Documente Academic

Documente Profesional

Documente Cultură

An Experimental Study of Ball-On-flat Wear On A Newly Developed Rotational Tribometer

Încărcat de

David Rafael RamírezTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

An Experimental Study of Ball-On-flat Wear On A Newly Developed Rotational Tribometer

Încărcat de

David Rafael RamírezDrepturi de autor:

Formate disponibile

Proceedings of the ASME 2015 International Mechanical Engineering Congress and Exposition

IMECE2015

November 13-19, 2015, Houston, Texas

IMECE2015-51148

GRADUATION DESIGN PROJECT: DESIGNING AND BUILDING A PIN-ON-DISK

TRIBOMETER

Elspeth Ochs Patricia Iglesias Victoria

1

Mechanical Engineering Department Mechanical Engineering Department

Rochester Institute of Technology, Rochester Institute of Technology,

Rochester, NY, USA Rochester, NY, USA

508-360-3699, elsmochs@gmail.com

ABSTRACT I second moment of inertia (arm) [m4]

J Polar moment of inertia [kg-cm2]

The purpose of this paper is to describe an independent

L length between supports (lead screw)[m]

study project required before graduation with a master of

L10 bearing life with 90% reliability (bearings) [cycles]

engineering degree in the department of mechanical

M moment around neutral axis [N-m]

engineering at Rochester Institute of Technology. The goal of

M‹x› third order singularity equation (arm) [N-m]

this graduation project was to design and build a Pin-on-Disk

N fixity (lead screw) [--]

Tribometer. The tribometer will be used by the department for

P applied load (arm) [N]

future student research projects. This paper includes the details

R rotating speed (motor) [RPM]

of the design process, such as adaptations from existing

Tfric torque due to friction (motor) [Nm]

tribometers, all required calculations, and descriptions of the

Trod torque due to rotation (motor) [Nm]

machining and assembly. New design concepts presented

V‹x› second order singularity equation (arm) [N]

demonstrate simplicity of construction and use. The required

Varm arm volume (arm) [m3]

calculations include shear and bending moments in the arm,

VCW counterweight volume (arm) [m3]

bearing calculations, lead screw load analysis, counterweight

Vpin pin volume (arm) [m3]

balancing, torque calculations for selecting the correct motor,

Vrod1,Vrod2 volume of threaded rods holding applied

and strain calculations for determining the correct strain gage

weight and counterweight (arm) [m3]

set-up. The paper details part selection, pricing, machining, and

W load [kg]

assembly. Mistakes and alternate design considerations are

b base width (arm)[m]

also discussed.1

c centroid (arm) [m]

NOMENCLATURE d root diameter (lead screw) [m]

e ball bearing constant (bearings)[--]

The nomenclature for this paper includes: g gravity [m/s2]

C dynamic load capacity (bearings) [N] h height (arm) [m]

Cl critical load (lead screw) [N] l1, l2 length of arm, length of threaded rod (arm) [m]

Cs critical speed (lead screw) [RPM] m1, m2 mass of arm, mass of threaded rod (arm) [m]

D diameter of scratch (pin) [m] q‹x› first order singularity equation (arm) [N/m]

E Young’s modulus [Pa] t time (motor) [s]

FA force at point A/pin (arm) [N] x distance from front end of arm (arm) [m]

FB force at point B/bearing pivot (arm) [N] xarm distance from arm pivot (arm) [m]

FC force at point C/counterweight (arm) [N] xCW distance from counterweight (arm) [m]

FN normal force (pin) [N] ε strain (strain gage) [--]

FR reacting force (pin) [N] μk coefficient of kinetic friction [--]

ρ density [kg/m3]

1

Elspeth now works full-time at UTC Aerospace Systems.

1 Copyright © 2015 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/conferences/asmep/86927/ on 05/26/2017 Terms of Use: http://www.asme.org/abo

INTRODUCTION 1 Arm

assembly

Every year, much of the energy that the world consumes is 2 Counter

wasted through friction and wear in mechanical and weight

3 Applied

electromechanical systems. It has been estimated that weight

approximately 11% of the total energy annually consumed in 4 Pin

the U.S. in the four major areas of transportation, 5 Specimen

turbomachinery, power generation and industrial processes can 6 Disk

7 Plunger

be saved through new developments in lubrication and assembly

tribology [1]. Friction is responsible for a major loss of useful 8 Motor

mechanical energy and wear is a major reason for replacing (below

equipment. Thus, a better understanding and utilization of the table)

9 Lead

principles of tribology is particularly important for conservation screw

of energy and materials in engineering design [2]. assembly

The Pin-on-Disk tribometer [3] is the most common type 10 Mount

of friction and wear testing machine. Its basic design consists of 11 Swivel

12 Table

an arm with a pin (rolling ball) attached to the end of an arm

with the pin in direct contact with a test specimen secured on a

rotating disk. A normal load is applied at the end of the arm Figure 1. The pin-on-disk tribometer with labeled parts.

directly onto the pin, which causes the rolling ball inside the

pin to scratch the surface of the disk. The radius of scratch and Creo

the sliding speed can be adjusted. The friction force is The entire design was modeled with Creo as the first step

measured, in this case using a strain gage attached to the arm. in the design process. Once the three-dimensional model was

The amount of wear can be calculated by measuring the wear created, two-dimensional drawings were made for references

width of both specimens [3], from the change of cross- during the machining process. The Creo model is included in

sectional area measured with a profilometer [4] and weighting Fig. 2. All the designs discussed in the paper were first

both specimens before and after the test. developed in Creo. The three-dimensional model was the

The task at hand was to design and build a custom version primary tool developing the design process.

for Dr. Patricia Iglesias Victoria, a faculty of the mechanical

engineering department and tribologist. The rig will be used by

Dr. Iglesias and future graduate and other research students

working with her.

DESCRIPTION OF THE APPARATUS

In this design, an arm holds a pin and, by means of a

counterweight, balances so the pin is just touching the surface

of the tested material. The pin holds a 1.5 mm diameter ball.

The specimen is clamped down onto a plate below the pin.

Before the test begins, a known weight (FN) is added to the top

of the arm directly above the pin, this is the normal force. As

the test begins, the specimen rotates at a constant predesignated

speed and the pin wears the specimen surface in a circle. The

friction coefficient between pin and specimen can be measured

from strain in the arm and converted to force (FR). Using these

two known forces, the coefficient of friction can be calculated

using Eq. (1).

(eq. 1)

The radius of the wear track can be adjusted with a lead

screw. A swivel allows the arm to rotate out, and can lock at set Figure 2. The pin-on-disk tribometer modeled in Creo.

positions to keep the arm stationary both for testing and

changing the pin. The motor and strain gage recordings are CALCULATIONS AND DESIGN

controlled with LabVIEW software. The final assembly is The requirements of the tribometer were to test the

shown in Fig. 1. coefficient of friction between a specimen and the pin. The rig

2 Copyright © 2015 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/conferences/asmep/86927/ on 05/26/2017 Terms of Use: http://www.asme.org/abo

needed to test coefficients between .01 and .99 for both required, which could easily be assembled to one threaded rod

lubricated and dry tests. The table holding the specimen extended from the middle of the arm (alternate designs have

needed to spin at a constant speed up to 500 RPM. Test length multiple counterweights [4]).

must range from a few minutes to 15 hours or possibly more. For the middle of the arm, a ductile material was

Specimens and the pin must be replaceable, preferably easily, necessary to easily measure the strain. Additionally, aluminum

and the pin height needed to be adjusted. The rig required a is much easier/faster to machine. The corresponding shear and

way to adjust between the scratch radius. Components needed moment plots are shown in Fig. 4.

to be strong enough to perform properly, with addition of the

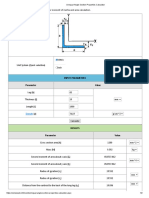

strain gage arm designed to be weak enough to measure strain. Shear Force for Aluminum

5

Finally, the rig must be safe to use with proper protection from 4

Shear Force (N)

possible harm and spray from lubricated tests. All of these 3

2

requirements are proven met within the calculations and design 1

section. 0

-1

-2

-3

Force and moment analysis in the arm -4

0 0.05 0.1 0.15 0.2 0.25 0.3

In order to decide which material would be best for the

Arm Length (m)

arm, a force and moment analysis was completed for both steel

and aluminum. For this calculation, the arm was assumed to be Bending Moment for Aluminum

Bending Moment (N-m)

one piece with the same cross section as the current arm front 0.00

and rear sections). The weight of the rod, threaded rod, counter

weight, and applied weight along with their displacements were -0.10

considered to find the bending and shear diagrams. The weight

was treated as an even load distribution along the arm. The free -0.20

body diagram is included in Fig. 3. The singularity equations

-0.30

are as follows in Eq. (2)-(4) below.

-0.40

0 0.05 0.1 0.15 0.2 0.25 0.3

Arm Length (m)

Figure 4. Shear and moment plots for Aluminum.

Counterweight

In order for the pin to sit on the surface of the specimen,

the arm needed a counterweight on the other side to balance it.

Figure 3. Free Body Diagram of force and moment analysis. Brass was chosen as the counterweight material because of its

large density. Because the volume of each part was known

(from Creo software) as well as the densities of the material,

the volume of the counterweight could be calculated using the

(eq. 2) following moment sum:

(eq. 3) (eq. 5)

Gravity can be canceled out from each term to simplify the

(eq. 4) above equation. The volume of the arm on the right of the

pivot was subtracted out with its same volume on the left side

The pivot was located at 0.21m, the end of the arm and of the pivot. Assuming a conservative distance for the

beginning of the threaded rod at 0.25m, and the threaded rod counterweight to be 9 cm from the pivot, the volume was

ended with the counter weight at 0.3m. calculated as just below 50,000 mm3. A rod with an outer

The factor of safety was also found for each case. Because diameter of 21 mm was available.A 6 mm diameter was

the factor of safety was so great (632 with aluminum), machined out of the counterweight for threading it onto the rod.

aluminum was determined to be the appropriate arm material. The length of the counterweight was machined to 38 mm, a

The exact weight of the counterweight was optimized, as well reasonable length. The corresponding mass of the

as the size. The counterweight is made of brass, as its high counterweight is .42kg.

density minimizes the size needed. Only one weight was

3 Copyright © 2015 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/conferences/asmep/86927/ on 05/26/2017 Terms of Use: http://www.asme.org/abo

Lead screw millimeters from the center of the specimen, and a lock to hold

the arm in place so it does not move during a test. The handle

In order to allow multiple tests on the same sample, the

hangs off the edge of the table to eliminate the possibility of

arm needed to be able to adjust linearly to change the diameter

hand or arm interference. This is shown in the Fig. 6.

of wear track. A simple solution for the linear movement was

to incorporate a lead screw assembly below the arm. An

example from the supplier is included in Fig. 5.

Figure 5. Lead screw assembly excluding shafts from

MiSUMi, the supplier [5].

The lead screw included two shafts to hold the weight of

the assembly, it is important that the screw did not take on any

extra weight. Each end of the screw has a pillow block bearing,

one fixed and one supported. The lead screw length needed to

include difference in radius of scratch, thickness of the mount,

and addition space on each side to keep the lead nut from

bottoming out.

The critical speed of the screw is determined in Eq. 6 to Figure 6. The lead screw assembly incorporated on the

decide whether it will meet the assembly needs: tribometer.

(eq. 6) Swivel design

A design requirement was to make the pin height

N is 1.47 (one end fixed, one end supported) in this case, and d adjustable and completely removable in order to replace the

is provided by the supplier. ball within. To do this, the arm would need to move enough

distance from the testing surface for easy accessibility. A

common approach with pin-on-disk tribometers is to allow the

arm to bend up at a very high angle, possibly up to 45º [4].

This method did not seem desirable for the sake of the

Obviously the lead screw will not exceed its critical speed, it is counterweight interfering with the lead screw assembly beneath

plenty thick and it is much too short for it to be unstable. it. This could be avoided by raising the height of the arm above

The critical load of the lead screw was calculated as such: the lead screw a considerable distance, installing two lead

screws instead of one and the weight would drop down between

them (a common solution), or resolving a way for the

(eq. 7)

counterweight to move entirely out of the way, such as to the

side or completely off. None of these results sounded desirable.

N is 2.00 for one end fixed, one end supported. Because N is It was best if the arm didn’t tilt upwards to replace the pin, so

provided for English units and the supplier dimensions are an alternate to this was to rotate the arm out to the side.

English, the load was first calculated in pounds and converted Originally, the idea was to rotate just the arm above the lead

back to metric. screw, but a locking swivel that was the right size for that

application was not easy to find. Slightly larger locking

swivels, however, were available, but would not fit easily

between the lead screw and arm. The design of the swivel

location needed to be reevaluated. The idea came to put the

Again, the critical scenario is not close to being reached, so this swivel below the entire lead screw assembly. Because the

lead screw more than satisfies the requirements. tribometer is small in general, the locking swivels were large

At the end of the assembly is: a handle to rotate the screw, enough in size to fit the lead screw assembly above it. The arm

a position indicator, which tells the location of the pin in did not need to swing up at a steep angle in order to replace the

4 Copyright © 2015 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/conferences/asmep/86927/ on 05/26/2017 Terms of Use: http://www.asme.org/abo

pin, which made for an easy replacement. The swivel and the (eq. 9)

subassembly it supported is pictured in Fig. 7.

The max condition values were used for calculating the

torque, so assuming the maximum size of the sample (causes

larger moment of inertia), largest wear track radius, largest

coefficient of friction, and maximum applied load. The

moments of inertia were calculated assuming circular sections

except for the plungers, which were point loads. It was

assumed the motor accelerated from naught to 500 RPM in one

second. The following torques were found:

(eq. 10)

The torque is then converted to English units for referrencing

the supplier given chart.

Figure 8 shows that motor 23MD106 will be appropiate

considering the RPS of 8.3 s and max torque of 62.5 oz in. The

motor is connected to the data acquisition (DAQ) system,

Figure 7. Side view of the swivel. which acts as a counter for the motor, and the DAQ is

connected to a computer. A LabVIEW Virtual Instrument (VI)

Once the swivel was purchased, the lock and rotation code was written to control the motor. An external power

worked sufficiently for a commercial product, but there was supply was also required separately to power the motor, which

some considerable play in the locked position considering the had 24 V and 2.7 A voltage and amperage requirements,

design needed to minimize any possible source of vibration. In respectively.

order to tighten up the locking mechanism, the swivel was

partially disassembled, the locking pin hole was bored out

larger for a boss to be press fit in, and a new pin was made to

be long enough to hold in the new boss. A section of the swivel

plate was also machined out in order for the handle to rise up

higher for the longer locking pin.

Motor selection

A motor needed to be selected to meet the torque

requirements at the speed of 500 RPM (8.3 RPS). The motor

speed would kept at a constant throughout a test. A stepper

motor would easily fit the requirements, and Aneheim

Automation provides stepper motors. Stepper motors are less

expensive than servo, and the precision of a servo motor was

not necessary because only the speed being output needed to be

known. Figure 8. Torque curve for motor selections available.

In order to calculate which motor would satisfy the Taken from Anaheim Automation website [6].

conditions, the torque generated by the assembly upon start up

needed to be calculated. The torque caused by all the rotating Strain gage calculation

elements acts similarly to a flywheel and can be found using

During testing, the resulting friction force needed to be

Eq. (8)

measured, this is done by means of a strain gauge mounted on

the arm. Three kinds of strain could act on the arm: axial,

(eq. 8) torsional, and bending. As a frictional force is applied to the tip

of the pin, no axial strain acts on the arm, and both bending and

The torque caused by the friction from the pin is calculated as: torsion strain act on arm. Torsional forces cancel from the full

bridge setup of strain gage, this will be explained further on.

5 Copyright © 2015 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/conferences/asmep/86927/ on 05/26/2017 Terms of Use: http://www.asme.org/abo

The only remaining strain is caused by bending, the equation The strain gage acts as a resistor in a Wheatstone bridge

for pure bending strain is noted below: (Fig. 10), a circuit which can measure unknown resistance.

(eq. 11)

The Young’s Modulus will be the same with each experiment,

and the load will vary from 8.8N (1kg, μ=.9) to .05N (500g,

μ=.01) as extremes, depending on the mass applied to the top of

the arm and the range of estimated coefficient of friction. The

strain value calculated needs to fall in a measurable range of 10- Figure 11. Wheatstone bridge circuitry.

3

and 10-6 strain, so the length, width, and height of the section

are altered to maximize the strain values. The dimensions In a full bridge, each resistor is replaced with a strain gage.

selected were a length of 76mm, width of 10mm, and thickness Gages experiencing positive strain are connected directly with

of 6mm. gages experiencing negative strain (Fig. 12).

Typically, a section of the arm is machined down to alter

the length, width, and thickness parameters to get the strain to a

measurable value. The same concept is applied here, but

instead of machining down the surface, a smaller section of the

arm is detachable. Making this section removable benefits the

design, for example if the smaller section is bent, it can be

replaced with a new piece, and the detailed machining work in

the rest of the arm would not need to be redone. On top of this, Figure 12. Wheatstone bridge with respect to strain layout.

the option to remove the arm is available for replacing the

strain gage. This section is pictured in Fig. 9. Because each resistor is being replaced with a strain gage in

a full bridge set-up, effects such as change in ambient

temperature and extraneous loads cancel out, as long as each

strain gage is centered and parallel to the beam as well as the

strain gages on opposite sides are symmetrically loaded.

Because both the strain gage and the arm are fastened in the

center of the arm, torsional effects are also canceled out.

Arm mid-section design

Figure 9. Strain gage bonded to surface and lead wires Because the middle section of the arm was designed to be

soldered. weaker to increase the axial bending (and strain), it was

important to check if it could hold the weight of the arm and

The configuration of the purchased strain gage for the pin. One possible rudimentary calculation involves making

tribometer is shown in Fig 10. Mounting a strain gage on both sure the stress in the arm did not exceed the yield stress, which

sides of the arm will result in a full bridge set-up, which calculates stress as:

maximizes accuracy of the strain measurement.

(eq. 12)

Each is calculated in Equations (13)-(15).

(eq. 13)

(eq. 14)

(eq. 15)

Stress is solved as:

Figure 10. Strain gage purchased. The yield limit of aluminum is 200 MPa. The dimensions of

the arm are satisfactory.

6 Copyright © 2015 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/conferences/asmep/86927/ on 05/26/2017 Terms of Use: http://www.asme.org/abo

Because the mid-section of the arm was designed to be Shaft

weaker, it is also designed to be removable. This is because if

Simply put, the rotation of the motor transfers into the

it ever needed to be replaced, the detailed machining work at

mounting plate. In order for rotational output from the motor to

both ends would not need to be redone. If the mid-section ever

properly transfer into the plate, specific design considerations

needed to be replaced, the length of the exposed section should

needed to be accounted for in order to minimize slop and

be fastened to be exactly 76.2 mm so that the pin is centered

wobble within the subassembly. The motor shaft and hardened

properly on the disk. A rubber stop is included just below the

shaft are connected by means of a flexible coupling (Fig. 14).

arm towards the back so that the counterweight hanging off the

The shaft connects to the plate by a machined part, it was press

back would never smash into the position indicator directly

fit and secured with set screws to keep from slipping. The part

below it.

is flanged and bolted into the plate. A flanged ball bearing is

bolted to the table, which takes care of a great amount wobble

Plunger design in the shaft. In between this bearing and the machined part is a

Many current tribometer designs mount the test specimen flat bearing; this small piece is important because it allows the

by either bolting down the specimen at its center [X] or by weight of the plate to be held by the table through the bearing it

clamping down the specimen to a plate to a specific bolt pattern sits on. Without it, the motor would not be able to function

[X]. Both designs have advantages. The first allowing the with the weight of the plate assembly pressing down on it.

specimen to be any diameter (assuming it is big enough to fit a Lastly, spacers are surrounding the bolts holding the motor in

bolt and leave enough room to test), but takes time to machine order to further prevent wobble.

each test sample. The second does not need any adjustments

made to the sample, but takes time to unbolt and bolt the

clamps for each test that mounts a different size specimen.

Although this method allows the samples to be a range of

diameters, they still have to be specific.

The goal was to design something that was both quick to

set-up and allowed for any size diameter within a defined range

(.5 mm to 23.5 mm scratch radius was requested). Machining

into the part was not an option, as the specimen size is small coupling

and would leave little room for testing. The solution was

simply to clamp down the specimen with an adjustable threaded

fixture (Fig. 13). This fixture was a stationary piece with a

threaded hole. A long screw was added with a nut to hold it in

place, and a rubber tip to hold the specimen down. Because the

plate will never spin faster than 500 RPM and the pin does not

exert much lateral force on the specimen, tightening the

specimen down with hand tightness is enough to keep the

specimen from moving during tests, The nut can be tightened

with a wrench for a more comfortable clamp.

The specimen also has a range of heights (10 mm to 50

mm). This can be accounted for with the pin height.

Figure 14. Shaft assembly and counterparts.

The platform was machined with a ring pattern to allow the

specimen to be centered visibly. Bearing calculations

The bearing life of the flat bearing can be calculated as

such:

(eq. 16)

C is provided by the supplier. If the load capacity was the same

as the load applied to the bearing, the bearing would last 106

revolutions. The value e is 3 for ball bearings, so is the same

value for each bearing in the tribometer. Assuming that the

bearing runs at 400 RPM (on average) and is used for 10 hours

a day, the flat bearing will fail in 362.5 days (according to that

calculation). In actuality, the tribometer will go without being

Figure 13. Specimen mounted and tightened with plungers. used for many days at a time throughout the year. This bearing

7 Copyright © 2015 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/conferences/asmep/86927/ on 05/26/2017 Terms of Use: http://www.asme.org/abo

is easy to replace, only one screw on the coupling needs to be All surfaces being built upon each other needed to be

loosened, and the entire plate assembly lifts out, and the precision ground. All the ground parts include the table, both

bearing simply sits in place. the plate and platform which mount the specimen, as well as

The flanged linear ball bearing would see the same number the arm mount and plate the arm assembles too. The ground

of rotations, but not a huge amount of force. There may be surfaces (Fig. 15) are flat within a tolerance of .13 mm.

some force from the motor jerking, but not enough to notice

visibly, as it runs smoothly. Very little force would be exerted Case

from the weight tilting because it is restrained from tilting

much, a fraction of the 23N. The dynamic load capacity of the A case was also designed for both safety reasons and to

bearing is 320 N, so the bearing will easily last a long time. prevent splatter for lubricated tests. Because of the handle

The remaining bearings barely rotate or rotate slowly. hanging off the back of the assembly, it made more sense to

These bearings include the two ball bearings in the arm at the only enclose the rotating section instead of the entire assembly.

pivot, the two linear ball bearings sliding on each shaft on The case was designed to not interfere with the arm when

either side of the lead screw, and the two ball bearings in the stationary or rotated out, and needed to be removed for easy

pillow blocks. Because they all do not move much, as long as access to sample set-up. Instead of making one side removable,

the load on the bearings does not exceed the load capacity, it is all four sides were attached together for rigidity, and a

safe to assume these bearings would last plenty of time to serve detachable piece allowed space for the arm to rotate out. The

the assembly. Table 1 shows the loads and load capacities for piece is attached with hand screws and a bracket. The sides

each remaining bearing. were fixed together with an acrylic chemical that melts the

plastic together. The case overhangs the edges on three sides

Table 1. Bearing load capacities and loads and the forth side is supported by the table; on the opposite

edge, the case is held up/kept from sliding out with two

BEARING LOAD LOAD brackets. The case is made of plexiglas (Fig. 16).

LOCATION CAPACITY [N] [N]

Arm pivot 3247 5.40

Linear shafts 262 30.3

Pillow blocks 1300 10.0

Normal force

Once the arm is balanced, a known weight is applied to the

top of the arm directly above the pin. The masses range from

100g to 1000g in 100g increments. The normal force is simply

the mass times gravity:

(eq. 17)

Although this may seem trivial, it is important to simplify the

design whenever possible.

Figure 16. Case assembled and mounted on tribometer.

Detachable piece removed for arm to rotate out.

Ground surfaces

Because acrylic cracks easily when drilled through, it was

risky to drill right into the sides, holes were drilled in a separate

piece and attached to the handles, then glued to the case. The

pieces with holes were taped during the drilling process to keep

them from cracking, and machined slowly with soapy water as

lubricant.

ASSEMBLY

The entire machining and assembly process was completed

over the final three months of the project. The first parts and

materials arrived right before this period, on schedule for

machining.

Figure 15. Table during grounding process.

8 Copyright © 2015 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/conferences/asmep/86927/ on 05/26/2017 Terms of Use: http://www.asme.org/abo

Machined parts Arm subassembly to mount

Most components in the assembly were machined, either Threaded rods, counterweight, applied weight, and pin to arm

entirely or partially. Aluminum was used whenever something Motor and linear bearing to table

stronger was not necessary to simplify the machining. All of Disk subassembly, flat bearing unattached to motor/linear

the machined parts are included in Table 2. Figure 17 includes bearing, coupling fastened last

a picture of the fully machined front end of the arm, showing Case, sitting on table/brackets fastened to table

that individual parts have much machined detail.

The mounting block provides a good example of a part that

Table 2. Fully and partially machined parts needed precision machining and benefited from partial

FULLY MACHINED PARTICALLY MACHINED assembly. The bearing holes were bored out for a press fit

Arm front Threaded rods (2) installation. Their locations were determined from the shafts

Arm back Shaft already assembled to the plate. The press fit requirement

Arm mid section Swivel allowed almost no location and diametral tolerance. This

Arm mid section mounting Handle scenario is similar anywhere something was press fit, such shaft

brackets (2) and other bearing transitions.

Counterweight Lead screw The arm was able to unattach easily. It was helpful during

Mounting block Case the assembly process for machining updates and strain gage

Plate installment.

Disk Another feature that benefited from machining during the

Platform assembly process was the shaft hole in the table. This was

Plunger holders (4) machined after the arm was installed, marked by the location of

Shaft to disk connection the pin. The four motor mounting holes were machined with

Table respect to the shaft. This step is captured in Fig. 18.

Legs (4)

Figure 17. Front end of arm detached after completed

machining.

Assembly order

The advantage of doing an independent project over an

industry product is the order of assembly does not have to be Figure 18. Tribometer partially assembled during machining

entirely defined before the parts have arrived or even before the process.

machining process is complete. This advantage allowed many

parts to be marked with respect to a location of another part’s or The final mechanical assembly was the case. As previously

subassembly’s geometry. This lessened the tolerance on many mentioned, the case was assembled with an acrylic paste, and

machined details, which is important for precision work. the handles attached first by a separate piece then pasted onto

The order of assembly is as follows in Table 3. prevent cracking the main plexiglas.

The strain gage and motor were then wired to the DAQ,

Table 3. Assembly order summarized which connected to the computer.

ASSEMBLY ORDER

Table including legs CONCLUSIONS

Swivel to table As expected, many issues arouse during the machining and

Plate with mounting block and lead screw subassembly to assembly process, due to either unforeseen circumstances or

swivel inexperience. Many design improvements were made along the

Lock and handle to lead screw

9 Copyright © 2015 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/conferences/asmep/86927/ on 05/26/2017 Terms of Use: http://www.asme.org/abo

way. The design already is a streamlined version of existing Engineering Degree with a focus in Mechanics and Design.

pin-on-disk tribometers, but it could be streamlined even Elspeth now works full-time at UTC Aerospace Systems in

further, in terms of both function and physical appeal. For Windsor Locks, CT as a Mechanical Design Engineer in the

example, making the plate, platform, and shaft transition pieces Space Systems group. Her current work supports the design for

lighter would have greatly reduced the power the motor needed. the Orion Spacecraft.

In terms of overall aesthetics, it would have been more visually

pleasing if the bolts were threaded into the plate instead of

attached with nuts. The idea was to minimize tolerance, but REFERENCES

threading into material has a much nicer appearance. The final [1] Bronshteyn, L. A., and Kreiner, J. A. H., 1999, "Energy

difference would be to know many of the design change Efficiency of Industrial Oils," 42, pp. 771-776.

descisions beforehand as to keep shipping costs down. [2] Czichos, H., 1983, "Tribology: Scope and Future Directions

Overall, the tribometer was a success, both for providing of Friction and Wear Research," Journal of Metals, 35(9), pp.

equipment to the department and as a learning experience. 18-20.

[3] Standard test method for wear testing with a pin-on-disk

ACKNOWLEDGMENTS apparatus, ASTM G99-05.

[4] Iglesias, P., Bermudez, M. D., Moscoso, W., Rao, B. C.,

The authors would like to acknowledge the financial

Shankar, M. R., and Chandrasekar, S., 2007, "Friction and Wear

support of the Mechanical Engineering Department at the

of Nanostructured Metals Created by Large Strain Extrusion

Rochester Institute of Technology. Special thanks to the RIT

Machining," Wear, 263(1-6 SPEC. ISS.), pp. 636-642.

machine shop for allowing use of their machines and answering

[5] MiSUMi-Product Specifications. “Lead Screws –For

questions throughout the production process. Additional thanks

Support Units-” June 2014.

to professors, peers, and staff willing to provide feedback and

[6] Anaheim Automation. “23MD - Stepper Motors with

answer questions throughout the entire design, build, and

Integrated Drivers.” 2011. June 2014.

writing process.

[7] CSM Instruments. “CSM TRIBOMETERS--Nano & Micro

range for Tribological studies.” pp. 2. June 2014

About the author

[8] Nanovea. “Tribometers.” pp. 1-4. June 2014.

The project was completed at the Rochester Institute of

Technology while Elspeth was working towards her Master of

10 Copyright © 2015 by ASME

Downloaded From: http://proceedings.asmedigitalcollection.asme.org/pdfaccess.ashx?url=/data/conferences/asmep/86927/ on 05/26/2017 Terms of Use: http://www.asme.org/abo

S-ar putea să vă placă și

- 2 Vikky Kumhar VSRDIJMCAPE 5555 Research Paper 5 5 May 2015Document7 pagini2 Vikky Kumhar VSRDIJMCAPE 5555 Research Paper 5 5 May 2015Kiet Truong AnhÎncă nu există evaluări

- Beam - To-Column Connection PDFDocument5 paginiBeam - To-Column Connection PDFValentinoÎncă nu există evaluări

- Caculation Sheet of MAIN FACTORY-SANG-F18Document28 paginiCaculation Sheet of MAIN FACTORY-SANG-F18Gia Vinh Bui TranÎncă nu există evaluări

- A Contribution To The Selection and Calculation of Screws in High Duty Bolted JointsDocument11 paginiA Contribution To The Selection and Calculation of Screws in High Duty Bolted Jointsخوێندن لە ئەوروپاÎncă nu există evaluări

- Aircraft DesignsDocument101 paginiAircraft DesignsZhest BrownvileÎncă nu există evaluări

- Published Paper - FCGDocument24 paginiPublished Paper - FCGDouglas RossÎncă nu există evaluări

- DETERMINATION OF OPTIMAL CUTTING CONDITIONS Chua Et Al 1991Document9 paginiDETERMINATION OF OPTIMAL CUTTING CONDITIONS Chua Et Al 1991ROZIKINÎncă nu există evaluări

- Experiment p1 Metal Cutting ProcessDocument13 paginiExperiment p1 Metal Cutting Processvipin_shrivastava25Încă nu există evaluări

- A New Dynamic Model For Drilling and Reaming Processes Yang2002Document13 paginiA New Dynamic Model For Drilling and Reaming Processes Yang2002RihabChommakhÎncă nu există evaluări

- Itatech Activity Group ExcavationDocument12 paginiItatech Activity Group ExcavationÜlgen ÜmitÎncă nu există evaluări

- Performance of Dynamometer With Sensor Type Single Bar For Measuring Drive Power of Rotary Friction Welding MachineDocument8 paginiPerformance of Dynamometer With Sensor Type Single Bar For Measuring Drive Power of Rotary Friction Welding MachineAldi muhammad al-muhdarÎncă nu există evaluări

- Ecs258 - Lab Report (Co4: Po4) : Faculty of Civil EngineeringDocument9 paginiEcs258 - Lab Report (Co4: Po4) : Faculty of Civil EngineeringSyafiq FauziÎncă nu există evaluări

- Motion Analysis of 4 Axis Robotic Arm With Inverse Kinematics For Industrial ApplicationDocument9 paginiMotion Analysis of 4 Axis Robotic Arm With Inverse Kinematics For Industrial ApplicationAkky AkkyÎncă nu există evaluări

- Dip 3rd UnitDocument54 paginiDip 3rd UnitSuresh BalamÎncă nu există evaluări

- Instruction Sheet of Sessional - ME 2204Document8 paginiInstruction Sheet of Sessional - ME 2204Nafiul Alam SnigdhoÎncă nu există evaluări

- Diez 2012Document11 paginiDiez 2012Pramod AÎncă nu există evaluări

- MIED179306Document206 paginiMIED179306khalil alhatabÎncă nu există evaluări

- Unequal Angle Section Properties CalculatorDocument4 paginiUnequal Angle Section Properties CalculatorPinku MaitiÎncă nu există evaluări

- Computer Aided Modeling Cost Estimation of A Hand TruckDocument4 paginiComputer Aided Modeling Cost Estimation of A Hand TruckIJARP PublicationsÎncă nu există evaluări

- 304 DesignDocument39 pagini304 DesignPramod KulkarniÎncă nu există evaluări

- Robot StanfordDocument8 paginiRobot StanfordLong TrầnÎncă nu există evaluări

- Torsion TestDocument3 paginiTorsion Testmjayrajsharma19Încă nu există evaluări

- Engine Loads PredictionDocument88 paginiEngine Loads PredictionAdhi1971Încă nu există evaluări

- Lab Manual (ME 3802)Document22 paginiLab Manual (ME 3802)Pranto ShuvoÎncă nu există evaluări

- Chatter Stability of Metal Cutting and Grinding: Al (108) and Byrne Et Al (18) Reviewed The MachiningDocument24 paginiChatter Stability of Metal Cutting and Grinding: Al (108) and Byrne Et Al (18) Reviewed The Machiningsundaramaks saravana muruganÎncă nu există evaluări

- Design and Analyses Re - Bar Bending MachineDocument3 paginiDesign and Analyses Re - Bar Bending MachineMircea100% (1)

- D Liu-Shao2015 Article ANewDynamicModelForVibrationAnDocument23 paginiD Liu-Shao2015 Article ANewDynamicModelForVibrationAnVivek ParmarÎncă nu există evaluări

- Staff College Hyderabad - 2Document38 paginiStaff College Hyderabad - 2Om PrakashÎncă nu există evaluări

- Lecture 11,12&13 PDFDocument29 paginiLecture 11,12&13 PDFRaynier Rellosa KaharianÎncă nu există evaluări

- Solanki (2015) - Weight Optimization in Crane HookDocument5 paginiSolanki (2015) - Weight Optimization in Crane HookGogyÎncă nu există evaluări

- Moment of Inertia of An AreaDocument8 paginiMoment of Inertia of An AreaEzequiel Guillermo Trejo NavasÎncă nu există evaluări

- Stability Prediction Maps in Turning of Difficult-To-Cut MaterialsDocument9 paginiStability Prediction Maps in Turning of Difficult-To-Cut Materialssundaramaks saravana muruganÎncă nu există evaluări

- %1 Lifting Boom, Davits Application and Design Equations and Calculator - Engineers EdgeDocument4 pagini%1 Lifting Boom, Davits Application and Design Equations and Calculator - Engineers EdgePereañez JorgeÎncă nu există evaluări

- Analytical Modelling and Experimental Validation of Micro-Ball-EndDocument15 paginiAnalytical Modelling and Experimental Validation of Micro-Ball-EndChoy Hau YanÎncă nu există evaluări

- A Matlab Program To Study Gust Loading On A Simple Aircraft ModelDocument83 paginiA Matlab Program To Study Gust Loading On A Simple Aircraft Modelmohammadrezamadadi100% (5)

- Dynamic Analysis of Runout Correction in MillingDocument9 paginiDynamic Analysis of Runout Correction in MillingPramod AÎncă nu există evaluări

- Lab Experiment # 02: ObjectiveDocument7 paginiLab Experiment # 02: ObjectiveAbdul WahabÎncă nu există evaluări

- Ultimate Strength of High-Strength Composite Columns After Sustained Service LoadingDocument9 paginiUltimate Strength of High-Strength Composite Columns After Sustained Service LoadingArielÎncă nu există evaluări

- Measuring The Hysteresis LoopDocument15 paginiMeasuring The Hysteresis LoopHassen BrahimÎncă nu există evaluări

- 1 - A New Method For Establishing The Depths of Cut For Cast Iron Parts TurningDocument13 pagini1 - A New Method For Establishing The Depths of Cut For Cast Iron Parts TurningVICTOR HUAMANÎncă nu există evaluări

- Optimization Method For The Design of Axial Hydraulic TurbinesDocument8 paginiOptimization Method For The Design of Axial Hydraulic TurbinesЖивотаЛазаревићÎncă nu există evaluări

- Appropriate Design Method Adopted For Single Point Cutting ToolDocument7 paginiAppropriate Design Method Adopted For Single Point Cutting ToolInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- UIT-ahyan Ince2Document23 paginiUIT-ahyan Ince2Md MehtabÎncă nu există evaluări

- NuTTS 2019 Wawrzusiszyn Kolodziej Bielicki Final VersionDocument6 paginiNuTTS 2019 Wawrzusiszyn Kolodziej Bielicki Final VersionMaciej ReichelÎncă nu există evaluări

- Design Calculation of Frame: AbstractDocument4 paginiDesign Calculation of Frame: AbstractDr. Aung Ko LattÎncă nu există evaluări

- Proj 2021-2Document5 paginiProj 2021-2RAUL J COLON-OLIVERASÎncă nu există evaluări

- Attachment 1638181293Document5 paginiAttachment 1638181293Faizan AlyÎncă nu există evaluări

- UTA016 Engineering Design Project-IDocument5 paginiUTA016 Engineering Design Project-IVishal SinghÎncă nu există evaluări

- DynamometerDocument21 paginiDynamometerHussam El'SheikhÎncă nu există evaluări

- Analysis of Cutting Forces of The Lathe Tool DynamometerDocument8 paginiAnalysis of Cutting Forces of The Lathe Tool DynamometerIJIERT-International Journal of Innovations in Engineering Research and TechnologyÎncă nu există evaluări

- 925261.vulic2016 Damping Excitation in TVCDocument14 pagini925261.vulic2016 Damping Excitation in TVCAamir BalochÎncă nu există evaluări

- Behavior and Analysis of Inverted T Shaped RC Beams Under Shear and Torsion PDFDocument14 paginiBehavior and Analysis of Inverted T Shaped RC Beams Under Shear and Torsion PDFJing CaoÎncă nu există evaluări

- CHIBLI - Texas A - M - Expermental and Numerical Investigation of Profile and Secondary Losses in High Pressure Axial TurbinesDocument245 paginiCHIBLI - Texas A - M - Expermental and Numerical Investigation of Profile and Secondary Losses in High Pressure Axial TurbinesNico ScheggiaÎncă nu există evaluări

- Bjoerheim Per SteinarDocument144 paginiBjoerheim Per SteinarSHARATHÎncă nu există evaluări

- Keplerian Orbit Elements: Cartesian State VectorsDocument3 paginiKeplerian Orbit Elements: Cartesian State VectorsPrithwiraj PaulÎncă nu există evaluări

- Finite Element Analysis of Spur Gear UseDocument7 paginiFinite Element Analysis of Spur Gear UseDevendranath MagantiÎncă nu există evaluări

- Equal Angle Section Properties CalculatorDocument2 paginiEqual Angle Section Properties CalculatorPinku Maiti100% (1)

- (IJETA-V11I1P7) :shubham Mishra, Vikas KumarDocument5 pagini(IJETA-V11I1P7) :shubham Mishra, Vikas KumarIJETA - EighthSenseGroupÎncă nu există evaluări

- Foundation 1 Design ReportDocument5 paginiFoundation 1 Design Reportyug draciÎncă nu există evaluări

- Cancer, Sunlight and Vitamin DDocument8 paginiCancer, Sunlight and Vitamin DDavid Rafael RamírezÎncă nu există evaluări

- Síndrome Visual Informatico PDFDocument17 paginiSíndrome Visual Informatico PDFDavid Rafael RamírezÎncă nu există evaluări

- Sleep Deprivation Accelerates The Progression of Alzheimer's Disease PDFDocument7 paginiSleep Deprivation Accelerates The Progression of Alzheimer's Disease PDFDavid Rafael RamírezÎncă nu există evaluări

- G99 36017Document5 paginiG99 36017David Rafael RamírezÎncă nu există evaluări

- Tribological Analysis of Thin Films by Pin-On-Disc Evaluation of Friction PDFDocument10 paginiTribological Analysis of Thin Films by Pin-On-Disc Evaluation of Friction PDFDavid Rafael RamírezÎncă nu există evaluări

- Leonardo Da Vinci's Studies of FrictionDocument16 paginiLeonardo Da Vinci's Studies of FrictionDavid Rafael RamírezÎncă nu există evaluări

- Nikola Tesla and Samuel ClemensDocument39 paginiNikola Tesla and Samuel ClemensDavid Rafael RamírezÎncă nu există evaluări

- Textbook PDFDocument280 paginiTextbook PDFAnonymous vtFJOT5m92Încă nu există evaluări

- XSteam Excel v2.6Document3 paginiXSteam Excel v2.6pchanycÎncă nu există evaluări

- 14.4D ExerciseDocument18 pagini14.4D ExerciseKnyazev DanilÎncă nu există evaluări

- For ECT & ECE Board ExamDocument60 paginiFor ECT & ECE Board ExamRalph Alvin Quizon100% (2)

- Final DemoDocument7 paginiFinal DemoKiela ArizobalÎncă nu există evaluări

- Ap Physics 1investigation4conservationofenergy PDFDocument17 paginiAp Physics 1investigation4conservationofenergy PDFMir'atun Nissa QuinalendraÎncă nu există evaluări

- Auto Collimator SDocument7 paginiAuto Collimator SRamanjooloo DeelanÎncă nu există evaluări

- Guia Procedimiento Inspeccion MFL PDFDocument6 paginiGuia Procedimiento Inspeccion MFL PDFleonciomavarezÎncă nu există evaluări

- Vfd-E: Parameter ManualDocument26 paginiVfd-E: Parameter ManualMohamed ElsayedÎncă nu există evaluări

- Lec2 - Elementary and Higher Surveying - 2013-2014Document1 paginăLec2 - Elementary and Higher Surveying - 2013-2014Jesus Ray M. MansayonÎncă nu există evaluări

- BC Series 7 - 04-05-10Document39 paginiBC Series 7 - 04-05-10Krista TranÎncă nu există evaluări

- By Dr. Gamal Helmy, PH.D., P.EDocument43 paginiBy Dr. Gamal Helmy, PH.D., P.EAhmed ArafaÎncă nu există evaluări

- Phase/State Transitions of Confectionery Sweeteners: Thermodynamic and Kinetic AspectsDocument16 paginiPhase/State Transitions of Confectionery Sweeteners: Thermodynamic and Kinetic AspectsAlicia MartinezÎncă nu există evaluări

- Sample of Absract, Tableofcontent, ListoffiguresymboletcDocument10 paginiSample of Absract, Tableofcontent, ListoffiguresymboletcEddy FadleyÎncă nu există evaluări

- FlashForge Creator Pro Users Guide PDFDocument40 paginiFlashForge Creator Pro Users Guide PDFkristian1107Încă nu există evaluări

- Large Hadron ColliderDocument23 paginiLarge Hadron ColliderPrakhar AgrawalÎncă nu există evaluări

- Measurements of Dynamic Friction Between Rock andDocument54 paginiMeasurements of Dynamic Friction Between Rock andLuiz Francisco MacedoÎncă nu există evaluări

- HT NotesDocument197 paginiHT NotesT.AnbukumarÎncă nu există evaluări

- Physics 141 Week 2 Solutions - UNLDocument3 paginiPhysics 141 Week 2 Solutions - UNLDillon HikeÎncă nu există evaluări

- Mathcad - Trinity Bearing Capacity - MDKDocument5 paginiMathcad - Trinity Bearing Capacity - MDKjcazÎncă nu există evaluări

- 10 Impedance TubeDocument17 pagini10 Impedance TubeMarco DanielÎncă nu există evaluări

- 22.05 Reactor Physics Part Seventeen: Energy Dependence of FluxDocument12 pagini22.05 Reactor Physics Part Seventeen: Energy Dependence of FluxmsakowskÎncă nu există evaluări

- Computer Vision Three-Dimensional Data From ImagesDocument12 paginiComputer Vision Three-Dimensional Data From ImagesminhtrieudoddtÎncă nu există evaluări

- Flexiweigh Balance AccuracyDocument6 paginiFlexiweigh Balance AccuracyArfan SubhaniÎncă nu există evaluări

- Effect of Corrugation Angle On Performance Evaluation of Plate Type Heat ExchangerDocument6 paginiEffect of Corrugation Angle On Performance Evaluation of Plate Type Heat ExchangerZaw Htet WinÎncă nu există evaluări

- PVT DaneshDocument202 paginiPVT Daneshegv2000Încă nu există evaluări

- Direct Shear Test of Soils Under Consolidated Drained ConditionsDocument9 paginiDirect Shear Test of Soils Under Consolidated Drained ConditionsKoppolu SrinivasuluÎncă nu există evaluări

- Fundamentals of Noise and Vibration Analysis For Engineers: Second EditionDocument9 paginiFundamentals of Noise and Vibration Analysis For Engineers: Second EditionjeyaselvanÎncă nu există evaluări

- Comet Mystery Boxes: Educator GuideDocument4 paginiComet Mystery Boxes: Educator GuideABD00LÎncă nu există evaluări

- Mechanism and Degrees of Freedom 2Document10 paginiMechanism and Degrees of Freedom 2Hamza TariqÎncă nu există evaluări