Documente Academic

Documente Profesional

Documente Cultură

UG40 Actuator

Încărcat de

SaasiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

UG40 Actuator

Încărcat de

SaasiDrepturi de autor:

Formate disponibile

Product Specification

LY

37516A

UG40 Actuator

ON

Hydraulic Powered

Electric Actuator

for Control of Larger

Proportional

E

Engines electric/hydraulic

actuator

US

Uses UG40 case

and drive for

economical

installation

Works with

Woodward

20–160 mA output

NG

electronic controls

DESCRIPTION APPLICATIONS Self-contained oil

supply

The UG40 Actuator converts a given The UG40 Actuator is used on diesel,

electrical input signal to a proportional gas, and gasoline engines, (also steam Integral magnetic

hydraulic output-shaft position to control and industrial gas turbines) to replace pickup available

engine-fuel flow. UG32 or UG40 type governors, providing

NI

the advantages of electronic control and

The actuator provides the muscle for

load sharing systems with the

Woodward analog controls such as the

convenience of the existing UG40 type

2301A, as well as Woodward digital

drive and linkage.

controls.

The UG40 Actuator is recommended for

AI

The standard UG40 Actuator produces 85

installation involving unattended starts.

N m (63 lb-ft) of work over 38 degrees of

rotary output. Stalled torque is 129 N m The UG40 Actuator has its own 7.0-liter

(95 lb-ft). Work output and stalled torque (7.4-quart) oil sump and does not need a

are the same as the UG40 Governor. separate oil supply.

TR

The UG40 Actuator uses the same cast- The actuator will operate with a drive

iron case as the UG Governor. The oil speed from 350 to 1300 rpm. A cooler

pump is the proven high-output Gerotor, may be needed for applications with a

designed to provide long life with minimal high drive speed and high ambient

maintenance. The actuator uses standard temperatures.

UG40 output shafts, power levers, power

A magnetic pickup (MPU) may be easily

pistons, and piston links. The base will fit

installed in the actuator to make retrofit of

any drive designed for a UG40 Governor.

R

engines from mechanical to electronic

Maintenance procedures are similar to

control easier. A UG drive in good

those needed with a UG40 Governor.

mechanical condition makes an excellent

The electric-to-hydraulic transducer in the MPU signal source. Low cranking speeds

FO

UG40 Actuator uses a Woodward-built may require override of the electronic

torque motor which converts the 20-160 failsafe.

mA control signal to a given output

position.

SPECIFICATIONS

LY

Work Output

129 N m (95 lb-ft) stalled torque, 85 N m (63 lb-ft) of work over 38 degrees

ON

E

Electrical

Electrical Connector

Coil Resistance

Calibration

23–26 W at 20 °C US

3 pin, US MIL-STD 3102E-14S-7P, located in cover

1–2 degrees at 20 mA, 32 ±2 degrees additional travel from 20 mA to 160

mA; reaches maximum fuel at less than 200 mA

NG

Control Qualities

Hysteresis Within 3% of maximum travel when measured over full 38 degree travel.

Within 0.5% of maximum travel when measured over 4% of full travel at 1

Hz.

Temperature Drift Nominally ±1 degree per 38 °C (100 °F)

Time Constant 150 to 170 ms for ±50 mA step with 1724 kPa (250 psi) actuator oil pressure

Linearity Within 2.5% of full 38 degree output travel

NI

Construction

Case, base and power block are cast iron. Covers are aluminum. Internal parts are case-hardened steel.

Pump Gerotor: low speed 350–1000 rpm, high speed 600–1300 rpm; relief valve

set at 1725 kPa (250 psi)

AI

Output Shaft (2) 0.750-48 inch serrated; in same location relative to drive as UG40

governor

Drive Shaft 1.125-48 serration is standard; 0.625 keyed drive shaft with 0.625-18

threads available

Weight 29 kg (64 lbs), dry weight

TR

Vibration Resistance Vibration tested to US MIL-STD 810C, Curve H (10 G to 2000 Hz)

Drive/Hydraulic Specifications

Drive Speed and Rotation Actuator available with either high or low speed pump. High speed pump:

600 to 1300 rpm. Low speed pump: 350 to 1000 rpm. Drive operates in one

direction only.

Drive Power Requirement Drive will use a maximum of 525 W (0.7 hp)

Hydraulic Supply Self contained sump, 7.0 liter (7.4 quart) capacity. See Woodward Manual

25071, Oils for Hydraulic Controls, for specific recommendations. In most

R

cases the same type and weight of oils used in the engine can be used in

the governor.

Ambient Temperature Range –29 to +93 °C (–20 to +200 °F)

Operating Temperature –29 to +93 °C (–20 to +200 °F) (within the limits of the oil being used in the

FO

governor)

Technical Manual 37515

LY

ON

E

US

NG

NI

AI

TR

R

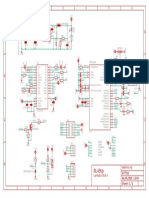

UG40 Actuator Outline Drawing

(Do not use for construction)

FO

LY

PO Box 1519

Fort Collins CO, USA

80522-1519

1000 East Drake Road

Fort Collins CO 80525

Ph: +1 (970) 482-5811

Fax: +1 (970) 498-3058

ON

Distributors & Service

Woodward has an

international network of

distributors and service

facilities. For your nearest

representative, call the

Fort Collins plant or see

the Worldwide Directory

on our website.

E

Corporate Headquarters

Rockford IL, USA

Ph: +1 (815) 877-7441

US

www.woodward.com

NG

NI

AI

TR

This document is distributed

for informational purposes For more information contact:

R

only. It is not to be construed

as creating or becoming part

of any Woodward Governor

Company contractual or

warranty obligation unless

expressly stated in a written

FO

sales contract.

© Woodward 1993

All Rights Reserved

04/7/F

S-ar putea să vă placă și

- Solutions Through Dowsing PDFDocument106 paginiSolutions Through Dowsing PDFkumar100% (6)

- PGA-EG 58/200 WoodwardDocument4 paginiPGA-EG 58/200 WoodwardKelvin Jesus50% (2)

- Woodward UG ActuatorDocument4 paginiWoodward UG ActuatorИгорь100% (2)

- Woodward Ug ActuatorDocument4 paginiWoodward Ug ActuatorfajarÎncă nu există evaluări

- Woodward Ug ActuatorDocument4 paginiWoodward Ug ActuatorfajarÎncă nu există evaluări

- Actuador Woodward 37511 PDFDocument4 paginiActuador Woodward 37511 PDFComassur SA de CV100% (1)

- UG40 Actuator: ApplicationsDocument4 paginiUG40 Actuator: ApplicationsDan Alin MirceaÎncă nu există evaluări

- EGB 29P and EGB 58P: ApplicationsDocument4 paginiEGB 29P and EGB 58P: Applicationslee soon hwanÎncă nu există evaluări

- PGPL Actuator/Driver: Hydraulic Powered Electric Actuator For Gas Engine or Steam Turbine ControlDocument4 paginiPGPL Actuator/Driver: Hydraulic Powered Electric Actuator For Gas Engine or Steam Turbine ControlTilak TiwariÎncă nu există evaluări

- PG EG ActuatorDocument4 paginiPG EG ActuatorabdullahÎncă nu există evaluări

- Pgeg 200Document4 paginiPgeg 200Carlos Alberto Cunha100% (1)

- TG17EDocument4 paginiTG17EdogagbaÎncă nu există evaluări

- Woodward UG MAS GovernorDocument4 paginiWoodward UG MAS GovernorJaya RamanÎncă nu există evaluări

- Gp3500io Spec Sheet 10000016702Document2 paginiGp3500io Spec Sheet 10000016702DanielRamirezVieraÎncă nu există evaluări

- Servo Actuator UM CutsheetDocument2 paginiServo Actuator UM CutsheetPradeep TripathiÎncă nu există evaluări

- Features: GP SeriesDocument2 paginiFeatures: GP SeriesDanielRamirezVieraÎncă nu există evaluări

- TM 55P Actuator: ApplicationDocument4 paginiTM 55P Actuator: Applicationdew lp63Încă nu există evaluări

- EMC-compliant Connection: Maintenance Switches ForDocument16 paginiEMC-compliant Connection: Maintenance Switches ForANDREA NICOLASÎncă nu există evaluări

- TECO GS510 ManualDocument61 paginiTECO GS510 ManualabdiÎncă nu există evaluări

- Honeywell m7284 ManualDocument4 paginiHoneywell m7284 Manualflatron445Încă nu există evaluări

- Welders Brochure DataId 313376 Version 7Document8 paginiWelders Brochure DataId 313376 Version 7Leonel FGÎncă nu există evaluări

- EGB-29P 58P Product SpecDocument4 paginiEGB-29P 58P Product SpecFathima ReginÎncă nu există evaluări

- Woodward PGG EG Governor ActuatorDocument4 paginiWoodward PGG EG Governor ActuatorsebastienÎncă nu există evaluări

- Proact Iii IvDocument4 paginiProact Iii IvJavier Conesa OutedaÎncă nu există evaluări

- AGB200Document6 paginiAGB200FadFad100% (2)

- Pg-Eg.03381 ADocument4 paginiPg-Eg.03381 AabdullahÎncă nu există evaluări

- UG40 GovernorDocument5 paginiUG40 GovernorSaasi100% (2)

- LSC440S3 6Document4 paginiLSC440S3 6Frank HigueraÎncă nu există evaluări

- Manual Omron 3 G3 VHDocument176 paginiManual Omron 3 G3 VHJuan Manuel Sánchez SánchezÎncă nu există evaluări

- General Characteristics: DescriptiveDocument5 paginiGeneral Characteristics: DescriptiveXuân Huy NguyễnÎncă nu există evaluări

- SP FLX SGT 50.v3Document2 paginiSP FLX SGT 50.v3sungkarsÎncă nu există evaluări

- Gcuu 104Document2 paginiGcuu 104Eli SharmaÎncă nu există evaluări

- General Characteristics: Power DefinitionDocument5 paginiGeneral Characteristics: Power DefinitionXuân Huy NguyễnÎncă nu există evaluări

- Yaskawa Ga700Document72 paginiYaskawa Ga700Free TrailÎncă nu există evaluări

- LM24 SR 2.0 US 4Nm 19559Document2 paginiLM24 SR 2.0 US 4Nm 19559Multiservici Campo EliasÎncă nu există evaluări

- E Lectro-H Ydraulic Steering GearsDocument20 paginiE Lectro-H Ydraulic Steering GearsCarri Tezaa100% (1)

- Component Type SS21-UL Type: Speed Control MotorsDocument7 paginiComponent Type SS21-UL Type: Speed Control Motorshenry barbozaÎncă nu există evaluări

- 1800reozm Specification KohlerDocument4 pagini1800reozm Specification KohlerTrần Quang TuyênÎncă nu există evaluări

- General Characteristics: DescriptiveDocument5 paginiGeneral Characteristics: DescriptiveXuân Huy NguyễnÎncă nu există evaluări

- 510 Braking ManualDocument29 pagini510 Braking Manualiveth oliverÎncă nu există evaluări

- 200kVA Himoinsa HRFW 200 T5 Data SheetDocument2 pagini200kVA Himoinsa HRFW 200 T5 Data Sheetmahmoudelwan1998Încă nu există evaluări

- Energy Onix Eco-5 Eco-22 Eco-25Document2 paginiEnergy Onix Eco-5 Eco-22 Eco-25Vh0n Vh0nÎncă nu există evaluări

- Kohler KK16 - 0519Document5 paginiKohler KK16 - 0519Nguyen Vu Hoang ThachÎncă nu există evaluări

- Configuracion SelectorDocument5 paginiConfiguracion SelectorpatricioÎncă nu există evaluări

- Switch Rotatorio LW32Document5 paginiSwitch Rotatorio LW32symantec37Încă nu există evaluări

- M9220HGA3Document9 paginiM9220HGA3Greg MartinÎncă nu există evaluări

- WEG w40 IP23Document12 paginiWEG w40 IP23Ivan AbbáÎncă nu există evaluări

- 20 and 22kw Spec Sheet Generac New - 2Document6 pagini20 and 22kw Spec Sheet Generac New - 2Eiseo ObregonÎncă nu există evaluări

- Egb10p 13p 35pDocument4 paginiEgb10p 13p 35pJaime ZamÎncă nu există evaluări

- M9116, M9124, and M9132 Series Electric Non-Spring-Return ActuatorsDocument4 paginiM9116, M9124, and M9132 Series Electric Non-Spring-Return ActuatorsharishupretiÎncă nu există evaluări

- Woodward R-11 ActuatorDocument5 paginiWoodward R-11 ActuatorMari Carmen RodriguezÎncă nu există evaluări

- STP 210ms 229Document2 paginiSTP 210ms 229TATA URUSAN TEKNOLOGI & JARINGANÎncă nu există evaluări

- Turbo 250 Datasheet PDFDocument1 paginăTurbo 250 Datasheet PDFgalih santosoÎncă nu există evaluări

- Industrial Diesel Generator Set - 50 HZ: KOHLER SDMO Premium QualityDocument6 paginiIndustrial Diesel Generator Set - 50 HZ: KOHLER SDMO Premium Qualityquangtruc106Încă nu există evaluări

- Izn Two Stage CompressorDocument2 paginiIzn Two Stage CompressorLhexter Mhervin CoÎncă nu există evaluări

- 2001 V3 ALR 190 - Data - Sheet 07 01 08 Bs enDocument6 pagini2001 V3 ALR 190 - Data - Sheet 07 01 08 Bs enSunthron SomchaiÎncă nu există evaluări

- Speed Control MotorDocument32 paginiSpeed Control MotorMASOUD0% (1)

- GeneratorDocument2 paginiGeneratorReden DemdamÎncă nu există evaluări

- Gele ATSCDocument10 paginiGele ATSCAde ApriÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- BC 700 PB ManualDocument60 paginiBC 700 PB ManualSaasiÎncă nu există evaluări

- Fisher GX Control Valve and Actuator System: Scope of ManualDocument44 paginiFisher GX Control Valve and Actuator System: Scope of ManualSaasiÎncă nu există evaluări

- VACON NX All in One Application Guide DPD00903H enDocument354 paginiVACON NX All in One Application Guide DPD00903H enSaasiÎncă nu există evaluări

- BP1-R - Reverse Power RelayDocument8 paginiBP1-R - Reverse Power RelaySaasiÎncă nu există evaluări

- BC 600 PB ManualDocument44 paginiBC 600 PB ManualSaasiÎncă nu există evaluări

- Originally Published in Nistir 6785: Matml - Materials Markup Languageworkshop ReportDocument13 paginiOriginally Published in Nistir 6785: Matml - Materials Markup Languageworkshop ReportSaasiÎncă nu există evaluări

- DET+ & DET-1600/1620 Detonation Sensing Monitors: Detects Detonation and Avoids Consequential Engine DamageDocument2 paginiDET+ & DET-1600/1620 Detonation Sensing Monitors: Detects Detonation and Avoids Consequential Engine DamageSaasiÎncă nu există evaluări

- ACC 2613B Crank Angle EncoderDocument4 paginiACC 2613B Crank Angle EncoderSaasiÎncă nu există evaluări

- RGPR30NS40: BV 400 30V I 30A V 1.6V E 300mJDocument11 paginiRGPR30NS40: BV 400 30V I 30A V 1.6V E 300mJSaasiÎncă nu există evaluări

- Designing A Dual-Fuel Motor Management System With Zynq: Frank de BontDocument35 paginiDesigning A Dual-Fuel Motor Management System With Zynq: Frank de BontSaasiÎncă nu există evaluări

- Bl49Sp: Spiceorder 1 Spiceorder 2Document1 paginăBl49Sp: Spiceorder 1 Spiceorder 2SaasiÎncă nu există evaluări

- Fuel Feed Pump: Wärtsilä Vasa 32 Engine SPC 174-0019ADocument4 paginiFuel Feed Pump: Wärtsilä Vasa 32 Engine SPC 174-0019ASaasiÎncă nu există evaluări

- MPC563xM-based Cost Effective ECU Chipset: Operation of The Suitcase DemoDocument11 paginiMPC563xM-based Cost Effective ECU Chipset: Operation of The Suitcase DemoSaasiÎncă nu există evaluări

- Servo Motor SpecificationDocument1 paginăServo Motor SpecificationSaasiÎncă nu există evaluări

- DKX3 v3.0.1 0C EDocument192 paginiDKX3 v3.0.1 0C ESaasiÎncă nu există evaluări

- Instrumentation and Automation: 23.1 Monitoring Equipment Mounted On The EngineDocument28 paginiInstrumentation and Automation: 23.1 Monitoring Equipment Mounted On The EngineSaasi100% (1)

- Wartsila 14 Product GuideDocument70 paginiWartsila 14 Product GuideSaasiÎncă nu există evaluări

- Liebherr d934 122 MM Diesel EngineDocument28 paginiLiebherr d934 122 MM Diesel EngineSaasiÎncă nu există evaluări

- AN 730: Nios II Processor Booting Methods in MAX 10 FPGA DevicesDocument89 paginiAN 730: Nios II Processor Booting Methods in MAX 10 FPGA DevicesSaasiÎncă nu există evaluări

- AN 370: Using The Intel FPGA Serial Flash Loader With The Intel Quartus Prime SoftwareDocument16 paginiAN 370: Using The Intel FPGA Serial Flash Loader With The Intel Quartus Prime SoftwareSaasiÎncă nu există evaluări

- Quantum: With Concept and Proworx Hardware Reference ManualDocument904 paginiQuantum: With Concept and Proworx Hardware Reference ManualSaasiÎncă nu există evaluări

- Schematics - Lambda Shield 2Document1 paginăSchematics - Lambda Shield 2SaasiÎncă nu există evaluări

- CPU-XL VariSpark IOM 12-13Document97 paginiCPU-XL VariSpark IOM 12-13SaasiÎncă nu există evaluări

- Montrose Port Tide Table 2020 2021Document7 paginiMontrose Port Tide Table 2020 2021SaasiÎncă nu există evaluări

- Cylinder Pressure SensorDocument2 paginiCylinder Pressure SensorSaasiÎncă nu există evaluări

- Akr 3 Installation Instructions 4189340792 UkDocument17 paginiAkr 3 Installation Instructions 4189340792 UkSaasiÎncă nu există evaluări

- Tech Note 508 - Troubleshooting App Server ProcessesDocument5 paginiTech Note 508 - Troubleshooting App Server ProcessesSaasiÎncă nu există evaluări

- TXM Pmi Mkii 01 LRDocument2 paginiTXM Pmi Mkii 01 LRSaasiÎncă nu există evaluări

- 2021 Manual of Clinical Phonetics Siêu HayDocument564 pagini2021 Manual of Clinical Phonetics Siêu HaydaohailongÎncă nu există evaluări

- Kirlian PhotographyDocument18 paginiKirlian PhotographyjoseÎncă nu există evaluări

- 2010 Summer SchoolDocument31 pagini2010 Summer SchoolAlbanita MendesÎncă nu există evaluări

- Books Vs EbooksDocument9 paginiBooks Vs EbooksThe United IndianÎncă nu există evaluări

- Practices Venn DiagramDocument2 paginiPractices Venn DiagramNathanÎncă nu există evaluări

- Unit - 1 HTDocument57 paginiUnit - 1 HTSoham PendseÎncă nu există evaluări

- Department of Education: Performance Monitoring and Coaching Form SY 2021-2022Document3 paginiDepartment of Education: Performance Monitoring and Coaching Form SY 2021-2022Sheena Movilla96% (24)

- SY2021 2022 2ndsemesterDocument2 paginiSY2021 2022 2ndsemesterWilfredo III DayagdagÎncă nu există evaluări

- Improved Mini-Silo For Studying Fermentation of Silage in Laboratory ConditionsDocument8 paginiImproved Mini-Silo For Studying Fermentation of Silage in Laboratory ConditionsCk_psihÎncă nu există evaluări

- Pump NPSHDocument3 paginiPump NPSHDurjoy ChakrabortyÎncă nu există evaluări

- Lab 10 InterferenceDocument5 paginiLab 10 InterferenceSarin TumtongÎncă nu există evaluări

- Bending Moment PresentationDocument21 paginiBending Moment PresentationRiethanelia UsunÎncă nu există evaluări

- Rubric For Use When Evaluating Lesson Plan PresentationsDocument1 paginăRubric For Use When Evaluating Lesson Plan PresentationsSajid AwanÎncă nu există evaluări

- About The ProjectDocument5 paginiAbout The Projectanand kumarÎncă nu există evaluări

- Incubator GinevriDocument24 paginiIncubator GinevriDivino Elisanto SitinjakÎncă nu există evaluări

- A & A Food NutritionDocument2 paginiA & A Food NutritionAnil SodhaÎncă nu există evaluări

- Rocket PropulsionDocument29 paginiRocket PropulsionPrajwal Vemala JagadeeshwaraÎncă nu există evaluări

- CH 15Document42 paginiCH 15mah b0% (1)

- Danik Bhaskar Jaipur 05-24-2014Document28 paginiDanik Bhaskar Jaipur 05-24-2014bhaskar_newsÎncă nu există evaluări

- Attitude Summary MFDocument8 paginiAttitude Summary MFAraz YagubluÎncă nu există evaluări

- Experiencing Meanings in Spark S The Prime of Miss Jean BrodieDocument18 paginiExperiencing Meanings in Spark S The Prime of Miss Jean BrodieMaria AgusÎncă nu există evaluări

- Who Am I MemoDocument2 paginiWho Am I Memoapi-652685391Încă nu există evaluări

- Multilevel Viewpoint of A MachineDocument4 paginiMultilevel Viewpoint of A MachineDikshikaAryaÎncă nu există evaluări

- Ice305 Lab5Document13 paginiIce305 Lab5Arnab SarkerÎncă nu există evaluări

- Using Fonts Installed in Local Texlive - TeX - LaTeX Stack ExchangeDocument8 paginiUsing Fonts Installed in Local Texlive - TeX - LaTeX Stack ExchangeFuncionario CepaaÎncă nu există evaluări

- Condition Monitoring of Pumps - How To Save Three Ways: Session OneDocument35 paginiCondition Monitoring of Pumps - How To Save Three Ways: Session OneJorge FracaroÎncă nu există evaluări

- Q4 TLE AFA Horticulture 9 Week3Document4 paginiQ4 TLE AFA Horticulture 9 Week3Dash Bello100% (1)

- 1.draw The Circuit Diagram of A Mod-16 Asynchronous Counter and Explain Its Working WithDocument4 pagini1.draw The Circuit Diagram of A Mod-16 Asynchronous Counter and Explain Its Working WithRajeshwari SÎncă nu există evaluări

- Datasheet Axiom Control BoardDocument15 paginiDatasheet Axiom Control BoardZEN ONEÎncă nu există evaluări