Documente Academic

Documente Profesional

Documente Cultură

Job Safety Analysis

Încărcat de

Qin QinDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Job Safety Analysis

Încărcat de

Qin QinDrepturi de autor:

Formate disponibile

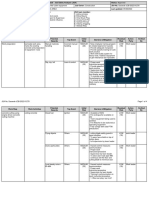

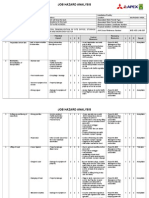

JOB SAFETY ANALYSIS

Company: ABC JSA No. ______________________

BIG PROJECT

TASK: Work Description: Geotechnical Soils Investigation

Work Location: Area outside north and south of contractor parking

Estimated start date/duration: November 19, 2010 for approximately 2 weeks

Trade Groups (Including sub-contractors): Geotechnical Technicians, Labours, Operating Engineers

Major Equipment: Drill Rig

Reference Material: Soils Investigation Specification, Bore Hole Location Sketch

Job: To Begin (Date)

Department: Supervisor in Charge:

Prepared By: Approved By: Date approved:

JOB-STEPS HAZARDS BARRIERS or CONTROL

1. Establish general Spray paint or other chemical marking products - MSDS sheet or consumer product labels

locations for boreholes during

initial site walk-about. Electrical environment - Have owner-authorized personnel accompany

- Approved electrically-resistant footwear

Personnel contacting live electrical apparatus - Safe limits of approach

Moving vehicles in vicinity - Reflective safety vests or other clothing

- Stay within visible barriers when required

2. Take samples for Electrical environment - Have owner-authorized personnel accompany

contaminants at six proposed - Approved electrically-resistant footwear

borehole locations.

Personnel or equipment contacting live electrical - Safe limits of approach

apparatus

Moving vehicles in vicinity - Reflective safety vests or other clothing

- Stay within visible barriers when required

Contact of underground electrical apparatus - Excavate by hand only

Pinches, cuts, strains - Personnel wear hard hats, gloves

- Safe lifting practices

Possible contaminated fill soils - Approved sampling and handling practices

3. Locate underground Electrical environment - Approved electrically-resistant footwear

utilities. False or missing locates due to static or induction - Plans showing underground utility locations

electric fields - Appropriate locate instrumentation

- Documentation of locates

Personnel or equipment contacting live electrical - Safe limits of approach

apparatus

Moving vehicles in vicinity - Reflective safety vests or other clothing

- Stay within visible barriers when required

4. Set up drill rig at borehole Electrical environment - Approved electrically-resistant footwear

locations Moving vehicles in vicinity - Reflective safety vests or other clothing

- All work to be carried out within visible barriers

- Lane closure and/or door closure permits at

Boreholes 3, 5, 6, 7 and 8

Pipe rack overhead at Borehole 3 - Use half-tower on drill rig

Equipment or personnel contacting live electrical - Safe limits of approach

apparatus

Ground potential rise, induction - Ground drill rig using two 4/0 portable grounds

- Borehole 9 may need to drive ground rods due

to non-availability of station grounds; see Step 3

Proximity of borehole to buried services / utilities - Hand excavate to expose services

5. Drill boreholes to required Electrical environment - Approved electrically-resistant footwear

depth Moving vehicles in vicinity - Reflective safety vests or other clothing

- All work to be carried out within visible barriers

High speed rotating augers - Maintain safe distance away from augers

- Wear close-fitting clothing

- Recognized drilling practices

High decibel levels during drilling - Hearing protection

Flying particles / debris - Approved eye protection

Contact of underground electrical apparatus by - Plans showing underground utility locations

augers or samplers - Locates done using appropriate equipment

- Drill within defined area

- Excavation permits

Equipment or personnel contacting live electrical - Safe limits of approach

apparatus

Ground potential rise, induction - Ground drill rig using two 4/0 portable ground

rods

Proximity of borehole to buried services / utilities - Hand excavate to expose services

Possible contaminated fills / soils - Personnel wear gloves, eye protection

- Approved practices per results of chemical

analysis

- If unknown contaminants encountered, stop

work in that area and notify the owner; do not

resume work until conditions are identified and

appropriate protective measures are taken

Possible contaminated soil cuttings or slurry - Approved handling practices, per chemical test

resulting from drilling activities results

- Soils to be contained in drums, if contaminated,

for disposal at licensed off-site facility

Bentonite, cement and other drilling agents - MSDS sheets or consumer product labels

- Approved personal protective equipment

Pinches, cuts, strains - Personnel wear hard hats, gloves

- Safe lifting practices

6. Move drill rig off of and Electrical environment - Have owner-authorized personnel accompany

between borehole locations - Approved electrically-resistant footwear

Moving vehicles in vicinity - Reflective safety vests or other clothing

Equipment or personnel contacting live electrical - Safe limits of approach

apparatus

NOTES:

1. Borehole locations shown on attached plan.

Instructions: 1. To be prepared by the Supervisor most directly involved in the work.

2. Must be approved by preparer's management Supervisor.

3. Must be reviewed by all workers involved in the work.

4. Emergency Plan must be considered.

5. Change in work plan requires review of JSA with all addenda documented.

S-ar putea să vă placă și

- JSA Demolition and DisposalDocument7 paginiJSA Demolition and Disposalm4l4ysia60% (5)

- Jsa ExcavatorDocument1 paginăJsa Excavatorbladeliger220% (1)

- Crane JSADocument5 paginiCrane JSAKritsada Tiwutanon100% (1)

- NWC Corporate Projects Risk Assessment Forms: Job / TaskDocument3 paginiNWC Corporate Projects Risk Assessment Forms: Job / TaskNowfal HabeebÎncă nu există evaluări

- Jsa For Civil Confined Space EntryDocument11 paginiJsa For Civil Confined Space EntryKhuda BukshÎncă nu există evaluări

- Jha For RoadworksDocument15 paginiJha For RoadworksHenry RajahÎncă nu există evaluări

- JSA-001 Earth Works & Civil WorksDocument5 paginiJSA-001 Earth Works & Civil WorksMoaatazz Nouisri50% (2)

- JSA For Bore Hole DrillingDocument4 paginiJSA For Bore Hole DrillingWit world77% (13)

- Concrete Cutting JsaDocument4 paginiConcrete Cutting JsaMohammad Irfan Kiki IsmailÎncă nu există evaluări

- JHA For Pipeline Construction - Rev.03Document15 paginiJHA For Pipeline Construction - Rev.03Sreekumar67% (3)

- Simple Workbench Plans - The Family Handyman PDFDocument7 paginiSimple Workbench Plans - The Family Handyman PDFsokiÎncă nu există evaluări

- Manual Excavation JSADocument1 paginăManual Excavation JSATausif Khan100% (2)

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Document7 paginiHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Osiobe Ewomazino50% (2)

- Jsa For Road WorksDocument11 paginiJsa For Road Worksyc safety75% (12)

- Sinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Document3 paginiSinopec Northen Construction Camp - Tilenga Job Hazard Analysis (Jha)Nora Afzam Abd WahabÎncă nu există evaluări

- JSA MasnoryDocument4 paginiJSA Masnorysubhanmusadiq100% (1)

- JSA For Installation of Precast SlabDocument4 paginiJSA For Installation of Precast Slabyc safety100% (3)

- JSA For Cutting, Grinding and WeldingDocument4 paginiJSA For Cutting, Grinding and Weldingyc safety100% (3)

- JSA-Site Survey and Downloading of Relay ConfigurationDocument4 paginiJSA-Site Survey and Downloading of Relay Configurationfrancis_e_tan100% (2)

- JOB HAZARD ANALYSIS (Pipe Laying)Document9 paginiJOB HAZARD ANALYSIS (Pipe Laying)jay R100% (3)

- JHA - Civil Work - Excavation (Manual & Mechanical), Form Work & Concreting For Marlin ProjectDocument9 paginiJHA - Civil Work - Excavation (Manual & Mechanical), Form Work & Concreting For Marlin ProjectKelvin TanÎncă nu există evaluări

- JHA DrillingDocument4 paginiJHA Drillingjay RÎncă nu există evaluări

- JSA DrillingDocument12 paginiJSA DrillingAbdus SamadÎncă nu există evaluări

- Mie-Hse-Jha-001 - Mobilization, Demobilization of Site Office, Storage Container and Workshop SetupDocument5 paginiMie-Hse-Jha-001 - Mobilization, Demobilization of Site Office, Storage Container and Workshop SetupLuqman Osman100% (4)

- Draft JSA Levelling & GradingDocument9 paginiDraft JSA Levelling & GradingAzeem Khan33% (3)

- Job Safety Analysis: Required References Jsa ReviewDocument4 paginiJob Safety Analysis: Required References Jsa ReviewMoaatazz Nouisri100% (4)

- JSA For Concrete WorkDocument6 paginiJSA For Concrete Worklê ngọc tùng0% (1)

- JSA Demolition Wall B#3Document2 paginiJSA Demolition Wall B#3tit somm100% (3)

- Operation and Maintenance Manual Mitsubishi SS Series Engelska PDFDocument93 paginiOperation and Maintenance Manual Mitsubishi SS Series Engelska PDFHữu Dũng Nguyễn100% (1)

- JSA HandToolsDocument2 paginiJSA HandToolsCristina Rican100% (3)

- Jha RoofingDocument4 paginiJha Roofingahmadhatake100% (1)

- JSA For Brick WorkDocument3 paginiJSA For Brick Workwahyu nugroho83% (6)

- 004 Piling JSADocument5 pagini004 Piling JSAmidozotyÎncă nu există evaluări

- Jsa CraneDocument3 paginiJsa Cranenattwa201075% (24)

- JHA Scaffolding ErectionDocument12 paginiJHA Scaffolding ErectionChayank TiwariÎncă nu există evaluări

- IPIMS Background Learning - Drillstring, Drill Bits and Drilling FluidDocument14 paginiIPIMS Background Learning - Drillstring, Drill Bits and Drilling Fluidfebry_rfÎncă nu există evaluări

- JHA For Excavation Backfilling and Compaction R 01Document6 paginiJHA For Excavation Backfilling and Compaction R 01Sreekumar100% (2)

- Job Safety Analysis: Manual ExcavationDocument2 paginiJob Safety Analysis: Manual Excavationfdfddf dfsdfÎncă nu există evaluări

- Sr. No. Location Type TR Qty: Area SheetDocument20 paginiSr. No. Location Type TR Qty: Area SheetNandan Raje100% (1)

- Demolition PDFDocument2 paginiDemolition PDFvinothÎncă nu există evaluări

- JSA-Manual Lifting of MaterialsDocument3 paginiJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- Halliburton: Mobilize Equipment Job Safety AnalysisDocument1 paginăHalliburton: Mobilize Equipment Job Safety Analysisaneshse100% (2)

- R1937-JSA-004 Job Safety Analysis For Pipe PullDocument3 paginiR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalÎncă nu există evaluări

- Concrete Work JSADocument1 paginăConcrete Work JSAAnonymous goXrLOI33% (3)

- KPC-Core Logging ManualDocument44 paginiKPC-Core Logging ManualSupriyanto Drs0% (1)

- Excavation and Back Filling Works JsaDocument3 paginiExcavation and Back Filling Works Jsarashid zaman76% (17)

- JHA Civil WorksDocument2 paginiJHA Civil Worksethelchudi100% (11)

- Gap AnalysisDocument12 paginiGap AnalysisQin QinÎncă nu există evaluări

- Excavation and Back Filling Works JsaDocument3 paginiExcavation and Back Filling Works JsaNazir Hussain67% (12)

- SWMS 001 Drilling Soil BoresDocument3 paginiSWMS 001 Drilling Soil BoresEngr Faheem AkhtarÎncă nu există evaluări

- JSA-010 Excavation Sampling PDFDocument5 paginiJSA-010 Excavation Sampling PDFArgaYurIstiawanÎncă nu există evaluări

- 1.SW-JSA - Piping-1 - Fabrication and Erection of Piping ActivityDocument5 pagini1.SW-JSA - Piping-1 - Fabrication and Erection of Piping ActivityAnwar AliÎncă nu există evaluări

- JSA-Road Crossing of 6'' PipelineDocument6 paginiJSA-Road Crossing of 6'' PipelineRidha BennasrÎncă nu există evaluări

- Jsa Working at Height (Maintenance & Cleaning)Document2 paginiJsa Working at Height (Maintenance & Cleaning)Nur Syafiqah Mat Rapie100% (2)

- Jsa General HousekeepingDocument2 paginiJsa General HousekeepingHow Chin Engineering Sdn Bhd44% (9)

- Job Safety Analysis PlumbersDocument5 paginiJob Safety Analysis Plumbersallen2912100% (1)

- Data Centre Design and Operational Best Practices ABBDocument26 paginiData Centre Design and Operational Best Practices ABBYashveer TakooryÎncă nu există evaluări

- 013 JSA For Earthwork at Receiving BasinDocument4 pagini013 JSA For Earthwork at Receiving BasinHilbrecht De Pedro100% (1)

- JSA Piling WorkDocument6 paginiJSA Piling WorkAhmad 'mat' Rahmat100% (2)

- Job Safety Analysis (JSA) Worksheet Attachment III PTW No.: - Date IssuedDocument3 paginiJob Safety Analysis (JSA) Worksheet Attachment III PTW No.: - Date IssuedSawLaiBoyanÎncă nu există evaluări

- Piling Hazards and RisksDocument6 paginiPiling Hazards and Risksjoaonunes.40544364% (11)

- Aluminium 7075 SpecDocument2 paginiAluminium 7075 Specadam.el.polaco7881Încă nu există evaluări

- JSA-009a Drilling and Mon Well Construction-SonicDocument4 paginiJSA-009a Drilling and Mon Well Construction-SonicDedi Apriadi86% (7)

- Hip & Jsa For Abqq-472Document13 paginiHip & Jsa For Abqq-472javithÎncă nu există evaluări

- Excavations JSA Final 2015Document5 paginiExcavations JSA Final 2015jithin shankarÎncă nu există evaluări

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Document6 paginiJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganÎncă nu există evaluări

- Boiler InstallationDocument2 paginiBoiler InstallationRod Kenneth LubongÎncă nu există evaluări

- PTW JHA Electrical Wiring Installation Work at Air Dryer RoomDocument4 paginiPTW JHA Electrical Wiring Installation Work at Air Dryer RoomPHH9834Încă nu există evaluări

- WMD 2003 Paper PDFDocument16 paginiWMD 2003 Paper PDFQin QinÎncă nu există evaluări

- Hand Saw SopDocument4 paginiHand Saw SopQin QinÎncă nu există evaluări

- Quekia Plastic Factory's Accidents Cause Knowledge About Safety, and Etc. Increasing Every Year Quekia Plastic Factory'sDocument6 paginiQuekia Plastic Factory's Accidents Cause Knowledge About Safety, and Etc. Increasing Every Year Quekia Plastic Factory'sQin QinÎncă nu există evaluări

- The Plastics FactoryDocument6 paginiThe Plastics FactoryQin QinÎncă nu există evaluări

- Popset Data Sheet NewDocument1 paginăPopset Data Sheet NewQin QinÎncă nu există evaluări

- 232-02 Ceramic Foam FilterDocument6 pagini232-02 Ceramic Foam Filternagola10Încă nu există evaluări

- SD5076 DRAFT BREEAM UK New Construction 2014 Technical Manual ISSUE 0.1Document401 paginiSD5076 DRAFT BREEAM UK New Construction 2014 Technical Manual ISSUE 0.1MBMÎncă nu există evaluări

- Temp TransducerDocument32 paginiTemp TransducerGunjan VarshneyÎncă nu există evaluări

- PWC - Water Cooled Packaged UnitsDocument12 paginiPWC - Water Cooled Packaged UnitsSameera LakmalÎncă nu există evaluări

- ProMinent Operating Instructions Meta HM-HKDocument20 paginiProMinent Operating Instructions Meta HM-HKivan_shterevÎncă nu există evaluări

- 00 RRL Development of Bamboo Floor TilesDocument6 pagini00 RRL Development of Bamboo Floor TilesShanaia Bual0% (1)

- Aw-Sd130 150 SS SMDocument36 paginiAw-Sd130 150 SS SMDiana MarzukiÎncă nu există evaluări

- Scramjet EngineDocument12 paginiScramjet EngineAditya UÎncă nu există evaluări

- Productdisassemblychart 1Document2 paginiProductdisassemblychart 1api-450114937Încă nu există evaluări

- Problem Set 1-Special Term-Thermo and Fluid MechanicsDocument2 paginiProblem Set 1-Special Term-Thermo and Fluid MechanicsChristian Husmillo ValenzuelaÎncă nu există evaluări

- Brosura - Sursa Putere PS100 - 2011 (En) PDFDocument2 paginiBrosura - Sursa Putere PS100 - 2011 (En) PDFCata CatalinÎncă nu există evaluări

- Allectra 12 KF IsoDocument20 paginiAllectra 12 KF Isomsyan1965Încă nu există evaluări

- TCM Brochure 2016Document2 paginiTCM Brochure 2016George YapÎncă nu există evaluări

- Cold and Dry Climatic Zone of IndiaDocument16 paginiCold and Dry Climatic Zone of IndiaAnirudh BabbarÎncă nu există evaluări

- 2116complete PDFDocument94 pagini2116complete PDFΑνέστηςΓιαννογλούδηςÎncă nu există evaluări

- Pipe Inspection RobotDocument13 paginiPipe Inspection RobotJeevan Landge PatilÎncă nu există evaluări

- GRP-32-Lighting and Ventilation of TunnelDocument24 paginiGRP-32-Lighting and Ventilation of TunnelKaushal MehtaÎncă nu există evaluări

- Honda NSR250 MC21-28 Crankshaft AssemblyDocument1 paginăHonda NSR250 MC21-28 Crankshaft AssemblyShahrizal OmarÎncă nu există evaluări

- Contract ID: Contract NameDocument7 paginiContract ID: Contract NameGraceÎncă nu există evaluări

- Proline Prosonic FlowDocument24 paginiProline Prosonic FlowDavid Cruz ZamoraÎncă nu există evaluări

- McqsDocument13 paginiMcqssezulfiqarÎncă nu există evaluări

- Civil Rate Anyl 1Document72 paginiCivil Rate Anyl 1SarinÎncă nu există evaluări

- งานนำเสนอ1Document22 paginiงานนำเสนอ1piangphetÎncă nu există evaluări