Documente Academic

Documente Profesional

Documente Cultură

QITP 002 Part 1

Încărcat de

ivanbfDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

QITP 002 Part 1

Încărcat de

ivanbfDrepturi de autor:

Formate disponibile

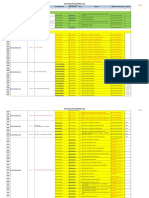

ACTION

RESPONSIBLE DOCUMENT DELIVERABLE COLUMNS

ITEM ACTIVITY SPECIFICATION PROCEDURE

PERSON GENERATED YES/NO

TC BP

1.0 CONTRACT REVIEW Review Board ISO 9001:

1.1. Review all contract documents and drawings to ensure that: PM and TC ISO 9001: TC-QUA-005 MINUTES OF NO D

board MEETING

- Contract requirements are adequately

defined and documented.

CONTRACT REVIEW

- That TC have the capability to fulfil DOCUMENTATION

contractual requirements. INCLUDING

- There are no changes in contract MINUTES OF

requirements from the tender. INAUGURAL

- The environmental impact of the project MEETING AND

is analysed to identify risks and environmentally sensitive COPIES OF TENDER

areas. CLARIFICATIONS

BETWEEN TC AND

- Conflicting requirements and

BP.

discrepancies are identified and documented.

- Commercial viability

- Scope of work

- Design criteria

- Contract documents and drawings

- Resources and Personnel requirements

- Technical Specification/Contents

- Quality Assurance Requirements

- Lead Time

- Suitability

- Specification & Standards

- Local Authority Rules & Regulations

1.2 Visit the proposed location of the works to assess the CM N/A N\A REPORT NO R

requirements for geotechnical surveys.

1.3 Hold meetings with BP, raise potential Contract Modifications, CM/QAM ISO 9001 As agreed MINUTES OF YES V

resolve discrepancies and clarify requirements. between BP and MEETING

TC

QUALITY INSPECTION AND TEST PLAN TC-QUA-002 PAGE NUMBER: 1 OF 12

SECTION 12.0 PART 1 REVISION 0 DATE: 23.09.18

ACTION

RESPONSIBLE DOCUMENT DELIVERABLE COLUMNS

ITEM ACTIVITY SPECIFICATION PROCEDURE

PERSON GENERATED YES/NO

TC BP

1.4 Identify and procure Contract Standards and Specifications QAM/PCM N/A N/A NONE N/A V

where specified by BP.

2.0 PROJECT ORGANISATION

2.1 Select Project Team members for organisational and planning PM CONTRACT N/A ORGANISATION YES D

activities. CHART

2.2 Identify all job functions which have an influence on the QAM ISO 9001 TC-MAN-001 JOB DESCRIPTIONS NO V

achievement of the project quality objectives.

2.3 Review qualifications of personnel to establish training and QAM ISO 9001 N/A PERSONNEL FILE NO D

recruitment requirements.

2.4 Identify organisational and technical interfaces between BP, QAM/PM ISO 9001 TC-MAN-001 ORGANISATION YES V

sub-suppliers and internal departments. CHART

2.5 Prepare and distribute organisation charts depicting QAM ISO 9001 TC-MAN-001 ORGANIGRAMS and NO N/A

management and reporting structure for all project activities. TRANSMITTAL

NOTE

2.6 Approval of organisation chart. PM / TC Board N/A N/A SIGNED NO V

ORGANISATION

CHART

2.7 Review job descriptions, revise as required and issue to PM N/A TC-MAN-001 JOB DESCRIPTIONS NO V

personnel.

3.0 PLANNING

3.1 Program prepared for the execution of the project. PM N/A PROGRAM YES V

3.2 Allocate resources for all activities. PM N/A N/A N/A N/A N/A

QUALITY INSPECTION AND TEST PLAN TC-QUA-002 PAGE NUMBER: 2 OF 12

SECTION 12.0 PART 1 REVISION 0 DATE: 23.09.18

ACTION

RESPONSIBLE DOCUMENT DELIVERABLE COLUMNS

ITEM ACTIVITY SPECIFICATION PROCEDURE

PERSON GENERATED YES/NO

TC BP

3.3 Identify Project Quality System elements. QAM ISO 9001 TC-QUA-005 PROJECT QUALITY YES N/A

PROGRAMME

3.4 Define requirements for and prepare project specific Procedures QAM ISO 9001 CONSTRUCTION YES V

and Work Instructions. PROCEDURES &

SPECIFICATIONS

3.5 Project Quality Programme prepared for construction and post QAM ISO 9001 N/A QUALITY YES V

construction phases. PROGRAMME

3.6 Quality Programme Reviewed, revised as required and PM N/A N/A QUALITY YES D

approved. PROGRAMME

3.7 Quality Programme Submitted to BP for approval. PM N/A N/A DOCUMENT YES H

TRANSMITTAL

NOTE

3.8 Prepare schedules for internal audits to verify compliance with QAM ISO 9001 TC-QUA-004 AUDIT SCHEDULES YES V

Contract requirements.

3.9 Prepare Project Safety Management Plan and Program. CM N/A TC-SAF-001 SAFETY PLAN YES V

3.10 Prepare HSE Procedure and Program. CM ISO 14001 & TC-SAF-001 HSE PROCEDURE YES V

18001

3.11 Transmit HSE Procedure to BP for information. PM N/A N/A TRANSMITTAL YES V

NOTE

3.12 Liase with BP and Local Authorities to obtain information PM N/A N/A CORRESPONDENCE YES V

regarding locations of services and restriction governing the

execution of the works.

4.0 PROCUREMENT

4.1 Prepare Procurement Procedure. PCM N/A TC-PROC-001 PROCEDURE NO D

QUALITY INSPECTION AND TEST PLAN TC-QUA-002 PAGE NUMBER: 3 OF 12

SECTION 12.0 PART 1 REVISION 0 DATE: 23.09.18

ACTION

RESPONSIBLE DOCUMENT DELIVERABLE COLUMNS

ITEM ACTIVITY SPECIFICATION PROCEDURE

PERSON GENERATED YES/NO

TC BP

4.2 Material and certification requirements identified by reference PCM/QAM ISO 9001 TC-PROC-001 NONE N/A D

to Contract Specifications.

4.3 Selection of Sub-suppliers. PCM/QAM ISO 9001 TC-PROC-001 APPROVED NO M

SUPPLIER LIST

4.4 Where specified, obtain BP approval of proposed Sub-suppliers. PCM N/A TC-PROC-001 CORRESPONDENCE NO H

4.5 Identify requirements for Sub supplier inspections. QAM ISO 9001 TC-QUA-011 INSPECTION NO V

SCHEDULE

4.6 Quality Programmes and/or Procedures requested from Sub- QAM ISO 9001 TC-QUA-011 TRANSMITTAL NO V

suppliers. NOTE

4.7 Quality Programmes and Procedures reviewed and QAM N/A N/A CORRESPONDENCE NO V

approved/amended.

4.8 Purchasing Documents prepared. PCM ISO 9001 TC-PROC-001 PURCHASING NO M

DOCUMENTS

4.9 Purchasing Documents independently checked for accuracy. PCM/QAM ISO 9001 TC-PROC-001 NONE N/A V

4.10 Orders placed. PCM N/A TC-PROC-001 PURCHASE ORDER NO V

4.11 Quality audits carried out at Sub-suppliers premises i.a.w. audit QM ISO 9001 & TC-QUA-004 AUDIT SCHEDULE, YES V

schedule. 19011 CHECK LISTS,

AUDIT REPORT

4.12 Vendor Inspection and expediting performed i.a.w. with CM ISO 9001 NONE INSPECTION YES H

Contract requirements. REPORT

5.0 CLIENT SUPPLIED PRODUCT N/A N/A N/A N/A N/A N/A N/A

6.0 MOBILISATION AND SITE ESTABLISHMENT

6.1 Establish project site offices and infrastructure PM N/A N/A N/A NO N/A

QUALITY INSPECTION AND TEST PLAN TC-QUA-002 PAGE NUMBER: 4 OF 12

SECTION 12.0 PART 1 REVISION 0 DATE: 23.09.18

ACTION

RESPONSIBLE DOCUMENT DELIVERABLE COLUMNS

ITEM ACTIVITY SPECIFICATION PROCEDURE

PERSON GENERATED YES/NO

TC BP

7.0 ENTRY INTO BP TERRITORY

7.1 Apply to BP for Entry Permits. PCM CONTRACT N/A CORRESPONDENCE NO N/A

8.0 IMPLEMENTATION OF SITE QUALITY SYSTEM (SQS)

8.1 Document and Data Control DC ISO 9001 TC-DOC-003

8.1.1 Drawing and document registers prepared. DC DOCUMENT & NO N/A

DRAWING

REGISTER

8.1.2 Drawing and document distribution lists prepared. DC DISTRIBUTION NO N/A

MATRIX

8.1.3 Documents/drawings issued to appropriate persons. DC TRANSMITTAL NO N/A

NOTE

8.2 Training and Recruitment PERSONNEL NO N/A

RECORDS

8.2.1 Personnel selected and recruited PM JOB NO N/A

SPECIFICATIONS &

JOB DESCRIPTIONS

8.2.2 Training requirements identified. QAM TRAINING MATRIX NO N/A

8.2.3 Training carried out and records kept of attendees and subjects QCM/DS TRAINING NO N/A

covered during training, which will include safety induction CERTIFICATE

courses, etc.

8.3 Site Contract Review PCM/QAM/CM TC-QUA-005

QUALITY INSPECTION AND TEST PLAN TC-QUA-002 PAGE NUMBER: 5 OF 12

SECTION 12.0 PART 1 REVISION 0 DATE: 23.09.18

ACTION

RESPONSIBLE DOCUMENT DELIVERABLE COLUMNS

ITEM ACTIVITY SPECIFICATION PROCEDURE

PERSON GENERATED YES/NO

TC BP

8.3.1 Discipline Contract Review carried out by TC Site personnel Project Team TC-QUA-005 MINUTES OF NO V

and main subcontractors. and MEETING

Subcontractors

8.3.2 Prepare and administer Change Orders, Requests for PCM/CM RFI, YES D

Information where applicable. CHANGE ORDERS

8.4 Requests for Information

8.4.1 TC and sub-supplier RFI generated and handed to PCM. CM/PCM RFI YES V

8.4.2 RFI reviewed to confirm contractual validity and entered in PCM RFI LOGS NO V

RFI Log.

8.4.3 Response to RFI by PCM or raised formally with BP. PCM RFI LOG YES D

8.4.4 Replies from BP recorded and copied to RFI originator. PCM RFI LOG NO V

8.5 Engineering / Design Control

8.5.1 Appoint design subcontractor(s). PM/PCM/CM

8.5.2 Liaise with design contractor(s). CM/DCM M

8.5.3 Review design input, design criteria, drawings, specifications PM/PCM/CM ISO 9001 TC-ENG-003 DESIGN REVIEW NO V

& design process against BP and legal requirements. REPORTS / MINUTES

OF MEETINGS

8.5.4 Issue design Plan. PM TC-ENG-020 DESIGN PLAN YES V

8.6 Process Procedures

8.6.1 Prepare process and special process procedures as required by PM/QAM ISO 9001 PROCEDURES YES V

Contract Scope of Work.

QUALITY INSPECTION AND TEST PLAN TC-QUA-002 PAGE NUMBER: 6 OF 12

SECTION 12.0 PART 1 REVISION 0 DATE: 23.09.18

ACTION

RESPONSIBLE DOCUMENT DELIVERABLE COLUMNS

ITEM ACTIVITY SPECIFICATION PROCEDURE

PERSON GENERATED YES/NO

TC BP

8.6.2 Submit process and special process procedures to BP for PM TRANSMITTAL YES V

approval. NOTE

8.6.3 Issue approved procedures to appropriate personnel i.a.w. QAM DOCUMENT NO M

distribution list. TRANSMITTAL

8.7 Control of Sub suppliers PM/CM ISO 9001 TC-PROC-001

8.7.1 Monitor sub supplier performance. QAM/CM TC-QUA-004 AUDIT AND NO V

INSPECTION

REPORTS

8.7.2 Administer sub-supplier RFI's and Change Orders. PM/PCM RFI’s and CHANGE NO V

ORDERS

8.8 Inspection and Testing

8.8.1 Prepare inspection and test procedures as required by Contract SUBCON/QAM ISO 9001 PROCEDURES YES V

Scope of Work.

8.8.2 Submit inspection and test procedures to BP for approval. PM/QAM N/A DOCUMENT YES H

TRANSMITTAL

8.8.3 Issue approved procedures to appropriate personnel i.a.w. PM/QAM DOCUMENT NO V

distribution list. TRANSMITTAL

8.9 Inspection, Measuring and Test Equipment. ISO 9001 TC-CON-024 PROCEDURES YES V

8.9.1 List of measuring and test equipment prepared (including sub- CM ISO 9001 EQUIPMENT LIST NO V

supplier’s equipment).

8.9.2 Capability of measuring and test equipment verified. CM ISO 9001 CALIBRATION NO H

REPORT

8.9.3 Requirement for calibration of measuring and test equipment CM ISO 9001 CALIBRATION LIST NO V

ascertained.

QUALITY INSPECTION AND TEST PLAN TC-QUA-002 PAGE NUMBER: 7 OF 12

SECTION 12.0 PART 1 REVISION 0 DATE: 23.09.18

ACTION

RESPONSIBLE DOCUMENT DELIVERABLE COLUMNS

ITEM ACTIVITY SPECIFICATION PROCEDURE

PERSON GENERATED YES/NO

TC BP

8.9.4 Calibration status of measuring and test equipment verified and CM ISO 9001 CALIBRATION LIST NO V

monitored to ensure that calibration status is maintained. AND REGISTER

8.9.5 Maintain records of usage of calibrated equipment in order to CM ISO 9001 CALIBRATION LIST NO R

trace measurements made by equipment found to be out of AND REGISTER

calibration.

8.10 Stores and Material Control ISO 9001 TC-QUA-006

8.10.1 Provide stores and inspection personnel with all necessary PCM/MC ISO 9001 WORK NO V

information regarding storage conditions and certification INSTRUCTION

requirements.

8.10.2 Confirm that the conditions of storage facilities are appropriate MC/CM INSPECTION/AUDIT NO V

for the storage of all materials. REPORT

8.10.3 Receive incoming materials and equipment. MC STORES RECEIPT NO D

AND INSPECTION

REPORT

8.10.4 Receive Client supplied Materials and equipment. MC REPORT YES H

8.10.5 Inspect materials and equipment to confirm that quantity and MC STORES RECEIPT NO I

quality is i.a.w. specified requirements. Verify that the material AND INSPECTION

identification is correct. REPORT

8.10.6 Confirm that material certificates have been received where MC NONE N/A V

applicable.

8.10.7 Place any unacceptable items in the stores quarantine area. MC NCR YES V

8.9.9 Non -conformity reports generated for all unacceptable items. MC TC-QUA-003 NCR REPORT YES V

QUALITY INSPECTION AND TEST PLAN TC-QUA-002 PAGE NUMBER: 8 OF 12

SECTION 12.0 PART 1 REVISION 0 DATE: 23.09.18

ACTION

RESPONSIBLE DOCUMENT DELIVERABLE COLUMNS

ITEM ACTIVITY SPECIFICATION PROCEDURE

PERSON GENERATED YES/NO

TC BP

8.10.10 Ensure that materials with a limited shelf-life are used before MC TC-QUA-006 NONE N/A V

the expire date.

8.10.11 Issue materials as required. MC MATERIAL ISSUE NO V

REPORT

8.10.12 Preservation of materials as required. MC PRESERVATION NO M

DOCUMENT

8.11 Material Traceability ISO 9001 TC-QUA-008

8.11.1 Unique identification numbers recorded when materials are MC STORES RECEIPT NO V

received and maintained during storage. AND INSPECTION

REPORT

8.11.2 Unique numbers recorded at time of material issue. MC MATERIAL NO V

REQUEST AND

ISSUE REPORT

8.11.3 Installation location of materials recorded. DS AS-BUILTS, YES D

ELECTRONIC FILES

8.12 Non-Conformance and Corrective Action TC-QUA-003

8.12.1 Non-Conformities identified and corrective actions QAM ISO 9001 NCR REPORT YES D

recommended.

8.12.2 Corrective action taken. PM/SUBCON/ CAR REPORT YES D

DS

8.12.3 Verification of corrective action. QAM CAR REPORT NO D

QUALITY INSPECTION AND TEST PLAN TC-QUA-002 PAGE NUMBER: 9 OF 12

SECTION 12.0 PART 1 REVISION 0 DATE: 23.09.18

ACTION

RESPONSIBLE DOCUMENT DELIVERABLE COLUMNS

ITEM ACTIVITY SPECIFICATION PROCEDURE

PERSON GENERATED YES/NO

TC BP

9.0 SPECIAL PROCESS PROCEDURES

9.1 Welding

9.1.1 Welding procedures prepared and submitted to BP for approval. SUBCON/QAM EN 287; EN288 WELDING YES H

API 1104 PROCEDURES

9.1.2 Procedure Qualification welds carried out and all parameters QAM/SUBCON INSPECTION YES M

recorded. /DS REPORTS; WPS;

CALIBRATION

CERTS.

9.1.3 Non-destructive testing carried out i.a.w. Contract TC TC-CON-013 NDT REPORTS YES V

requirements.

9.1.4 Acceptable welds cut out and marked-up for destructive testing. QAM/ EN 287 TC-

API 1104

9.1.5 Destructive tests carried out. BP Approved EN 287 TEST REPORTS YES V

Test Laboratory

9.1.6 Welding Procedure Specification Sheets (WPS) amended to QAM EN 287 WPS YES H

incorporate changes. API 1104

9.1.7 Revise WPS, Procedure Qualification Record, test reports and QAM N/A WPS YES H

material certificates submitted to BP as complete package for

review and approval.

9.1.8 Welders selected and tested as required. QAM/SUBCON EN 287 QUALIFICATION YES V

TC-CON-011 CERTIFICATES

9.1.9 Welder performance monitored. QAM/DS TC-CON-011 INSPECTION NO R

REPORTS

9.2 Painting/Insulation

QUALITY INSPECTION AND TEST PLAN TC-QUA-002 PAGE NUMBER: 10 OF 12

SECTION 12.0 PART 1 REVISION 0 DATE: 23.09.18

ACTION

RESPONSIBLE DOCUMENT DELIVERABLE COLUMNS

ITEM ACTIVITY SPECIFICATION PROCEDURE

PERSON GENERATED YES/NO

TC BP

9.2.1 Procedures prepared in accordance with Contract Specification HERTEL/QAM TC-CON-010 PROCEDURES/ YES H

and transmitted to BP for approval. TC–CON-012 TRANSMITTAL

NOTE

9.2.2 Painting operatives selected from personnel with experience of HERTEL NONE N/A V

paint application.

10.0 INSPECTION AND TESTING

10.1 Non-Destructive Testing (NDT)

10.1.1 NDT procedures qualified as required by Contract and all CM EN 1435, 1290, EN &NDT PROCEDURES YES H

parameters recorded. 1712, 25817 PROCEDURES

10.1.2 Results reviewed by TC and passed to BP for review and QAM N/A N/A TRANSMITTAL NO V

approval if acceptable. NOTE

10.1.3 NDT procedures modified to incorporate any changes and QAM EN 1435, 1290, TC-QUA-013 REVISED YES H

transmitted to BP for approval. 1712, 25817 PROCEDURES

10.1.4 NDT technicians selected from personnel in possession of CM TC-QUA-010 NONE N/A V

current Colombian approvals.

10.1.5 List of NDT technicians and certified copies of approvals DC N/A APPROVED LIST, YES V

maintained. COPIES OF

QUALIFICATIONS:

TC NDT

10.1.6 NDT performed as indicated in section 13.21 of Construction EN 1435, 1290, TC-QUA-013 NDT REPORTS YES D

Activities and documented i.a.w. Inspection Procedures. 1712, 25817

10.2 Hydrostatic Testing B31.3 97/23/EC TC-

CON-031

10.2.1 Hydrostatic Testing Procedure prepared and submitted to BP for PM TC-CON-031 TEST PROCEDURE YES H

approval.

QUALITY INSPECTION AND TEST PLAN TC-QUA-002 PAGE NUMBER: 11 OF 12

SECTION 12.0 PART 1 REVISION 0 DATE: 23.09.18

ACTION

RESPONSIBLE DOCUMENT DELIVERABLE COLUMNS

ITEM ACTIVITY SPECIFICATION PROCEDURE

PERSON GENERATED YES/NO

TC BP

10.2.2 Piping Spool Test sections selected. CM TC-CON-031 TEST REPORTS YES V

10.2.3 Hydrostatic tests carried out as indicated in this Plan. CM TC-CON-031 TEST REPORTS; YES V

CHARTS; ETC:

11.0 INSPECTION AND TEST STATUS INSPECTION

PROCEDURES

TC

11.1 Welds which have been radiographed marked i.a.w. Inspection N/A N/A N/A

procedure.

11.2 Weld results marked on Pipe Book. TC TC-QUA-008 PIPE BOOK YES M

TC

11.3 NDT Results copied to welding and painting supervisors. N/A N/A N/A N/A

11.4 Accepted joints painted. HERTEL TC-CON-010 N/A N/A N/A

11.5 Review of all weld and coating acceptance prior to preparation CM N/A N/A N/A D

for hydrotest.

QUALITY INSPECTION AND TEST PLAN TC-QUA-002 PAGE NUMBER: 12 OF 12

SECTION 12.0 PART 1 REVISION 0 DATE: 23.09.18

S-ar putea să vă placă și

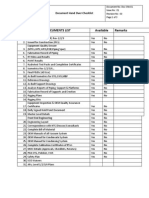

- Structural Steel Fabrication Inspection and Test PlanDocument3 paginiStructural Steel Fabrication Inspection and Test Plansivagnanam sÎncă nu există evaluări

- SNC-LAVALIN FAYEZ ENGINEERING MR CHECKLISTDocument2 paginiSNC-LAVALIN FAYEZ ENGINEERING MR CHECKLISTsalman1111a100% (1)

- Create Gantt Chart Using Conditional FormattingDocument3 paginiCreate Gantt Chart Using Conditional FormattingDurga Charan DasÎncă nu există evaluări

- Bending ProcedureDocument1 paginăBending ProcedureabbasÎncă nu există evaluări

- PWE April 2019Document25 paginiPWE April 2019Serban Ionescu100% (1)

- PROJECT SCHEDULE AND COST SUMMARYDocument98 paginiPROJECT SCHEDULE AND COST SUMMARYJaymark SorianoÎncă nu există evaluări

- Package 2s E0001 - Jupiter DCR 30-10-2021Document96 paginiPackage 2s E0001 - Jupiter DCR 30-10-2021senthilÎncă nu există evaluări

- Oman Tank Terminal Company (Ottco) : Project: Ras Markaz Crude Oil Park Project (Phase 1)Document2 paginiOman Tank Terminal Company (Ottco) : Project: Ras Markaz Crude Oil Park Project (Phase 1)ANIL PLAMOOTTILÎncă nu există evaluări

- AMCO - RBI Engineer - Mr. Syed Hameed HussainDocument4 paginiAMCO - RBI Engineer - Mr. Syed Hameed HussainOwais MalikÎncă nu există evaluări

- Process Document: Health Safety & Environment Management (Version 1.0)Document8 paginiProcess Document: Health Safety & Environment Management (Version 1.0)Tonmay MajumderÎncă nu există evaluări

- Ts 16949 Proc Forms MatrixDocument1 paginăTs 16949 Proc Forms MatrixRob WillestoneÎncă nu există evaluări

- DMZCO Safety Manual Job Skill Training ProgramDocument3 paginiDMZCO Safety Manual Job Skill Training ProgramAnonymous voA5Tb0Încă nu există evaluări

- Document Numbering Procedure 20-10-14Document7 paginiDocument Numbering Procedure 20-10-14MohamedÎncă nu există evaluări

- 28"NB 24"NB 20"NB 18"NB 16"NB 14"NB 12"NB 10"NB 8"NB 6"NB 4"NB 3"NB 2"NB 1"NB 3/4"NBDocument3 pagini28"NB 24"NB 20"NB 18"NB 16"NB 14"NB 12"NB 10"NB 8"NB 6"NB 4"NB 3"NB 2"NB 1"NB 3/4"NBBimal DeyÎncă nu există evaluări

- SA048-WSP-GEN-MTS-MNCR-2 Non-Conformance Report - Tested Stockpile BarricationDocument2 paginiSA048-WSP-GEN-MTS-MNCR-2 Non-Conformance Report - Tested Stockpile BarricationmustafaansmeÎncă nu există evaluări

- 5.43-F04 Vendor EHS Document Submittal LogDocument1 pagină5.43-F04 Vendor EHS Document Submittal LogVijayakumar KarunanidhiÎncă nu există evaluări

- As Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-05 Rev No Rev DateDocument1 paginăAs Per ISO 9001:2015 & IATF 16949:2016: Doc No CH-SMS-05 Rev No Rev DaterohitÎncă nu există evaluări

- 01 33 00 - Submittal ProceduresDocument5 pagini01 33 00 - Submittal ProceduresSteve LezamaÎncă nu există evaluări

- Daily Contractor ReportDocument4 paginiDaily Contractor ReportHytham El-NoubyÎncă nu există evaluări

- Sejiram Mill 80 TPH Project: Feasibility Phase Feasibility PhaseDocument10 paginiSejiram Mill 80 TPH Project: Feasibility Phase Feasibility PhaseSlamat Parulian Simamora100% (1)

- Saudi Aramco Inspection ChecklistDocument6 paginiSaudi Aramco Inspection Checklistnisha_khanÎncă nu există evaluări

- Paint Specification - Package ADocument53 paginiPaint Specification - Package AMohammedÎncă nu există evaluări

- Supplier Document TransmittalDocument1 paginăSupplier Document Transmittaljc2010gpÎncă nu există evaluări

- Documet Transmittal FormDocument2 paginiDocumet Transmittal FormMohammedÎncă nu există evaluări

- Welding Inspector Contract DocumentDocument1 paginăWelding Inspector Contract Documentabu hanifaÎncă nu există evaluări

- Office Critical Issue Office Critical Issue: LegalDocument6 paginiOffice Critical Issue Office Critical Issue: LegalAndrew RoddaÎncă nu există evaluări

- Product Chemical CompositionDocument1 paginăProduct Chemical CompositionMohammed HamedÎncă nu există evaluări

- Comment Response Sheet SVDN CPP M 0002 D01 0003 (r01)Document2 paginiComment Response Sheet SVDN CPP M 0002 D01 0003 (r01)Tuấn Vũ0% (1)

- 07D4 YSR DS 007 Rev09 - Control Valves ListDocument2 pagini07D4 YSR DS 007 Rev09 - Control Valves ListAli JameelÎncă nu există evaluări

- S-3000-3130-001 - 0-General Specification For Steel Structure and Miscellenous MaterialsDocument15 paginiS-3000-3130-001 - 0-General Specification For Steel Structure and Miscellenous MaterialsMessaoud Goutas100% (1)

- Anzan KojimaDocument1 paginăAnzan Kojimamayna2010Încă nu există evaluări

- PF-001, Supplier Evaluation FormDocument2 paginiPF-001, Supplier Evaluation Formvirous08Încă nu există evaluări

- Certificate of InspectionDocument1 paginăCertificate of InspectionHaekal RamadhanÎncă nu există evaluări

- Lafarge Quality Control PlanDocument64 paginiLafarge Quality Control Planmanu_giteÎncă nu există evaluări

- NO. PNB/DC-QAD-04/ ISSUE:2.0 / Revision: 00/ DATE:-01.04.16 Page 1 of 2Document2 paginiNO. PNB/DC-QAD-04/ ISSUE:2.0 / Revision: 00/ DATE:-01.04.16 Page 1 of 2sonnu151Încă nu există evaluări

- ASME Code Section 8 ContentDocument6 paginiASME Code Section 8 ContenttasingenieriaÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechDocument1 paginăSaudi Aramco Inspection Checklist: Welding Overlay Workmanship Assessment SAIC-W-2027 31-Aug-11 MechAnonymous 4e7GNjzGWÎncă nu există evaluări

- NGWK PK 0001 VDQC Plit 0006Document7 paginiNGWK PK 0001 VDQC Plit 0006stdshopÎncă nu există evaluări

- Drawing Log - PC 118 (Rev 6)Document29 paginiDrawing Log - PC 118 (Rev 6)Dilshad AhemadÎncă nu există evaluări

- BMI-WI-5711-14 Ball Valve 2in-900# Manufacturing Process Rev.0Document12 paginiBMI-WI-5711-14 Ball Valve 2in-900# Manufacturing Process Rev.0MacelÎncă nu există evaluări

- Reference Ncpar No.: Ncpar # 14-005 (Deviation Notice) Department: QC/R&D DepartmentDocument4 paginiReference Ncpar No.: Ncpar # 14-005 (Deviation Notice) Department: QC/R&D DepartmentSusie GorospeÎncă nu există evaluări

- Quality Assurance (QA) StructureDocument10 paginiQuality Assurance (QA) Structureyuwantoni100% (1)

- SATR-J-6913 Rev 0 PDFDocument6 paginiSATR-J-6913 Rev 0 PDFAdel KlkÎncă nu există evaluări

- AITM-056, Rev. 1 - 05.22.2014 - Job Descriptions ManualDocument56 paginiAITM-056, Rev. 1 - 05.22.2014 - Job Descriptions ManualAdhi GunantoÎncă nu există evaluări

- Supplier Pre-Qualification Document - September 2020Document23 paginiSupplier Pre-Qualification Document - September 2020cephas ventures enterprisesÎncă nu există evaluări

- List of Internal Auditors & Competency - Qms Auditor: Updation Freq - YearlyDocument1 paginăList of Internal Auditors & Competency - Qms Auditor: Updation Freq - YearlyShaili SharmaÎncă nu există evaluări

- Milestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Document4 paginiMilestone Certificate: Project/Contract No: Waad Al-Shamal ISCC Power Plant / 4400006770Raghad GÎncă nu există evaluări

- Edir CommentsDocument16 paginiEdir CommentsEslam HusseinÎncă nu există evaluări

- RFP Lifting Equipment Inspection MaintenanceDocument17 paginiRFP Lifting Equipment Inspection Maintenanceomar sadiqÎncă nu există evaluări

- Sub Process: Purchased Parts, Pass Through, Material ManagementDocument2 paginiSub Process: Purchased Parts, Pass Through, Material ManagementNikhilesh NaikÎncă nu există evaluări

- Iqwq-Ce1092-Cpzzz-00-0003 - 0 - Civil Work Construction Procedure PDFDocument12 paginiIqwq-Ce1092-Cpzzz-00-0003 - 0 - Civil Work Construction Procedure PDFNassim SabriÎncă nu există evaluări

- For Approval: Nghi Son 2 Bot Thermal Power Plant Project (2 X 600 MW)Document12 paginiFor Approval: Nghi Son 2 Bot Thermal Power Plant Project (2 X 600 MW)Nguyễn Chinh100% (1)

- F-05 Corrective Action FormDocument1 paginăF-05 Corrective Action Formsuhara hussainÎncă nu există evaluări

- Hse Approved SpecificationDocument16 paginiHse Approved SpecificationPrasit MeeboonÎncă nu există evaluări

- Format SEI-HC-PS-C403: Check List For Hvac Duct LayoutDocument3 paginiFormat SEI-HC-PS-C403: Check List For Hvac Duct Layoutarunima04Încă nu există evaluări

- Document Hndover ChecklistDocument3 paginiDocument Hndover ChecklistM Uzair ShaikhÎncă nu există evaluări

- Execution Plan Piping Prefabrication Works: REV 33000667-TCM-DH2-CO-PLN-00010 4078-LZ-PL-9000000052Document16 paginiExecution Plan Piping Prefabrication Works: REV 33000667-TCM-DH2-CO-PLN-00010 4078-LZ-PL-9000000052tomas budrysÎncă nu există evaluări

- BTC003-B020-CM-PRJ-00015 C02 Qualiti Control PlansDocument11 paginiBTC003-B020-CM-PRJ-00015 C02 Qualiti Control PlansLevan JaparidzeÎncă nu există evaluări

- Etihad Towers Project: Inspection & Test Plan - Hollow Core SlabsDocument2 paginiEtihad Towers Project: Inspection & Test Plan - Hollow Core SlabsjiniÎncă nu există evaluări

- ETIHAD SOUTHSIDE CATERING ELECTRICAL TESTINGDocument81 paginiETIHAD SOUTHSIDE CATERING ELECTRICAL TESTINGAnandu AshokanÎncă nu există evaluări

- GPTs Are GPTS: An Early Look at The Labor Market Impact Potential of Large Language ModelsDocument35 paginiGPTs Are GPTS: An Early Look at The Labor Market Impact Potential of Large Language ModelsJuan PeÎncă nu există evaluări

- Session 3 PDFDocument31 paginiSession 3 PDFivanbfÎncă nu există evaluări

- Session 4Document50 paginiSession 4ivanbfÎncă nu există evaluări

- BCG Art of Risk Management Apr 2017 Tcm9 153878Document21 paginiBCG Art of Risk Management Apr 2017 Tcm9 153878Alma LanderoÎncă nu există evaluări

- Gestion de GerenciaDocument27 paginiGestion de GerenciaivanbfÎncă nu există evaluări

- Sarkar, Debashis-5S For Service Organizations and Offices - A Lean Look at Improvements-ASQ Quality Press (2006)Document144 paginiSarkar, Debashis-5S For Service Organizations and Offices - A Lean Look at Improvements-ASQ Quality Press (2006)Zulay Rincon GomezÎncă nu există evaluări

- Session 3 PDFDocument31 paginiSession 3 PDFivanbfÎncă nu există evaluări

- Principios de Gerencia Chandon Cap 1Document47 paginiPrincipios de Gerencia Chandon Cap 1ivanbfÎncă nu există evaluări

- Session 2Document40 paginiSession 2ivanbfÎncă nu există evaluări

- Session 5Document62 paginiSession 5ivanbfÎncă nu există evaluări

- Handbook PmbokDocument300 paginiHandbook PmbokivanbfÎncă nu există evaluări

- Communication SkillsDocument80 paginiCommunication SkillsSalemÎncă nu există evaluări

- Process Costing: 17 - 1 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/FosterDocument66 paginiProcess Costing: 17 - 1 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Fostersweetyasir47Încă nu există evaluări

- Process Costing: 17 - 1 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/FosterDocument66 paginiProcess Costing: 17 - 1 ©2003 Prentice Hall Business Publishing, Cost Accounting 11/e, Horngren/Datar/Fostersweetyasir47Încă nu există evaluări

- Choose the Right Process Improvement MethodDocument9 paginiChoose the Right Process Improvement MethodGopal-2009Încă nu există evaluări

- VisualDocument23 paginiVisualivanbfÎncă nu există evaluări

- Arroba Risk For ProjetsDocument2 paginiArroba Risk For ProjetsivanbfÎncă nu există evaluări

- 8 Deepak Prabhakar PDocument8 pagini8 Deepak Prabhakar PBrian FreemanÎncă nu există evaluări

- Crystal Ball La BibliaDocument107 paginiCrystal Ball La BibliaivanbfÎncă nu există evaluări

- Email EttiquetesDocument34 paginiEmail EttiquetesSajal ChakarvartyÎncă nu există evaluări

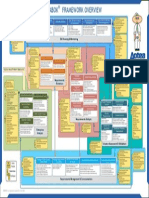

- BABOK - Business Analysis PosterDocument1 paginăBABOK - Business Analysis PosterfaositoÎncă nu există evaluări

- English Grammar Guide from Colegio Concertado Ntra. Sra. de la ProvidenciaDocument27 paginiEnglish Grammar Guide from Colegio Concertado Ntra. Sra. de la ProvidenciaJose Andres Martinez Garcia100% (2)

- BABOK Process Aotea Big Poster PDFDocument1 paginăBABOK Process Aotea Big Poster PDFParulekar RajuÎncă nu există evaluări

- Babok 30 PosterDocument3 paginiBabok 30 PosterivanbfÎncă nu există evaluări

- BABOK Process Aotea Big Poster PDFDocument1 paginăBABOK Process Aotea Big Poster PDFParulekar RajuÎncă nu există evaluări

- Fractura CriticaDocument30 paginiFractura CriticaivanbfÎncă nu există evaluări

- IIBA Global BusinessAnalysis CoreStandardDocument50 paginiIIBA Global BusinessAnalysis CoreStandardkorrait100% (1)

- Grammatical summary of the English and Spanish languagesDocument49 paginiGrammatical summary of the English and Spanish languagesFabián Araneda Baltierra100% (1)

- Spanish Grammar!!!!!!!Document47 paginiSpanish Grammar!!!!!!!Keshiya Renganathan100% (11)

- Project Report Samples For MBADocument23 paginiProject Report Samples For MBASRIPRIYAÎncă nu există evaluări

- Lecture#08 - Web Project ManagementDocument15 paginiLecture#08 - Web Project ManagementMalik SalmanÎncă nu există evaluări

- Xpandion Hosted GRCDocument1 paginăXpandion Hosted GRCapi-203336861Încă nu există evaluări

- ACC209 Assignment 2 AlternateDocument14 paginiACC209 Assignment 2 Alternatehtet aungÎncă nu există evaluări

- Manpower PlanningDocument18 paginiManpower PlanningShamz SiddiquiÎncă nu există evaluări

- Sap Case Study Divekar November 2011Document2 paginiSap Case Study Divekar November 2011Mohit NiranjaneÎncă nu există evaluări

- Chapter 5 Sourcing Materials and Services - Version 1.2Document37 paginiChapter 5 Sourcing Materials and Services - Version 1.2Zin Mar OoÎncă nu există evaluări

- Through-Process OptimizationDocument7 paginiThrough-Process OptimizationHay LisÎncă nu există evaluări

- ASQ Global State of Quality 2013Document18 paginiASQ Global State of Quality 2013mseymour91Încă nu există evaluări

- Solving business inventory problems with computer systemsDocument2 paginiSolving business inventory problems with computer systemsAbdulhamid HalawaÎncă nu există evaluări

- MKU January, May & September 2023 IntakesDocument2 paginiMKU January, May & September 2023 IntakesBAKAR ALIÎncă nu există evaluări

- QIP ProcessDocument17 paginiQIP ProcessIvan LuzuriagaÎncă nu există evaluări

- Value Chain Analysis and Five Force AnalysisDocument22 paginiValue Chain Analysis and Five Force Analysisreagan blaireÎncă nu există evaluări

- Customer-driven Quality Management for Long-term SuccessDocument7 paginiCustomer-driven Quality Management for Long-term SuccessSrinivasa VarmaÎncă nu există evaluări

- Arefat ShemsuDocument57 paginiArefat ShemsuYitbarek MohammedÎncă nu există evaluări

- Strategic Management and AnalysisDocument7 paginiStrategic Management and AnalysisLisaÎncă nu există evaluări

- Gulick PDFDocument216 paginiGulick PDFGabriela YañezÎncă nu există evaluări

- Ebook1 1Document594 paginiEbook1 1Jason Rodrigues50% (2)

- Agile Project Management: A Case Study On Agile PracticesDocument66 paginiAgile Project Management: A Case Study On Agile Practicesmico pamplona100% (1)

- Strategies of Persuasion With Gary Orren PDFDocument3 paginiStrategies of Persuasion With Gary Orren PDFchevistarÎncă nu există evaluări

- Ais Chapter 2Document6 paginiAis Chapter 2jhell dela cruzÎncă nu există evaluări

- Project Report On Training and Development by Thommandru Supriya RaniDocument82 paginiProject Report On Training and Development by Thommandru Supriya RaniChandra Sekhar JujjuvarapuÎncă nu există evaluări

- The Diaper Industry in 1974 - GR - 7 - ADocument15 paginiThe Diaper Industry in 1974 - GR - 7 - AaabfjabfuagfuegbfÎncă nu există evaluări

- Zeeshan Jamil Rana........Document8 paginiZeeshan Jamil Rana........Gul ShairÎncă nu există evaluări

- BS Industrial Security Management Evaluation InstrumentDocument13 paginiBS Industrial Security Management Evaluation Instrumentrodolfo king bautista100% (1)

- Management Accounting Techniques CompilationDocument40 paginiManagement Accounting Techniques CompilationGracelle Mae Oraller100% (1)

- Abellano Fria Mae - Macctngprei01-Tqm Case StudyDocument3 paginiAbellano Fria Mae - Macctngprei01-Tqm Case StudyNelia AbellanoÎncă nu există evaluări

- TUI Business StrategyDocument20 paginiTUI Business StrategyMuhammad Sajid Saeed86% (7)

- Human Resource Management: Sub Code 556Document330 paginiHuman Resource Management: Sub Code 556jugal bariÎncă nu există evaluări

- Zara Clothing Supply Chain Case StudyDocument2 paginiZara Clothing Supply Chain Case StudyIshika SaharanÎncă nu există evaluări