Documente Academic

Documente Profesional

Documente Cultură

Turtle Diagram Type and Extent Control For QA Department

Încărcat de

suresh kumarDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Turtle Diagram Type and Extent Control For QA Department

Încărcat de

suresh kumarDrepturi de autor:

Formate disponibile

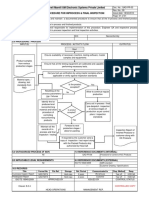

Doc. No.

TYPE AND EXTENT OF CONTROL ( QUALITY ASSURANCE & INCOMING

Page No.

INSPECTION )

KEY PERFORMANCE

WITH WHAT? INDICATORS

(Mtrl/M/c/Equipment) LINKAGES/AFFECTED PARTIES WITH WHO? 1.In Process Rejection PPM

1.Asst Manager 2.Customer end Rejection

PPM

1.Product Samples 1.Control of NC Products Quality 3.No of customer complaints

2.Gauges/Instruments 2.Corrective Action 2.Quality Engineers 4.Supplier PPM

3.QC Inspectors 5.No of SPQR Raised

FREQUENCY

OUTPUT

Monthly

INPUT

1.Incoming materials from 1.Incoming Inspection

customer/supplier 2.SPQR

QUALITY ASSURANCE 3.First Off/Line

2.Control plan

3.Gauges/Instruments

AND 4.Final Inspection

4.Supplier Inspection / Test 5.Rejection Node

report

MITIGATION ACTION

1. Reviewing & updating Incoming

RISKS Inspection plan frequently

1. Incoming Inspection plan not captured the 2. Ensuring availability of WIS &

HOW ?

requirement adherence

(METHOD/PROCEDURES/T

2.Non availability of WIS 3. Ensuring test standards are available

ECH)

3. Non avauilability of testing Standards 4. Ensuring test equipments are

1. Inspection plan

4. Non availability of test test equipments available

2.Work Instructions

5. Supplier process not controlled 5. Ensure Supplier process are audited

3.Test Standard

4.Raw Material test frequently

PREPARED BY REVIEWED BY APPROVED BY

S-ar putea să vă placă și

- Process Validation ReportDocument4 paginiProcess Validation ReportSUBODHHÎncă nu există evaluări

- QP Nonconforming Product Sample 2014Document2 paginiQP Nonconforming Product Sample 2014Anna Maree100% (1)

- Evidences To Be Maintained As Per APQP For PMDocument3 paginiEvidences To Be Maintained As Per APQP For PMSachin RamdurgÎncă nu există evaluări

- APQP Training MaterialDocument13 paginiAPQP Training Materialsuresh kumar100% (1)

- Customer Complaint RegisterDocument1 paginăCustomer Complaint Registersuresh kumarÎncă nu există evaluări

- Risk Assessment GuidanceDocument1 paginăRisk Assessment Guidancesuresh kumar100% (2)

- Corrective Action (8D) Report: Part Number CustomerDocument2 paginiCorrective Action (8D) Report: Part Number Customersuresh kumar50% (2)

- Interested Parties & Needs-Expectations - As Per Iatf 16949 - 2016Document4 paginiInterested Parties & Needs-Expectations - As Per Iatf 16949 - 2016suresh kumar95% (38)

- Fmea For Injection MoldingDocument4 paginiFmea For Injection Moldingsuresh kumar77% (13)

- IMS Quality Manual MSSL 2018 LatestDocument46 paginiIMS Quality Manual MSSL 2018 LatestManjeet RanaÎncă nu există evaluări

- Turtle DiagramDocument22 paginiTurtle DiagramVikas0% (1)

- QAD Procedure - Inspection & Testing (Inprocess & Final Inspection)Document1 paginăQAD Procedure - Inspection & Testing (Inprocess & Final Inspection)suman100% (2)

- DELIGHT Official e BookDocument418 paginiDELIGHT Official e BookIsis Jade100% (3)

- 2.procedures Initial Supply Control UpdatedDocument3 pagini2.procedures Initial Supply Control UpdatedKapil Karhana100% (1)

- Layered Process Audit ChecksheetDocument7 paginiLayered Process Audit Checksheetalliceyew100% (3)

- 4M Inspection ReportDocument4 pagini4M Inspection ReportKaran Malhi100% (1)

- APQP Training MaterialDocument13 paginiAPQP Training Materialsuresh kumar100% (1)

- QMS Risk IdentificationDocument6 paginiQMS Risk IdentificationyogshastriÎncă nu există evaluări

- Control Plan & FmeaDocument9 paginiControl Plan & FmeaManu SharmaÎncă nu există evaluări

- (2-19) Audit Check SheetDocument1 pagină(2-19) Audit Check SheetKumaravelÎncă nu există evaluări

- Guideline 4M Change MatrixDocument3 paginiGuideline 4M Change MatrixAman JasujaÎncă nu există evaluări

- Company Name: Engineering Location: Customer Name: Model Year / PlatformDocument45 paginiCompany Name: Engineering Location: Customer Name: Model Year / Platformsuresh kumar0% (1)

- QMP-18 Initial Production ControlDocument5 paginiQMP-18 Initial Production Controlom cncÎncă nu există evaluări

- IATF Objective Data Analysis - Quality - ExampleDocument1 paginăIATF Objective Data Analysis - Quality - ExampleSachin RamdurgÎncă nu există evaluări

- Procedure For NPD HandoverDocument1 paginăProcedure For NPD HandoverTushar Wagh100% (1)

- Red Bin AnalysisDocument5 paginiRed Bin AnalysisDINESHCHOUDHARY88Încă nu există evaluări

- Quality Alert FormatDocument1 paginăQuality Alert Formatsuresh kumar75% (4)

- P13-Process For APQPDocument6 paginiP13-Process For APQPBangali Singh100% (1)

- Abnormality Handling - R2Document4 paginiAbnormality Handling - R2Sagar Daund100% (4)

- Shriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)Document5 paginiShriram Pistons & Rings LTD, Pathredi: Layered Audit Check Sheet Monthly (Plant Hod)deepak sharma100% (1)

- 4th Edition PPAPDocument83 pagini4th Edition PPAPTerri Paleno Lebow100% (1)

- Internal Audit Check Sheet MaintDocument3 paginiInternal Audit Check Sheet MaintRamdas Paithankar100% (1)

- SMT Generic Control PlanDocument3 paginiSMT Generic Control PlanPedro Lopez Rodriguez100% (1)

- Control Plan TrainingDocument20 paginiControl Plan TrainingGAURAV SHARMAÎncă nu există evaluări

- Attribute MSA 4th EditionDocument4 paginiAttribute MSA 4th EditionSachin RamdurgÎncă nu există evaluări

- (As Per IS 2500, ISO 2859-1 & DIN 40080) : Sampling PlanDocument1 pagină(As Per IS 2500, ISO 2859-1 & DIN 40080) : Sampling PlanLOGANATHAN V100% (1)

- Supplier Audit Check Sheet For New & NON ISO SupplierDocument7 paginiSupplier Audit Check Sheet For New & NON ISO SupplierManoj Kaushik100% (1)

- MSIL Audit Cheklist 16Document22 paginiMSIL Audit Cheklist 16Pravin Balasaheb GunjalÎncă nu există evaluări

- Red Bin Analysis FormatDocument1 paginăRed Bin Analysis FormatPRABHAT RANJAN100% (1)

- Ipc & Ipp Logbook or FlowDocument8 paginiIpc & Ipp Logbook or FlowKaran Malhi100% (1)

- FM - MKT - 02 Quality Control Process ChartDocument4 paginiFM - MKT - 02 Quality Control Process Chartbarja subarjaÎncă nu există evaluări

- IATF 16949 DocumenDocument1 paginăIATF 16949 Documenpunitg_2Încă nu există evaluări

- Control PlanDocument1 paginăControl Planilaya rajaÎncă nu există evaluări

- Training Effectiveness RecordDocument1 paginăTraining Effectiveness Recordsuresh kumar50% (2)

- QRQCDocument1 paginăQRQCmoez50% (2)

- Perioperative Care For CABG PatientsDocument32 paginiPerioperative Care For CABG PatientsAya EyadÎncă nu există evaluări

- Kova Fasteners (P) LTD: Sampling PlanDocument1 paginăKova Fasteners (P) LTD: Sampling PlanAmandeep SinghÎncă nu există evaluări

- 4M Change Control Management Matrix For Supplier: MonthDocument1 pagină4M Change Control Management Matrix For Supplier: Monthsuresh kumar100% (4)

- Melt Flow Work InstructionDocument1 paginăMelt Flow Work Instructionsuresh kumarÎncă nu există evaluări

- MRM FormatDocument3 paginiMRM FormatPk NimiwalÎncă nu există evaluări

- 2023 VGP Checklist Rev 0 - 23 - 1 - 2023 - 9 - 36 - 20Document10 pagini2023 VGP Checklist Rev 0 - 23 - 1 - 2023 - 9 - 36 - 20mgalphamrn100% (1)

- IATF 16949 Awareness Training-Terms OnlyDocument18 paginiIATF 16949 Awareness Training-Terms Onlysuresh kumar67% (3)

- HF-0467 - Product Audit Report - C - 2015-08-06Document44 paginiHF-0467 - Product Audit Report - C - 2015-08-06Enis SirbegovicÎncă nu există evaluări

- QAF12 Process Audit Rev 09Document4 paginiQAF12 Process Audit Rev 09ukavathekarÎncă nu există evaluări

- Audit Checkpoint For ISO 9001 2015 & 14001 2015Document2 paginiAudit Checkpoint For ISO 9001 2015 & 14001 2015suresh kumar100% (1)

- Operator Observation SheetDocument1 paginăOperator Observation Sheet25aprilÎncă nu există evaluări

- Procedure: Measurement System Analysis ExecutionDocument1 paginăProcedure: Measurement System Analysis Executionaslam100% (1)

- Wi SPCDocument4 paginiWi SPCSujeet Kumar100% (1)

- Rejection Analysis - in HouseDocument24 paginiRejection Analysis - in Housesuresh kumar100% (1)

- Cycle Time Calculation (2 Process Method)Document4 paginiCycle Time Calculation (2 Process Method)suresh kumarÎncă nu există evaluări

- Supplier Audit Check Sheet.Document1 paginăSupplier Audit Check Sheet.ALI ASGHARÎncă nu există evaluări

- Document Change RequestDocument1 paginăDocument Change Requestsuresh kumarÎncă nu există evaluări

- Iatf ActivitiesDocument6 paginiIatf ActivitiesWizard tube and Engineered componentÎncă nu există evaluări

- Cash and Cash Equivalents ReviewerDocument4 paginiCash and Cash Equivalents ReviewerEileithyia KijimaÎncă nu există evaluări

- One Point LessonDocument8 paginiOne Point LessonVenkatesanÎncă nu există evaluări

- Skill Required Skill Required Skill Required Skill Required Skill Required Skill RequiredDocument2 paginiSkill Required Skill Required Skill Required Skill Required Skill Required Skill RequiredRavi YadavÎncă nu există evaluări

- Process Audit - Sheet New ......Document1 paginăProcess Audit - Sheet New ......MUKESH KUMARÎncă nu există evaluări

- Required Doc For IATFDocument3 paginiRequired Doc For IATFAbhayÎncă nu există evaluări

- Sop SeDocument60 paginiSop SemanttupandeyÎncă nu există evaluări

- Kaizen Format SimplifiedDocument4 paginiKaizen Format Simplifiedsuresh kumarÎncă nu există evaluări

- Sampling System Inspection Process Flow Chart 1Document1 paginăSampling System Inspection Process Flow Chart 1sakshi patilÎncă nu există evaluări

- Iatf Process Audit Check Sheet FormatDocument14 paginiIatf Process Audit Check Sheet FormatPuspavathi S Rama NaiduÎncă nu există evaluări

- Training Effectiveness Evaluation FormatDocument1 paginăTraining Effectiveness Evaluation Formatsuresh kumar50% (2)

- T2 VSA With RequirementDocument8 paginiT2 VSA With RequirementSandeep K Malhotra100% (3)

- Product Audit Check SheetDocument3 paginiProduct Audit Check SheetLakshmanan Venkatesan100% (1)

- Quinta RuedaDocument20 paginiQuinta RuedaArturo RengifoÎncă nu există evaluări

- Ref Flow Charts Layout InspectionDocument1 paginăRef Flow Charts Layout Inspectionrajesh.bÎncă nu există evaluări

- Manufacturing Process AuditDocument1 paginăManufacturing Process Auditmurilocabrini100% (1)

- .013-00-Checking AidsDocument3 pagini.013-00-Checking Aidsdaniel_sasikumarÎncă nu există evaluări

- MACE Formats 1Document46 paginiMACE Formats 1Ashish VaidÎncă nu există evaluări

- New Enquiry Feasibility Review FormatDocument3 paginiNew Enquiry Feasibility Review FormatUlhas KavathekarÎncă nu există evaluări

- Ipp Tag FormatDocument1 paginăIpp Tag FormatSKAI AUTO100% (1)

- Worksheet in SQ Checksheet Part1Document50 paginiWorksheet in SQ Checksheet Part1Jetesh Devgun100% (1)

- Api Monogram Program/Erw 20'' (Api 5L) : Embosal Steel Mills LLCDocument2 paginiApi Monogram Program/Erw 20'' (Api 5L) : Embosal Steel Mills LLCRavi TyagiÎncă nu există evaluări

- Towel Management in Common PlacesDocument1 paginăTowel Management in Common Placessuresh kumarÎncă nu există evaluări

- Visual Control Format For Injection Molding DefectDocument2 paginiVisual Control Format For Injection Molding Defectsuresh kumarÎncă nu există evaluări

- Mounting Bracket Data Sheet-HoneywellDocument1 paginăMounting Bracket Data Sheet-Honeywellsuresh kumarÎncă nu există evaluări

- Fire Cabinet - SF - 600 SeffcoDocument4 paginiFire Cabinet - SF - 600 Seffcosuresh kumarÎncă nu există evaluări

- Heat Treatment Chart FormatDocument2 paginiHeat Treatment Chart Formatsuresh kumarÎncă nu există evaluări

- Contract Review FormatDocument1 paginăContract Review Formatsuresh kumarÎncă nu există evaluări

- Hardness Conversion ChartDocument1 paginăHardness Conversion ChartFresly JayaÎncă nu există evaluări

- Management of Change-MOC Notification FormatDocument1 paginăManagement of Change-MOC Notification Formatsuresh kumarÎncă nu există evaluări

- Management of Change FormatDocument1 paginăManagement of Change Formatsuresh kumarÎncă nu există evaluări

- GDT Training BasicDocument21 paginiGDT Training Basicsuresh kumar100% (1)

- Chapter 11-15Document172 paginiChapter 11-15Mansoor AhmadÎncă nu există evaluări

- Wada Defending Cannabis BanDocument18 paginiWada Defending Cannabis Banada UnknownÎncă nu există evaluări

- Wago PCB Terminal Blocks and Connectors Catalog 7Document105 paginiWago PCB Terminal Blocks and Connectors Catalog 7alinupÎncă nu există evaluări

- API 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)Document10 paginiAPI 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)tutuionutÎncă nu există evaluări

- UK FreshTECH Jammer RecipeBook 0Document24 paginiUK FreshTECH Jammer RecipeBook 0Temet NoscheÎncă nu există evaluări

- SRV SLB222 en - 05062020Document2 paginiSRV SLB222 en - 05062020Nguyen ThuongÎncă nu există evaluări

- Capacity Requirement PlanningDocument17 paginiCapacity Requirement PlanningvamsibuÎncă nu există evaluări

- The Benefits of RunningDocument1 paginăThe Benefits of Runningefendi odidÎncă nu există evaluări

- Transmission Line Loading Sag CalculatioDocument25 paginiTransmission Line Loading Sag Calculatiooaktree2010Încă nu există evaluări

- Polikanov 2019-05-14 Curriculum Vitae YuryDocument6 paginiPolikanov 2019-05-14 Curriculum Vitae Yuryapi-460295531Încă nu există evaluări

- Just Another RantDocument6 paginiJust Another RantJuan Manuel VargasÎncă nu există evaluări

- Wes Jackson PM PMP OhioDocument10 paginiWes Jackson PM PMP Ohioraj jdsÎncă nu există evaluări

- AppendicitisDocument7 paginiAppendicitisTim LuoÎncă nu există evaluări

- Citizen's 8651 Manual PDFDocument16 paginiCitizen's 8651 Manual PDFtfriebusÎncă nu există evaluări

- Assignment 2: Loan Submission For Equipment FinanceDocument6 paginiAssignment 2: Loan Submission For Equipment FinanceIT'S SIMPLEÎncă nu există evaluări

- Consent CertificateDocument5 paginiConsent Certificatedhanu2399Încă nu există evaluări

- EDAH EnglishDocument2 paginiEDAH EnglishMaría SanchoÎncă nu există evaluări

- Virtual or Face To Face Classes Ecuadorian University Students' Perceptions During The Pandemic by Julia Sevy-BiloonDocument1 paginăVirtual or Face To Face Classes Ecuadorian University Students' Perceptions During The Pandemic by Julia Sevy-BiloonPlay Dos ChipeadaÎncă nu există evaluări

- Denagard-CTC US Knowledge ReportDocument4 paginiDenagard-CTC US Knowledge Reportnick224Încă nu există evaluări

- Traditional vs. Enterprise Risk Management - How Do They DifferDocument4 paginiTraditional vs. Enterprise Risk Management - How Do They DifferJaveed A. KhanÎncă nu există evaluări

- Hydrogen Production From The Air: Nature CommunicationsDocument9 paginiHydrogen Production From The Air: Nature CommunicationsdfdffÎncă nu există evaluări

- TC 000104 - VSL MadhavaramDocument1 paginăTC 000104 - VSL MadhavaramMK BALAÎncă nu există evaluări

- 1 BSC Iriigation Engineering 2018 19 Std1Document70 pagini1 BSC Iriigation Engineering 2018 19 Std1Kwasi BempongÎncă nu există evaluări

- ResearchDocument13 paginiResearchCHOYSON RIVERALÎncă nu există evaluări

- Ajr.09.2772 Grading Neuroforaminal StenosisDocument4 paginiAjr.09.2772 Grading Neuroforaminal StenosisOscar NogueraÎncă nu există evaluări