Documente Academic

Documente Profesional

Documente Cultură

Comparison ASTM A 3388 & ISO 11496

Încărcat de

Rahul Moottolikandy0 evaluări0% au considerat acest document util (0 voturi)

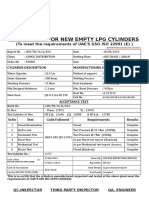

113 vizualizări1 paginăThis document provides a detailed comparison of the requirements of ASTM A 388 and ISO 11496 standards for ultrasonic testing of steel products. Some key differences are that ASTM A 388 specifically covers ultrasonic testing of heavy steel forgings, while ISO 11496 covers end inspection of seamless or welded tubular products. ISO 11496 allows a larger maximum transducer width of 25mm compared to 30mm in ASTM A 388. Both standards require a flat bottom hole reference block, but with slightly different dimensions. Finally, ISO 11496 does not discuss back wall loss acceptance criteria like ASTM A 388 does.

Descriere originală:

a

Titlu original

Comparison ASTM a 3388 & ISO 11496

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOC, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis document provides a detailed comparison of the requirements of ASTM A 388 and ISO 11496 standards for ultrasonic testing of steel products. Some key differences are that ASTM A 388 specifically covers ultrasonic testing of heavy steel forgings, while ISO 11496 covers end inspection of seamless or welded tubular products. ISO 11496 allows a larger maximum transducer width of 25mm compared to 30mm in ASTM A 388. Both standards require a flat bottom hole reference block, but with slightly different dimensions. Finally, ISO 11496 does not discuss back wall loss acceptance criteria like ASTM A 388 does.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

113 vizualizări1 paginăComparison ASTM A 3388 & ISO 11496

Încărcat de

Rahul MoottolikandyThis document provides a detailed comparison of the requirements of ASTM A 388 and ISO 11496 standards for ultrasonic testing of steel products. Some key differences are that ASTM A 388 specifically covers ultrasonic testing of heavy steel forgings, while ISO 11496 covers end inspection of seamless or welded tubular products. ISO 11496 allows a larger maximum transducer width of 25mm compared to 30mm in ASTM A 388. Both standards require a flat bottom hole reference block, but with slightly different dimensions. Finally, ISO 11496 does not discuss back wall loss acceptance criteria like ASTM A 388 does.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 1

Detailed Comparison of ASTM A 388 & ISO 11496 Requirements

Item ASTM A 388 ISO 11496 Significant differences

between ASTM A 388

vs. ISO 11496

Ref. Description Cl. Content Cl. Content Yes/ Details

# # # No

1 Scope 1.1 This practice covers the examination 1.1 This International Standard Yes A 388-specifically

procedures for the contact, pulse- specifies requirements for full for heavy steel

echo ultrasonic examination of peripheral ultrasonic testing of forging.

heavy steel forgings by the straight- the ends of seamless and welded

and angle-beam techniques. The tubes for the detection of ISO 11496 End

straight-beam techniques include laminar imperfections. circumferential

utilization of the DGS (Distance Gain It is intended to detect, over a inspection of

Size) method. zone at the ends of plain end seamless or

and beveled end tubes, welded tubular

laminar imperfections which may product.

interfere with subsequent

fabrication operations (e.g.

welding, ultrasonic inspection

of welds. etc,),

5 Apparatus 5.2 Search Units having a transducer 4.3 The maximum width of Yes ISO 11496 –

App with 1 -1/ 8 in. [30 mm] maximum each individual transducer, allowable

endi dimensions shall be used for measured parallel to the major maximum

x straight-beam scanning. axis of the tube, shall be 25 mm. transducer dia.

(X2) 25mm

8 Reference Block 8.2. A flat bottom hole with 6.5mm² 6 6mm FBH or 6mm length of No.

for calibration 2.2 reflection area of reference curve rectangular recess with 6 (+10%,

-0%) width reflector.

11 Acceptance 11.3 Any back wall loss in some %. 8 Any indication equal to or crossing Yes ISO 11496 –

Criteria Any indication equal to or crossing threshold/trigger alarm shall not doesn’t talk about

DAC/Thresholds shall not be be acceptable. BW loss

acceptable.

Note this document is not intended to replace the standards but rather as a tool to facilitate comparison between standard

Prepared by: Shailendra Singh

S-ar putea să vă placă și

- Hydro Test Key PointsDocument16 paginiHydro Test Key PointsRahulÎncă nu există evaluări

- NDT Magnetic Particle (Home Study) PDFDocument411 paginiNDT Magnetic Particle (Home Study) PDFdonciriusÎncă nu există evaluări

- U5 - Ultrasonic InspectionDocument83 paginiU5 - Ultrasonic InspectionSuraj B SÎncă nu există evaluări

- 3x Exemplar 2017 en PDFDocument4 pagini3x Exemplar 2017 en PDFgudzalovÎncă nu există evaluări

- Advanced Materials '93: Computations, Glassy Materials, Microgravity and Non-Destructive TestingDe la EverandAdvanced Materials '93: Computations, Glassy Materials, Microgravity and Non-Destructive TestingÎncă nu există evaluări

- Brinell Hardness of Metallic Materials: Standard Test Method ForDocument32 paginiBrinell Hardness of Metallic Materials: Standard Test Method ForJeffersonCruzÎncă nu există evaluări

- Insulation Inspection ReportDocument1 paginăInsulation Inspection ReportKarthikÎncă nu există evaluări

- Welding Gauges PDFDocument4 paginiWelding Gauges PDFsopan kharcheÎncă nu există evaluări

- Guide To Fillet WeldingDocument7 paginiGuide To Fillet WeldingPeter KyawÎncă nu există evaluări

- E428Document6 paginiE428valentinÎncă nu există evaluări

- Draft Wps Astm A 743 GR - Ca6nmDocument2 paginiDraft Wps Astm A 743 GR - Ca6nmIlham PaneÎncă nu există evaluări

- ppt1 PDFDocument48 paginippt1 PDFOmar SalihÎncă nu există evaluări

- High Voltage Porosity2Document14 paginiHigh Voltage Porosity2Alejandro EstremadoyroÎncă nu există evaluări

- Evaluation of The Ductile-To-Brittle Transition Temperature in Steel Low CarbonDocument12 paginiEvaluation of The Ductile-To-Brittle Transition Temperature in Steel Low CarbonBurag HamparyanÎncă nu există evaluări

- VT & PT - NotesDocument10 paginiVT & PT - Notessanjeev sahota100% (1)

- HHHHHHHHJJJJJJ: O O O ODocument1 paginăHHHHHHHHJJJJJJ: O O O OAli MoosaviÎncă nu există evaluări

- Visual Testing of Asme Codes & Iso Standars Differences and SimilaritiesDocument2 paginiVisual Testing of Asme Codes & Iso Standars Differences and SimilaritiesNaik Kiran GopiÎncă nu există evaluări

- 1.2 Resistance and Special WeldingDocument14 pagini1.2 Resistance and Special WeldingnikhilbathamÎncă nu există evaluări

- Spec Sheet - Handler 187Document4 paginiSpec Sheet - Handler 187Hobart Welding ProductsÎncă nu există evaluări

- Welding Gauge: Crown Height Fillet Weld Leg HeightDocument1 paginăWelding Gauge: Crown Height Fillet Weld Leg Heightabhics67Încă nu există evaluări

- Hashemite University - NDT Overview PDFDocument7 paginiHashemite University - NDT Overview PDFgeorgescribd1103Încă nu există evaluări

- National Institute of Technology: M. Tech. DEGREE IN Non - Destructive TestingDocument39 paginiNational Institute of Technology: M. Tech. DEGREE IN Non - Destructive TestingAvijit DebnathÎncă nu există evaluări

- RT Standards NotesDocument4 paginiRT Standards NotesprabhuÎncă nu există evaluări

- LS - prt.TUB.073 Residual Magnetic Inspection MethodDocument6 paginiLS - prt.TUB.073 Residual Magnetic Inspection MethodAlphonse YACKAMAMBO DIBACKAÎncă nu există evaluări

- Resistance Welding WpsDocument1 paginăResistance Welding WpsQwertyÎncă nu există evaluări

- Material Data Sheet: Casting Material: Stainless Steel CF8MDocument9 paginiMaterial Data Sheet: Casting Material: Stainless Steel CF8MakshayÎncă nu există evaluări

- Welder Qualification ReportDocument2 paginiWelder Qualification ReportSyed Mahmud Habibur RahmanÎncă nu există evaluări

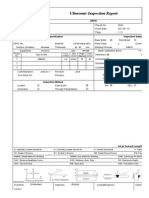

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocument6 paginiUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mÎncă nu există evaluări

- RT ProcedureDocument10 paginiRT ProcedureSandeep SundriyalÎncă nu există evaluări

- Wis5 TermsDocument29 paginiWis5 Termsravi00098Încă nu există evaluări

- Calibrating Pressure GaugesDocument4 paginiCalibrating Pressure GaugesRonny AndalasÎncă nu există evaluări

- What Is NDT ?: Detection of Damage Before BreakdownDocument40 paginiWhat Is NDT ?: Detection of Damage Before BreakdownAnik hasan BadhonÎncă nu există evaluări

- Industrial radiography A Complete Guide - 2019 EditionDe la EverandIndustrial radiography A Complete Guide - 2019 EditionÎncă nu există evaluări

- NoticeDocument1 paginăNoticeAnirban Sen SharmaÎncă nu există evaluări

- API2000 Tank Venting CalcsDocument5 paginiAPI2000 Tank Venting Calcsruhul01Încă nu există evaluări

- NATCO Presentation - Desalters PDFDocument12 paginiNATCO Presentation - Desalters PDFshahmkamalÎncă nu există evaluări

- Industrial Radiography PDFDocument1 paginăIndustrial Radiography PDFLalit MohanÎncă nu există evaluări

- Is 7310 RequirementsDocument4 paginiIs 7310 RequirementsRavichandran Tirupattur SubramaniamÎncă nu există evaluări

- Chemical Composition - Is 2062 - Anx - BDocument2 paginiChemical Composition - Is 2062 - Anx - BTuhin Subhra Mondal100% (4)

- Wps Imco Is-101801-17 Saw Twin Arc - Aws d1.1 Rev 01Document14 paginiWps Imco Is-101801-17 Saw Twin Arc - Aws d1.1 Rev 01Mark AnthonyÎncă nu există evaluări

- Barc NDT PDFDocument7 paginiBarc NDT PDFSAYAN GHOSHALÎncă nu există evaluări

- UT Outline Training LV IIIDocument4 paginiUT Outline Training LV IIITrung Tinh HoÎncă nu există evaluări

- Specifications For Plates: Chemical Composition Mechanical PropertiesDocument7 paginiSpecifications For Plates: Chemical Composition Mechanical Propertiesprajakt_pieÎncă nu există evaluări

- ANSWER: Dye Penetrant Test Explanation:: No Explanation Is Available For This Question!Document4 paginiANSWER: Dye Penetrant Test Explanation:: No Explanation Is Available For This Question!shyamkumar rakoti0% (1)

- Jayesh ResumeDocument3 paginiJayesh ResumeJayeshÎncă nu există evaluări

- Ect SurfaceDocument3 paginiEct SurfaceTrung Tinh HoÎncă nu există evaluări

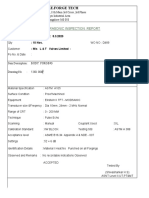

- M.E.Forge Tech: Ultrasonic Inspection ReportDocument1 paginăM.E.Forge Tech: Ultrasonic Inspection ReportK.s. Raghavendra KumarÎncă nu există evaluări

- SSIS Visual Examination Report FormatDocument1 paginăSSIS Visual Examination Report FormatSalman KhanÎncă nu există evaluări

- QAP Seamless PipeDocument2 paginiQAP Seamless Pipechetan85Încă nu există evaluări

- Cast Steel GradesDocument5 paginiCast Steel Gradessohan_miyawala1906Încă nu există evaluări

- PT Outline Training LV IIIDocument2 paginiPT Outline Training LV IIITrung Tinh HoÎncă nu există evaluări

- Ultrasonic Testing of Tube To Tube SheetDocument6 paginiUltrasonic Testing of Tube To Tube SheetDARSHIL RAJPURAÎncă nu există evaluări

- 096 SelDocument3 pagini096 SelPiyush SrivastavaÎncă nu există evaluări

- Sievert India Pvt. LTD.: Question PaperDocument10 paginiSievert India Pvt. LTD.: Question PaperPrabhuÎncă nu există evaluări

- Ultrasonic NotesDocument5 paginiUltrasonic NotesannapoornaavulaÎncă nu există evaluări

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDDocument9 pagini2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanÎncă nu există evaluări

- Neutron RadiographyDocument29 paginiNeutron RadiographyKaitlyn SmallfootÎncă nu există evaluări

- En583 6Document22 paginiEn583 6chungndtÎncă nu există evaluări

- 08 Omniscan ConventionsDocument11 pagini08 Omniscan ConventionsLương Hồ VũÎncă nu există evaluări

- Radiographic Testing Training OutlineDocument2 paginiRadiographic Testing Training OutlineTino SabalÎncă nu există evaluări

- Updated Asnt-Ndt Level - II in RT Ut MT PTDocument4 paginiUpdated Asnt-Ndt Level - II in RT Ut MT PTJason RogersÎncă nu există evaluări

- IPBD Instruction Manual PDFDocument41 paginiIPBD Instruction Manual PDFrobinknit2009Încă nu există evaluări

- Impact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989De la EverandImpact of Non-Destructive Testing: Proceedings of the 28th Annual British Conference on Non-Destructive Testing, Sheffield, UK, 18-21 September 1989C. BrookÎncă nu există evaluări

- Art 23 AsmeDocument10 paginiArt 23 AsmeKirvi16Încă nu există evaluări

- Material Inspected This Visit Pipe Unloading Inspection at Sohar PortDocument7 paginiMaterial Inspected This Visit Pipe Unloading Inspection at Sohar PortRahul MoottolikandyÎncă nu există evaluări

- Need of Surface TreatmentDocument6 paginiNeed of Surface TreatmentRahul MoottolikandyÎncă nu există evaluări

- Paint GlossaryDocument18 paginiPaint Glossaryramaraj_37Încă nu există evaluări

- OrganicDocument11 paginiOrganicRahul MoottolikandyÎncă nu există evaluări

- 1Document17 pagini1Rahul MoottolikandyÎncă nu există evaluări

- What Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Document1 paginăWhat Is Surface Cleanliness?? How Do You Relate It With Surface Profile?? Where Do You Find Details About Surface Profile??Rahul MoottolikandyÎncă nu există evaluări

- Material Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 paginiMaterial Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyÎncă nu există evaluări

- Presented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaDocument6 paginiPresented To The Philippine Welding Society, 11th October 1997 by John W. Hill BA (Chem) General Manager Specialty Products, Callington Haven Pty LTD, Sydney, AustraliaRahul MoottolikandyÎncă nu există evaluări

- Report #19aDocument2 paginiReport #19aRahul MoottolikandyÎncă nu există evaluări

- Report #16ADocument2 paginiReport #16ARahul MoottolikandyÎncă nu există evaluări

- Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 paginiItem Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyÎncă nu există evaluări

- Date Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalDocument1 paginăDate Inspectors Mandays Rahul Sandip 7am To 7pm 7pm To 7am 4/7/2018 1.5 1.5 3 4/8/2018 1.5 7 Am To 10pm TotalRahul MoottolikandyÎncă nu există evaluări

- Stainless 20Document45 paginiStainless 20k_sivakumar16Încă nu există evaluări

- Material Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 paginiMaterial Inspected This Visit Item Code Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyÎncă nu există evaluări

- Pipeline Pressure Testing Calculations Client: Date: Project: Pipeline Details: From KP 0.012 To KP 22.3 (Insert (A) To (D) )Document3 paginiPipeline Pressure Testing Calculations Client: Date: Project: Pipeline Details: From KP 0.012 To KP 22.3 (Insert (A) To (D) )Rahul MoottolikandyÎncă nu există evaluări

- Inspection NotesDocument1 paginăInspection NotesRahul MoottolikandyÎncă nu există evaluări

- HYDocument6 paginiHYRahul MoottolikandyÎncă nu există evaluări

- Safety Relief ValveDocument1 paginăSafety Relief ValveRahulÎncă nu există evaluări

- Safety Relief ValveDocument1 paginăSafety Relief ValveRahulÎncă nu există evaluări

- Mass Earth's Atmosphere: DensityDocument23 paginiMass Earth's Atmosphere: DensityRahul MoottolikandyÎncă nu există evaluări

- 026 To 033test ReportsDocument40 pagini026 To 033test ReportsRahul MoottolikandyÎncă nu există evaluări

- 026 To 033test ReportsDocument40 pagini026 To 033test ReportsRahul MoottolikandyÎncă nu există evaluări

- Intresting To KnowDocument1 paginăIntresting To KnowRahul MoottolikandyÎncă nu există evaluări

- Report #01Document4 paginiReport #01Rahul MoottolikandyÎncă nu există evaluări

- Material Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryDocument5 paginiMaterial Inspected This Visit: Marking On The Pipes Were Randomly Checked and Found To Be SatisfactoryRahul MoottolikandyÎncă nu există evaluări

- Gate Pass Request Form: Requested Date: Reference NoDocument1 paginăGate Pass Request Form: Requested Date: Reference NoRahul MoottolikandyÎncă nu există evaluări

- Material Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoDocument3 paginiMaterial Inspected This Visit Item No. Quantity Description Tag No., Batch No., Serial No., Cast, Heat NoRahul MoottolikandyÎncă nu există evaluări

- Material Inspected This Visit Pipe Unloading Inspection at Sohar PortDocument7 paginiMaterial Inspected This Visit Pipe Unloading Inspection at Sohar PortRahul MoottolikandyÎncă nu există evaluări

- Learning MenuDocument8 paginiLearning Menuapi-464525668Încă nu există evaluări

- Oculus SDK OverviewDocument47 paginiOculus SDK OverviewparaqueimaÎncă nu există evaluări

- Effect of Petrol Fumes On An Anthropometry and Ventilatory Function Among Petrol Pump Workers of Puducherry, IndiaDocument13 paginiEffect of Petrol Fumes On An Anthropometry and Ventilatory Function Among Petrol Pump Workers of Puducherry, IndiaABHINABA GUPTAÎncă nu există evaluări

- Sqluser v11r1Document199 paginiSqluser v11r1samnolenÎncă nu există evaluări

- EI 6702-Logic and Distributed Control SystemDocument2 paginiEI 6702-Logic and Distributed Control SystemMnskSaro50% (2)

- MD Manu en Megaflex WebDocument58 paginiMD Manu en Megaflex WebPhu, Le HuuÎncă nu există evaluări

- Week 1 Lesson 1 2nd QuarterDocument2 paginiWeek 1 Lesson 1 2nd QuarterKristine Jewel MacatiagÎncă nu există evaluări

- Urban Road Types 25.01.2022Document5 paginiUrban Road Types 25.01.2022Balogun IbrahimÎncă nu există evaluări

- Design and Analysis of Monopole Circularly Polarised Microstrip Patch Antenna Using HFSSDocument17 paginiDesign and Analysis of Monopole Circularly Polarised Microstrip Patch Antenna Using HFSSKashif FurkanÎncă nu există evaluări

- Product Specifications: Handheld Termination AidDocument1 paginăProduct Specifications: Handheld Termination AidnormÎncă nu există evaluări

- Dynamic Force AnalysisDocument13 paginiDynamic Force AnalysisJakesÎncă nu există evaluări

- Sewage: Vag Hade Flap ValveDocument4 paginiSewage: Vag Hade Flap ValveAhmedRamadanÎncă nu există evaluări

- Life Processes: Science Unit 1Document19 paginiLife Processes: Science Unit 1patil pratikÎncă nu există evaluări

- فيزياء لغات ثانوية عامة أنجليزى-webDocument462 paginiفيزياء لغات ثانوية عامة أنجليزى-webMohamed RayanyÎncă nu există evaluări

- Test Bank Chapter (4) : Choose The Correct AnswerDocument2 paginiTest Bank Chapter (4) : Choose The Correct AnswerteafÎncă nu există evaluări

- Serie W11 PDFDocument2 paginiSerie W11 PDFOrlandoÎncă nu există evaluări

- PRD Doc Pro 3201-00001 Sen Ain V31Document10 paginiPRD Doc Pro 3201-00001 Sen Ain V31rudybestyjÎncă nu există evaluări

- CSIE Fisa Disciplina - Baze de DateDocument4 paginiCSIE Fisa Disciplina - Baze de DateCostin CheluÎncă nu există evaluări

- PS1Document2 paginiPS1Nitesh Kumar DubeyÎncă nu există evaluări

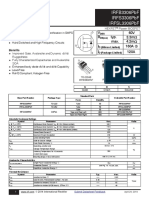

- Irfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADocument12 paginiIrfb3306Pbf Irfs3306Pbf Irfsl3306Pbf: V 60V R Typ. 3.3M: Max. 4.2M I 160A C I 120ADirson Volmir WilligÎncă nu există evaluări

- STD XTH Geometry Maharashtra BoardDocument35 paginiSTD XTH Geometry Maharashtra Boardphanikumar50% (2)

- Lab 3.1 - Configuring and Verifying Standard ACLsDocument9 paginiLab 3.1 - Configuring and Verifying Standard ACLsRas Abel BekeleÎncă nu există evaluări

- GTG - TFA Belt DrivenDocument2 paginiGTG - TFA Belt Drivensuan170Încă nu există evaluări

- Pioneer Car Stereo System DVH-735AVDocument85 paginiPioneer Car Stereo System DVH-735AVJs LópezÎncă nu există evaluări

- Hindu Temples Models of A Fractal Universe by Prof - Kriti TrivediDocument7 paginiHindu Temples Models of A Fractal Universe by Prof - Kriti TrivediAr ReshmaÎncă nu există evaluări

- The Big TEGO. Products Services Data Sheets-75-150-16!76!31-61Document31 paginiThe Big TEGO. Products Services Data Sheets-75-150-16!76!31-61DWI RAHMASARI FATMAWATIÎncă nu există evaluări