Documente Academic

Documente Profesional

Documente Cultură

A319 Aircraft Characteristics 95 PDF

Încărcat de

Thar LattTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A319 Aircraft Characteristics 95 PDF

Încărcat de

Thar LattDrepturi de autor:

Formate disponibile

@A319

AIRCRAFT CHARACTERISTICS - AIRPORT AND MAINTENANCE PLANNING

**ON A/C A319-100 A319neo

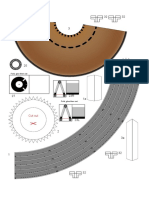

Engine and Nacelle

**ON A/C A319-100

1. Engine and Nacelle - CFM Engine

A. Engine

The engine is a dual-rotor, variable stator, high bypass ratio turbofan powerplant for subsonic

services. The principal modules of the engine are:

- low pressure compressor (fan stator and fan rotor)

- high pressure compressor

- turbine frame

- combustion chamber

- high pressure turbine

- low pressure turbine

- accessory drives (gear box).

The 9 stage high pressure compressor is driven by 1 stage high pressure turbine, and the

integrated front fan and booster is driven by 4 stage low pressure turbine. An annular combustor

converts fuel and compressor discharge air into energy to provide engine thrust part through

primary exhaust and to drive the turbines. The accessory drive system extracts energy from the

high pressure rotor to drive the engine accessories and the engine mounted aircraft accessories.

Reverse thrust for braking the aircraft after landing is supplied by an integrated system which

acts on the fan discharge airflow.

B. Nacelle

The cowls enclose the periphery of the engine so as to form the engine nacelle. Each engine is

housed in a nacelle suspended from a pylon attached to the wing lower surface. The nacelle

consists of the demountable powerplant, the fan cowls and the thrust reverser cowls.

The nacelle installation is designed to provide cooling and ventilation air for engine accessories

mounted along the fan and core casing. The nacelle provides:

- protection for the engine and the accessories

- airflow around the engine during its operation

- lighting protection

- HIRF and EMI attenuation.

2. Engine and Nacelle - IAE Engine

A. Engine

The engine is a two spool, axial flow, high bypass ratio turbofan powerplant for subsonic service.

The main modules of the engine are:

Page 4

2-12-0 Feb 01/18

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Launch Escape System Lattice & SkirtDocument4 paginiLaunch Escape System Lattice & SkirtThar LattÎncă nu există evaluări

- ေထြးျမ - AkhayarsaloneDocument5 paginiေထြးျမ - AkhayarsaloneThar Latt50% (2)

- Saturn V Paper Craft Pattern PDFDocument19 paginiSaturn V Paper Craft Pattern PDFLuanne Dela CruzÎncă nu există evaluări

- ,,-./01234456 37 4819426 /4,: : :?@ Abcdaef Ghij KF L@Document15 pagini,,-./01234456 37 4819426 /4,: : :?@ Abcdaef Ghij KF L@Thar Latt83% (6)

- အန္တီနန္း - Akhayarsalone PDFDocument9 paginiအန္တီနန္း - Akhayarsalone PDFThar LattÎncă nu există evaluări

- အန္တီနန္း - Akhayarsalone PDFDocument9 paginiအန္တီနန္း - Akhayarsalone PDFThar LattÎncă nu există evaluări

- အန္တီနန္း - Akhayarsalone PDFDocument9 paginiအန္တီနန္း - Akhayarsalone PDFThar LattÎncă nu există evaluări

- 3Document1 pagină3Thar LattÎncă nu există evaluări

- 2Document1 pagină2Thar LattÎncă nu există evaluări

- J2 EnginesDocument7 paginiJ2 EnginesThar LattÎncă nu există evaluări

- Lunar ModuleDocument4 paginiLunar ModuleThar LattÎncă nu există evaluări

- J2 Engine InstructionsDocument11 paginiJ2 Engine InstructionsThar LattÎncă nu există evaluări

- Inter StageDocument13 paginiInter StageThar LattÎncă nu există evaluări

- Saturn V Base InstructionsDocument11 paginiSaturn V Base InstructionsThar LattÎncă nu există evaluări

- Interstage InstructionsDocument5 paginiInterstage InstructionsThar LattÎncă nu există evaluări

- Stage One InstructionsDocument9 paginiStage One InstructionsThar LattÎncă nu există evaluări

- F1 Engine InstructionsDocument5 paginiF1 Engine InstructionsThar LattÎncă nu există evaluări

- 1Document34 pagini1Thar Latt100% (1)

- Apollo / Saturn V: Scale 1:48 © Greelt A. Peterusma F1 Engine Part 1 Print On 160 - 180 Grams PaperDocument20 paginiApollo / Saturn V: Scale 1:48 © Greelt A. Peterusma F1 Engine Part 1 Print On 160 - 180 Grams PaperThar LattÎncă nu există evaluări

- Apollo 11 Saturn V 02Document38 paginiApollo 11 Saturn V 02Thar LattÎncă nu există evaluări

- 1mm Card Stock: Apollo / Saturn VDocument3 pagini1mm Card Stock: Apollo / Saturn VThar LattÎncă nu există evaluări

- Stage Three InstructionsDocument3 paginiStage Three InstructionsThar LattÎncă nu există evaluări

- Stage Three InstructionsDocument3 paginiStage Three InstructionsThar LattÎncă nu există evaluări

- Service Module InstructionsDocument3 paginiService Module InstructionsThar LattÎncă nu există evaluări

- Stage TwoDocument34 paginiStage TwoThar LattÎncă nu există evaluări

- Stage Two InstructionsDocument3 paginiStage Two InstructionsThar LattÎncă nu există evaluări

- Thrust InstructionsDocument7 paginiThrust InstructionsThar LattÎncă nu există evaluări

- Thruster StructureDocument17 paginiThruster StructureThar LattÎncă nu există evaluări

- Thrust InstructionsDocument7 paginiThrust InstructionsThar LattÎncă nu există evaluări

- Geometric Shapes To Print or Color RectangleDocument5 paginiGeometric Shapes To Print or Color RectangleJojo YongÎncă nu există evaluări