Documente Academic

Documente Profesional

Documente Cultură

Kolokium Zaki

Încărcat de

Rahmat ZakiDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Kolokium Zaki

Încărcat de

Rahmat ZakiDrepturi de autor:

Formate disponibile

IMEN Postgraduate Colloquium 2018

Analysis of Center Hole on Backplate MEMS

Capacitive Microphone

Rahmat Zaki Auliya HM, Burhanuddin Yeop Majlis

Institute of Microengineering and Nanoelectronic (IMEN),

Universiti Kebangsaan Malaysia

43000 Kajang, Selangor, MALAYSIA.

Email : rahmatzaki@siswa.ukm.edu.my

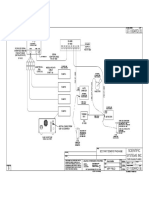

Abstract—Center hole on backplate of MEMS capacitive II. DESIGN OF CENTER HOLE

microphone has been designed and simulated by using finite

element method. Bigger center hole will make higher membrane

displacement and sesnsitivity, but reduce capacitance value due Analysis of center hole effect is made using finite element

to smaller surface area of electrode. method. Cross section of MEMS capacitive microphone with

center hole is shown in figure 1. In order to simplify the

Keywords—MEMS capacitive microphone, center hole, computation, design is made in 2D-axissymmetric dimension.

backplate, sensitivity, membrane displacement. It means membrane and center hole is circle shape. In this

study, membrane radius is 500 µm and membrane thickness is

I. INTRODUCTION 10 µm. Material used as the membrane is silicon with young

Perforated backplate of MEMS capacitive microphone is modulus 170 GPa.

useful due to easy sacrificial etching fabrication technique and

lessen air damping inside the air gap[1]. Furthermore, holes in

backplate can enhance membrane displacement of microphone

because trapped air is able to flow out through holes[2].

However, wide area of holes reduces electrode area on the

surface of backplate and lessens capacitance value obtained

based on equation 1. Hence, total area of holes must be

considered to get optimum result. In equation 1, capacitance

(C) is proportional to total area of electrode (A) and inversely

proportional with distance between two electrodes (d), while

2 4 Fig 1. Cross section of MEMS capacitive micropohone with

𝜀0 is 8.854 x 10-12 𝐴 𝑠 ⁄𝑘𝑔. 𝑚3 and 𝜀𝑟 is dielectric constant

center hole on backplate

between two plates.

𝜀0 𝜀𝑟 𝐴 (1) To understand effect of center hole, radius of hole (G) is

𝐶= varied from 50 µm to 200 µm. Electrodes are placed on

𝑑

membrane and backplate surface. So, it means electrode

surface will be lessen while hole radius is bigger. DC voltage

Numerous approaches have been conducted on MEMS applied into terminal is about 8 V.

capacitive microphone design in order to get better response of III. RESULTS AND DISCUSSION

microphone. Membrane shape and material take a big role on

membrane ability to deflect and also improve sensitivity of Performance of microphone is analyzed along frequency

microphone[3,4]. However, hole shape and size could be audio, 20 Hz until 20 kHz. So, response of membrane can be

designed as well to improve membrane deflection along seen in this human audible range.

audible frequency range. This paper is purposed to study A. Total displacement analysis

effect of hole size on membrane deflection and microphone

Total displacement of center point of membrane is shown

sensitivity. In equation 2, sensitivity is shown by comparison

in figure 3. Maximum membrane displacement is yielded

of output voltage (Vout) with input pressure (Pin).

when hole radius is 200 µm. This is happened because air

𝑉𝑜𝑢𝑡 (2) damping inside the air gap is much decreased when pressure is

𝑆𝑒𝑛𝑠𝑖𝑡𝑖𝑣𝑖𝑡𝑦(𝑑𝐵) = 20𝑙𝑜𝑔10 ( ) applied to surface of membrane.

𝑃𝑖𝑛

IMEN Postgraduate Colloquium 2018

because electrode surface is smaller when hole size is enlarged

as presented in equation 1.

1.00

0.98

0.96

0.94

Capacitance (pF)

0.92

0.90

0.88

Fig 2. Total displacement of membrane microphone with 0.86

different hole radius (G) 0.84

0.82

40 60 80 100 120 140 160 180 200 220

B. Sensitivity analysis Hole radius (um)

Higher sensitivity is achieved by microphone with hole

Fig 4. Capacitance against hole radius

radius 200 µm. From 1 Hz until 1 kHz, sensitivity is -96.91 in

all hole radius size. However, sensitivity is getting higher in

200 µm hole radius, and getting lower in 100 µm and 50 µm IV. CONCLUSIONS

hole radius. This result is related with decreased air damping

in big hole size.

This study is analyzing effect of center hole on backplate of

MEMS capacitive microphone on sensitivity and membrane

displacement. Center hole size has a good effect on membrane

displacement and sensitivity, but on the other hand, it reduce

capacitance value between two electrodes.

REFERENCES

[1] Y. B. Ning, A. W. Mitchell, R.N. Tait, “Fabrication of a silicon

micromachined capacitive microphone using a dry eth process”, Sensors

and Actuators A, vol. 53, pp. 237-242, 1996.

[2] A. Dehe, “ Silicon microphone development and application”, Sensors

and Actuators A, vol. 133, pp. 283-287, 2007.

[3] H. S. Kwon, K. C. Lee, “Double-chip condenser microphone for rigid

Fig 3. Sensitivity of microphone with different hole radius backplate using DRIE and wafer bonding technology”, Sensors and

(G) Actuators A, vol. 138, pp. 81-86, 2007.

[4] P. C. Hsu, C. H. Mastrangelo, K. D. Wise, “A high sensitivity

polysilicon diaphragm condenser microphone”, MEMS conference,

1998.

C. Capacitance analysis

Differ from previous result, capacitance value is decreased

when hole radius is increased as shown in figure 5. This is

S-ar putea să vă placă și

- C7 Cat - Dcs.sis - ControllerDocument2 paginiC7 Cat - Dcs.sis - Controllerrodinei80% (5)

- 07-1004RD 07-1004RD B B: Scientific Systems IncDocument1 pagină07-1004RD 07-1004RD B B: Scientific Systems IncSyed RizviÎncă nu există evaluări

- MEMS Capacitive Microphones: Acoustical, Electrical, and Hidden Thermal-Related IssuesDocument9 paginiMEMS Capacitive Microphones: Acoustical, Electrical, and Hidden Thermal-Related IssuessivakumarÎncă nu există evaluări

- Design of A High Sensitivity FET Integrated MEMS Microphone: Procedia ChemistryDocument4 paginiDesign of A High Sensitivity FET Integrated MEMS Microphone: Procedia Chemistryjeet_charanÎncă nu există evaluări

- 1995 - Novotny, Pohl, Hecht - Scanning Near-Field Optical Probe With Ultrasmall Spot Size - Optics LettersDocument4 pagini1995 - Novotny, Pohl, Hecht - Scanning Near-Field Optical Probe With Ultrasmall Spot Size - Optics LettersClaudio BiaginiÎncă nu există evaluări

- InTech-Mems Silicon MicrophoneDocument17 paginiInTech-Mems Silicon MicrophoneWalter Macasiano GravadorÎncă nu există evaluări

- Design and Fabrication of An Integrated Programmable Floating-Gate MicrophoneDocument4 paginiDesign and Fabrication of An Integrated Programmable Floating-Gate MicrophonedenghueiÎncă nu există evaluări

- Measured Performance of High Gain Dielectric Lens Antenna in 300 GHZ BandDocument2 paginiMeasured Performance of High Gain Dielectric Lens Antenna in 300 GHZ BandPhan HưngÎncă nu există evaluări

- An EMI Estimate For Shielding-Enclosure EvaluationDocument10 paginiAn EMI Estimate For Shielding-Enclosure EvaluationSelin IşıkÎncă nu există evaluări

- Bend Ali 2011Document31 paginiBend Ali 2011Denis JaissonÎncă nu există evaluări

- Improving of Shielding Effectiveness of A RectanguDocument7 paginiImproving of Shielding Effectiveness of A RectanguYasin TunaÎncă nu există evaluări

- Size Determination of Contaminants in HV Xlpe Cable Insulation WDocument4 paginiSize Determination of Contaminants in HV Xlpe Cable Insulation WNoé Rafael Colorado SósolÎncă nu există evaluări

- New Hybrid Mode-Stirring Technique For SE Measurement of Enclosures Using Reverberation ChambersDocument6 paginiNew Hybrid Mode-Stirring Technique For SE Measurement of Enclosures Using Reverberation ChambersSandra GrecoÎncă nu există evaluări

- 8438 2 PDFDocument10 pagini8438 2 PDFMiguel PérezÎncă nu există evaluări

- A Novel Ultra Wideband (UWB) Filter With Double Tunable NotchBands Using MEMS CapacitorsDocument3 paginiA Novel Ultra Wideband (UWB) Filter With Double Tunable NotchBands Using MEMS CapacitorspramodinibidharÎncă nu există evaluări

- Absorbing Photonic Crystals For Thin Film PhotovoltaicsDocument6 paginiAbsorbing Photonic Crystals For Thin Film PhotovoltaicsedirozemberghÎncă nu există evaluări

- Focused High Frequency Ultrasonic Transducers For Minimally Invasive ImagingDocument4 paginiFocused High Frequency Ultrasonic Transducers For Minimally Invasive ImagingdenghueiÎncă nu există evaluări

- 1995 - Novotny, Pohl, Hecht - Scanning Near-Field Optical Probe With Ultrasmall Spot Size - Optics LettersDocument3 pagini1995 - Novotny, Pohl, Hecht - Scanning Near-Field Optical Probe With Ultrasmall Spot Size - Optics LettersClaudio BiaginiÎncă nu există evaluări

- IJEAS0601006Document5 paginiIJEAS0601006MU Strongest ChannelÎncă nu există evaluări

- Acoustic Measurements: M. Vorl AnderDocument31 paginiAcoustic Measurements: M. Vorl AnderDanielRaoÎncă nu există evaluări

- Science 276 5321 2012Document4 paginiScience 276 5321 2012Marcos San MiguelÎncă nu există evaluări

- World Academy of Science, Engineering and Technology 49 2009Document3 paginiWorld Academy of Science, Engineering and Technology 49 2009BarirAs-Syifa'Încă nu există evaluări

- Simple High Gain 60 GHZ AntennaDocument2 paginiSimple High Gain 60 GHZ AntennaQuyền PhạmÎncă nu există evaluări

- Ultra-Thin Wideband Polarization-Insensitive Metasurface Absorber For Aviation TechnologyDocument7 paginiUltra-Thin Wideband Polarization-Insensitive Metasurface Absorber For Aviation TechnologyGHADAÎncă nu există evaluări

- Effects of Ground Plane On A Square Graphene RibboDocument15 paginiEffects of Ground Plane On A Square Graphene RibboRodrigo PaivaÎncă nu există evaluări

- Wang 2020Document2 paginiWang 2020sanaÎncă nu există evaluări

- Challenges With Optically Transparent Patch Antennas For Small SatellitesDocument4 paginiChallenges With Optically Transparent Patch Antennas For Small SatellitesThiripurasundari DÎncă nu există evaluări

- Physics Lab 3 Capacitors PDFDocument4 paginiPhysics Lab 3 Capacitors PDFLawrence Hitucas SalvadorÎncă nu există evaluări

- B&K 4134 and Others in COMSOL PDFDocument74 paginiB&K 4134 and Others in COMSOL PDFasdfÎncă nu există evaluări

- Antennas & Wave Propagation (EC0542) Dr.M.RajuIII I CLDocument3 paginiAntennas & Wave Propagation (EC0542) Dr.M.RajuIII I CLshyamsundermeruguÎncă nu există evaluări

- MEMS Pressure Sensor Array For Aeroacoustic Analysis of The Turbulent Boundary LayerDocument4 paginiMEMS Pressure Sensor Array For Aeroacoustic Analysis of The Turbulent Boundary Layerphantom_nc91Încă nu există evaluări

- Magnetic Cores FOR Hall Effect Devices: Technical BulletinDocument6 paginiMagnetic Cores FOR Hall Effect Devices: Technical BulletinChenaker HamzaÎncă nu există evaluări

- Nagaraja PaperDocument5 paginiNagaraja PaperHasanÎncă nu există evaluări

- 2-A Terahertz Antenna Loaded With Dielectric LensDocument3 pagini2-A Terahertz Antenna Loaded With Dielectric LensBilal MalikÎncă nu există evaluări

- Focusing Microwaves by A Periodic Arrangement of Conducting WiresDocument4 paginiFocusing Microwaves by A Periodic Arrangement of Conducting WirespinoÎncă nu există evaluări

- Vortex Lens: Features ApplicationsDocument2 paginiVortex Lens: Features ApplicationsDu RoyÎncă nu există evaluări

- Re VerbDocument8 paginiRe Verbrobert588Încă nu există evaluări

- A New Efficient Thickness Profile Design Method For Streamlined Airborne RadomesDocument6 paginiA New Efficient Thickness Profile Design Method For Streamlined Airborne RadomesLEANDRO DELGADO AHUMADAÎncă nu există evaluări

- Session 4 Management Covering Blast DesignDocument112 paginiSession 4 Management Covering Blast DesignSebastián MorenoÎncă nu există evaluări

- 50-Khz Capacitive Micromachined Ultrasonic Transducers For Generating Highly Directional Sound With Parametric ArraysDocument4 pagini50-Khz Capacitive Micromachined Ultrasonic Transducers For Generating Highly Directional Sound With Parametric ArraysPoonam KaurÎncă nu există evaluări

- FEM Simulation of CMUT Cell For NDT ApplicationDocument7 paginiFEM Simulation of CMUT Cell For NDT ApplicationShuvam5 GuptaÎncă nu există evaluări

- Optical Characterization of Ultra-High Diffraction Efficiency GratingsDocument8 paginiOptical Characterization of Ultra-High Diffraction Efficiency Gratingscaroluna8007Încă nu există evaluări

- Design and Simulation of E-Shape Microstrip Patch Antenna For Wideband ApplicationsDocument6 paginiDesign and Simulation of E-Shape Microstrip Patch Antenna For Wideband ApplicationshosseinÎncă nu există evaluări

- White Et Al. 2009 Extraordinary Optical Absorption Through Sub Wavelength Slits. Optics LettersDocument3 paginiWhite Et Al. 2009 Extraordinary Optical Absorption Through Sub Wavelength Slits. Optics LettersEMWaveÎncă nu există evaluări

- Khuyen 2017Document7 paginiKhuyen 2017anhtrinhndÎncă nu există evaluări

- Progress in Electromagnetics Research, Vol. 132, 369-388, 2012Document20 paginiProgress in Electromagnetics Research, Vol. 132, 369-388, 2012Pol AlemanyÎncă nu există evaluări

- Espectroscopia 3 inDocument19 paginiEspectroscopia 3 inErika ApazaÎncă nu există evaluări

- Ultra-Wideband Symmetric G-Shape Metamaterial-Based Microwave AbsorberDocument9 paginiUltra-Wideband Symmetric G-Shape Metamaterial-Based Microwave AbsorberGHADAÎncă nu există evaluări

- CAD Cavity Model Analysis of High TC Superconducting Rectangular Patch Printed On Anisotropic SubstratesDocument4 paginiCAD Cavity Model Analysis of High TC Superconducting Rectangular Patch Printed On Anisotropic SubstratesHoucine HoucineÎncă nu există evaluări

- Mezaal 2016Document4 paginiMezaal 2016Ahlam BOUANIÎncă nu există evaluări

- Modelo Antena Conica - Simulação ComSolDocument16 paginiModelo Antena Conica - Simulação ComSolOsvaldo AmorimÎncă nu există evaluări

- My Jases PaperDocument9 paginiMy Jases PaperZainab Baba mallamÎncă nu există evaluări

- Active Temperature Compensation For MEMS CapacitivDocument5 paginiActive Temperature Compensation For MEMS CapacitivSamy OuazineÎncă nu există evaluări

- Analysis of Acoustic Characteristics According To Design Parameter of DiaphragmDocument5 paginiAnalysis of Acoustic Characteristics According To Design Parameter of Diaphragmrajendra_krishna_1Încă nu există evaluări

- Ieee Argencon 2016 Paper 89Document5 paginiIeee Argencon 2016 Paper 89ademargcjuniorÎncă nu există evaluări

- Progress in Electromagnetics Research, Vol. 113, 103-110, 2011Document8 paginiProgress in Electromagnetics Research, Vol. 113, 103-110, 2011Rasheduzzaman SifatÎncă nu există evaluări

- getPDF BDocument7 paginigetPDF BZakwan ZakariahÎncă nu există evaluări

- Wax Retraction As A Technique For Compensating The Effect of Surface Irregularities in High-Energy RadiotherapyDocument9 paginiWax Retraction As A Technique For Compensating The Effect of Surface Irregularities in High-Energy RadiotherapyoomganapathiÎncă nu există evaluări

- Optimized Aperture Load 2023-12-06Document4 paginiOptimized Aperture Load 2023-12-06Yasin TunaÎncă nu există evaluări

- MOS Integrated Circuit DesignDe la EverandMOS Integrated Circuit DesignE. WolfendaleÎncă nu există evaluări

- Shielding of Electromagnetic Waves: Theory and PracticeDe la EverandShielding of Electromagnetic Waves: Theory and PracticeÎncă nu există evaluări

- Motorway Signal Mark 3 (MS3) 02Document2 paginiMotorway Signal Mark 3 (MS3) 02BogdanBÎncă nu există evaluări

- חוברת הפעלה למכונה לגילוף חוטיםDocument22 paginiחוברת הפעלה למכונה לגילוף חוטים208020Încă nu există evaluări

- Honda EPS For F1 CarDocument6 paginiHonda EPS For F1 CarSean ChanÎncă nu există evaluări

- Hoja de Datos Modulo AXIpremiun BLKDocument2 paginiHoja de Datos Modulo AXIpremiun BLKYoslin RuizÎncă nu există evaluări

- EM6400 RegisterMapDocument6 paginiEM6400 RegisterMaprohilla_rohillaÎncă nu există evaluări

- Electrical Safety in The Workplace-Understanding NFPA 70E Annexes and Supplemental Materials-Course 211, Lesson 8Document13 paginiElectrical Safety in The Workplace-Understanding NFPA 70E Annexes and Supplemental Materials-Course 211, Lesson 8Anonymous NwnJNOÎncă nu există evaluări

- Wej Electronic Co.,Ltd: General Purpose Silicon RectifierDocument2 paginiWej Electronic Co.,Ltd: General Purpose Silicon RectifierPaola PaolaÎncă nu există evaluări

- Teletek Intruder Alarm PDFDocument12 paginiTeletek Intruder Alarm PDFBabali MedÎncă nu există evaluări

- L6 Rectifier, PIVDocument25 paginiL6 Rectifier, PIVkaloy33Încă nu există evaluări

- Guide Lines: Field Component ManualDocument21 paginiGuide Lines: Field Component ManualOsman ElmaradnyÎncă nu există evaluări

- Al802Ulada: NAC Power Extender Installation GuideDocument12 paginiAl802Ulada: NAC Power Extender Installation GuideChristine May CagaraÎncă nu există evaluări

- AN764 Debounce SwitchDocument15 paginiAN764 Debounce Switchd.c.delatorre2200Încă nu există evaluări

- Kcap Manual r1.0Document12 paginiKcap Manual r1.0fvozzella3Încă nu există evaluări

- KX-TEA308 Installation ManualDocument86 paginiKX-TEA308 Installation Manualmoky_ro100% (1)

- SpeedStile Installation Guidlines Rev 1Document14 paginiSpeedStile Installation Guidlines Rev 1WERMERMÎncă nu există evaluări

- Energizer L92: Product Datasheet Product DatasheetDocument2 paginiEnergizer L92: Product Datasheet Product DatasheetDot N SpotÎncă nu există evaluări

- Computers As Components 2nd Edi - Wayne WolfDocument815 paginiComputers As Components 2nd Edi - Wayne WolfShubham RajÎncă nu există evaluări

- Dodem DS567 ADSL TesterDocument2 paginiDodem DS567 ADSL TesterSteveÎncă nu există evaluări

- VCBDocument80 paginiVCBPham LongÎncă nu există evaluări

- Zerner DiodeDocument11 paginiZerner DiodeSaurabh RS100% (1)

- Methode of Statement Lightning Protection & Earthing System Review 4Document27 paginiMethode of Statement Lightning Protection & Earthing System Review 4firman zakirÎncă nu există evaluări

- NetSure 211 - 20091105Document2 paginiNetSure 211 - 20091105Michell Quiroz OlivaresÎncă nu există evaluări

- PZ-G PZ-G: Series SeriesDocument2 paginiPZ-G PZ-G: Series SeriesDulce Martinez TolentinoÎncă nu există evaluări

- ps60 SmanualDocument19 paginips60 Smanualaknet99Încă nu există evaluări

- 3.2 Genertaor and Excitation SystemDocument42 pagini3.2 Genertaor and Excitation Systemonur.sezerÎncă nu există evaluări

- Liebert eXM UPS 10-200kVADocument8 paginiLiebert eXM UPS 10-200kVARakhmat Al VarisÎncă nu există evaluări

- ZorcDocument15 paginiZorcputrasejahtraÎncă nu există evaluări