Documente Academic

Documente Profesional

Documente Cultură

Beam Splice

Încărcat de

PaoloEduardoCarusid'EmpaireDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Beam Splice

Încărcat de

PaoloEduardoCarusid'EmpaireDrepturi de autor:

Formate disponibile

PROJECT : PAGE :

CLIENT : DESIGN BY :

JOB NO. : DATE : REVIEW BY :

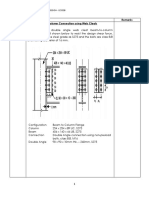

Beam Bolted Splice Design Based on AISC 360-10/16

INPUT DATA & DESIGN SUMMARY (Flange Plate 5.71 in x 19.5 in x 1 in)

WF BEAM SECTION = > W21X48

WF STEEL YIELD STRESS Fy = 50 ksi

PLATE STEEL YIELD STRESS Fyp = 36 ksi

FLANGE PLATE THICKNESS tfp = 1 in

WEB PLATE THICKNESS twp = 0.75 in

BEAM AXIAL LOAD, ASD T = 70 kips, ( 20% WF's Pn / Wt)

VERTICAL SHEAR FORCE, ASD V = 100 kips, ( 69% WF's Vn / Wv)

MOMENT AT SPLICE, ASD M = 80 ft-k, ( 30% WF's Mn / Wb)

BOLT DIAMETER f = 1 in ( 1 in)

BOLT MATERIAL (A307, A325, A490) ASTM = A325

HOLE TYPE (STD, NSL, OVS, SSL, LSL) => STD

STD = Standard round holes ( d + 1/16 " )

NSL = Long or short-slotted hole normal to load direction

OVS = Oversize round holes

SSL = Short-slotted holes (Web Plate 9.5 in x 13.5 in x 0.75 in)

LSL = Long-slotted holes

CONNECTION TYPE (SC, N, X) => N

SC = Slip critical connection THE DESIGN IS ADEQUATE.

N = Bearing-type connection with threads included in the shear plane

X = Bearing-type connection with threads excluded from the shear plane

FLANGE BOLTS 2 rows 3 bolts on each row (total 6 bolts at each end)

WEB BOLTS 2 vert rows 3 bolts on each row (total 6 bolts at each end)

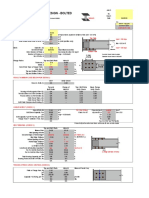

ANALYSIS

SECTION PROPERTIES (AISC Manual Table 1)

d tw tf k bf A Zx

20.6 0.35 0.43 0.93 8.14 14.1 107

DETERMINE PLATE DIMENSIONS

Bolt spacing required = 3.00 in, (Tab J3.3) Bolt spacing used = 3.00 in [Satisfactory]

Edge spacing required = 1.75 in, (Tab J3.4) Edge spacing used = 1.75 in [Satisfactory]

Flange Plate B = 5.71 in < bf [Satisfactory]

Lfp = 19.5 in

Web Plate D = 9.5 in < d - 2k [Satisfactory]

Lwp = 13.5 in

CHECK CAPACITY OF BOLTS (AISC 360 J3)

Allowable shear capacity Rn / Wv = 18.8 kips / bolt, (AISC Manual Table 7)

Flange bolt shear v = T / AT + M / S = 11.7 kips / bolt < Rn / Wv [Satisfactory]

Web bolt shear v = [(T / AT)2 + (V / AV)2]0.5 = 17.1 k / bolt < Rn / Wv [Satisfactory]

where AT = 18 bolts, (total one end bolts)

S= 123.6 in-bolts, (flange bolts only)

AV = 6 bolts, (one end web bolts only)

CHECK WEB PLATE FOR SHEAR CAPACITY (AISC 360 G2)

V / (D twp) = 14.0 ksi < 0.6 Fyp Cv / Wv = 0.6 Fyp 1.0 / 1.5 = 14.4 ksi [Satisfactory]

CHECK FLANGE PLATE FOR TENSION CAPACITY (AISC 360 D)

T / (2 B tfp + D twp) + M / (d B tfp) = 11.9 ksi < Fyp / Wt = Fyp / 1.67 = 21.56 ksi [Satisfactory]

CHECK FLANGE NET TENSION FRACTURE (AISC 360 J4.1)

Fup = 58 ksi ( for plate, AISC Manual page. 2-39)

0.5 T + M / d = 81.60 kips < Fup / W [ B - n (ds + 1/8 ) ] tfp = 100 kips [Satisfactory]

CHECK FLANGE NET SHEAR FRACTURE (AISC 360 J4.2)

Fu = 65 ksi ( for WF, AISC Manual page. 2-39)

0.5 T + M / d = 81.60 kips < 0.6 Min( Fu tf , Fup tfp) / W ( S shear length) = 82.80 kips

[Satisfactory]

CHECK WEB PLATE BLOCK SHEAR (AISC 360 J4)

lh = 4.9 in

lv = 1.2 in

V= 100.00 kips < 0.6 Av Fup / W + At Fup / W = (0.3 lv + 0.5 lh) twp Fup = 122.89 kips

[Satisfactory]

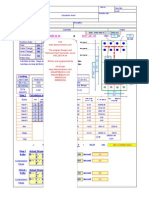

TABLE 7-1 SHEAR (AISC 13th)

NOMINAL BOLT DIAMETER, d ( in )

5/8 3/4 7/8 1 1-1/8 1-1/4 1-3/8 1-1/2

ASTM 0.625 0.75 0.875 1.00 1.125 1.25 1.375 1.50

Designation Conn. Hole Fv Loading AREA BASED ON NOMINAL DIAMETER ( in^2 )

Type Type ( ksi ) 0.307 0.442 0.601 0.785 0.994 1.227 1.485 1.767

A307 - STD 12 S 3.68 5.30 7.22 9.42 11.90 14.70 17.80 21.20

- NSL D 7.36 10.60 14.40 18.80 23.90 29.50 35.60 42.40

STD S 4.29 6.33 8.81 11.50 12.70 16.00 19.20 23.30

SC D 8.59 12.70 17.60 23.10 25.30 32.10 38.40 48.60

CLASS OVS, S 3.65 5.38 7.49 9.80 10.80 13.60 16.30 19.80

A SSL D 7.30 10.80 15.00 19.60 21.50 27.30 32.70 39.60

A325 LSL S 3.01 4.43 6.17 8.07 8.86 11.20 13.40 16.30

D 6.01 8.86 12.30 16.10 17.70 22.50 26.90 32.60

N STD, 24 S 7.36 10.60 14.43 18.85 23.86 29.45 35.64 42.41

NSL D 14.73 21.21 28.86 37.70 47.71 58.90 71.28 84.82

X STD, 30 S 9.2 13.3 18.0 23.6 29.8 36.8 44.5 53.0

NSL D 18.4 26.5 36.1 47.1 59.6 73.6 89.1 106.0

STD S 5.42 7.91 11.10 14.50 18.10 23.10 27.30 33.40

SC D 10.80 15.80 22.10 28.90 36.20 46.10 54.70 66.90

CLASS OVS, S 4.61 6.72 9.41 12.30 15.40 19.60 23.20 28.40

A SSL D 9.22 13.40 18.80 24.60 30.70 39.20 46.50 56.90

A490 LSL S 3.80 5.54 7.75 10.00 12.70 16.10 19.10 23.40

D 7.59 11.10 15.50 20.20 25.30 32.30 38.30 46.80

N STD, 30 S 9.20 13.25 18.04 23.56 29.82 36.81 44.55 53.01

NSL D 18.41 26.51 36.08 47.12 59.64 73.62 89.10 106.02

X STD, 37.5 S 11.5 16.6 22.5 29.5 37.3 46.0 55.7 66.3

NSL D 23.0 33.1 45.1 58.9 74.6 92.0 111.4 132.5

TABLE 1-E. BEARING (AISC 9th)

Slip-critical and Bearing-type Connections

Fu = 58 ksi Fu = 65 ksi Fu = 70 ksi Fu = 100 ksi

Bolt Dia Bolt Dia Bolt Dia Bolt Dia

Material

Thickness 0.75 0.875 1 0.75 0.875 1 0.75 0.875 1 0.75 0.875 1

1/8 6.5 7.6 8.7 7.3 8.5 9.8 7.9 9.2 10.5 11.3 13.1 15.0

3/16 9.8 11.4 13.1 11.0 12.8 14.6 11.8 13.8 15.8 16.9 19.7 22.5

1/4 13.1 15.2 17.4 14.6 17.1 19.5 15.8 18.4 21.0 22.5 26.3 30.0

5/16 16.3 19.0 21.8 18.3 21.3 24.4 19.7 23.0 26.3 28.1 32.8 37.5

3/8 19.6 22.8 26.1 21.9 25.6 29.3 23.6 27.6 31.5 33.8 39.4 45.0

7/16 22.8 26.6 30.5 25.6 29.9 34.1 27.6 32.2 36.8 45.9 52.5

1/2 26.1 30.5 34.8 29.3 34.1 39.0 31.5 36.8 42.0 60.0

9/16 29.4 34.3 39.2 32.9 38.4 43.9 41.3 47.3

5/8 32.6 38.1 43.5 42.7 48.8 45.6 52.5

11/16 41.9 47.9 46.9 53.6 57.8

3/4 45.7 52.2 58.5

13/16 56.6

7/8 60.9

15/16

1 52.2 60.9 69.6 58.5 68.3 78.0 63.0 73.5 84.0 90.0 105.0 120.0

S = Single shear

D = Double shear

SC = Slip critical connection

N = Bearing-type connection with threads included in the shear plane

X = Bearing-type connection with threads excluded from the shear plane

STD = Standard round holes ( d + 1/16 " )

LSL = Long-slotted holes

NSL = Long or short-slotted hole normal to load direction

OVS = Oversize round holes

SSL = Short-slotted holes holes

S-ar putea să vă placă și

- Bolted Moment ConnectionDocument18 paginiBolted Moment ConnectionAlpha50% (2)

- Beam Connection of Conventional Configuration Based On AISC 360-10Document4 paginiBeam Connection of Conventional Configuration Based On AISC 360-10Alpha100% (2)

- BraceconnectionDocument10 paginiBraceconnectionLeonardo PimentelÎncă nu există evaluări

- End Plate Moment ConnectionDocument4 paginiEnd Plate Moment Connectionteguh andriantoÎncă nu există evaluări

- Calculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataDocument1 paginăCalculation Sheet: Base Plate & Anchor Bolt Design - Moment Connection Base Plate DataLaurence Arcon Banal0% (1)

- Column Base Plate DesignDocument1 paginăColumn Base Plate DesignBunkun15Încă nu există evaluări

- Calculation of Beam/Column Splice: HB-300x300x10x15Document5 paginiCalculation of Beam/Column Splice: HB-300x300x10x15amachmouchiÎncă nu există evaluări

- Double Angle CleatsDocument6 paginiDouble Angle CleatsKaushal KishoreÎncă nu există evaluări

- Beam-Column Using Double Angle CleatDocument7 paginiBeam-Column Using Double Angle CleatNur Syahira100% (1)

- End Plate Connection Design Per AISCDocument5 paginiEnd Plate Connection Design Per AISCAdam Michael GreenÎncă nu există evaluări

- End Plate DesignDocument4 paginiEnd Plate DesignAgnon Fung100% (4)

- AISC LRFD Moment Connections BoltedDocument531 paginiAISC LRFD Moment Connections BoltedManoj JaiswalÎncă nu există evaluări

- Splice Connection CHSDocument180 paginiSplice Connection CHSRaveendra Babu Cherukuri100% (2)

- Base Plate Design by Aisc-AsdDocument8 paginiBase Plate Design by Aisc-AsdPurnima Arkalgud100% (2)

- Beam SpliceDocument17 paginiBeam SpliceBoddu Ramakrishna100% (1)

- Connection Design Standard Document PDFDocument47 paginiConnection Design Standard Document PDFclam2014Încă nu există evaluări

- Thin Composite BeamDocument1 paginăThin Composite BeamBilly BobÎncă nu există evaluări

- End Plate Beam To Column Moment ConnectionDocument84 paginiEnd Plate Beam To Column Moment Connectionakshay chauhanÎncă nu există evaluări

- Shear Connection - Beam - Steel Column - Fin PlateDocument30 paginiShear Connection - Beam - Steel Column - Fin Platekalpanaadhi100% (3)

- Moment Connection HSS Top Plate 9-27-2014Document36 paginiMoment Connection HSS Top Plate 9-27-2014Jesus Rafael Curiel PensoÎncă nu există evaluări

- Typical Anchor BoltsDocument33 paginiTypical Anchor BoltslucianduÎncă nu există evaluări

- Connection - Foundation To PileDocument5 paginiConnection - Foundation To PileSandesh Kumar100% (1)

- Combined Gusset Plate DesignDocument3 paginiCombined Gusset Plate Designkalpanaadhi100% (3)

- Cap PlateDocument18 paginiCap PlateVinoth KumarÎncă nu există evaluări

- Steel Beam Design As Per AISC ASDDocument2 paginiSteel Beam Design As Per AISC ASDKov Chanthy100% (1)

- Extended Fin Plate Connection - LRFDDocument22 paginiExtended Fin Plate Connection - LRFDkalpanaadhiÎncă nu există evaluări

- Calculation Sheet: Design PhilosophyDocument18 paginiCalculation Sheet: Design PhilosophyrammohanÎncă nu există evaluări

- Connection DesignDocument31 paginiConnection Designroshini nayarÎncă nu există evaluări

- Bolted ConnectionDocument86 paginiBolted ConnectionPooja MistryÎncă nu există evaluări

- Design of End Plate ConnectionDocument2 paginiDesign of End Plate ConnectionAndro RebuyasÎncă nu există evaluări

- Stiffner Design For Beam Column ConnectionsDocument84 paginiStiffner Design For Beam Column ConnectionsfabnameÎncă nu există evaluări

- Design Connection AISCDocument49 paginiDesign Connection AISCAmey Gudigar100% (1)

- Base PlateDocument27 paginiBase PlateSabih Hashim AlzuhairyÎncă nu există evaluări

- Bracing ConnectionDocument15 paginiBracing ConnectionrajedmaglinteÎncă nu există evaluări

- ConnectionDocument68 paginiConnectionErshadÎncă nu există evaluări

- AISC2005 Anchor Bolt Version22042015 FixDocument8 paginiAISC2005 Anchor Bolt Version22042015 FixThuyTranÎncă nu există evaluări

- Biaxial Base Plate2Document3 paginiBiaxial Base Plate2abdul kareeÎncă nu există evaluări

- Bracing Gusset Connection - LRFDDocument4 paginiBracing Gusset Connection - LRFDkalpanaadhi75% (4)

- Base Plate 2Document5 paginiBase Plate 2Bunkun15Încă nu există evaluări

- Connection DesignDocument33 paginiConnection Designjesus curielÎncă nu există evaluări

- Bolted Moment ConnectionDocument18 paginiBolted Moment ConnectionHugo EzequielÎncă nu există evaluări

- Endplmc9 - End Plate Moment ConnectionsDocument26 paginiEndplmc9 - End Plate Moment ConnectionsLyhalim Seth50% (2)

- Welded Splice Connection-R2Document33 paginiWelded Splice Connection-R2Anonymous cG5MyHM100% (1)

- 11 Steel Connection Design As Per AISC 23052014Document2 pagini11 Steel Connection Design As Per AISC 23052014Ahmad Badsha Quadri50% (2)

- Base Plate Design1Document24 paginiBase Plate Design1John Paul UmaliÎncă nu există evaluări

- Prying ActionDocument8 paginiPrying ActionjoseherreramogollonÎncă nu există evaluări

- Moment Connection DETAIL 2Document5 paginiMoment Connection DETAIL 2way2vaseemÎncă nu există evaluări

- Steel ColumnDocument2 paginiSteel ColumnNikki Roberts100% (2)

- Beam Column Connection-Design2Document16 paginiBeam Column Connection-Design2abdul kareeÎncă nu există evaluări

- Column Beam Seismic ConnectionDocument8 paginiColumn Beam Seismic ConnectionPrakash Singh RawalÎncă nu există evaluări

- MOMENT EndplateDocument10 paginiMOMENT EndplateALPHYL BALASABASÎncă nu există evaluări

- Isolated Foundation Calculation Sheet: Greater Mekong Power Network Develvopment ProjectDocument7 paginiIsolated Foundation Calculation Sheet: Greater Mekong Power Network Develvopment ProjectSereyponleu Khun100% (1)

- The Stability of Frames: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionDe la EverandThe Stability of Frames: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionÎncă nu există evaluări

- Beam Bolted Splice Design Based On AISC 360-10/16: Input Data & Design SummaryDocument1 paginăBeam Bolted Splice Design Based On AISC 360-10/16: Input Data & Design SummaryKaren Esther Acuña Velasquez100% (1)

- Moment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16Document4 paginiMoment Connection Design For Beam To Weak Axis Column Based On AISC 360-10/16gyanwapiÎncă nu există evaluări

- Bolt Connection Design Based On AISC 360-10/16: Input Data & Design SummaryDocument1 paginăBolt Connection Design Based On AISC 360-10/16: Input Data & Design SummaryKaren Esther Acuña VelasquezÎncă nu există evaluări

- Beam ConnectionDocument3 paginiBeam ConnectionLeonardo PimentelÎncă nu există evaluări

- Beam Connection of Conventional Configuration Based On AISC 360-10/16Document1 paginăBeam Connection of Conventional Configuration Based On AISC 360-10/16Karen Esther Acuña VelasquezÎncă nu există evaluări

- Ultratech PPC 53 Grade CementDocument1 paginăUltratech PPC 53 Grade CementGovind SharmaÎncă nu există evaluări

- Single Tension Fastener Away From Edges Based On ACI 318-02Document2 paginiSingle Tension Fastener Away From Edges Based On ACI 318-02civixxÎncă nu există evaluări

- Bridge LectureDocument33 paginiBridge LectureAtta E Mustafa Mughal100% (3)

- Steel References PDFDocument8 paginiSteel References PDFAlfia BanoÎncă nu există evaluări

- Fem Design EngDocument12 paginiFem Design EngdesignmukeshÎncă nu există evaluări

- Concept of Camber and Method For Assembly of OwgsDocument21 paginiConcept of Camber and Method For Assembly of OwgsARUN RAJ100% (3)

- 1973v03 PDFDocument16 pagini1973v03 PDFTugba TekbenÎncă nu există evaluări

- Estimate Chovar SchoolDocument108 paginiEstimate Chovar SchoolSailesh BudhathokiÎncă nu există evaluări

- Project Management ChecklistDocument4 paginiProject Management ChecklistTravis Yee ShuiÎncă nu există evaluări

- CE133-4 - LEC10 - Design of Timber ColumnsDocument28 paginiCE133-4 - LEC10 - Design of Timber Columnsgarhgelh100% (1)

- Kinerja Precentage Refusal Density (PRD) Terhadap Campuran Hot Sawit Sebagai Agregat HalusDocument7 paginiKinerja Precentage Refusal Density (PRD) Terhadap Campuran Hot Sawit Sebagai Agregat Halusashadi asriÎncă nu există evaluări

- Presentation-Seismic Performance Assessment of High Rise Buildings With The Effect of Masonry InfillDocument18 paginiPresentation-Seismic Performance Assessment of High Rise Buildings With The Effect of Masonry Infillnirez14Încă nu există evaluări

- Fabrication and Installation of 200Mm X 200Mm Concrete PilesDocument2 paginiFabrication and Installation of 200Mm X 200Mm Concrete PilesArden NeriÎncă nu există evaluări

- ArcelorMittal - HZ Wall SystemDocument32 paginiArcelorMittal - HZ Wall SystemolcayuzÎncă nu există evaluări

- Knauf Compound Flyer - 2022 - ENDocument2 paginiKnauf Compound Flyer - 2022 - ENAnastasya YusufÎncă nu există evaluări

- 1 PDFDocument7 pagini1 PDFJose Luis Martinez SaavedraÎncă nu există evaluări

- 6.1 Calculation of Deflection: 1) Short Term Deflection at Transfer 2) Long Term Deflection Under Service LoadsDocument7 pagini6.1 Calculation of Deflection: 1) Short Term Deflection at Transfer 2) Long Term Deflection Under Service LoadsAllyson DulfoÎncă nu există evaluări

- Bridge Temporary DesignDocument4 paginiBridge Temporary DesignRaditya AzkaLaodeÎncă nu există evaluări

- EarthQuake Loads ETABSDocument12 paginiEarthQuake Loads ETABShala012100% (1)

- Laterally Braced Cold-Formed Steel Flexural Members With Edge Stiffened Flangesn - Schafer, PekozDocument10 paginiLaterally Braced Cold-Formed Steel Flexural Members With Edge Stiffened Flangesn - Schafer, PekozamokeÎncă nu există evaluări

- Type of Structures For High Rise BuildingsDocument31 paginiType of Structures For High Rise Buildingsfahad zakir100% (1)

- Tank SluiceDocument3 paginiTank SluiceThippeswamy PhÎncă nu există evaluări

- Concrete Centre How To Design Concrete Structures To EC 2Document116 paginiConcrete Centre How To Design Concrete Structures To EC 2mauÎncă nu există evaluări

- Anchor Bolt Design Apdx D ACI318 05Document4 paginiAnchor Bolt Design Apdx D ACI318 05Mohammed HanafiÎncă nu există evaluări

- Deck Slab Design: Ii. Design Criteria A. Design Codes, Standards, and SpecificationsDocument34 paginiDeck Slab Design: Ii. Design Criteria A. Design Codes, Standards, and SpecificationsAirine Carreon VerdaderoÎncă nu există evaluări

- Chapter 3 - Design of Steel Frames by Second-Order Analysis Fulifilling Code RequirementsDocument54 paginiChapter 3 - Design of Steel Frames by Second-Order Analysis Fulifilling Code RequirementsIvan KlyuchkaÎncă nu există evaluări

- 20KL GLSRDocument41 pagini20KL GLSRMahadev VijayÎncă nu există evaluări

- Vernacular Terms For Architecture Philip PDFDocument2 paginiVernacular Terms For Architecture Philip PDFBon CacpalÎncă nu există evaluări

- Applications of Basic Magnesium Sulfate Cement in Civil EngineeringDocument6 paginiApplications of Basic Magnesium Sulfate Cement in Civil EngineeringPrashant GaradÎncă nu există evaluări

- 2chapter LOADS ON BUILDINGS AND STRUCTURES (Wind Load)Document82 pagini2chapter LOADS ON BUILDINGS AND STRUCTURES (Wind Load)Tarif Aziz MarufÎncă nu există evaluări