Documente Academic

Documente Profesional

Documente Cultură

Stationary Kompensator: Maintenance Procedures

Încărcat de

Jaime CamoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Stationary Kompensator: Maintenance Procedures

Încărcat de

Jaime CamoDrepturi de autor:

Formate disponibile

STATIONARY MAINTENANCE ®

KOMPENSATOR INSTRUCTIONS

Stationary Kompensator® for

FW8-77XX Series

FW35-77XX Series

FW7040-77XX Series

FW2040-77XX Series (obsolete)

FW3540-77XX Series (obsolete)

MAINTENANCE PROCEDURES

Failure to read, understand and follow the important information contained herein may

result in a hazardous condition or cause a hazardous condition to develop.

All maintenance must be performed by a qualified person using proper tools and safe

procedures.

All maintenance must be performed while the tractor is uncoupled from the trailer.

NOTE:

The maintenance procedures contained in this manual apply mainly to the Kompensator® base subassembly portion of

the fifth wheel assembly. Additional procedures beyond those discussed in this manual are required for the fifth wheel

top plate. Contact your nearest Holland distributor for the appropriate additional information.

XL-FW208-06 1

More user manuals on ManualsBase.com

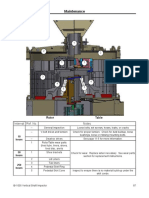

AS-NEEDED LUBRICATION FIGURE 2

The following should be performed before putting into Check for warn,

use and then at least once per week or more bent, or broken

parts. Replace with

frequently as required by operating conditions. Holland parts only.

Perform the following steps while in the uncoupled

condition to allow correct application of lubricant.

While lifting up on the fifth wheel top plate, apply

grease to the: Check for

cracked,

1. ...fittings on the fifth wheel top plate (see Check bolt torque. broken, or

FIGURE 1, ❶) that supply grease to lubricate Replace missing distorted

or damaged bolts. components.

the bracket shoe cap and top plate pocket.

(NOTE: LowLube or NoLube top plates do not

have these fittings.)

2. ...fittings ➋ on the side of the shoes (Item 3) Do not use any fifth

that fill a reservoir that requires approximately wheel which does not

2 pounds of grease. operate properly

3. ...fittings ➌ on the base (ends) of the cradle

(Item 14). B. Check the adjustment of the fifth wheel

4. ...fittings ➍ on the front and back of the cradle locks by moving the lock tester fore and

(Item 15). aft when locked in the locking mechanism.

Fore and aft play should be adjusted to less

FIGURE 1 than 0.06˝ (1/16˝). Adjust the fifth wheel

➊ Grease top plate contact

surfaces. The grease fitting is locks as described in Holland Publications

on the side or under the front

of the top plate. “Fifth Wheel Maintenance Procedures”

XL-FW303-XX, XL-FW308-XX, and

XL-FW354-XX for the particular type of

locking mechanism. If the locks cannot be

Grease

resevoir ➋ Fill reservoirs properly adjusted due to wear, the fifth

with grease,

then apply wheel should be repaired or replaced. Your

grease to shoes

using zerks. HOLLAND Distributor has parts, part kits

➍ and fifth wheel top plates available.

Grease front

cradle zerks.

➌

Grease cradle zerks.

Improper adjustment can

All of the following must be performed after the cause improper locking of

initial 5,000 miles of service and then every 60,000 the mechanism.

miles or 6 months, whichever comes first.

Perform all inspections and adjustments C. The trailer kingpin should also be

after a thorough steam cleaning. inspected for wear and damage.

NOTE: Severe service applications may require A HOLLAND Kingpin Gauge (TF-0110)

more frequent intervals. is available to aid this inspection.

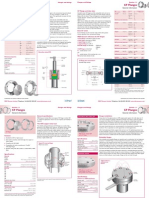

1. Inspection – General 3. Kompensator Base Sub-Assembly:

A. Inspect the fifth wheel mounting. Check Measure Fore-Aft Movement.

bolt torque and replace any loose, A. Measure the fore and aft movement of the

missing, or damaged bolts. Check for shoe sub-assembly in the Kompensator

broken, distorted, or cracked components. bracket. (See Figure 3.)

Repair or replace as needed.

Check fore/aft Bearing plate

B. Inspect fifth wheel top plate and movement of shoe. ITEM 12, ITEM 13

Kompensator assembly for bent, worn, Shim if greater

than .060".

cracked, or broken parts. Replace with Shim ITEM 11

HOLLAND parts only. (See Figure 2.)

2. Fifth Wheel Locking Mechanism: Measure

Fore-Aft Movement.

A. Test the operation of the fifth wheel locking

mechanism using a Holland TF-TLN-5001,

2˝ Kingpin or TF-TLN-1500, 31/2˝ Kingpin FIGURE 3 FIGURE 4

Lock Tester. Inspect for proper locking.

2 XL-FW208-06

More user manuals on ManualsBase.com

Add shims (ITEM 11) and/or new bearing If disassembly is required, follow the

plates (ITEM 12 or ITEM 13) when this steps below:

movement exceeds 0.060˝ (1/16˝). See Figures

1. Remove the fifth wheel top plate from

3 through 6.

the Kompensator base removing the

appropriate roll pins and bracket

FIGURE 5 FIGURE 6 pins or cotter pins, nuts and bolts,

BEARING

PLATE depending upon model.

SHIM

2. Remove all loose internal parts (shoes,

tie rod, etc.).

3. Inspect all parts for distortion, wear

and cracking. Replace if necessary.

4. Measure the thickness of the curved

base of the shoe sub-assembly

(ITEM 2). The shoe should be replaced if

the base thickness measures less than

0.31˝ (5/16˝). See Figure 8.

B. If shimming is required, shim as follows:

5. Reassemble and lubricate as noted

1. Remove shoes and disassemble above. Check for free lateral and

Kompensator. See Figure 3. fore-aft movement of the shoe

2. Remove bearing plates (ITEM 12 and sub-assemblies after reassembly.

ITEM 13). Measure thickness if less than

FIGURE 8

.31˝ ( 5/16˝) thick. Replace with new

Holland part. SHOE BASE

3. Install shims.

4. Check for free lateral movement of shoe

Measure shoe base

in frame. DO NOT over shim. thickness. Replace if

it is less than .31˝

Recheck fore and aft movement of the

(5/16˝).

shoe subassembly. Movement is to be less

than .06˝ (1/16˝).

C. Inspect the cushions (ITEM 5) and other

components for distortion and splitting or NOTE:

cracking. If disassembly is required, follow For severe dusty/dirty environments, shoe

steps 1–5 under section 4 below, and replace dust covers (see Figure 9) are available.

as required. request Holland parts XA-0128-L

and XA-0128-R.

4. Kompensator Base Subassembly: Measure

Upward Movement:

A. Measure upward clearance on the assembly. FIGURE 9

DUST COVERS

Do this on one side at a time by lifting the fifth

wheel top plate upward manually with the aid

of a bar (see Figure 7). Clamp the shoe (ITEM 2)

on the opposite side to prevent its movement,

which will affect the measurement (see Figure

7). If the total movement exceeds 0.5˝ (1/2˝),

the unit should be disassembled for further

inspection.

FIGURE 7

Pry or lift one side at a time.

Disassemble if it exceeds 0.5".

XL-FW208-06 3

More user manuals on ManualsBase.com

Parts Breakdown

20

9

21 9 10

10 9 11

11 10

13

3 12 3

4* or 4A**

5

5 6

6

7 8 7

2

4* or 4A**

2

14

15 15

RK-01370 KIT – OPTIONAL

LOCKOUT PARTS 18 14

(BOTH SIDES)

15 15

19

17 1

16

ITEM PART NO. NO. PART NAME ITEM PART NO. NO. PART NAME

1 XA-45-77XX 1 Kompensator® Frame 11 XA-0014 2 Shim (as required)

2 XA-0024 2 Shoes Subassembly – includes part no. (3) 12 XA-01997 1 Bearing Plate – Right Hand

3 XB-H-38-F 2 Grease Fitting 13 XA-01998 1 Bearing Plate – Left Hand

4* XB-0011 2 Rubber Cushion 14 XB-H-38-A 4 90° Grease Fitting

4A** XB-0012 2 Rubber Cushion 15 XB-H-38 4 Grease Fitting

5 XB-0009 2 Cushion 16 XA-01429 2 “L” Pin Subassembly

6 XA-1284-2 2 Washer 17 XA-01427 2 Lockout Stop

7 XB-01923 2 Spring 18 XB-382 2 Cotter Pin .19˝ x 1.25˝

8 XA-39 1 Tie Bar 19 XB-847 2 Shackle Pin

9 XB-C-59 4 Hex Nut 1/2˝-13 20 XA-0128-L 1 Dust Cover (optional)

10 XB-T-45-1 4 Lock Washer 1/2˝ 21 XA-0128-R 1 Dust Cover (optional)

* Bushings used in conjunction with FW8, FW35, FW2040, FW3540 or FW3640 series fifth wheels.

** Bushings used in conjunction with FW7040 series fifth wheels.

HOLLAND USA, INC.

1950 Industrial Blvd. • P.O. Box 425 • Muskegon, MI 49443-0425

Phone 888-396-6501 • Fax 800-356-3929

www.thehollandgroupinc.com

Copyright © February 2004 • The Holland Group, Inc.

Holland USA, Inc. Facilities: Holland International, Inc. Holland Hitch of Canada, Ltd. Holland Equipment, Ltd. Holland Hitch of Canada, Ltd.

Dumas, AR Warrenton, MO Holland, MI Woodstock, Ontario • Canada Norwich, Ontario • Canada Surrey, British Columbia • Canada

Holland, MI Wylie, TX Phone: 616-396-6501 Phone: 519-537-3494 Phone: 519-863-3414 Phone: 604-574-7491

Muskegon, MI Fax: 616-396-1511 Fax: 800-565-7753 Fax: 519-863-2398 Fax: 604-574-0244

Ph: 888-396-6501 Fax: 800-356-3929

4 XL-FW208-06

S-ar putea să vă placă și

- Diagrama International VT365Document2 paginiDiagrama International VT365Edwin Motta Piamba89% (55)

- Diagrama Electronico DT466Document2 paginiDiagrama Electronico DT466Aldo Fran Vargas82% (22)

- DDEC II and III Wiring DiagramsDocument13 paginiDDEC II and III Wiring Diagramstwhiteman200682% (49)

- CAT Service ManualDocument41 paginiCAT Service Manualhelder.santos111460% (10)

- Honda XR50R Service Manual 2000 2003Document197 paginiHonda XR50R Service Manual 2000 2003aurongayÎncă nu există evaluări

- Service Manual: GP15K, GP18K, GP20K, GP25K, GP30K, GP35K DP15K, DP18K, DP20K, DP25K, DP30K, DP35K Chassis & MastDocument7 paginiService Manual: GP15K, GP18K, GP20K, GP25K, GP30K, GP35K DP15K, DP18K, DP20K, DP25K, DP30K, DP35K Chassis & MastDmitry75% (4)

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Drag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Document2 paginiDrag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Arthur Saw Sher-QenÎncă nu există evaluări

- Manual Chipeadora 18XP (059-119)Document61 paginiManual Chipeadora 18XP (059-119)Mantenimiento BiocicloÎncă nu există evaluări

- Enzymes and Effects of PHDocument4 paginiEnzymes and Effects of PHSeph Cordova50% (2)

- 1 Introduction To Thermal System DesignDocument43 pagini1 Introduction To Thermal System DesignAbhishek KullurÎncă nu există evaluări

- Centrifugation (Separation Processes)Document25 paginiCentrifugation (Separation Processes)Allyana Marie Tiemsim100% (2)

- Mtto Kompensator DeslizableDocument8 paginiMtto Kompensator DeslizableJames Scott ValderramaÎncă nu există evaluări

- 3541RL 3541RL: Service Manual Service ManualDocument18 pagini3541RL 3541RL: Service Manual Service Manualyousef ALadwanÎncă nu există evaluări

- Abs Landing Gear Guide2Document60 paginiAbs Landing Gear Guide2Fayçal MahieddineÎncă nu există evaluări

- Gives You The Techlock System AdvantageDocument8 paginiGives You The Techlock System AdvantageMTK2016Încă nu există evaluări

- FH FW Skhd3836g En-De Ower ManualDocument19 paginiFH FW Skhd3836g En-De Ower ManualEnrico TondiniÎncă nu există evaluări

- Torque-Hub Planetary Final Drive S12A4 & 6 Series Service ManualDocument58 paginiTorque-Hub Planetary Final Drive S12A4 & 6 Series Service Manualrafasel otubo guatia100% (1)

- HI-KALIBRE ActuatorDocument22 paginiHI-KALIBRE ActuatorProyectil De ProyectoÎncă nu există evaluări

- Rotary Tiller: Operation, Service & Parts Manual For "AS" SeriesDocument16 paginiRotary Tiller: Operation, Service & Parts Manual For "AS" SeriesSuryaSuryaÎncă nu există evaluări

- FSO 300 Thru 700 FSO 750 Thru 1027 FS 750 Thru 1027: Installation InstructionsDocument6 paginiFSO 300 Thru 700 FSO 750 Thru 1027 FS 750 Thru 1027: Installation InstructionsEzequiel CeccarelliÎncă nu există evaluări

- Century 125Document63 paginiCentury 125gravi26Încă nu există evaluări

- Maintenance: Rotor Interval Ref. No. NotesDocument11 paginiMaintenance: Rotor Interval Ref. No. NotesEduardo AcostaÎncă nu există evaluări

- Showa 47u Front ForkDocument27 paginiShowa 47u Front ForkToine Van Den Brandt100% (1)

- RTS TG M78Document9 paginiRTS TG M78woosah1234Încă nu există evaluări

- Installation Instructions BA ... RDocument10 paginiInstallation Instructions BA ... RdenisÎncă nu există evaluări

- BOV FV Instruction ManualDocument5 paginiBOV FV Instruction ManualRayseanKangÎncă nu există evaluări

- Warning Warning Caution: Ing-02.fm Page 51 Wednesday, December 15, 1999 4:17 PMDocument50 paginiWarning Warning Caution: Ing-02.fm Page 51 Wednesday, December 15, 1999 4:17 PMCARLOS GONZALEZÎncă nu există evaluări

- Sealey Jack FJ45Document2 paginiSealey Jack FJ45Alain DefoeÎncă nu există evaluări

- FX-375 ServiceDocument21 paginiFX-375 ServiceMauro PerezÎncă nu există evaluări

- 05 1964 CH-Rear AxleDocument3 pagini05 1964 CH-Rear AxleJose LaproviteraÎncă nu există evaluări

- Manual Estibadora CBGDocument13 paginiManual Estibadora CBGJhon F VargasÎncă nu există evaluări

- Qa-Lhb-Draft Gear & CouplingDocument4 paginiQa-Lhb-Draft Gear & CouplingSriram SubramanianÎncă nu există evaluări

- Kf22Qt Sec4 FRDDocument21 paginiKf22Qt Sec4 FRDMauro PerezÎncă nu există evaluări

- Camshaft Installation Instructions: Intermediate Shaft Notes: ALL ALLDocument12 paginiCamshaft Installation Instructions: Intermediate Shaft Notes: ALL ALLGabriel ChiavettoÎncă nu există evaluări

- 8 - Iknow Machinery Co., Ltd. (IK)Document7 pagini8 - Iknow Machinery Co., Ltd. (IK)khan asifÎncă nu există evaluări

- Manual 600 NEWDocument5 paginiManual 600 NEWabhayuietÎncă nu există evaluări

- Service Bulletin: Landoll Corp. Warranty DepartmentDocument4 paginiService Bulletin: Landoll Corp. Warranty DepartmentChristian BedoyaÎncă nu există evaluări

- Victa Lawnmower Assembly and Owner's Manual: Assembly - Operating K6 Final - QXD 8/12/04 1:33 PM Page 1Document28 paginiVicta Lawnmower Assembly and Owner's Manual: Assembly - Operating K6 Final - QXD 8/12/04 1:33 PM Page 1johnÎncă nu există evaluări

- Red Max G2500TS PDFDocument36 paginiRed Max G2500TS PDFKevinÎncă nu există evaluări

- Troubleshooting LawnmoversDocument6 paginiTroubleshooting LawnmoversnamkvalÎncă nu există evaluări

- Agitadores PlentyDocument16 paginiAgitadores Plentyrolando tapiaÎncă nu există evaluări

- Inside Vehiclegeneral MaintenanceDocument4 paginiInside Vehiclegeneral MaintenanceEdson CRÎncă nu există evaluări

- FGRT 210 Ducati 848-1098-1198Document4 paginiFGRT 210 Ducati 848-1098-1198djotenÎncă nu există evaluări

- Drive Shaft Installation InstructionDocument7 paginiDrive Shaft Installation InstructionYonas MuluÎncă nu există evaluări

- Operation & Preventive Maintenance Manual Winch Model 527Document14 paginiOperation & Preventive Maintenance Manual Winch Model 527Gissel CQÎncă nu există evaluări

- Brake SystemDocument8 paginiBrake SystemDomingo BravoÎncă nu există evaluări

- Rboat Davit MAINTENANCE MANUAL PDFDocument14 paginiRboat Davit MAINTENANCE MANUAL PDFAnoop AnupÎncă nu există evaluări

- Driveline System - General Information: Principle of OperationDocument15 paginiDriveline System - General Information: Principle of OperationSergeyÎncă nu există evaluări

- ScanDocument25 paginiScanmichaelshelterÎncă nu există evaluări

- SM95C AgDocument7 paginiSM95C AghernanÎncă nu există evaluări

- W3C Service Manual 3-7-13Document54 paginiW3C Service Manual 3-7-13angel017100% (1)

- Fork Rebuilding PDFDocument2 paginiFork Rebuilding PDFmxckcxzlm.c,Încă nu există evaluări

- LRE Propshaft MaintenanceDocument2 paginiLRE Propshaft Maintenancestef2122177Încă nu există evaluări

- Spring Manual: V3.3 EnglishDocument32 paginiSpring Manual: V3.3 EnglishSinca LucianÎncă nu există evaluări

- MIL ON WITH DTC P0741, P0744, P0746, P0776, P0841, P0965, P2857, P2858, P2859, AND/OR P285A STORED, and May Have Hesitation And/Or Lack of PowerDocument22 paginiMIL ON WITH DTC P0741, P0744, P0746, P0776, P0841, P0965, P2857, P2858, P2859, AND/OR P285A STORED, and May Have Hesitation And/Or Lack of Powerdamian berduscoÎncă nu există evaluări

- SPL U Joint Service Guide PDFDocument2 paginiSPL U Joint Service Guide PDFLeonardo PeñalozaÎncă nu există evaluări

- Service Manual: Fuller Mid Range Transmissions October 2007Document34 paginiService Manual: Fuller Mid Range Transmissions October 2007Ralfmax GearboxÎncă nu există evaluări

- 126e PTP Shale Shaker Operations ManualDocument13 pagini126e PTP Shale Shaker Operations ManualAndrew GoadÎncă nu există evaluări

- Torque-Hub Planetary Final Drive 7HA00/7HB00 Series Service ManualDocument46 paginiTorque-Hub Planetary Final Drive 7HA00/7HB00 Series Service ManualMonty100% (1)

- DODGE Type C Pillow Blocks, Flange Bearings, Hanger Bearings and UnitsDocument4 paginiDODGE Type C Pillow Blocks, Flange Bearings, Hanger Bearings and UnitsMuhammadAmmarÎncă nu există evaluări

- InstructionsDisc Brake InstallDocument2 paginiInstructionsDisc Brake InstallPeter JasonÎncă nu există evaluări

- Goulds Pumps Spare Parts PDFDocument32 paginiGoulds Pumps Spare Parts PDFjhonny barrantesÎncă nu există evaluări

- Section 4 - Cam Followers/Tappets - Group 04Document9 paginiSection 4 - Cam Followers/Tappets - Group 04Miodrag HuberÎncă nu există evaluări

- Outside Vehicle: General MaintenanceDocument8 paginiOutside Vehicle: General MaintenanceDean BÎncă nu există evaluări

- Hydraulic Stacker - Model No. Mn397: Operating Instructions and Parts ListDocument9 paginiHydraulic Stacker - Model No. Mn397: Operating Instructions and Parts ListAJ MusicÎncă nu există evaluări

- MX6Document31 paginiMX6John GillisÎncă nu există evaluări

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDe la EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementÎncă nu există evaluări

- Fallas de EncendidoDocument2 paginiFallas de EncendidoJaime CamoÎncă nu există evaluări

- Torque Pernos PDFDocument5 paginiTorque Pernos PDFRimbertÎncă nu există evaluări

- Manual Puesta A Punto - FEDERAL MOGULDocument107 paginiManual Puesta A Punto - FEDERAL MOGULjsdrums100% (2)

- Ford Wiring HarnessDocument2 paginiFord Wiring Harnessapi-19801659Încă nu există evaluări

- Sony CFD-G700CP-G770CP-G-770CPKDocument70 paginiSony CFD-G700CP-G770CP-G-770CPKvideoson100% (1)

- Vernier Throttle For CAT - NewDocument8 paginiVernier Throttle For CAT - NewDuy KhaÎncă nu există evaluări

- FM 15D310B LST USServiceManualDocument136 paginiFM 15D310B LST USServiceManualJaime CamoÎncă nu există evaluări

- Android Magazine PDFDocument92 paginiAndroid Magazine PDFJaime CamoÎncă nu există evaluări

- Spaicer PSDO 165-18ADocument36 paginiSpaicer PSDO 165-18AJaime CamoÎncă nu există evaluări

- Dell Mini 10 - Compal La-5091p Kiu20 - Rev 1.0secDocument39 paginiDell Mini 10 - Compal La-5091p Kiu20 - Rev 1.0secChris ParryÎncă nu există evaluări

- GE Sentry For Windows Manual Ver3-0Document20 paginiGE Sentry For Windows Manual Ver3-0Jaime CamoÎncă nu există evaluări

- LG GU230 Dimsun Service ManualDocument164 paginiLG GU230 Dimsun Service ManualjaimecamoÎncă nu există evaluări

- Nokia Lumia 822 UG enDocument93 paginiNokia Lumia 822 UG enJaime CamoÎncă nu există evaluări

- LogisticsDocument72 paginiLogisticsqzm74lÎncă nu există evaluări

- 9365Document69 pagini9365Kivanc NEROGLUÎncă nu există evaluări

- Under Slung Steel Truss Bridge With Composite RCC Deck BridgeDocument5 paginiUnder Slung Steel Truss Bridge With Composite RCC Deck BridgeShaileshRastogiÎncă nu există evaluări

- Appendix. 505 Program Mode Worksheets: 505 Digital Governor Manual 85017V1Document3 paginiAppendix. 505 Program Mode Worksheets: 505 Digital Governor Manual 85017V1gonzalesÎncă nu există evaluări

- Need and Future of Electronics and Automation inDocument21 paginiNeed and Future of Electronics and Automation inAjay Kumar VermaÎncă nu există evaluări

- Ratings Remote-Mounted DFR: Powershift Transmissions Funk Drivetrain SpecificationsDocument2 paginiRatings Remote-Mounted DFR: Powershift Transmissions Funk Drivetrain SpecificationsJIM CAMPBELL100% (1)

- T30 T10 Intelligent Flight Battery User Guide v1.2 10langsDocument85 paginiT30 T10 Intelligent Flight Battery User Guide v1.2 10langstamerÎncă nu există evaluări

- Pacom S72724+PDR32-RMT-HYB+ManualDocument130 paginiPacom S72724+PDR32-RMT-HYB+ManualDavidChisholmÎncă nu există evaluări

- E-TON Vector ST 250 Vxl-250 St-Part ManualDocument53 paginiE-TON Vector ST 250 Vxl-250 St-Part ManualmariusgrosyÎncă nu există evaluări

- Scania Jenerator DC1372A - 438-487kW PDFDocument2 paginiScania Jenerator DC1372A - 438-487kW PDFMehmet ErenÎncă nu există evaluări

- Sec1 1 1Document2 paginiSec1 1 1rajfmc100% (1)

- Am 3517Document221 paginiAm 3517mudit9_mÎncă nu există evaluări

- Differential Current-Based Fault Protection With Adaptive Threshold For Multip (Le PV Based DC MicrogridDocument13 paginiDifferential Current-Based Fault Protection With Adaptive Threshold For Multip (Le PV Based DC MicrogridANURAAGÎncă nu există evaluări

- 5e17f Toshiba Satellite l40 Compal La9862p Compal La9862p r10 Laptop SchematicsDocument46 pagini5e17f Toshiba Satellite l40 Compal La9862p Compal La9862p r10 Laptop Schematicsamier jrs100% (1)

- (52621001078) DM - DM Half Inch Flex Jumper Spec SheetDocument2 pagini(52621001078) DM - DM Half Inch Flex Jumper Spec SheetmicroqualÎncă nu există evaluări

- LGP4247L-12LPB-3P Eay62608902 PLDF-L103B Psu SM PDFDocument74 paginiLGP4247L-12LPB-3P Eay62608902 PLDF-L103B Psu SM PDF00dark100% (1)

- Important RCC Questions-Short and LongDocument15 paginiImportant RCC Questions-Short and LongmailjoelsamuelÎncă nu există evaluări

- Armare La Strapungere Pentru Palnsee Dale Jda B en D Teh 56465Document24 paginiArmare La Strapungere Pentru Palnsee Dale Jda B en D Teh 56465mihaitimofteÎncă nu există evaluări

- The Punjab Factory RuleDocument313 paginiThe Punjab Factory Rulesafety_rliÎncă nu există evaluări

- HSE FRM 32 Final Incident ReportDocument6 paginiHSE FRM 32 Final Incident ReportDilshad aliÎncă nu există evaluări

- Company Names and Number UAEDocument35 paginiCompany Names and Number UAESoju Suresh100% (1)

- GU Pipette Quick Check ENDocument20 paginiGU Pipette Quick Check ENCeren Alim DavutluoğluÎncă nu există evaluări

- Instrument and Control Designer Rev01Document5 paginiInstrument and Control Designer Rev01masilamaniÎncă nu există evaluări

- Computational Organometallic Chemistry (Cundari, Thomas R.) (1st Edition, 2001) (0824704789) (428p)Document441 paginiComputational Organometallic Chemistry (Cundari, Thomas R.) (1st Edition, 2001) (0824704789) (428p)EisernesHerzÎncă nu există evaluări

- Free and Forced Vibration of Repetitive Structures: Dajun Wang, Chunyan Zhou, Jie RongDocument18 paginiFree and Forced Vibration of Repetitive Structures: Dajun Wang, Chunyan Zhou, Jie RongRajesh KachrooÎncă nu există evaluări

- Calculating The Maximum Attenuation For Optical Fiber LinksDocument5 paginiCalculating The Maximum Attenuation For Optical Fiber LinksMiguel LiceagaÎncă nu există evaluări