Documente Academic

Documente Profesional

Documente Cultură

FT16-Emergency Plan TML O&M FY2018 - 19

Încărcat de

sanjeev kumarDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

FT16-Emergency Plan TML O&M FY2018 - 19

Încărcat de

sanjeev kumarDrepturi de autor:

Formate disponibile

EMERGENCY PREPAREDNESS

AND RESPONSE MANUAL

1 X 10 MW CPP O&M,

M/s.TATA METALIKS LIMITED,

Samraipur, Kharagpur

Dist : Medinapur, WEST BENGAL

Prepared by: Approved by: Issued On Page

Core Team Management Appointee 12th January 2017 1 of 13

OHS/FT16

On Site Emergency Plan

1 Scope

This plan details, the emergency procedures in place at

Site Name: 1 X 10 MW CPP,O&M , TML, KHARAGPUR

Site Address: Thermax Ltd, C/o- Tata Metallic Ltd.,

Samaraipur, West MedinaPur, Kharagpur, West Bengal- 721301

2 Objective

This plan has been developed to:

1.1 Describe the procedure to be followed when an emergency is declared so that

immediate specific actions by people or on plant can be taken to lessen the loss of life

and property.

1.2 Control or limit any effect that an emergency or potential emergency may have on

Thermax Ltd, C/o- Tata Metallic Ltd.,Samaraipur, West Midnapur, Kharagpur, West

Bengal- 721301 Site.

1.3 Facilitate emergency response and provide assistance on the site as may be

appropriate to the occasion.

1.4 Ensure communication of all vital information to appropriate internal and external

parties as soon as possible.

1.5 Facilitate reorganization activities so that operations can be resumed.

1.6 Provide training so that an appropriate level of preparedness can be continually

maintained.

1.7 Provide for a basis for updating and reviewing emergency procedures.

3 Definition

3.1 Emergency

An emergency is any condition or situation, which requires assistance over and above

the capability of personnel present and which has the potential to cause serious injury

Prepared by: Approved by: Issued On Page 2

Core Team Management Appointee 12th January 2017 2 of 13

OHS/FT16

On Site Emergency Plan

or loss of life, major damage to property and disruptions on-site and/or off-site and

requires the use of outside resources to handle it effectively.

3.2 Emergency Response Plan

The Emergency Plan basically provides a clear statement of definite assignments of

responsibilities and authorities of the Emergency Organization. Its objective is to help

contain and control incidents, to safeguard employees and others who may be

affected and to minimize damage.

3.3 Site main Controller

The Site main Controller is overall responsible for establishing and operating the

emergency plan; schedules and reviews trials of the emergency plan; ensures

emergency coordinators have trained emergency squads; and decides the best use of

resources during emergency.

3.4 Incidence Controller

The Incidence Controller is the head of emergency operation team. He controls the

activities of all emergency coordinators being physically present at site and gives feed

back to Site main Controller.

3.5 Fire Team Coordinator

Fire team Coordinator refers to someone responsible for ensuring trained fire fighters

are available round the clock in plant with required equipments to meet any fire hazard

and ensures that suitably trained alternate is available.

3.6 First Aid Team Coordinator

First Aid / Rescue Coordinator refers to someone responsible for ensuring that there is

available a group of trained ‘First Aiders’ to provide assistance to victims in

emergency; identifies an emergency sick bay in conjunction with the emergency

controller; and ensures basic first aid kits and equipment are available for emergency

purposes.

3.7 Mechanical Service Coordinator

Mechanical Service Coordinator refers to someone responsible for ensuring that

support services with regards to any mechanical system is in place; trained squad is

available to provide support for mechanical system; and suitably trained alternate is

available.

3.8 Electrical Service Coordinator

Electrical Service Coordinator refers to someone responsible for ensuring that plant and site

main switches are identified and could be safely isolated during emergency.

3.9 Emergency Control Centre

Emergency Control Centre is a place safe away from danger zone having all

communication media to command and control the operation team as well as to seek

help from external sources.

Emergency Control Centre of TML site is at Control room.

3.10 Communication officer

Communication officer refers to a person is authorized to establish the

Communication with customer, Govt. authorities and also seek help from other external

agencies.

3.11 Assembly point

Prepared by: Approved by: Issued On Page 3

Core Team Management Appointee 12th January 2017 3 of 13

OHS/FT16

On Site Emergency Plan

Assembly point is the safer place defined for people to be assembled during

emergency where the head counter will ensure that all people are evacuated safely

from hazardous area.

The assembly points defined for TML site is

1. Assembly point 1 : Front of Cooling Tower area

2. Assembly point 2 : In front of GSA office In between both boilers.

3. Assembly Point 3 : TML main gate area.

4 ORGANISATION CHART OF EMERGENCY CONTROL TEAM

Site Main Controller

Incident Controller

Safety Officer ERT Team Members Communication

Officer

Fire fighting crew Engineers,

Electrician,

Operators, Helpers

First Aid Team

Prepared by: Approved by: Issued On Page 4

Core Team Management Appointee 12th January 2017 4 of 13

OHS/FT16

On Site Emergency Plan

ROLE OF SITE MAIN CONTROLLER:-Site main controller is the main controller who will

lead the controlling of the fire incident. He will -

Call the fire tender.

Ensure that unwanted persons are safely removed from the effected area

Direct the fire tender to reach the affected area

Ensure that have gathered in the demarcated area, called Assembly point.

Extend medical help for wounded.

Remove casualties.

ROLE OF INCIDENT CONTROLLER:-In absence of site main controller he will act as

main

Site controller. He will –

Inform site main controller about the incident.

Call the fire tender.

Ensure that unwanted persons are safe removed from the effected area.

Direct the fire tender to reach the affected area.

Ensure that have gathered in the demarcated area, called Assembly point.

Provide Safety Appliance.

Guide external fire tender to approach the affected area.

Help in searching for casualties.

Collect and preserve evidence fire further inquiry.

ROLE OF TEAM MEMBER: - Team member are the field operating staff that will be

always available at site. During fire fighting operation they will assist the fire man.

Note: If client has its own emergency plan and as per that the roles and

responsibilities of individuals and teams are defined and in case of emergency the

effects spread beyond our site, Thermax (Site main controller) has to inform client for

getting help of Emergency Services like Fire brigade, additional ambulance, security,

etc.

Prepared by: Approved by: Issued On Page 5

Core Team Management Appointee 12th January 2017 5 of 13

OHS/FT16

On Site Emergency Plan

5 Emergency Contact Numbers

1.1 INTERNAL EMERGENCY TELEPHONE NUMBERS:

CPP-3 Control Room Emergency Control Center 9073965967/

9073907409

Mr.Manas Rakshit Site Main Controller 8420002711

Mr.Indrajit Kr. Dey Incident Controller 7501628994

Tapas Chakraborty EHSO TML 9476106704

Janardan Singh Fire Fighting Team Leader 9064072678

Bijay Behera First Aider 8980372010

Prasanjit Mandal Team Member 9609907242

Utpal Bhattacharya Communication Officer 9432159011

Shift In charge Team Member 9073907408

Alok Roy Team Member 9474019295

Sandeep Das( TML) Team Member 8420002264

1.2 LOCAL EMERGENCY TELEPHONE NUMBERS:

Inter com No Mobile No

Plant Emergency Control Main gate No. 229, 230 9073331142

First Aid Centre(OHC) 243 9073966947

Ambulance Service 9635032258

Medical Officer 314 9073904474

5.3 EXTERNAL EMERGENCY TELEPHONE NUMBERS:

Fire service station Kharagpur 03222-255709

Govt. Hospital Kharagpur. 03222-259125

Prepared by: Approved by: Issued On Page 6

Core Team Management Appointee 12th January 2017 6 of 13

OHS/FT16

On Site Emergency Plan

6. GENERAL INCIDENT

6.1 EMERGENCY PLAN – EXECUTION

Emergency Control Center is at control room TML site

Personnel from all departments/agencies should be assembled orderly at their

assembly point where headcount can be carried out by headcounter.

Personnel are to remain at the assembly point until instruction is given by the Site

main Controller / Incident Controller that the emergency is over and they could return

to normal duties. The assembled personnel can then leave the assembly point in an

orderly manner.

6.2 EMERGENCY DECLARATION

6.2.1 INITIATION OF EMERGENCY PLAN

The emergency plan comes into effect when an emergency is declared at TML site.

The plan may be affected to the whole site or any particular area(s) of site depending

up on the nature of emergency. The applicability will be decided by Site main

Controller / Incident Controller.

6.2.2 DETERMINATION OF EMERGENCY

Any employee can declare an emergency in situation that involves an escalating fire,

serious injury, loss of life, extensive damage to property or temporary or permanent

damage to the environment and which requires actions that are beyond and above the

capability of personnel present at that time.

6.2.3 ASSESMENT OF EMERGENCY.

Initially at site the person first observed the situation can alert others by blowing

whistle repeatedly. The work group supervisor/ concerned engineer/ any site person

should inform the same to CEC/ SEC/ any emergency team member as soon as

Prepared by: Approved by: Issued On Page 7

Core Team Management Appointee 12th January 2017 7 of 13

OHS/FT16

On Site Emergency Plan

possible. An emergency is declared by actuating the Emergency Alarm. This will

sound a wailing siren 3 times for 10s at gap of 5 seconds.

/ \_/ \_/ \

10s 5s 10s 5s 10s

6.2.4 PROCEDURES

(a) Site main controller will rush to emergency control room and take over the

command and control.

(b) Incident controller and his coordinators will rush to the exact location of

emergency. Incident controller will give feed back of location to Site main

controller. Emergency /department coordinators will lead their respective teams for

emergency actions as instructed by Site main controller.

(c) Other Members of the emergency team should as far as practicable proceed

immediately to the scene of emergency and report to their respective coordinators.

(d) After getting information from Incident controller, he will specify the suitable safe

assembly point away from emergency. Site main controller will check the head

count of emergency response team members before starting operation.

(e) Emergency coordinators who are at the scene of emergency could communicate

with the Control Center using walkie-talkie or phone.

(e) All personnel (employees and visitors) should stop the task they are performing

and evacuate plant safely and accumulate at the suitable assembly point as

declared and those who are not part of emergency response team should stay at

assembly point, report to head counter and continue to remain at the assembly

point in an orderly manner until the Site main controller gives instruction to return to

normal duties.

No employee should go to the site of emergency unless he is a

Member of the Emergency Response team or has been advised to do so.

7. MOST PROBABLE TYPES OF EMERGENCY.

At TML site the most probable hazardous conditions those might generate an

emergency situation are as follows.

Medical Emergencies.

Major Fire hazards.

Leakage of cock oven gas

Natural disaster like Earth quake & cyclone.

Bomb Threat.

8. ACTION DURING EMERGENCY.

Prepared by: Approved by: Issued On Page 8

Core Team Management Appointee 12th January 2017 8 of 13

OHS/FT16

On Site Emergency Plan

8.1 MEDICAL EMERGENCY OR PERSONNEL INJURY:

A medical emergency may appear at site due to several reasons like

Fall from height.

Electric shock & Burn.

Snake bite/Insects bite.

People drown in deep water.

ACTION REQUIRED:

The emergency preparedness & response team should rush to the location as soon as

possible after getting the information.

Avoid unnecessary gathering of people at the spot.

If the emergency is associated with live electric line then quick action should be taken

to cut the power supply.

The victim(s) should be rescued from the hazardous area and shifted to a safer place.

Provide First Aid to all injured employees regardless of severity.

Follow appropriate first aid methods as per nature of injury.

Give artificial respiration if the victim is unconscious.

Call ambulance service if the injury is major and beyond control under first aid.

Immediately shift the victim(s) to hospital if the injury is serious and needs immediate

medical treatment.

Immediately shift the victim(s) to hospital if the injury is serious and needs immediate

medical treatment.

If required give CPR.

Stretchers with ropes should be used to bring the casualties out of the reservoir.

Call for ambulance service and shift the victim to hospital.

After ensuring all victims are safely rescued give all clear report.

If breathing is stopped then immediate action should be taken to clear the air path and

give artificial respiration.

8.2 MAJOR FIRE HAZARDS:

An emergency situation can occur in the event of major fire at different locations in

side plant. The fire may be a result of electric fault or spark from hot works like

welding, gas cutting. The most probable classes of fire are

On event of Fire following actions needs to be taken on top priority:

Prepared by: Approved by: Issued On Page 9

Core Team Management Appointee 12th January 2017 9 of 13

OHS/FT16

On Site Emergency Plan

Isolate the area.

Switch off supply.

Evacuate all personnel to safe assembly point.

Assembly point should be chosen considering wind direction

Try & Shut off the source of Fire

Operate Fire Extinguishers if it’s a small fire.

Operate Fire Hydrant network from different approachable points

Call for Emergency services if needed.

Start Rescue operation if any personal are trapped in the fire.

Ensure that affected personal (if any) are moved to a safe & well- Ventilated place.

First Aid Treatment to be provided to affected personnel (if any)

Move affected to hospital if needed (if any).

On event of Electrical Fire or short circuit:

Immediately isolate the supply between two junction points or as directed by site

coordinator

Use CO2 extinguisher to put off the fire if it’s small.

Call Fire service department, TML in case of major fire.

8.3 LEAKAGE OF COCK OVEN GAS

COG is toxic and flammable gas and has a very strong odor. Its toxic properties are due

to the presence of CO (typically 9% v/v) in the gas. COG has a specific gravity of 0.43

and therefore, is a very buoyant gas, which tends to disperse rapidly when released to

the atmosphere. The high concentration of hydrogen and methane in COG suggests that

the gas can be ignited by a low ignition energy (e.g., static). Therefore, the probability of

ignition of COG leaks is likely to be high relative to other flammable gases.

8.3.1 Flue gas Details:

Gas flow in Boiler inlet duct – 56000 Nm3/hr.

Gas temperature in Boiler inlet – 950°C.

Gas temperature in boiler outlet duct – 185± 5° C.

8.3.2 Flue gas Composition

CO2 18.8%

H2O 12.5%

N2 36.3%

O2 3.8%

CO 0.9%

H2 0.6%

Action Required.

Prepared by: Approved by: Issued On Page 10

Core Team Management Appointee 12th January 2017 10 of 13

OHS/FT16

On Site Emergency Plan

Evacuate the personal to safe area / assembly point

Shut off the electric supply in direction of site controller , if situation demand

Ensure that no source of ignition is present at the site

Barricade the area do not allow unauthorized person and vehicle to endanger area

Ensure safe shutdown of gas supply if possible with appropriate PPEs or activate

the emergency shut off switch of gas supply system,

Declare the emergency if leak is major

If local control point is not accessible or not working properly then try to shut off

from the previous isolation point.

Inform TML authorities to stop the supply of gas from source.

Provide the appropriate PPEs and self-contained breathing apparatus to

emergency response team.

Advise and direct the firefighting team about the compatibility of fire extinguishing

equipment or any special product hazard , if requires

Seek the help from external agencies , if the situation is beyond control

Give first aid to the affected people.

Call ambulance and shift victim(s) to hospital if required

8.4 NATURAL DISASTER LIKE EARTH QUAKE & CYCLONE

As it is known we don’t have control over natural calamities. Hence we can take no

measure to stop the emergency generated due to a natural disaster.

In case of having prior information regarding the possibility of such calamities all

work should be stopped for the period of these exist.

In case of sudden arrival of such disasters the following measures can be taken to

minimize the destructive effect of the same.

8.4.1 Cyclonic winds

On event of Cyclonic Wind following actions needs to be taken on top priority:

Switch “Off” power and utilities so that damages to property & life can be

restricted.

Stop all height works and outdoor works.

Ensure all personnel are relocated to a safe destination.

Contact External emergency services for help if required.

8.4.2 Earthquake

On event of Earthquake following actions needs to be taken on top priority:

Immediately stop all project activities at site.

Ensure all personnel are relocated to a safe destination.

Prepared by: Approved by: Issued On Page 11

Core Team Management Appointee 12th January 2017 11 of 13

OHS/FT16

On Site Emergency Plan

Keep all cylinder in upright position and well tight with chain or other material to

restrict from falling.

Close all product supply from the source.

First Aid Treatment to be provided to affected personnel wherever required.

Contact External emergency services for help if required.

8.5 BOMB THREAT

Terrorism is biggest threat faced by Indians .Terrorists use a variety of means to carry

out their goals, Thermax employees and their families must be sensitized to their

techniques and appropriate countermeasures. Education and awareness training is

an excellent tool for lessening the potential for being a victim. Thermax employees

should be alert to suspicious activities and know how to report concerns to the

appropriate authorities

Receiver of the call to obtain and record information from call.

On recording all the information receiver will inform Site main controller.

Site main controller will then inform police and TML. Communication to media can

be sent through TML.

Site main controller will then assemble the emergency response team.

Emergency response team will plan for evacuation route and destination assembly

point.

Evacuation of site personnel to be controlled by Incidence Controller.

Site main controller & Incidence controller will provide information to Police upon

their arrival.

9.0 PROCEDURE TO BE FOLLOWED IN CASE OF A MEDICAL EMERGENCY OR

ACCIDENT

In the event of a medical emergency or accident within the site during working hours,

the employee or the supervisor should inform the Station Manager /Admin /Safety

personals, they immediately arrange for the medical attention or seek other medical

attention i.e First aid from the client First aid centre which ever deems appropriate.

The Clients ambulance is used for the serious medical emergency which requires

hospital aid. The injured Personals are shifted to the hospital for further treatment.

10.0TERMINATION OF EMERGENCY

This is applicable for emergency situation which requires evacuation.

Termination of emergency will be declared by Site main controller.

Before declaring termination Site main controller will ensure that the emergency

situation is handled successfully and no more potential hazard is there.

Prepared by: Approved by: Issued On Page 12

Core Team Management Appointee 12th January 2017 12 of 13

OHS/FT16

On Site Emergency Plan

The termination of emergency will be declared by raising the termination siren

continuously for 30 seconds.

11.0EMERGENCY EQUIPMENT

Fire detection, fire protection, and all other emergency equipment required in case

of emergency identified at site, will be adequately maintained at all locations by

contractors / agency working in the area. In case of default Thermax shall supply

and debit to the contractors.

Fire prevention measures will be maintained at the Centre to effectively protect the

safety of the employees and buildings/equipment, as well as to comply with

applicable fire codes and regulations by the client.

All equipment are to be tested and inspected regularly & periodically by the safety

officers to measure the effectiveness of the Firefighting equipment’s .

12.0FREQUENCY OF DRILLS

All type of emergency drill to be conducted once in a year.

Prepared by: Approved by: Issued On Page 13

Core Team Management Appointee 12th January 2017 13 of 13

S-ar putea să vă placă și

- Legal Register For Constriction SiteDocument33 paginiLegal Register For Constriction Sitesanjeev kumarÎncă nu există evaluări

- IJCRT2104315Document14 paginiIJCRT2104315sanjeev kumarÎncă nu există evaluări

- 10th Gate MeetingDocument13 pagini10th Gate Meetingsanjeev kumarÎncă nu există evaluări

- Cherry Picker Inspection Checklist for Emami Cement Grinding UnitDocument1 paginăCherry Picker Inspection Checklist for Emami Cement Grinding Unitsanjeev kumarÎncă nu există evaluări

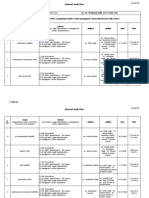

- FT20 Internal Audit PlanDocument5 paginiFT20 Internal Audit Plansanjeev kumarÎncă nu există evaluări

- 08 - First Aid Box Inspection ChecklistDocument1 pagină08 - First Aid Box Inspection Checklistsanjeev kumarÎncă nu există evaluări

- ISO 45001:2018 Awareness OverviewDocument73 paginiISO 45001:2018 Awareness Overviewsanjeev kumar100% (15)

- Revised Quotation For Ame - Bhabua CementDocument1 paginăRevised Quotation For Ame - Bhabua Cementsanjeev kumarÎncă nu există evaluări

- FormDocument1 paginăFormsanjeev kumarÎncă nu există evaluări

- 10 - Cherry Picker Inspection ChecklistDocument1 pagină10 - Cherry Picker Inspection Checklistsanjeev kumar100% (1)

- Emergency Response PlanDocument25 paginiEmergency Response Plansanjeev kumarÎncă nu există evaluări

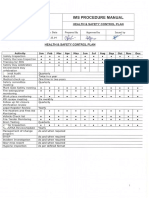

- o Ehs 08 Health & Safety Control PlanDocument1 paginăo Ehs 08 Health & Safety Control Plansanjeev kumarÎncă nu există evaluări

- Cherry Picker Inspection Checklist for Emami Cement Grinding UnitDocument1 paginăCherry Picker Inspection Checklist for Emami Cement Grinding Unitsanjeev kumarÎncă nu există evaluări

- Emergency Response PlanDocument25 paginiEmergency Response Plansanjeev kumarÎncă nu există evaluări

- 01 - Gas Cutting Set Inspection ChecklistDocument1 pagină01 - Gas Cutting Set Inspection Checklistsanjeev kumar100% (1)

- Total Productive Maintenance (TPM) : DescriptionDocument3 paginiTotal Productive Maintenance (TPM) : Descriptionsanjeev kumar100% (1)

- 9 Colour Code of Lubricants Alt 1Document3 pagini9 Colour Code of Lubricants Alt 1sanjeev kumarÎncă nu există evaluări

- Monthly Safety Activity Report: YEAR: - REPORTING LOCATIONDocument1 paginăMonthly Safety Activity Report: YEAR: - REPORTING LOCATIONHse Dinh Công VietÎncă nu există evaluări

- Mass Comminucution Metting On 21Document1 paginăMass Comminucution Metting On 21sanjeev kumarÎncă nu există evaluări

- Integrated Management SystemsDocument21 paginiIntegrated Management SystemsisaacbombayÎncă nu există evaluări

- Plant Illumination ChecklistDocument1 paginăPlant Illumination Checklistsanjeev kumarÎncă nu există evaluări

- House Keeping Check List: Sl. No. DescriptionDocument24 paginiHouse Keeping Check List: Sl. No. Descriptionsanjeev kumarÎncă nu există evaluări

- Ohsas 18001 2007Document32 paginiOhsas 18001 2007sanjeev kumarÎncă nu există evaluări

- Rating: Company Rating A 2 B 1 C 2 D 3 E 4 F 2 G H I J KDocument2 paginiRating: Company Rating A 2 B 1 C 2 D 3 E 4 F 2 G H I J Ksanjeev kumarÎncă nu există evaluări

- Risk Analysis ReportDocument1 paginăRisk Analysis Reportsanjeev kumarÎncă nu există evaluări

- Steps Involved in Starting Up of A HR DeptDocument19 paginiSteps Involved in Starting Up of A HR Deptsanjeev kumarÎncă nu există evaluări

- Airr CPPDocument121 paginiAirr CPPsanjeev kumarÎncă nu există evaluări

- Steps Involved in Starting Up of A HR DeptDocument19 paginiSteps Involved in Starting Up of A HR Deptsanjeev kumarÎncă nu există evaluări

- Sr. No. Name of The Employee DesignationDocument1 paginăSr. No. Name of The Employee Designationsanjeev kumarÎncă nu există evaluări

- Safety AuditSDocument5 paginiSafety AuditSsanjeev kumarÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5782)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Accomplishment ReportDocument31 paginiAccomplishment ReportDaniela VirgiliaÎncă nu există evaluări

- Resilience in Heritage Conservation and Heritage Tourism A Dissertation by ... (Pdfdrive)Document217 paginiResilience in Heritage Conservation and Heritage Tourism A Dissertation by ... (Pdfdrive)ristya arintaÎncă nu există evaluări

- Army's Role in Disaster ManagementDocument41 paginiArmy's Role in Disaster ManagementJaypee MasculinoÎncă nu există evaluări

- Evaluate School FacilitiesDocument20 paginiEvaluate School FacilitiesAaron Paul CasabarÎncă nu există evaluări

- Hyogo Framework Mid-Term ReviewDocument103 paginiHyogo Framework Mid-Term Reviewpk_agronomÎncă nu există evaluări

- Uf Health Job EvaluationDocument17 paginiUf Health Job Evaluationapi-534681987Încă nu există evaluări

- RADIUS Report PDFDocument46 paginiRADIUS Report PDFJesus RomanÎncă nu există evaluări

- SYBA/SYBCOM/SYBSC Foundation Course Semester III MCQ Chapter No. I............. Human Rights Violations and RedressalDocument23 paginiSYBA/SYBCOM/SYBSC Foundation Course Semester III MCQ Chapter No. I............. Human Rights Violations and RedressalUnknown Aman100% (1)

- Unit-1 Disaster Meaning, Factors and SignificanceDocument11 paginiUnit-1 Disaster Meaning, Factors and Significancevg_mrt0% (1)

- NEMA HandbookDocument140 paginiNEMA HandbookElijah Miller100% (1)

- Barangay Disaster Risk Reduction Management PlanDocument25 paginiBarangay Disaster Risk Reduction Management PlanGain Gain100% (1)

- SHS CORE SUBJECTS - Most-Essential-Learning-Competencies-Matrix PDFDocument47 paginiSHS CORE SUBJECTS - Most-Essential-Learning-Competencies-Matrix PDFJoanne Ragudos-AbetoÎncă nu există evaluări

- Sample SWOCDocument3 paginiSample SWOCBarangay La Libertad100% (1)

- Vinex Ias Academy®: About Us VINEX Is Promoted by Best Most Trusted IAS FacultyDocument19 paginiVinex Ias Academy®: About Us VINEX Is Promoted by Best Most Trusted IAS FacultyDhoorjati VommiÎncă nu există evaluări

- 008 Si Berong Bumbero, Unawain Mo Kabayan PDFDocument27 pagini008 Si Berong Bumbero, Unawain Mo Kabayan PDFMyk Twentytwenty NBeyondÎncă nu există evaluări

- Cause and Effect EssayDocument4 paginiCause and Effect EssayJordana Marbely López GuerraÎncă nu există evaluări

- Area IV - Support To Students: Program and ServicesDocument7 paginiArea IV - Support To Students: Program and ServicesJD MacalindongÎncă nu există evaluări

- Synthesis of The Study GuideDocument3 paginiSynthesis of The Study GuideMark Jerome GuzmanÎncă nu există evaluări

- Earthquake DrillDocument2 paginiEarthquake Drillapi-114144039Încă nu există evaluări

- CIGREDocument126 paginiCIGREFeodor RadilovÎncă nu există evaluări

- Who Hse GCR Lyo 2014.4 EngDocument64 paginiWho Hse GCR Lyo 2014.4 EngNita AlvzÎncă nu există evaluări

- Earthquake Drill For Schools NewDocument67 paginiEarthquake Drill For Schools NewAlvin BenaventeÎncă nu există evaluări

- CCD3A8 Risk Management Plan TemplateDocument17 paginiCCD3A8 Risk Management Plan TemplateDasaka BrahmendraÎncă nu există evaluări

- Module 1 Disaster and Disaster RiskDocument36 paginiModule 1 Disaster and Disaster RiskSarah Joy CruzÎncă nu există evaluări

- SOP Kids Club COVID 19 Measure For GO 2Document2 paginiSOP Kids Club COVID 19 Measure For GO 2adjcdaughtÎncă nu există evaluări

- Lesson 14 - Emergency PreparednessDocument26 paginiLesson 14 - Emergency PreparednessAmeenudeenÎncă nu există evaluări

- Search and RescueDocument42 paginiSearch and Rescuelaurence limoicoÎncă nu există evaluări

- DR Sanayanbi HodamDocument15 paginiDR Sanayanbi HodamAnkit KumarÎncă nu există evaluări

- Disaster RecoveryDocument19 paginiDisaster RecoveryRajeev DuttaÎncă nu există evaluări

- 2021-EO Reorganization CIC EOCDocument5 pagini2021-EO Reorganization CIC EOCDennis CosmodÎncă nu există evaluări