDFThiago Ribeiro da SilvaÎncă nu există evaluări

- MSS SP-6 (2001)Document6 paginiMSS SP-6 (2001)Vijay KumarÎncă nu există evaluări

- Duplex Stainless Steels Welding Guidelines EN Juin 2019 WebDocument56 paginiDuplex Stainless Steels Welding Guidelines EN Juin 2019 WebMohamed YousufÎncă nu există evaluări

- Regulator Seat Leakage: American National StandardDocument7 paginiRegulator Seat Leakage: American National StandardThiago Ribeiro da SilvaÎncă nu există evaluări

- Classification and components of shielding gasesDocument2 paginiClassification and components of shielding gasesshivendrakumarÎncă nu există evaluări

- ASTM A 3 - 01 (Reapproved 2006) PDFDocument3 paginiASTM A 3 - 01 (Reapproved 2006) PDFRamsi AnkziÎncă nu există evaluări

- BS en 1515-4 2009Document22 paginiBS en 1515-4 2009Thiago Ribeiro da Silva100% (1)

- Astm A240Document9 paginiAstm A240Thiago Ribeiro da SilvaÎncă nu există evaluări

- Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger TubesDocument14 paginiSeamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger TubesThiago Ribeiro da SilvaÎncă nu există evaluări

- Forged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts For High-Temperature ServiceDocument16 paginiForged or Rolled Alloy and Stainless Steel Pipe Flanges, Forged Fittings, and Valves and Parts For High-Temperature ServiceThiago Ribeiro da SilvaÎncă nu există evaluări

- Astm A65/07Document4 paginiAstm A65/07Thiago Ribeiro da SilvaÎncă nu există evaluări

- Astm A 99 - 03Document3 paginiAstm A 99 - 03Er WidodoÎncă nu există evaluări

- A135A135MDocument9 paginiA135A135Msamy7354Încă nu există evaluări

- Laser Welding Fundamentals PDFDocument42 paginiLaser Welding Fundamentals PDFThiago Ribeiro da SilvaÎncă nu există evaluări

- A105 12 PDFDocument5 paginiA105 12 PDFThiago Ribeiro da SilvaÎncă nu există evaluări

- A203 12Document3 paginiA203 12Thiago Ribeiro da SilvaÎncă nu există evaluări

- A65Document3 paginiA65Muhammad IkramÎncă nu există evaluări

- ASTM A 111 - 99a Reapproved 2004Document3 paginiASTM A 111 - 99a Reapproved 2004bgdaniel07Încă nu există evaluări

- 2015 - Plate Spec Guide PDFDocument80 pagini2015 - Plate Spec Guide PDFDanny SeeÎncă nu există evaluări

- 2015 - Plate Spec Guide PDFDocument80 pagini2015 - Plate Spec Guide PDFDanny SeeÎncă nu există evaluări

- Carbon Steel Forgings, For General-Purpose PipingDocument3 paginiCarbon Steel Forgings, For General-Purpose PipingThiago Ribeiro da SilvaÎncă nu există evaluări

- Astm A3 01 PDFDocument3 paginiAstm A3 01 PDFJavier Ricardo Romero BohorquezÎncă nu există evaluări

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 paginiSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Thiago Ribeiro da SilvaÎncă nu există evaluări

- Astm A82 05Document5 paginiAstm A82 05Thiago Ribeiro da SilvaÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- A Study On The Application of Operations Research in The Airline IndustryDocument14 paginiA Study On The Application of Operations Research in The Airline IndustryInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Wikborg Rein Update Shipping Offshore June 2021 WebDocument21 paginiWikborg Rein Update Shipping Offshore June 2021 WebMaan MrabetÎncă nu există evaluări

- Fuse Panel Identification: 1994 Chevrolet Cavalier 1994 Chevrolet CavalierDocument4 paginiFuse Panel Identification: 1994 Chevrolet Cavalier 1994 Chevrolet CavalierMarcoÎncă nu există evaluări

- Traffic Collision Investigation Manual For Patrol OfficersDocument119 paginiTraffic Collision Investigation Manual For Patrol Officerssithlord_shag8697100% (1)

- 767 CheckrideDocument342 pagini767 CheckrideChristiano Santos100% (8)

- Rule: National Driver Register Problem Driver Pointer System Participation and Data Receipt ProceduresDocument8 paginiRule: National Driver Register Problem Driver Pointer System Participation and Data Receipt ProceduresJustia.com100% (1)

- Crew Resource Management PDFDocument20 paginiCrew Resource Management PDFAli Ghanipour100% (1)

- Important Topic For Eassy WritingDocument19 paginiImportant Topic For Eassy WritingAshikur Rahman0% (1)

- Get More LeafletDocument6 paginiGet More LeafletTafadzwa PiyoÎncă nu există evaluări

- Bridgestone - Medium Light Truck Databook - 2013Document130 paginiBridgestone - Medium Light Truck Databook - 2013Jose Angel MelendezÎncă nu există evaluări

- O-38 Anchor PDFDocument5 paginiO-38 Anchor PDFRABISH KumarÎncă nu există evaluări

- SO3 - B2+ - Unit Test - U1BDocument5 paginiSO3 - B2+ - Unit Test - U1BirishacrobatÎncă nu există evaluări

- Ts of 33 KV in Door Switch Board-IDocument29 paginiTs of 33 KV in Door Switch Board-ISunil SinghÎncă nu există evaluări

- Ro-Ro and Container Vessel ReferencesDocument28 paginiRo-Ro and Container Vessel ReferencesrafaÎncă nu există evaluări

- Spring Bolt and Nut Price List for Commercial VehiclesDocument10 paginiSpring Bolt and Nut Price List for Commercial VehiclesHemant PanpaliyaÎncă nu există evaluări

- Railway & Airport Engineering: UNIT - 3 To 5Document30 paginiRailway & Airport Engineering: UNIT - 3 To 5Civil RguktÎncă nu există evaluări

- International Airports MCQs (Solved) - World General KnowledgeDocument8 paginiInternational Airports MCQs (Solved) - World General KnowledgeshahzaibÎncă nu există evaluări

- Supercharging and TurbochargingDocument14 paginiSupercharging and TurbocharginglostwithabhiÎncă nu există evaluări

- Hyperco CatalogDocument24 paginiHyperco Catalogthrottleback1812Încă nu există evaluări

- Letter of Credit ProjectDocument42 paginiLetter of Credit ProjectBilal AhmadÎncă nu există evaluări

- Guidance for Controllers on Communication FailuresDocument6 paginiGuidance for Controllers on Communication Failureseak_ya5875Încă nu există evaluări

- Sewer Install GuideDocument54 paginiSewer Install GuideSurieduth BuskalowaÎncă nu există evaluări

- Bill of LandingDocument6 paginiBill of LandingJENNIFER TALIA CARRERA CUYAÎncă nu există evaluări

- 11883734-Clark NPR 17 NPR 20 Forklift Service Repair Workshop Manual DownloadDocument492 pagini11883734-Clark NPR 17 NPR 20 Forklift Service Repair Workshop Manual DownloadJUANNI5590% (10)

- Class 1 Pre-Trip InspectionDocument8 paginiClass 1 Pre-Trip InspectionHårmãñ S ÐhâñøáÎncă nu există evaluări

- Boeing 727-200: Microsoft Flight Simulator 2004Document4 paginiBoeing 727-200: Microsoft Flight Simulator 2004Raph 1123Încă nu există evaluări

- Research Article: Algorithms For Pallet Building and Truck Loading in An Interdepot Transportation ProblemDocument12 paginiResearch Article: Algorithms For Pallet Building and Truck Loading in An Interdepot Transportation ProblemHữu BìnhÎncă nu există evaluări

- Introduction To World Explorers Mini TestDocument3 paginiIntroduction To World Explorers Mini TestLaura CosteiuÎncă nu există evaluări

- Stock Towers BrochureDocument12 paginiStock Towers BrochurejsdfrklffsdfmÎncă nu există evaluări

- Volvo S40 ManualDocument226 paginiVolvo S40 ManualJiannis Kouts100% (1)