Documente Academic

Documente Profesional

Documente Cultură

Aisc Shapes Database v15.0

Încărcat de

Álvaro Chacón GarcíaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Aisc Shapes Database v15.0

Încărcat de

Álvaro Chacón GarcíaDrepturi de autor:

Formate disponibile

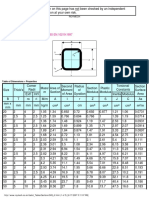

Shape W6X20 W 20.

00 Nominal weight, lb/ft

A 5.87 Cross-sectional area, in.2

d 6.20 Overall depth of member, in

bf 6.02 Flange width, in

tf 0.365 Flange thickness, in

tw 0.26 Web thickness, in

bf/2tf 8.25 Slenderness ratio

h/tw 19.10 Slenderness ratio

Ix 41.40 Moment of inertia about the x-axis, in.4

Zx 14.90 Plastic section modulus about the x-axis, in.3

Sx 13.40 Elastic section modulus about the x-axis, in.3

rx 2.66 Radius of gyration about the x-axis, in.

Iy 13.30 Moment of inertia about the y-axis, in.4

Zy 6.72 Plastic section modulus about the y-axis, in.3

Sy 4.41 Elastic section modulus about the y-axis, in.3

ry 1.50 Radius of gyration about the y-axis in.

J 0.24 Torsional moment of inertia, in.4

Cw 113.00 Warping constant, in.6

L12X12X1-3/8 33.3

L12X12X1-1/4 31.1

L12X12X1-1/8 29.0

L12X12X1 26.5

L10X10X1-3/8 22.0

L10X10X1-1/4 20.5

L10X10X1-1/8 19.1

L10X10X1 17.4

L10X10X7/8 15.9

L10X10X3/4 14.3

L8X8X1-1/8 12.0

L8X8X1 11.0

L8X8X7/8 10.0

L8X8X3/4 8.91

L8X8X5/8 7.73

L8X8X9/16 7.06

L8X8X1/2 6.45

L8X6X1 7.61

L8X6X7/8 6.70

L8X6X3/4 5.85

L8X6X5/8 4.91

L8X6X9/16 4.46

L8X6X1/2 3.98

L8X6X7/16 3.52

L8X4X1 3.45

L8X4X7/8 3.04

L8X4X3/4 2.65

L8X4X5/8 2.24

L8X4X9/16 2.03

L8X4X1/2 1.82

L8X4X7/16 1.61

L7X4X3/4 2.56

L7X4X5/8 2.17

L7X4X1/2 1.75

L7X4X7/16 1.55

L7X4X3/8 1.33

L6X6X1 5.67

L6X6X7/8 5.20

L6X6X3/4 4.64

L6X6X5/8 4.04

L6X6X9/16 3.71

L6X6X1/2 3.42

L6X6X7/16 3.03

L6X6X3/8 2.71

L6X6X5/16 2.30

L6X4X7/8 2.91

L6X4X3/4 2.50

L6X4X5/8 2.12

L6X4X9/16 1.91

L6X4X1/2 1.72

L6X4X7/16 1.51

L6X4X3/8 1.31

L6X4X5/16 1.09

L6X3-1/2X1/2 1.34

L6X3-1/2X3/8 1.02

L6X3-1/2X5/16 0.859

L5X5X7/8 3.44

L5X5X3/4 3.05

L5X5X5/8 2.70

L5X5X1/2 2.31

L5X5X7/16 2.04

L5X5X3/8 1.83

L5X5X5/16 1.57

L5X3-1/2X3/4 1.90

L5X3-1/2X5/8 1.59

L5X3-1/2X1/2 1.30

L5X3-1/2X3/8 0.983

L5X3-1/2X5/16 0.826

L5X3-1/2X1/4 0.665

L5X3X1/2 0.957

L5X3X7/16 0.840

L5X3X3/8 0.727

L5X3X5/16 0.608

L5X3X1/4 0.491

L4X4X3/4 1.81

L4X4X5/8 1.60

L4X4X1/2 1.35

L4X4X7/16 1.22

L4X4X3/8 1.08

L4X4X5/16 0.930

L4X4X1/4 0.778

L4X3-1/2X1/2 1.16

L4X3-1/2X3/8 0.939

L4X3-1/2X5/16 0.806

L4X3-1/2X1/4 0.653

L4X3X5/8 1.13

L4X3X1/2 0.929

L4X3X3/8 0.699

L4X3X5/16 0.590

L4X3X1/4 0.474

L3-1/2X3-1/2X1/2 1.02

L3-1/2X3-1/2X7/16 0.911

L3-1/2X3-1/2X3/8 0.830

L3-1/2X3-1/2X5/16 0.713

L3-1/2X3-1/2X1/4 0.594

L3-1/2X3X1/2 0.846

L3-1/2X3X7/16 0.773

L3-1/2X3X3/8 0.693

L3-1/2X3X5/16 0.602

L3-1/2X3X1/4 0.486

L3-1/2X2-1/2X1/2 0.651

L3-1/2X2-1/2X3/8 0.499

L3-1/2X2-1/2X5/16 0.418

L3-1/2X2-1/2X1/4 0.341

L3X3X1/2 0.704

L3X3X7/16 0.638

L3X3X3/8 0.573

L3X3X5/16 0.497

L3X3X1/4 0.415

L3X3X3/16 0.324

L3X2-1/2X1/2 0.568

L3X2-1/2X7/16 0.521

L3X2-1/2X3/8 0.463

L3X2-1/2X5/16 0.403

L3X2-1/2X1/4 0.329

L3X2-1/2X3/16 0.246

L3X2X1/2 0.411

L3X2X3/8 0.313

L3X2X5/16 0.263

L3X2X1/4 0.214

L3X2X3/16 0.163

L2-1/2X2-1/2X1/2 0.461

L2-1/2X2-1/2X3/8 0.374

L2-1/2X2-1/2X5/16 0.325

L2-1/2X2-1/2X1/4 0.273

L2-1/2X2-1/2X3/16 0.215

L2-1/2X2X3/8 0.295

L2-1/2X2X5/16 0.261

L2-1/2X2X1/4 0.213

L2-1/2X2X3/16 0.162

L2-1/2X1-1/2X1/4 0.120

L2-1/2X1-1/2X3/16 0.0906

L2X2X3/8 0.227

L2X2X5/16 0.200

L2X2X1/4 0.171

L2X2X3/16 0.137

L2X2X1/8 0.100

AISC Shapes Database v15.0

Readme File

November 2017

DISCLAIMER

The information presented in this spreadsheet has been prepared following recognized principles of

construction. While it is believed to be accurate, this information should not be used or relied upon for

application without competent professional examination and verification of its accuracy, suitability and appl

licensed engineer or architect. The publication of this information is not a representation or warranty on th

American Institute of Steel Construction, its officers, agents, employees or committee members, or of any

named herein, that this information is suitable for any general or particular use, or of freedom from infringe

patent or patents. All representations or warranties, express or implied, other than as stated above, ar

disclaimed. Anyone making use of the information presented in this publication assumes all liability arising from

Caution must be exercised when relying upon standards and guidelines developed by other bodies and inc

reference herein since such material may be modified or amended from time to time subsequent to the pr

edition. The American Institute of Steel Construction bears no responsibility for such material other than to r

incorporate it by reference at the time of the initial publication of this edition.

I. Database v15.0

AISC Shapes Database v15.0 is an update to Shapes Database v14.1. This version is consistent with shape properties and dimensions tabul

Steel Construction Manual, 15th Edition, 1st Printing. The database contains some additional section properties that are not included in the

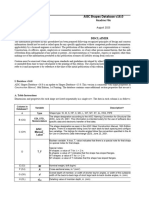

A. Table Instructions

Dimensions and properties for each shape are listed sequentially in a single row. The data in each column is as follows:

Column in

Variable Descriptiona

Databasea

A Type Shape type: W, M, S, HP, C, MC, L, WT, MT, ST, 2L, HSS, PIPE

The shape designation according to the AISC Naming Convention for Structural Steel Products for Use in Ele

EDI_ STD_ Interchange (EDI), June 25, 2001. This information is intended solely for the use of software developers to fac

B (CG)

Nomenclature electronic labeling of shape-specific data and electronic transfer of that data.

The shape designation as seen in the AISC Steel Construction Manual, 15th Edition. The exception to this is

AISC_ for double angles. There is a separate listing (row) for each back-to-back spacing and configuration. Therefor

C (CH) Manual_ designation reflects these two variables. The listings for double angles follow the convention specified in the A

Convention for Structural Steel Products for Use in Electronic Data Interchange (EDI), June 25, 2001.

Label

Boolean variable. A true, T, value indicates that there is a special note for that shape (see below). A false, F, v

that there are no special notes for that shape.

Special notes:

W-shapes: a value of T for: tf > 2 in.

D T_F

M-shapes: a value of T indicates that the shape has sloped flanges.

WT-shapes: a value of T for: tf > 2 in

MT-shapes: a value of T indicates that the shape has sloped flanges.

E (CI) W Nominal weight, lb/ft (kg/m)

F (CJ) A Cross-sectional area, in.2 (mm2)

Overall depth of member, or width of shorter leg for angles, or width of the outstanding legs of long legs back-

G (CK) d angles, or the width of the back-to-back legs of short legs back-to-back double angles, in. (mm)

Shapes Database v15.0

American Institute of Steel Construction

Overall depth of member, or width of shorter leg for angles, or width of the outstanding legs of long legs back-

G (CK) d angles, or the width of the back-to-back legs of short legs back-to-back double angles, in. (mm)

H (CL) ddet Detailing value of member depth, in. (mm)

I (CM) Ht Overall depth of square or rectangular HSS, in. (mm)

J (CN) h Depth of the flat wall of square or rectangular HSS, in. (mm)

K (CO) OD Outside diameter of round HSS or pipe, in. (mm)

L (CP) bf Flange width, in. (mm)

M (CQ) bfdet Detailing value of flange width, in. (mm)

N (CR) B Overall width of square or rectangular HSS, in. (mm)

Width of the flat wall of square or rectangular HSS, or width of the longer leg for angles, or width of the back-t

O (CS) b long legs back-to-back double angles, or width of the outstanding legs of short legs back-to-back double angl

P (CT) ID Inside diameter of round HSS or pipe, in. (mm)

Q (CU) tw Web thickness, in. (mm)

R (CV) twdet Detailing value of web thickness, in. (mm)

S (CW) twdet/2 Detailing value of tw/2, in. (mm)

T (CX) tf Flange thickness, in. (mm)

U (CY) tfdet Detailing value of flange thickness, in. (mm)

V (CZ) t Thickness of angle leg, in. (mm)

W (DA) tnom HSS and pipe nominal wall thickness, in. (mm)

X (DB) tdes HSS and pipe design wall thickness, in. (mm)

Y (DC) kdes Design distance from outer face of flange to web toe of fillet, in. (mm)

Z (DD) kdet Detailing distance from outer face of flange to web toe of fillet, in. (mm)

AA (DE) k1 Detailing distance from center of web to flange toe of fillet, in. (mm)

Horizontal distance from designated member edge, as defined in the AISC Steel Construction Manual, to mem

AB (DF) x axis, in. (mm)

Vertical distance from designated member edge, as defined in the AISC Steel Construction Manual, to memb

AC (DG) y axis, in. (mm)

Horizontal distance from designated member edge, as defined in the AISC Steel Construction Manual, to mem

AD (DH) eo center, in. (mm)

Horizontal distance from designated member edge, as defined in the AISC Steel Construction Manual, to mem

AE (DI) xp neutral axis, in. (mm)

Vertical distance from designated member edge, as defined in the AISC Steel Construction Manual, to memb

AF (DJ) yp axis, in. (mm)

AG (DK) bf/2tf Slenderness ratio

AH (DL) b/t Slenderness ratio for angles

AI (DM) b/tdes Slenderness ratio for square or rectangular HSS

AJ (DN) h/tw Slenderness ratio

AK (DO) h/tdes Slenderness ratio for square or rectangular HSS

AL (DP) D/t Slenderness ratio for round HSS and pipe, or tee shapes

AM (DQ) Ix Moment of inertia about the x-axis, in.4 (mm4 /106)

AN (DR) Zx Plastic section modulus about the x-axis, in.3 (mm3 /103)

AO (DS) Sx Elastic section modulus about the x-axis, in.3 (mm3 /103)

AP (DT) rx Radius of gyration about the x-axis, in. (mm)

AQ (DU) Iy Moment of inertia about the y-axis, in.4 (mm4 /106)

AR (DV) Zy Plastic section modulus about the y-axis, in.3 (mm3 /103)

AS (DW) Sy Elastic section modulus about the y-axis, in.3 (mm3 /103)

Shapes Database v15.0

American Institute of Steel Construction

AT (DX) ry Radius of gyration about the y-axis (with no separation for double angles back-to-back), in. (mm)

AU (DY) Iz Moment of inertia about the z-axis, in.4 (mm4 /106)

AV (DZ) rz Radius of gyration about the z-axis, in. (mm)

AW (EA) Sz Elastic section modulus about the z-axis, in.3 (mm3 /103)

AX (EB) J Torsional moment of inertia, in.4 (mm4 /103)

AY (EC) Cw Warping constant, in.6 (mm6 /109)

AZ (ED) C HSS torsional constant, in.3 (mm3 /103)

BA (EE) Wno Normalized warping function, as used in Design Guide 9, in.2 (mm2)

Warping statical moment at point 1 on cross section, as used in AISC Design Guide 9 and shown in Figures 1

BB (EF) Sw1 (mm4 /106)

Warping statical moment at point 2 on cross section, as used in AISC Design Guide 9 and shown in Figure 2,

BC (EG) Sw2

Warping statical moment at point 3 on cross section, as used in AISC Design Guide 9 and shown in Figure 2,

BD (EH) Sw3

Statical moment for a point in the flange directly above the vertical edge of the web, as used in AISC Design G

BE (EI) Qf (mm3 /103)

BF (EJ) Qw Statical moment for a point at mid-depth of the cross section, as used in AISC Design Guide 9, in.3 (mm3 /103)

BG (EK) ro Polar radius of gyration about the shear center, in. (mm)

BH (EL) H Flexural constant

BI (EM) tan(α) Tangent of the angle between the y-y and z-z axes for single angles, where a is shown in Figure 3

BJ (EN) Iw Moment of inertia about the w-axis for single angles, in.4 (mm4 /106)

BK (EO) zA Distance from point A to center of gravity along z-axis, as shown in Figure 3, in. (mm)

BL (EP) zB Distance from point B to center of gravity along z-axis, as shown in Figure 3, in. (mm)

BM (EQ) zC Distance from point C to center of gravity along z-axis, as shown in Figure 3, in. (mm)

BN (ER) wA Distance from point A to center of gravity along w-axis, as shown in Figure 3, in. (mm)

BO (ES) wB Distance from point B to center of gravity along w-axis, as shown in Figure 3, in. (mm)

BP (ET) wC Distance from point C to center of gravity along w-axis, as shown in Figure 3, in. (mm)

BQ (EU) SwA Elastic section modulus about the w-axis at point A on cross section, as shown in Figure 3, in.3 (mm3 /103)

BR (EV) SwB Elastic section modulus about the w-axis at point B on cross section, as shown in Figure 3, in.3 (mm3 /103)

BS (EW) SwC Elastic section modulus about the w-axis at point C on cross section, as shown in Figure 3, in.3 (mm3 /103)

BT (EX) SzA Elastic section modulus about the z-axis at point A on cross section, as shown in Figure 3, in.3 (mm3 /103)

BU (EY) SzB Elastic section modulus about the z-axis at point B on cross section, as shown in Figure 3, in.3 (mm3 /103)

BV (EZ) SzC Elastic section modulus about the z-axis at point C on cross section, as shown in Figure 3, in.3 (mm3 /103)

BW (FA) rts Effective radius of gyration, in. (mm)

BX (FB) ho Distance between the flange centroids, in. (mm)

Shape perimeter minus one flange surface (or short leg surface for a single angle), as used in Design Guide 1

BY (FC) PA

BZ (FD) PA2 Single angle shape perimeter minus long leg surface, as used in AISC Design Guide 19, in. (mm)

CA (FE) PB Shape perimeter, as used in AISC Design Guide 19, in. (mm)

CB (FF) PC Box perimeter minus one flange surface, as used in Design Guide 19, in. (mm)

CC (FG) PD Box perimeter, as used in AISC Design Guide 19, in. (mm)

CD (FH) T Distance between web toes of fillets at top and bottom of web, in. (mm)

The workable gage for the inner fastener holes in the flange that provides for entering and tightening clearanc

distance and spacing requirements. The actual size, combination, and orientation of fastener components sho

CE (FI) WGi compared with the geometry of the cross section to ensure compatibility. See AISC Manual Part 1 for addition

in. (mm)

Shapes Database v15.0

American Institute of Steel Construction

The bolt spacing between inner and outer fastener holes when the workable gage is compatible with four hole

CF(FJ) WGo flange. See AISC Manual Part 1 for additional information, in. (mm)

a

Values in parentheses "()" is for metric data.

Fig. 1. Location of warping statical Fig. 2. Location of warping statical Fig. 3. Location of Point A, B and C for single a

moment for W-, M-, S- and HP-shapes. moment for C- and MC-shapes.

B. New Shapes in v15.0

Shape Section Size

Type

W W40X655, W36X925, W36X853, W36X802,W36X723, W21X275, W21X248, W21X223, W14X873, W14X808

HP HP12X89

L12X12X1-3/8, L12X12X1-1/4, L12X12X1-1/8, L12X12X1, L10X10X1-3/8, L10X10X1-1/4, L10X10X1-1/8, L10X10X1, L10X10X

L L10X10X3/4

WT20X327.5, WT18X462.5, WT18X426.5, WT18X401, WT18X361.5, WT10.5X137.5, WT10.5X124, WT10.5X111.5, WT7X436

WT

2L12X12X1-3/8, 2L12X12X1-3/8X3/4, 2L12X12X1-3/8X1-1/2, 2L12X12X1-1/4, 2L12X12X1-1/4X3/4, 2L12X12X1-1/4X1-1/2, 2L

2L12X12X1-1/8X3/4, 2L12X12X1-1/8X1-1/2, 2L12X12X1, 2L12X12X1X3/4, 2L12X12X1X1-1/2, 2L10X10X1-3/8, 2L10X10X1-3

2L10X10X1-3/8X1-1/2, 2L10X10X1-1/4, 2L10X10X1-1/4X3/4, 2L10X10X1-1/4X1-1/2, 2L10X10X1-1/8, 2L10X10X1-1/8X3/4, 2L

2L 1/8X1-1/2, 2L10X10X1, 2L10X10X1X3/4, 2L10X10X1X1-1/2, 2L10X10X7/8, 2L10X10X7/8X3/4, 2L10X10X7/8X1-1/2, 2L10X10

2L10X10X3/4X3/4, 2L10X10X3/4X1-1/2

HSS24X12X3/4, HSS24X12X5/8, HSS24X12X1/2, HSS22X22X7/8, HSS22X22X3/4, HSS20X20X7/8, HSS20X20X3/4, HSS20

HSS20X20X1/2, HSS20X12X3/4, HSS18X18X7/8, HSS18X18X3/4, HSS18X18X5/8, HSS18X18X1/2, HSS16X16X7/8, HSS16

HSS HSS16X12X3/4, HSS14X14X7/8, HSS14X14X3/4, HSS12X12X3/4, HSS10X10X3/4

Pipe26STD, Pipe24STD, Pipe20STD, Pipe18STD, Pipe16STD, Pipe14STD, Pipe26XS, Pipe24XS, Pipe20XS, Pipe18XS, Pipe

Pipe Pipe14XS, Pips12XXS, Pipe10XXS

Shapes Database v15.0

American Institute of Steel Construction

C. New Variables in v15.0

· PA2

· Pc

· Pd

·T

· Wgi

· Wgo

D. Variables Removed in v15.0

· Qs

Shapes Database v15.0

American Institute of Steel Construction

recognized principles of design and

e used or relied upon for any specific

curacy, suitability and applicability by a

entation or warranty on the part of the

ittee members, or of any other person

or of freedom from infringement of any

than as stated above, are specifically

umes all liability arising from such use.

d by other bodies and incorporated by

time subsequent to the printing of this

ch material other than to refer to it and

e properties and dimensions tabulated in the AISC

perties that are not included in the Manual.

is as follows:

tural Steel Products for Use in Electronic Data

e use of software developers to facilitate the

a.

h Edition. The exception to this is the designation

pacing and configuration. Therefore, the shape

w the convention specified in the AISC Naming

nge (EDI), June 25, 2001.

at shape (see below). A false, F, value indicates

outstanding legs of long legs back-to-back double

ble angles, in. (mm)

Shapes Database v15.0

American Institute of Steel Construction

g for angles, or width of the back-to-back legs of

ort legs back-to-back double angles, in. (mm)

Steel Construction Manual, to member centroidal

eel Construction Manual, to member centroidal

Steel Construction Manual, to member shear

Steel Construction Manual, to member plastic

eel Construction Manual, to member plastic neutral

Shapes Database v15.0

American Institute of Steel Construction

ack-to-back), in. (mm)

n Guide 9 and shown in Figures 1 and 2, in.4

n Guide 9 and shown in Figure 2, in.4 (mm4 /106)

n Guide 9 and shown in Figure 2, in.4 (mm4 /106)

he web, as used in AISC Design Guide 9, in.3

SC Design Guide 9, in.3 (mm3 /103)

a is shown in Figure 3

, in. (mm)

3, in. (mm)

3, in. (mm)

3, in. (mm)

3, in. (mm)

3, in. (mm)

own in Figure 3, in.3 (mm3 /103)

own in Figure 3, in.3 (mm3 /103)

own in Figure 3, in.3 (mm3 /103)

wn in Figure 3, in.3 (mm3 /103)

wn in Figure 3, in.3 (mm3 /103)

wn in Figure 3, in.3 (mm3 /103)

angle), as used in Design Guide 19, in. (mm)

gn Guide 19, in. (mm)

mm)

or entering and tightening clearances and edge

ntation of fastener components should be

ee AISC Manual Part 1 for additional information,

Shapes Database v15.0

American Institute of Steel Construction

e gage is compatible with four holes across the

on of Point A, B and C for single angles.

4X873, W14X808

0X10X1-1/8, L10X10X1, L10X10X7/8,

.5X124, WT10.5X111.5, WT7X436.5, WT7X404

/4X3/4, 2L12X12X1-1/4X1-1/2, 2L12X12X1-1/8,

/2, 2L10X10X1-3/8, 2L10X10X1-3/8X3/4,

10X1-1/8, 2L10X10X1-1/8X3/4, 2L10X10X1-

/4, 2L10X10X7/8X1-1/2, 2L10X10X3/4,

X20X7/8, HSS20X20X3/4, HSS20X20X5/8,

X18X1/2, HSS16X16X7/8, HSS16X16X3/4,

24XS, Pipe20XS, Pipe18XS, Pipe16XS,

Shapes Database v15.0

American Institute of Steel Construction

Shapes Database v15.0

American Institute of Steel Construction

S-ar putea să vă placă și

- API 650 Tank Design 5Document44 paginiAPI 650 Tank Design 5Inamullah Khan93% (14)

- Design Capacity Tables For Structural Steel Hollow Sections PDFDocument182 paginiDesign Capacity Tables For Structural Steel Hollow Sections PDFDavid Le100% (6)

- Unit 16 Plastic AnalysisDocument34 paginiUnit 16 Plastic AnalysisTam AlasadiÎncă nu există evaluări

- Risa SectionDocument63 paginiRisa Section3cesÎncă nu există evaluări

- Shear Strength of High-Strength BoltsDocument61 paginiShear Strength of High-Strength Boltsloox600Încă nu există evaluări

- Fillet Weld Connection DesignDocument1 paginăFillet Weld Connection Designbalaji gmscÎncă nu există evaluări

- Sleeve Joint Connection Design, For Steel Cell Tower / Sign, Based On AISC 360-10 Input Data & Design SummaryDocument2 paginiSleeve Joint Connection Design, For Steel Cell Tower / Sign, Based On AISC 360-10 Input Data & Design SummaryAmey GudigarÎncă nu există evaluări

- Chequered DesignDocument2 paginiChequered DesignSaravana N100% (1)

- Rectangular Tank Design ROARKS FORMULADocument40 paginiRectangular Tank Design ROARKS FORMULANavasOT100% (2)

- Specification For Structural Steel Buildings ANSI/AISC 360-16 CHAPTER J - Design of ConnectionsDocument9 paginiSpecification For Structural Steel Buildings ANSI/AISC 360-16 CHAPTER J - Design of ConnectionsMr Incognito100% (1)

- M24 DIA Anchor Bolt ReinforcementDocument2 paginiM24 DIA Anchor Bolt ReinforcementYash SutharÎncă nu există evaluări

- Design of Tail LugDocument34 paginiDesign of Tail LugPrajwal Shetty100% (1)

- #160 Lifting Fixture 38tons 020807Document14 pagini#160 Lifting Fixture 38tons 020807halder_kalyan9216Încă nu există evaluări

- Design of 75T Crane Girder for 10m SpanDocument29 paginiDesign of 75T Crane Girder for 10m Spananbukgi100% (2)

- BaseplateDocument3 paginiBaseplateDushyantha JayawardenaÎncă nu există evaluări

- Bolt Shear CapacityDocument12 paginiBolt Shear Capacityrajedmaglinte0% (1)

- "Baseplt9" - Steel Column Base Plate Analysis: Program DescriptionDocument7 pagini"Baseplt9" - Steel Column Base Plate Analysis: Program Descriptionsivasan10006098Încă nu există evaluări

- Eccentric Footing Design Based On ACI 318-14: Input Data Design SummaryDocument3 paginiEccentric Footing Design Based On ACI 318-14: Input Data Design SummaryFatima tuz ZohraÎncă nu există evaluări

- Pipe Support2of 5Document1 paginăPipe Support2of 5Anonymous fLgaidVBhz100% (1)

- Load Combination STEEL - Service (Rev01-2011!02!02)Document429 paginiLoad Combination STEEL - Service (Rev01-2011!02!02)nazeer_mohdÎncă nu există evaluări

- BOLTGRP13Document33 paginiBOLTGRP13NEOÎncă nu există evaluări

- Anchor Design HILTIDocument14 paginiAnchor Design HILTIRohit GadekarÎncă nu există evaluări

- Structural Steelwork Connections: Bolted Gusset Plate Connection For Truss B.S. 5950 Part 1 Calculations & ScketchesDocument4 paginiStructural Steelwork Connections: Bolted Gusset Plate Connection For Truss B.S. 5950 Part 1 Calculations & ScketchessitheeqÎncă nu există evaluări

- Facilities On Offshore Installations: Guide For Building and ClassingDocument209 paginiFacilities On Offshore Installations: Guide For Building and ClassingKarthick VenkatswamyÎncă nu există evaluări

- SOM 2 MarksDocument8 paginiSOM 2 MarksSiva ShanmugamÎncă nu există evaluări

- MC ASD Prying Ref 0Document2 paginiMC ASD Prying Ref 0Roberto Ramirez AlcantarÎncă nu există evaluări

- Bolt TighteningDocument6 paginiBolt TighteningahmedbeaetÎncă nu există evaluări

- Columns DesignDocument60 paginiColumns DesignifsrebraÎncă nu există evaluări

- Square Hollow Sections - Cold FormedDocument5 paginiSquare Hollow Sections - Cold FormedAristotle MedinaÎncă nu există evaluări

- Base Plate ASDDocument7 paginiBase Plate ASDcataiceÎncă nu există evaluări

- Fatigue Analysis and Repair of A High Mast Light Pole: SynopsisDocument14 paginiFatigue Analysis and Repair of A High Mast Light Pole: SynopsisjaffliangÎncă nu există evaluări

- CYPECAD - User's Manual PDFDocument141 paginiCYPECAD - User's Manual PDFBelak1Încă nu există evaluări

- Purlin Designation Input Data: Purlin Geometry: Design of Z PurlinsDocument13 paginiPurlin Designation Input Data: Purlin Geometry: Design of Z Purlinsarif_rubinÎncă nu există evaluări

- Compression Design Section2Document10 paginiCompression Design Section2Anonymous sfkedkymÎncă nu există evaluări

- Calculation B14 039Document158 paginiCalculation B14 039Apichartj JusuayÎncă nu există evaluări

- Aisc Shapes Database v15.0Document14 paginiAisc Shapes Database v15.0ErickSimonÎncă nu există evaluări

- Aisc Shapes Database v15.0Document14 paginiAisc Shapes Database v15.0ErickSimonÎncă nu există evaluări

- "Prying13" - Aisc 13Th Ed. Prying Action Analysis ProgramDocument5 pagini"Prying13" - Aisc 13Th Ed. Prying Action Analysis ProgramNEOÎncă nu există evaluări

- Muk 61 2 PLL 0007 9H8Document34 paginiMuk 61 2 PLL 0007 9H8Suresh MahalingamÎncă nu există evaluări

- Steel Beam Design With Gravity Loading Based On AISC Manual 14th Edition (AISC 360-10)Document22 paginiSteel Beam Design With Gravity Loading Based On AISC Manual 14th Edition (AISC 360-10)AlphaÎncă nu există evaluări

- Heater: Cabine Box 6 MillionDocument2 paginiHeater: Cabine Box 6 MillionMohammed HamedÎncă nu există evaluări

- Design of HSS and Box Member ConnectionsDocument88 paginiDesign of HSS and Box Member ConnectionszcunÎncă nu există evaluări

- Gravity Dam StabilityDocument14 paginiGravity Dam StabilityHarilal Kishan67% (3)

- Connection Design ProcedureDocument3 paginiConnection Design ProcedurewendyÎncă nu există evaluări

- Allowable Thickness Diminution For Hull StructuresDocument13 paginiAllowable Thickness Diminution For Hull Structuresjstoute100% (1)

- Basic Design ValuesDocument4 paginiBasic Design Valuesnenpatel-1Încă nu există evaluări

- Especificacion para Construcciones de Acero - Aisc 360-16Document308 paginiEspecificacion para Construcciones de Acero - Aisc 360-16Armando Farías100% (1)

- Especificacion para Construcciones de Acero - Aisc 360-16Document308 paginiEspecificacion para Construcciones de Acero - Aisc 360-16Armando Farías100% (1)

- Fully Restrained - Moment Connection PDFDocument19 paginiFully Restrained - Moment Connection PDFMauricio RiquelmeÎncă nu există evaluări

- GM7R Tower PhotosDocument9 paginiGM7R Tower PhotosAmlan DasÎncă nu există evaluări

- Exhibition Stand - REV 0Document12 paginiExhibition Stand - REV 0shibu4321Încă nu există evaluări

- Civil Engineering Design GuidelinesDocument37 paginiCivil Engineering Design GuidelinesFcosmeÎncă nu există evaluări

- AISC 13ed - LRFD Bolted Moment Connections Post r4Document614 paginiAISC 13ed - LRFD Bolted Moment Connections Post r4kfischer13Încă nu există evaluări

- Import and Analyze SAP2000 Models in AFESDocument12 paginiImport and Analyze SAP2000 Models in AFESFauzankalibataÎncă nu există evaluări

- Calculating crack width and capacity of a reinforced concrete slabDocument3 paginiCalculating crack width and capacity of a reinforced concrete slabOmar MokhtarÎncă nu există evaluări

- WE-5-2 Fin Plate ConnectionDocument10 paginiWE-5-2 Fin Plate ConnectionPedro AlmeidaÎncă nu există evaluări

- Pile StirrupDocument1 paginăPile Stirrupbuffyto5377Încă nu există evaluări

- Beam AnalDocument7 paginiBeam Analgercho23Încă nu există evaluări

- NODE NO. FOR COMBINED FOOTING CALCULATIONDocument101 paginiNODE NO. FOR COMBINED FOOTING CALCULATIONkumsbamaÎncă nu există evaluări

- Comparision IS VS EURO PDFDocument7 paginiComparision IS VS EURO PDFRadhaKrishnanTÎncă nu există evaluări

- Design of bolts for shear and tensionDocument1 paginăDesign of bolts for shear and tensionRamesh SelvarajÎncă nu există evaluări

- Fixotec Technical CatalogueDocument71 paginiFixotec Technical CatalogueSaqib AliÎncă nu există evaluări

- Project Fire and Service Water Pump Shelter DesignDocument8 paginiProject Fire and Service Water Pump Shelter DesignHabibur RahmanÎncă nu există evaluări

- Steel Beam Flexural CapacityDocument6 paginiSteel Beam Flexural CapacitykstayroskÎncă nu există evaluări

- D 240 02 Calculation ReportDocument21 paginiD 240 02 Calculation Reportmuamer1Încă nu există evaluări

- Dimensional Solutions Mat3DDocument69 paginiDimensional Solutions Mat3DTimothy HancockÎncă nu există evaluări

- 1 Input Data: Profis Anchor 2.7.3Document7 pagini1 Input Data: Profis Anchor 2.7.3RamadanÎncă nu există evaluări

- Consistent determination of flexural and lateral buckling resistanceDocument106 paginiConsistent determination of flexural and lateral buckling resistanceAnonymous hprsT3WlPÎncă nu există evaluări

- ExcelFEM - 2D (For Excel 2007 & Excel 2010)Document2 paginiExcelFEM - 2D (For Excel 2007 & Excel 2010)motiur basumÎncă nu există evaluări

- Analysis of Reinforced Slopes Input Data: ProjectDocument30 paginiAnalysis of Reinforced Slopes Input Data: ProjectNOEL RODRIGUEZÎncă nu există evaluări

- Aisc Shapes Database v16.0Document7 paginiAisc Shapes Database v16.0Mohsen GhiasiÎncă nu există evaluări

- Aisc Database v15Document378 paginiAisc Database v15Samantha BolanteÎncă nu există evaluări

- AISC Shapes Database v15.0 Readme FileDocument635 paginiAISC Shapes Database v15.0 Readme FileFrederick AgliamÎncă nu există evaluări

- QUIZ Aisc Shapes Database v15 1 MarataDocument598 paginiQUIZ Aisc Shapes Database v15 1 MarataRYAN ANGELO MARATAÎncă nu există evaluări

- 14. Aisc Shapes Database v15.0Document8 pagini14. Aisc Shapes Database v15.0JOHN ARTHUR CULQUICONDOR MONDRAGONÎncă nu există evaluări

- Aisc Shapes Database v15.0Document892 paginiAisc Shapes Database v15.0Claire Rizsha QuilonÎncă nu există evaluări

- Aisc Shapes Database v16.0Document890 paginiAisc Shapes Database v16.0Paulo BinayugÎncă nu există evaluări

- KSCE EstimationoftheVibrationServiceabilityDeflectionLimitofaHigh SpeedDocument16 paginiKSCE EstimationoftheVibrationServiceabilityDeflectionLimitofaHigh SpeedÁlvaro Chacón GarcíaÎncă nu există evaluări

- Module 2 Part 2Document18 paginiModule 2 Part 2Edrick BelerÎncă nu există evaluări

- H Sections PDFDocument9 paginiH Sections PDFBouQan EynstenÎncă nu există evaluări

- RUUKKI - Structural Hollow Sections EN10219 - 10 2008 - ENDocument19 paginiRUUKKI - Structural Hollow Sections EN10219 - 10 2008 - ENFlorin CiocanelÎncă nu există evaluări

- Chapter 07 - Composite BeamsDocument21 paginiChapter 07 - Composite BeamsJohn Eduard GallegoÎncă nu există evaluări

- Structural Analysis and Design: STAAD - Pro Steel Design (FAQ)Document19 paginiStructural Analysis and Design: STAAD - Pro Steel Design (FAQ)Suhas NatuÎncă nu există evaluări

- Effective Width Criteria For Composite BeamsDocument7 paginiEffective Width Criteria For Composite BeamsJoey JoejoeÎncă nu există evaluări

- LysaghtZedsCeesPurlinsGirtsUserGuideJune2017 PDFDocument64 paginiLysaghtZedsCeesPurlinsGirtsUserGuideJune2017 PDFAmila KulasooriyaÎncă nu există evaluări

- Aisc Shape W M S and HP Metric SeriesDocument26 paginiAisc Shape W M S and HP Metric SeriesJustine MagnayeÎncă nu există evaluări

- Ce 4560.e01Document7 paginiCe 4560.e01NaifÎncă nu există evaluări

- ClarkDietrich Cold Formed Structural Framing Products Technical Design Guide Technical Notes 1530479Document100 paginiClarkDietrich Cold Formed Structural Framing Products Technical Design Guide Technical Notes 1530479Kris NauthÎncă nu există evaluări

- Cold Formed Steel Design Summary (EN1993) (Runet Software)Document16 paginiCold Formed Steel Design Summary (EN1993) (Runet Software)enriquegarbayoÎncă nu există evaluări

- En 10210-2LLDocument34 paginiEn 10210-2LLnicholas_j_vaughanÎncă nu există evaluări

- Table of Section Properties For IPE, HEA, HEB, HEM Profiles - Eurocode 3Document6 paginiTable of Section Properties For IPE, HEA, HEB, HEM Profiles - Eurocode 3Anonymous RmzEd3jAÎncă nu există evaluări

- Bending of BeamsDocument26 paginiBending of BeamsJovelyn DayonÎncă nu există evaluări

- Validation of reduced moment capacity for UB 406x178x74 beamDocument5 paginiValidation of reduced moment capacity for UB 406x178x74 beamGicuÎncă nu există evaluări