Documente Academic

Documente Profesional

Documente Cultură

Seated Beam Conns

Încărcat de

navinzhereDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Seated Beam Conns

Încărcat de

navinzhereDrepturi de autor:

Formate disponibile

The Results of Experiments on

Seated Beam Connections

CHARLES W. ROEDER AND RONALD H. DAILEY

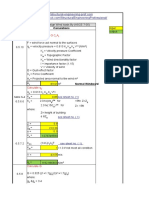

Seated beam connections have been used for many years. TABLE 1

They have historically been designed by tabular methods,1 LRFD Web Crippling Capacity—N=3½ in.

and this tradition was recently continued in the new LRFD Web t f/t w = 1 t f/t w = 1.5 t f/t w = 2

Manual.2 The derivation of these design tables are discussed Thick- Beam Depth Beam Depth Beam Depth

elsewhere3 and will not be repeated here. ness 10 12 16 10 12 16 10 12 16

It should be noted that the tables have historically 3/16 22 20 18 17 16 15

considered local yielding of the beam web under edge 4/16 39 36 32 33 30 27 29 27 25

5/16 61 56 49 51 47 43 46 43 40

loading, the strength of bolts or welds, the yielding capacity

6/16 88 81 71 73 68 62 66 62 57

of the seat angle and the normal detailing dimensions. 7/16 120 110 97 100 93 84 89 84 78

The new AISC LFRD Specification includes the new Resistance factor = .75—Load inkips for A36 steel

equation (K1-5) which checks the beam web for crippling or

buckling. In this paper, the term buckling is defined to mean The stiffened seat prevented yielding of the seat angle and

a vertical crimping or crippling of the web due to the assured that failure occurred in the beam rather than in the

application of a concentrated load on the flange. This is a connection. The top angle was L4 × 4 × ¼ and was attached

stability mode of failure rather than a web yielding failure as to the top flange or optional web location as indicated in

presently considered in ASD design (8th Edition Manual). Table 2. These two locations are required by the AISC design

Unlike a web yielding formula, it includes the depth and the procedure. The top or side angle is required to support the

flange thickness of the beam as variables. Table 1 beam, but the design calculations3 do not explicitly consider

summarizes LRFD beam web capacities according to Eq. it. To evaluate this effect, a third support configuration (Fig.

(K1-5) and a 3-½ in. bearing length. It can be seen that there 2) was used for each of the six sections. This third

are cases where the tabulated unstiffened seat capacities configuration employed 2 angles which were bolted to the

exceed the beam web buckling capacity. Therefore, AISC column but not to the beam. The angles guaranteed the

funded a research program at the University of Washington stability of the beam web, but they did not contribute to the

to study these connections. This paper summarizes some of capacity of the connection seat. Therefore, this configuration

the results of this experimental program. was the most realistic in evaluating the capacity of the

connection independent of any beam web attachments.

EXPERIMENTAL PROGRAM Four additional tests were performed with unstiffened

Six wide flange beams of grade 50 steel were tested in seat angles. The beam was a W14 × 26 or a W14 × 22 for

both stiffened and unstiffened seat connections. They were these tests, and the seat angle was ¾-in. thick. Three strain

the W8 × 10, W12 × 14, W12 × 22, W12 × 26, W14 × 22 gages were attached to the seat angle and monitored during

and W14 × 26. These sections were chosen because they the test. These gages were placed on the inside of the leg of

have thin webs and their predicted load capacity, with ½ in. the angle, which was bolted to the column, near the toe of the

bearing would be governed by web buckling, Eq. (K1-5). The fillet. They were spaced across the width of the angle so that

tests are summarized in Table 2, and the test setup is the distribution of strain could be measured. Three of the four

illustrated in Fig. 1. Each of the six sections were tested with flexible beam tests were made with the standard ½-in.

three different top angle arrangements and a stiffened seat. setback between the beam end and column face. The top

angle was located either on the top flange (standard), or on

the web (optional location) or an unbolted double angle detail

Charles W. Roeder is professor of civil engineering, University of

was used as shown in Fig. 2. The fourth unstiffened seat test

Washington, Seattle, Washington.

Ronald H. Dailey is a former graduate student, Department of used a 1-in. setback between the beam and the column face.

Civil Engineering, University of Washington and currently a partner This fourth test illustrated the effect of fabrication error or

of Loftus and Dailey, Consulting Engineers, Fairbanks, Alaska. inadvertent eccentricity on the connection detail. The bolts

90 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

© 2003 by American Institute of Steel Construction, Inc. All rights reserved. This publication or any part thereof must not be reproduced in any form without the written permission of the publisher.

Figure 1

were all ¾ in. A325 with calibrated washers. Lateral support applied near the quarter point of the eight foot span. This

was provided to the beam in the region of maximum moment loading was needed to develop the required end reaction of

with a light frame as shown in Fig. 3. The loads were applied the beam without yielding the beam in bending.

with a 2.3 million pound Baldwin hydraulic test machine, and Deflections were measured at three locations in the beam

a bearing stiffener was used to prevent damage to the beam at span with linear voltage displacement transducers (LVDTs)

the load point. An elastomeric pad was used to distribute the as shown in Fig. 1. The data were recorded with a Hewlett-

load and prevent local damage. The concentrated load was Packard computerized data acquisition system. The test spec-

TABLE 2

Experimental Program

Beam Seat Top Angle Ultimate

Size Detail Detail Reaction

W8×10 Stiffened Top Angle 18. A

W8×10 Stiffened Optional Web 18.3 A

W8×10 Stiffened Unbolted Web 18. A

W12×14 Stiffened Top Angle 36.8 A

W12×14 Stiffened Optional Web 36.3 A

W12×14 Stiffened Unbolted Web 27.6 A

W12×22 Stiffened Top Angle 61.4 A

W12×22 Stiffened Optional Web 60.3 A

W12×22 Stiffened Unbolted Web 60.8 A

W12×26 Stiffened Top Angle 64.5 B

W12×26 Stiffened Optional Web 68. C

W12×26 Stiffened Unbolted Web 57. C

W14×22 Stiffened Top Angle 58.5 C

W14×22 Stiffened Optional Web 57. C

W14×22 Stiffened Unbolted Web 54. C

W14×26 Stiffened Top Angle 60.9 C

W14×26 Stiffened Optional Web 58.5 C

W14×26 Stiffened Unbolted Web 45. C

W14×26 ¾L Top Angle 47. D

W14×26 ¾L Optional Web 47. D

W14×22 ¾L Unbolted Web 38. D

W14×26 ¾L Top Angle 33. D

A—Beam yielded under load point

B—Local flange buckling of the beam

C—Beam web buckled at seat

D—Angle seat bent and could not accept more load.

THIRD QUARTER / 1989 91

© 2003 by American Institute of Steel Construction, Inc. All rights reserved. This publication or any part thereof must not be reproduced in any form without the written permission of the publisher.

imens were all whitewashed and all yielding and buckling FD Manual of Steel Construction design procedure includes a

was carefully observed and photographed. The configurations method for calculating the bearing length to prevent both

were always tested in a given sequence. First, the beam was beam web yielding and buckling. To facilitate this

tested with the top angle, and the web and unbolted angles calculation, AISC has tabulated constants in the Load Tables

were tested sequentially. The first two tests were stopped for Uniform Load Constants for beams. Unless this tabulated

before excessive damage was done to the steel. This bearing length is considered, web buckling may be the limit

permitted the use of the same steel section for three tests. state as illustrated in Table 2 and the photograph of Fig. 6.

Obviously, a slightly larger load capacity could have been The buckling was typically accompanied by yielding of the

attained if more damage had been permitted in the first two steel and resulted in large permanent deformations. The

tests, but examination of the force-deflection behavior deformation probably contributed to the ability of the top

indicates that this effect is very small. More detailed data on angle to carry load. While web buckling is an important limit

the test procedures and test results are given elsewhere. state, it requires a relatively unusual loading condition to

achieve it. The experiments were performed with a

concentrated load at approximately the quarter point of an 8

EXPERIMENTAL RESULTS ft. span. This span is quite short for a 12 or 14 in. wide

The experiments were performed and some of the more flange beam. Further, the quarter point loading is relatively

general results are noted in Table 2, but several observations uncommon and despite these unusual conditions the W8 × 10,

require more elaborate description. W12 × 14 and W12 × 22 still failed by flexural yielding

First, it should be noted that comparison of the reaction before web buckling could occur. Web buckling is unlikely to

capacity obtained for the double angle support system shown occur with rolled wide flange beams under uniformly

in Fig. 2 with the reaction capacity obtained for identical seat distributed loading unless the span is very short compared to

connections with the top flange angle or the optional web the beam depth. In any case, beam web buckling can be

location angle, illustrates the percentage of the load carried avoided by following AISC Specification Eq. (K1-5) and

by the top angle. This effect is further illustrated in Figs. 4 using the procedure outlined in the Manual.

and 5 for typical stiffened and unstiffened seat connections. A third major observation is that unstiffened seat angle

The top angle carried between 8% and 35% of the end connections can adequately yield without fracture. The

reaction for connections which failed through web crippling. connections are capable of rotating, without distress, far

Further, the top angle or optional web angle may stiffen the beyond that required to accomodate the end rotation of the

seat somewhat in the elastic range and, therefore, delay beam it is connecting. The strain gages indicate that yielding

inelastic action. The reaction carried by the top angle is initiates near the toe of the fillet in the center of the leg of the

important to the connection behavior even though it is angle which is bolted to the column. Yielding propagated

ignored in the design model used to develop the connection along the length of the angle as indicated in Fig. 7, and again

load tables. However, not enough data is available at the the top angle reduces the load on the seat angle as illustrated

present time to warrant a less conservative model than that in Fig. 5. The experiments suggest that yielding of the seat

presently used. angle occurs near the toe of the fillet on the leg which is

The second observation is that web buckling is an bolted to the column; this measurement is supported by the

important mode of failure for the case when beams with thin observed plastic rotation at the location in the photo of Fig.

webs bear on stiffened seats. For this reason, the AISC LR- 8. It is interesting to note that the measured strains never ex-

Figure 2 Figure 3

92 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

© 2003 by American Institute of Steel Construction, Inc. All rights reserved. This publication or any part thereof must not be reproduced in any form without the written permission of the publisher.

TABLE 3

Comparison Of Experiments With Design Values

Beam Seat Top Angle Ultimate ASD DESIGN LRFD Design

Size Detail Detail Reaction Yield Ratio Yield Eq. (K1-5)

W12×26 Stiffened Top Angle 64.5 38 1.7 65 29

W12×26 Stiffened Optional Web 68. 38 1.8 65 29

W12×26 Stiffened Unbolted Web 57. 38 1.5 65 29

W14×22 Stiffened Top Angle 58.5 38 1.5 65 31

W14×22 Stiffened Optional Web 57. 38 1.5 65 31

W14×22 Stiffened Unbolted Web 54. 38 1.4 65 31

W14×26 Stiffened Top Angle 60.9 42 1.4 75 34

W14×26 Stiffened Optional Web 58.5 42 1.4 75 34

W14×26 Stiffened Unbolted Web 45. 42 1.1 75 34

W14×26 ¾L Top Angle 47. 27 1.7 49 34

W14×26 ¾L Optional Web 47. 27 1.7 49 34

W14×22 ¾L Unbolted Web 38. 27 1.1 49 31

ceeded 0.005 in./in. on the outer fibers, far less than the onset are not included in Table 3 because these tests did not result

of strain hardening. in a beam web failure.

Stiffened Seats

Comparison of the stiffened seat test results with the

VALIDITY OF SPECIFICATION PROVISIONS LRFD factored resistance shows that the LRFD beam web

The experimental results are compared to the ASD buckling rule, Eq. (K1-5), is conservative but can not be

provisions (1978 Specification) and the LRFD provisions in ignored. The specimens with top flange angles or optional

Table 3. The LRFD design limits include the appropriate web angles had measured strengths more than 72% greater

resistance factors. Under the ASD design rules, only beam than predicted by the LRFD rules, including web buckling. If

web yielding is considered. The LRFD rules consider both web buckling was not considered in the design calculations

web yielding as well as buckling calculated by Eq. (K1-5), only one test in six achieved the computed strength. These

using only a 3-½ in. bearing. It is clear that, for both the observations suggest that a check for web buckling is

stiffened and unstiffened case, web buckling should be essential but it is also apparent that LRFD Eq. (K1-5) is

considered. It is also interesting to note that, in the ASD probably too conservative. This equation was analyzed in

case, the two cases where the ratio of Ultimate Reaction to greater detail and compared to 69 other experiments in other

the Web Yielding Load was only 1.1 were cases not papers.4,6,7 There was great scatter in the experimental data

permitted by the ASD Specification (no top or side angle). and, when the statistical concepts of LRFD are employed,

The test results for the W8 × 10, W12 × 14 and W12 × 22 this scatter results in a small (0.75) resistance factor. The L-

Figure 4 Figure 5

THIRD QUARTER / 1989 93

© 2003 by American Institute of Steel Construction, Inc. All rights reserved. This publication or any part thereof must not be reproduced in any form without the written permission of the publisher.

RFD resistance for web buckling and yielding; and the the design tables. Beams with a top or side angle developed

smaller of the two values divided into the measured strength measured reactions which were 5% less than the computed

for the 69 experiments.5 The figure clearly shows that LRFD yield resistance, but they greatly exceeded the

strengths much larger than the design values were often predicted web buckling resistance. The third test in this group

achieved. Most of the experiments were performed more than had the unbolted double angle detail shown in Fig. 2. This

40 years ago. It would appear reasonable to ask if a new detail is consistant with the design assumptions3 used for

series of tests could reduce the scatter through good unstiffened seats but it is not consistant with the requirement

experimental control and permit a considerable increase in to provide a top or side angle. The measured strength for the

the assumed resistance and, in turn, the resistance factor. specimens with the double angle was below acceptable levels

for both the ASD and LRFD design. This again illustrates the

The third specimen in each group of three stiffened seat

importance of a securely fastened top or side angle. This

tests had unbolted double web angles as shown Fig. 2. This

angle carries a substantial portion of the end reaction, and the

test configuration is more nearly consistent with the design

loss of this capacity appears to result in an unconservative

model used to generate the tables for unstiffened seats.

estimate of the beam web buckling capacity. As noted earlier,

However, as has been pointed out, it is not permitted by

the unstiffened seats were able to deform sufficiently while

either the AISC ASD or LRFD Specification. The double

carrying the required load. It is concluded, therefore, that the

angles are not able to carry any part of the reaction, and as a

present or LRFD design procedure for the seat, itself, is

result the reaction is reduced by 7% to 27% over the seat

adequate. However, it is possible for the tabulated values to

when provided with a bolted top or side angle. These tests

exceed the buckling capacity of some beams with slender

illustrate the importance of a securely attached top angle

webs so it is essential that LRFD Eq. (K1-5) be checked.

which is of appropriate size for the connection. This third

detail is still very conservative when compared to the web

buckling equation. This observation supports the earlier

observation that the resistance factor of 0.75 may be small

for this application.

CONCLUSIONS AND PRACTICAL IMPLICATIONS

Similar observations may be made with respect to the

allowable stress (ASD) design provisions.1 ASD does not It can be concluded from the results of this research

require a web buckling check and, without the top or side that:

angle, an unconservative design may result for beams with 1. The top flange angle (or optional web angle) carries a

slender webs. Even with these angles, two tests indicated a substantial portion of the end reaction for both stiffened

load factor of 1.4. This again suggests that, even though no and unstiffened seat connections. This makes it essential

failures have been reported, a web buckling provision should that this angle be securely fastened and be of an

probably be included in the ASD Specification. appropriate size and strength for the connection.

2. Web buckling is the controlling failure mechanism for

Unstiffened Seats many beams with slender webs and small end bearing

Only three tests are available for the unstiffened seat lengths.

connection, since the 1 in. end spacing is not consistant with 3. ASD design provisions do not explicitly include a beam

Figure 6 Figure 7

94 ENGINEERING JOURNAL / AMERICAN INSTITUTE OF STEEL CONSTRUCTION

© 2003 by American Institute of Steel Construction, Inc. All rights reserved. This publication or any part thereof must not be reproduced in any form without the written permission of the publisher.

web buckling check and as a result, unconservative applications. Secondly, and very important, the top or side

designs could result, particularly if the required top or web angle carries a significant portion of the end shear, and,

side angle were omitted. if it is properly bolted and not too thin, it will help solve

4. LRFD provisions have an equation for web buckling, many potential problems. Finally, web buckling is most likely

Eq. (K1-5), but the experiments described in this paper to occur with stiffened seats or unstiffened seats with thick

suggest that this equation with a 0.75 resistance factor angles and when the requirement for a top or side angle is

may be overly conservative. However, it must be violated. The unlikely combination of all these factors

emphasized that 69 tests performed 40 years ago and explains why these connections have had such a good

described in other papers3,6 suggest that this formula performance record.

and resistance factor are approximately correct.

5. The three tests of unstiffened seats indicated that the

present design procedure results in seats that have

ample rotation capacity and strength. RECOMMENDATIONS

More research is needed to improve the design of seated

Practical Implications connection through:

1. Developing models for predicting the effect of the

The previous discussion suggests that the existing design

top or side angle on the connection strength.

rules for unstiffened seat connections are somewhat

2. Better estimates of the web buckling capacity and the

irrational. They employ a highly idealized and probably

LRFD resistance factor. There is a great deal of

unrealistic distribution of forces and they sometimes ignore

scatter in the existing data3 and this data was

the critical mode of failure. This conclusion is unavoidable

acquired more than 40 years ago. A well controlled

when the experimental evidence is considered. However, it

experimental program may well reduce this scatter

important that one not lose sight of several important

and provide more realistic strength estimates.

practical aspects. These connections have been used for many

3. Development of better models for predicting the

years and no problems have been noted and one must

distribution of forces in the connection material.

recognize why this is so. First, the buckling failure mode

described in this paper requires a high shear force and a

beam with a slender web. This would be unlikely to occur ACKNOWLEDGMENTS

with rolled shapes loaded uniformly. The limit states would

be more likely be a three hinge mechanism in these common The experiments described in this paper were performed

with funds provided by the American Institute of Steel

Construction.

REFERENCES

1. Manual of Steel Construction, 8th ed., Chicago: AISC,

1980.

2. Steel Research Needs for Buildings, NBS Special

Publication 693, U.S. Dept. of Commerce, Washington

D.C., 1985.

3. Load and Resistance Factor Design Specification for

Structural Steel Buildings, Chicago: AISC, 1986.

4. Elgaaly, M., "Web Design Under Compressive Edge

Loads," AISC Engineering Journal, Vol. 20, No. 4,

Chicago, 1983, pp. 153-171.

5. Roberts, T. M., "Slender Plate Girders Subjected to Edge

Loading," Proceedings Institution of Civil Engineers,

Part 2, Vol. 71, September 1981, pp. 805-819.

6. Ketchum, M. S., and J. O. Draffin, "Strength of Light I-

Beams," University of Illinois Engineering

Experimentation Station, Bulletin No. 24, February

1932.

7. Lyse, I., and J. H. Godfrey, "Web Buckling in Steel

Figure 8 Beams," Transactions, New York: ASCE, 1935.

THIRD QUARTER / 1989 95

© 2003 by American Institute of Steel Construction, Inc. All rights reserved. This publication or any part thereof must not be reproduced in any form without the written permission of the publisher.

S-ar putea să vă placă și

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- 1970 Johnson 1 5HP Outboard Service Manual PDFDocument5 pagini1970 Johnson 1 5HP Outboard Service Manual PDFChrisStainton50% (2)

- Engineering Design Manual: Metal BAR GratingDocument24 paginiEngineering Design Manual: Metal BAR GratingAhsan Sattar100% (4)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Conveyor Drawing Design Checking1Document3 paginiConveyor Drawing Design Checking1navinzhere100% (1)

- Axera D07Document79 paginiAxera D07Percy Chero100% (2)

- Comparision of Fabrication TolerancesDocument4 paginiComparision of Fabrication TolerancesSatish Keskar100% (1)

- Power System Protection - Part 10Document22 paginiPower System Protection - Part 10Matthew WongÎncă nu există evaluări

- Response Spectrum Method GuptaDocument181 paginiResponse Spectrum Method Guptagyan_th9229100% (2)

- Wind Loads Calculations by ASCE7 05 For Any BuildingDocument12 paginiWind Loads Calculations by ASCE7 05 For Any BuildingshubhamdereÎncă nu există evaluări

- Catalog ChinaDocument61 paginiCatalog Chinaa.muhammadÎncă nu există evaluări

- Code Standard Practice 7 EngDocument56 paginiCode Standard Practice 7 EngNarendar SaggamÎncă nu există evaluări

- H BeamsDocument1 paginăH BeamsnavinzhereÎncă nu există evaluări

- 2 Crane Models and Geometry PDFDocument28 pagini2 Crane Models and Geometry PDFgiapy0000Încă nu există evaluări

- Hollow Section capacities-AS4100Document182 paginiHollow Section capacities-AS4100Andreea LucaÎncă nu există evaluări

- DriftDocument4 paginiDriftsunilr_60Încă nu există evaluări

- Ajax PresentationDocument34 paginiAjax PresentationJesus lopezÎncă nu există evaluări

- Failure Modes and Effects Analysis: R.R. MohrDocument37 paginiFailure Modes and Effects Analysis: R.R. Mohrmh70100% (8)

- Leave Card - Sample PDFDocument2 paginiLeave Card - Sample PDFnavinzhere75% (4)

- BF08H00902 Components EngineDocument125 paginiBF08H00902 Components EngineHéctor Medina100% (1)

- Transmission Tower Modeling By: George T. Watson PEDocument11 paginiTransmission Tower Modeling By: George T. Watson PEGeorge MainaÎncă nu există evaluări

- CVEN483 Sample2 Spring07Document69 paginiCVEN483 Sample2 Spring07Kenaia AdeleyeÎncă nu există evaluări

- Support Structure Design ReportDocument31 paginiSupport Structure Design ReportnavinzhereÎncă nu există evaluări

- Weld Symbol Elements Ref. SHTDocument1 paginăWeld Symbol Elements Ref. SHTnavinzhereÎncă nu există evaluări

- Transmission Tower Modeling By: George T. Watson PEDocument11 paginiTransmission Tower Modeling By: George T. Watson PEGeorge MainaÎncă nu există evaluări

- For Nuclear STR Design of Anchors Bolts and Other Steel Embedments 1-3-190Document3 paginiFor Nuclear STR Design of Anchors Bolts and Other Steel Embedments 1-3-190Giovanni BoscoloÎncă nu există evaluări

- Design of Anchor BoltsDocument2 paginiDesign of Anchor BoltsnavinzhereÎncă nu există evaluări

- Bda 5 81 PDFDocument21 paginiBda 5 81 PDFAri PranantaÎncă nu există evaluări

- جداول قطاعات الحديدDocument36 paginiجداول قطاعات الحديدEsam Mady100% (2)

- Performance of PR ConnsDocument8 paginiPerformance of PR ConnsnavinzhereÎncă nu există evaluări

- Design TablesDocument59 paginiDesign TablesnavinzhereÎncă nu există evaluări

- ASTM A6 - What Recent Changes Mean For Designers and FabricatorsDocument2 paginiASTM A6 - What Recent Changes Mean For Designers and FabricatorsAngel Arturo Castellanos SantamariaÎncă nu există evaluări

- StructuralDocument67 paginiStructuralTamer Mostafa SamirÎncă nu există evaluări

- NPTEL BucklingDocument15 paginiNPTEL BucklingLakshmanan SreenivasanÎncă nu există evaluări

- Hollow Bolt PDFDocument8 paginiHollow Bolt PDFnavinzhereÎncă nu există evaluări

- Conference Preview: Howdoi Encourage Quality As Management?Document2 paginiConference Preview: Howdoi Encourage Quality As Management?navinzhereÎncă nu există evaluări

- 2.1 Material Model: True TrueDocument11 pagini2.1 Material Model: True TruenavinzhereÎncă nu există evaluări

- Theoretical ManualDocument10 paginiTheoretical ManualnavinzhereÎncă nu există evaluări

- Getrich PiperackDocument11 paginiGetrich PiperacknavinzhereÎncă nu există evaluări

- C Section PropertiesDocument2 paginiC Section PropertiesnavinzhereÎncă nu există evaluări

- FRR 500 - 500S Igm0087 - 6-CylDocument4 paginiFRR 500 - 500S Igm0087 - 6-CylMarvin White0% (1)

- Check List For Fire Pump - Nfpa 20 Systems General Submittal RequirementsDocument2 paginiCheck List For Fire Pump - Nfpa 20 Systems General Submittal Requirementssaus sambalÎncă nu există evaluări

- To Download List of A Books Available in Library I - 59d42dbc1723dd1de323c9b4 PDFDocument188 paginiTo Download List of A Books Available in Library I - 59d42dbc1723dd1de323c9b4 PDFRISHIKESH KUMARÎncă nu există evaluări

- Fluidic Muscle1Document39 paginiFluidic Muscle1alexanderfortis8628Încă nu există evaluări

- FD100 分Document17 paginiFD100 分Hadi FaisalÎncă nu există evaluări

- Weight Curves For ShipsDocument11 paginiWeight Curves For ShipsJuan Silva100% (1)

- Bircosir - NW 150: Stability and DiversityDocument5 paginiBircosir - NW 150: Stability and Diversityjagath2005ukÎncă nu există evaluări

- FGM Piston Liner Kit IndexDocument88 paginiFGM Piston Liner Kit IndexLuis Arturo Arevalo LeonÎncă nu există evaluări

- MEE322 Final Exam S20Document5 paginiMEE322 Final Exam S20Nabil SweidanÎncă nu există evaluări

- Rover 75 ATF Fluid ChangeDocument11 paginiRover 75 ATF Fluid ChangeRichardÎncă nu există evaluări

- Cdo CalcDocument3 paginiCdo CalcJeric FarinÎncă nu există evaluări

- Yamaha ServiceDocument57 paginiYamaha ServicesantonsÎncă nu există evaluări

- Chapter 2Document27 paginiChapter 2hailegebreselassie24Încă nu există evaluări

- DI7140N - EN-Expansion JointDocument1 paginăDI7140N - EN-Expansion JointHai PhanÎncă nu există evaluări

- Module 2Document43 paginiModule 2Manchimsetty Sri NidhiÎncă nu există evaluări

- Scheda Tecnica: IT-T1S Itb-T1SDocument1 paginăScheda Tecnica: IT-T1S Itb-T1SITALFIL S.p.A.Încă nu există evaluări

- Belt Drive Numerical 1Document6 paginiBelt Drive Numerical 1Prateek ridersÎncă nu există evaluări

- Art 10.1007 s00603-012-0220-7 Block Flexural Toppling Amini PDFDocument14 paginiArt 10.1007 s00603-012-0220-7 Block Flexural Toppling Amini PDFJosé Carlos Bustamante MoralesÎncă nu există evaluări

- Himalaya GasesDocument4 paginiHimalaya Gasesmitr_mmÎncă nu există evaluări

- Cooling System MechanicallDocument23 paginiCooling System MechanicallStuart FerreiraÎncă nu există evaluări

- Goodyear OTR Databook2009Document169 paginiGoodyear OTR Databook2009otr-tireman100% (1)