Documente Academic

Documente Profesional

Documente Cultură

Carbozinc 11 PDS

Încărcat de

SUBODHDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Carbozinc 11 PDS

Încărcat de

SUBODHDrepturi de autor:

Formate disponibile

®

Carbozinc 11

PRODUCT DATA SHEET

S E L E C T I O N & S P E C I F I C AT I O N D ATA

Generic Type Solvent Based Inorganic Zinc

Time-tested corrosion resistant primer that protects steel galvanically in the harshest environments.

Description For over five decades, Carbozinc 11 (CZ 11) has been the industry standard for high-performance

inorganic zinc protection on steel structures worldwide.

• Meets Class B slip co-efficient and creep testing criteria for use on faying surfaces.

• Rapid cure. Dry to handle in 45 minutes at 60°F (16°C) and 50% relative humidity.

• Low temperature cure down to 0°F (-18°C).

• High zinc loading.

• Meets FDA requirements.

• Zinc supplied meets ASTM D520 (Type II)*

Features

• Meets SSPC Paint 20 Type I, Level 1 for zinc content.

• Very good resistance to salting.

• May be applied with standard airless or conventional spray equipment.

• VOC compliant in certain areas

*Type III available on special order

Color Green (0300); Gray (0700)

Finish Flat

Primer Self Priming

2 - 3 mils (51 - 76 microns) per coat

Dry Film Thickness

Dry film thickness up to 6.0 mils (150 microns) is acceptable

By Volume 62.3% +/- 2%

Solid(s) Content

Measured in accordance with ASTM D 2697.

Total Zinc Dust in Dry By Weight: 85%

Film

2 2

1000 ft /gal at 1 mil (24.5 m /l at 25 microns) DFT

2 2

Coverage Rate 333 ft /gal at 3 mils (8.2 m /l at 75 microns) DFT

Measured in accordance with ASTM D 2697. Allow for loss in mixing and application.

As Supplied : EPA Method 24: 4.0 lbs./gal (479 g/l)

Thinned:

7 oz/gal w/ Thinner 21: 4.1 lbs./gal (492 g/l)

VOC Values

5 oz/gal w/ Thinner 26: 4.1 lbs./gal (492 g/l)

5 oz/gal w/ Thinner 33: 4.1 lbs./gal (492 g/l)

8 oz/gal w/ Thinner 254: 4.2 lbs./gal (503 g/l)

These are nominal values.

July 2018 0250 Page 1 of 5

®

Carbozinc 11

PRODUCT DATA SHEET

S E L E C T I O N & S P E C I F I C AT I O N D ATA

Untopcoated

Continuous: 750°F (400°C)

Maximum Service Non-Continuous: 800°F (427°C)

Temperature With recommended high heat topcoats:

Continuous: 1000°F (538°C)

Non-Continuous: 1200°F (649°C)

Can be topcoated with Epoxies, Polyurethanes, Acrylics, High-Heat Silicones and others as

recommended by your Carboline sales representative.

Topcoats

Not required for certain exposures. Under certain conditions, a mist coat is required to minimize

topcoat bubbling.

S U B S T R AT E S & S U R F A C E P R E PA R AT I O N

Surfaces must be clean and dry. Employ adequate methods to remove dirt, dust, oil and all other

General

contaminants that could interfere with adhesion of the coating.

Non-Immersion: SSPC-SP6 and obtain a 1.0-3.0 mil (25-75 micron) angular blast profile (Reference

Steel

ASTM D4417)

P E R F O R M A N C E D ATA

Test Method System Results

No blistering or rusting of coating or

AASHTO M300 Bullet Hole

1 ct. CZ11 over Abrasive blasted steel rusting of bare steel area after 650

Immersion Paragraph 4.6.9

hrs. Immersion in 5% sodium chloride.

Blasted Steel 1 ct. CZ 11

ASTM A-325 Slip Co-efficient 0.68; meets requirement for Class B rating

@6 mils (150 microns)

No rusting blistering cracking

1 ct CZ11 at 2 mils dry film

ASTM B117 Salt Spray delamination after 43000 hrs.

thickness over blasted steel.

Moderate salting of the surface only.

ASTM D3363 Pencil Hardness 1 ct. CZ11 Pencil Hardness "2H"

Test reports and additional data available upon written request.

MIXING & THINNING

Power mix base, then combine and power mix as follows. Pour zinc filler very slowly into premixed

base with continuous agitation. Mix until free of lumps. Pour mixture through a 30 mesh screen.

Mixing

Sifting zinc through a screen will aid in the mixing process by breaking up or catching dry zinc

lumps. DO NOT MIX PARTIAL KITS.

May be thinned up to 5 oz/gal (4%) with Thinner 26 or 33 for ambient and warm surfaces. For

extremely warm or windy conditions (above 85°F/29°C)may be thinned up to 8 oz/gal (6%) with

Thinner 254. In cool weather (below 40°F (4°C)), thin up to 7 oz/gal (6%) with Thinner 21. Use of

thinners other than those supplied or recommended by Carboline may adversely affect product

Thinning

performance and void product warranty, whether expressed or implied.

Thinner 216M (while not available in the US) may be used in the Middle East; but its use may

shorten pot life.

July 2018 0250 Page 2 of 5

®

Carbozinc 11

PRODUCT DATA SHEET

MIXING & THINNING

1 Gal. Kit - Part A - .75 gal

1 Gal Kit - Zinc Filler - 14.6lbs

Ratio

5 Gal Kit - Part A - 3.75 gal

5 Gal Kit - Zinc Filler - 73 lbs.

8 Hours at 75°F (24°C) and less at higher temperatures. Pot life ends when coating becomes too

Pot Life

viscous to use.

A P P L I C AT I O N E Q U I P M E N T G U I D E L I N E S

Listed below are general equipment guidelines for the application of this product. Job site conditions may require modifications

to these guidelines to achieve the desired results.

The following spray equipment has been found suitable and is available from equipment

Spray Application manufacturers. Keep material under mild agitation during application. If spraying stops for more

(General) than 10 minutes, recirculate the material remaining in the spray line. Do not leave mixed primer in

the hoses during work stoppages.

Agitated pressure pot equipped with dual regulators, 3/8” I.D. minimum material hose, with a

Conventional Spray

maximum length of 50 feet; 0.070” I.D. fluid tip and appropriate air cap.

Pump Ratio: 30:1 (min.)

GPM Output: 3.0 (min.)

Material Hose: 3/8” I.D. (min.)

Airless Spray

Tip Size: 0.019-0.023”

Output PSI: 1500-2000 Filter Size: 60 mesh

PTFE packings are recommended and available from the pump manufacturer.

For touch-up of areas less than one square foot only. Use medium bristle brush and avoid

Brush

rebrushing.

Roller Not recommended.

A P P L I C AT I O N C O N D I T I O N S

Condition Material Surface Ambient Humidity

Minimum 0°F (-18°C) 0°F (-18°C) 0°F (-18°C) 30%

Maximum 130°F (54°C) 200°F (93°C) 130°F (54°C) 95%

This product simply requires the substrate temperature to be above the dew point. Condensation due to substrate temperatures

below the dew point can cause flash rusting on prepared steel and interfere with proper adhesion to the substrate. Special

application techniques may be required above or below normal application conditions.

July 2018 0250 Page 3 of 5

®

Carbozinc 11

PRODUCT DATA SHEET

CURING SCHEDULE

Dry to Recoat & Topcoat

Surface Temp. Dry to Handle

w/ other finishes

0°F (-18°C) 4 Hours 7 Days

40°F (4°C) 1 Hour 48 Hours

60°F (16°C) 45 Minutes 24 Hours

80°F (27°C) 45 Minutes 18 Hours

100°F (38°C) 15 Minutes 16 Hours

These times are based on a 3.0-4.0 mil (75-100 micron) dry film thickness. Higher film thickness, insufficient ventilation or cooler

temperatures will require longer cure times and could result in solvent entrapment and premature failure. Humidity levels below

50% will require longer cure times. Notes: Maximum recoat time is unlimited. Must have a clean, dry surface free of chalk, zinc

salts, etc per typical good painting practices. Consult Carboline Technical Service for specific information. Also, loose zinc must

be removed from the cured film by rubbing with fiberglass screen wire if: 1) The Carbozinc 11 is to be used without a topcoat in

immersion service and "zinc pick up" could be detrimental, or 2) When "dry spray/overspray" is evident on the cured film and a

topcoat will be applied. For accelerated curing or where the relative humidity is below 40%, allow an initial 2-hour ambient

cure. Follow 2 hour cure with water misting or steam to keep the coated surface wet for a minimum of 8 hours and until the coated

surface achieves a "2H" pencil hardness per ASTM D3363.

CLEANUP & SAFETY

Use Thinner 21 or Isopropyl Alcohol. In case of spillage, absorb and dispose of in accordance with

Cleanup

local applicable regulations.

Read and follow all caution statements on this product data sheet and on the SDS for this product.

Safety

Employ normal workmanlike safety precautions.

When used as a tank lining or in enclosed areas, thorough air circulation must be used during and

after application until the coating is cured. The ventilation system should be capable of preventing

Ventilation the solvent vapor concentration from reaching the lower explosion limit for the solvents used. In

addition to ensuring proper ventilation, appropriate respirators must be used by all application

personnel.

PA C K A G I N G , H A N D L I N G & S T O R A G E

Part A: 12 months at 75°F (24°C)

Part B: 24 months at 75°F (24°C)

Shelf Life

*Shelf Life: (actual stated shelf life) when kept at recommended storage conditions and in original

unopened containers.

Storage Temperature & 40° -100°F (4-38°C).

Humidity 0-90% Relative Humidity

Store Indoors.

Storage This product is solvent based and not affected by excursions below these published storage

temperatures, down to 10°F, for a duration of no more than 14 days. Always inspect the product

prior to use to make sure it is smooth and homogeneous when properly mixed.

Shipping Weight 1 Gallon Kit - 23 lbs (10 kg)

(Approximate) 5 Gallon Kit - 113 lbs (51 kg)

Part A: 55°F (13°C)

Flash Point (Setaflash)

Zinc Filler: NA

July 2018 0250 Page 4 of 5

®

Carbozinc 11

PRODUCT DATA SHEET

WA R R A N T Y

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject

to change without prior notice. User must contact Carboline Company to verify correctness before specifying or ordering. No

guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no

responsibility for coverage, performance, injuries or damages resulting from use. Carbolines sole obligation, if any, is to replace

or refund the purchase price of the Carboline product(s) proven to be defective, at Carbolines option. Carboline shall not be liable

for any loss or damage. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE, EXPRESS OR

IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. All of the trademarks referenced above are the property of Carboline International Corporation unless

otherwise indicated.

July 2018 0250 Page 5 of 5

S-ar putea să vă placă și

- Carbozinc 858: Selection & Specification DataDocument4 paginiCarbozinc 858: Selection & Specification DataNico RoisnerÎncă nu există evaluări

- Interfine 691: Isocyanate-Free FinishDocument4 paginiInterfine 691: Isocyanate-Free FinishTrịnh Minh KhoaÎncă nu există evaluări

- Versiline Cui 56690Document4 paginiVersiline Cui 56690Luciano SalituriÎncă nu există evaluări

- Interzinc 52: Epoxy Zinc-RichDocument4 paginiInterzinc 52: Epoxy Zinc-RichKrishna VachaÎncă nu există evaluări

- Interzinc 52 TDSDocument4 paginiInterzinc 52 TDSDele TedÎncă nu există evaluări

- CODE Book List For PileDocument2 paginiCODE Book List For PileKaleeswari GÎncă nu există evaluări

- Primevera p6,8.2Document8 paginiPrimevera p6,8.2AftabAhmedBhattiÎncă nu există evaluări

- Ratliperl: The Modern Solution For Energy Efficient BuildingDocument20 paginiRatliperl: The Modern Solution For Energy Efficient BuildingChris BothaÎncă nu există evaluări

- Technical Specification For Auxiliary Cooling TowerDocument7 paginiTechnical Specification For Auxiliary Cooling TowerAnonymous vwbLPTpj100% (2)

- Austrian Practice of Natm Tunnelling Contracts AnnexDocument24 paginiAustrian Practice of Natm Tunnelling Contracts AnnexarslanpasaÎncă nu există evaluări

- FINAL Korea Japan China For GCE Blue Maritime Presentation PDFDocument61 paginiFINAL Korea Japan China For GCE Blue Maritime Presentation PDFyeÎncă nu există evaluări

- Mastertop 290: Iron Aggregate Hardener For Concrete FloorsDocument3 paginiMastertop 290: Iron Aggregate Hardener For Concrete FloorsFrancois-Încă nu există evaluări

- Electrically Dissipating Mortar for Tiling and Brick LiningsDocument2 paginiElectrically Dissipating Mortar for Tiling and Brick Liningsshankarkl100% (1)

- Emulsion Polymers For Soil StabilizationDocument18 paginiEmulsion Polymers For Soil StabilizationYuliusRiefAlkhalyÎncă nu există evaluări

- V001t02a007 Ipc2000 117Document10 paginiV001t02a007 Ipc2000 117zafarbadalÎncă nu există evaluări

- SLS 515.2003 Specification For Masonary CementDocument46 paginiSLS 515.2003 Specification For Masonary Cementisuru samaranayakeÎncă nu există evaluări

- Concrete Pavements and Linings Installed in Corrugated Steel Structures in The FieldDocument4 paginiConcrete Pavements and Linings Installed in Corrugated Steel Structures in The FieldDarwin Darmawan100% (1)

- LNG Seis GuideDocument66 paginiLNG Seis GuideDeepak KukretyÎncă nu există evaluări

- Refinery Cooling Plant SpecificationDocument8 paginiRefinery Cooling Plant SpecificationHatem ShawkiÎncă nu există evaluări

- Corrosion and Protection For Steel Pile: Yoshikazu Akira, Dr. EngDocument45 paginiCorrosion and Protection For Steel Pile: Yoshikazu Akira, Dr. EngAnand JadoenathmisierÎncă nu există evaluări

- Building Vertical Steel Tank FoundationsDocument12 paginiBuilding Vertical Steel Tank Foundationskaushik arunexcelloÎncă nu există evaluări

- Series 5000C Fiberglass Fiberlgass Pipe and Fittin PDFDocument8 paginiSeries 5000C Fiberglass Fiberlgass Pipe and Fittin PDFsandbadbahriÎncă nu există evaluări

- Properties and Testing of Concrete Materials - 80 PagesDocument11 paginiProperties and Testing of Concrete Materials - 80 PagessintayehuÎncă nu există evaluări

- RCC Chimney - CICIND CommentaryDocument65 paginiRCC Chimney - CICIND CommentaryVasanth KumarÎncă nu există evaluări

- Masterseal 588: Description Packaging and ColorsDocument2 paginiMasterseal 588: Description Packaging and ColorsmariaÎncă nu există evaluări

- Grout CatalogDocument36 paginiGrout CatalogJohneey DeepÎncă nu există evaluări

- BoilersDocument60 paginiBoilersعلي حسين علاوي ثوينيÎncă nu există evaluări

- Acceptance of Concrete Cube Test ResultsDocument3 paginiAcceptance of Concrete Cube Test ResultsNino Celso AstilleroÎncă nu există evaluări

- Asphalt Patching PDFDocument140 paginiAsphalt Patching PDFKarina Benavides BurgosÎncă nu există evaluări

- BS en 14620-3-2006 Part 3 Concrete ComponentsDocument24 paginiBS en 14620-3-2006 Part 3 Concrete ComponentsThụÎncă nu există evaluări

- Intumescent PFP Vs Lightweight Cementious BrochureDocument4 paginiIntumescent PFP Vs Lightweight Cementious BrochureKalaiRazBalanÎncă nu există evaluări

- Specification For The Use of Steel Tanks in The Water Industry PDFDocument15 paginiSpecification For The Use of Steel Tanks in The Water Industry PDFJorge Alberto Martinez OrtizÎncă nu există evaluări

- CNC Oxyacetylene Flame Cutting MachineDocument12 paginiCNC Oxyacetylene Flame Cutting MachineNaman JoharÎncă nu există evaluări

- Sikatherm® Foam 45 IN: Product Data SheetDocument4 paginiSikatherm® Foam 45 IN: Product Data SheetTarun KumarÎncă nu există evaluări

- Compressed Gases and Cryogenic Fluids CodeDocument5 paginiCompressed Gases and Cryogenic Fluids Codesudarshan jalluriÎncă nu există evaluări

- Prodorlac SPLDocument2 paginiProdorlac SPLkhrisna.dipa.utama50% (2)

- Basalt Rock Fiber Seminar ReportDocument25 paginiBasalt Rock Fiber Seminar Reportsaqib mujtabaÎncă nu există evaluări

- Increased use of clay pozzolana for cement productionDocument15 paginiIncreased use of clay pozzolana for cement productionsolomonayehÎncă nu există evaluări

- GroutDocument21 paginiGroutraahul_nÎncă nu există evaluări

- Concrete Coatings GuideDocument38 paginiConcrete Coatings GuiderudaqqeweeweweÎncă nu există evaluări

- Government Gazette - 18th October PADocument52 paginiGovernment Gazette - 18th October PAistructe100% (1)

- Seala Tank Belzona Application Procedure For Tank Base Corrosion Protect...Document2 paginiSeala Tank Belzona Application Procedure For Tank Base Corrosion Protect...mspÎncă nu există evaluări

- Compaction: Prof. (DR) K.S. WaghDocument60 paginiCompaction: Prof. (DR) K.S. WaghAshish KondalwadeÎncă nu există evaluări

- 1-Intro GFRP-RC 08102020Document74 pagini1-Intro GFRP-RC 08102020Mustufa F KanjetaÎncă nu există evaluări

- BY: Nagesh HDocument47 paginiBY: Nagesh HSilva NumaÎncă nu există evaluări

- Rilem Ii.4Document4 paginiRilem Ii.4manil_5Încă nu există evaluări

- Effect of Different Sand Grading On Strength Properties of Cement Grout PDFDocument8 paginiEffect of Different Sand Grading On Strength Properties of Cement Grout PDFyoussefÎncă nu există evaluări

- Material Safety Data Sheet: WAXTREAT 16707Document25 paginiMaterial Safety Data Sheet: WAXTREAT 16707n.hartono100% (1)

- Basf Masterprotect 1815 TdsDocument3 paginiBasf Masterprotect 1815 TdsEngTamer100% (1)

- Natural Gas Storage TankDocument10 paginiNatural Gas Storage TankSurya Budi WidagdoÎncă nu există evaluări

- Technical Datasheet HUS4 Technical Information ASSET DOC 16702828Document25 paginiTechnical Datasheet HUS4 Technical Information ASSET DOC 16702828James100% (1)

- Front-End Engineering - WikipediaDocument3 paginiFront-End Engineering - Wikipediakirthi83100% (1)

- 0693 Bs2752 c50 50 Shore Specification Neoprene Chloroprene CR Rubber SheetDocument2 pagini0693 Bs2752 c50 50 Shore Specification Neoprene Chloroprene CR Rubber SheetSerboÎncă nu există evaluări

- Basf Masterflow 950 TdsDocument3 paginiBasf Masterflow 950 TdsplmoÎncă nu există evaluări

- Reliability of Core TestDocument16 paginiReliability of Core TestAdesh RamnarineÎncă nu există evaluări

- Webforge Expanded Mesh BrochureDocument20 paginiWebforge Expanded Mesh BrochureKin Siang YapÎncă nu există evaluări

- Thermal Stresses and Temperature Control of Mass ConcreteDe la EverandThermal Stresses and Temperature Control of Mass ConcreteÎncă nu există evaluări

- Fluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984De la EverandFluid Mixing II: A Symposium Organised by the Yorkshire Branch and the Fluid Mixing Processes Subject Group of the Institution of Chemical Engineers and Held at Bradford University, 3-5 April 1984Încă nu există evaluări

- Corrosion Failures: Theory, Case Studies, and SolutionsDe la EverandCorrosion Failures: Theory, Case Studies, and SolutionsÎncă nu există evaluări

- Carbozinc 11: Selection & Specification DataDocument5 paginiCarbozinc 11: Selection & Specification DatajoehodohÎncă nu există evaluări

- Bill No.85Document1 paginăBill No.85SUBODHÎncă nu există evaluări

- For Individuals & Trusts: Valid For The Period October 14 - 31, 2022Document1 paginăFor Individuals & Trusts: Valid For The Period October 14 - 31, 2022SUBODHÎncă nu există evaluări

- JEE 24 TJ 1 BATCH (17-10-22 To 23-10-22)Document1 paginăJEE 24 TJ 1 BATCH (17-10-22 To 23-10-22)SUBODHÎncă nu există evaluări

- Pa 5 PDFDocument11 paginiPa 5 PDFSUBODHÎncă nu există evaluări

- Quality Management EssentialsDocument32 paginiQuality Management EssentialsSUBODH100% (1)

- X 0 OMBF0 D E88 Na DLCDocument14 paginiX 0 OMBF0 D E88 Na DLCSUBODHÎncă nu există evaluări

- AllZones Change of TPA Retirees 221104 145127Document3 paginiAllZones Change of TPA Retirees 221104 145127SUBODHÎncă nu există evaluări

- Economic Considerations For Industrial Coating Projects: Scope and ObjectivesDocument40 paginiEconomic Considerations For Industrial Coating Projects: Scope and ObjectivesSUBODH100% (2)

- Stock SelectionDocument2 paginiStock SelectionSUBODHÎncă nu există evaluări

- B Tech Integrated - Imp Dates Phase-331522Document1 paginăB Tech Integrated - Imp Dates Phase-331522SUBODHÎncă nu există evaluări

- Safety and Environmental Concerns For Owners and Coating ContractorsDocument34 paginiSafety and Environmental Concerns For Owners and Coating ContractorsSUBODHÎncă nu există evaluări

- Coating Failures - Causes, Identification, and AnalysisDocument36 paginiCoating Failures - Causes, Identification, and AnalysisSUBODH100% (1)

- Application Form 1Document7 paginiApplication Form 1SUBODHÎncă nu există evaluări

- Roles and Responsibilities of Contracting Parties Scope and ObjectivesDocument40 paginiRoles and Responsibilities of Contracting Parties Scope and ObjectivesSUBODH100% (1)

- Preparing, Awarding, and Managing Coating ContractsDocument24 paginiPreparing, Awarding, and Managing Coating ContractsSUBODH100% (1)

- Anita Moorjani's compelling story of healing from cancer through her near-death experienceDocument6 paginiAnita Moorjani's compelling story of healing from cancer through her near-death experienceMyself Noor100% (6)

- Specifications For Coatings Projects: Scope and ObjectivesDocument40 paginiSpecifications For Coatings Projects: Scope and ObjectivesSUBODH100% (2)

- Checklist For Corrosion ControlDocument30 paginiChecklist For Corrosion ControlAli AkramÎncă nu există evaluări

- Tsa Applicator Qualification Iso+14918-1998Document32 paginiTsa Applicator Qualification Iso+14918-1998Subodh Kulkarni100% (3)

- CH 01.02 Struc Design PDFDocument7 paginiCH 01.02 Struc Design PDFSUBODHÎncă nu există evaluări

- English Poem 8aDocument1 paginăEnglish Poem 8aSUBODHÎncă nu există evaluări

- SSPC Protective Coatings Inspector (PCI) Program Workshop Booklet Version 1, May 2005Document3 paginiSSPC Protective Coatings Inspector (PCI) Program Workshop Booklet Version 1, May 2005SUBODHÎncă nu există evaluări

- 2011 Bookmatter IntroductionToArtificialIntellDocument11 pagini2011 Bookmatter IntroductionToArtificialIntellSUBODHÎncă nu există evaluări

- BookReviewonNear DeathExperience2012 PDFDocument6 paginiBookReviewonNear DeathExperience2012 PDFSUBODHÎncă nu există evaluări

- Steel Shot Grit SizingDocument2 paginiSteel Shot Grit SizingSUBODHÎncă nu există evaluări

- Intertherm 898CSA: Heat Resistant Cold Spray AluminiumDocument4 paginiIntertherm 898CSA: Heat Resistant Cold Spray AluminiumSUBODHÎncă nu există evaluări

- Sumi PDFDocument6 paginiSumi PDFSUBODHÎncă nu există evaluări

- Oil Refinery Waste Treatment MethodsDocument2 paginiOil Refinery Waste Treatment MethodsSUBODHÎncă nu există evaluări

- Case StudyDocument21 paginiCase StudySUBODH100% (1)

- 777GDocument15 pagini777GJuan Ricardo Bolivar Pilco100% (1)

- Shutdown Maintenance Raw Mill Section July 2017Document3 paginiShutdown Maintenance Raw Mill Section July 2017vinodsnÎncă nu există evaluări

- Construction, Working, Operation and Maintenance of ESPsDocument91 paginiConstruction, Working, Operation and Maintenance of ESPsWill KisekiÎncă nu există evaluări

- Process Instrumentation Control ExamDocument2 paginiProcess Instrumentation Control ExamVinay DograÎncă nu există evaluări

- GrantPrideco Drill Pipe Data TablesDocument24 paginiGrantPrideco Drill Pipe Data TablesMaximo Biarrieta RodriguezÎncă nu există evaluări

- CNSLDocument18 paginiCNSLrafeekÎncă nu există evaluări

- IGNOU-HHML Motorcycle Technician Competency Development ProgrammeDocument25 paginiIGNOU-HHML Motorcycle Technician Competency Development Programmekulshreshtha_mÎncă nu există evaluări

- Catalogo Yg-1 2009 - CarburoDocument33 paginiCatalogo Yg-1 2009 - Carburo13pimoÎncă nu există evaluări

- Design of Bituminous Mixtures: Test Procedure ForDocument40 paginiDesign of Bituminous Mixtures: Test Procedure ForAlhilali ZiyadÎncă nu există evaluări

- Bill of Materials Northgate TownhouseDocument4 paginiBill of Materials Northgate TownhouseJohnÎncă nu există evaluări

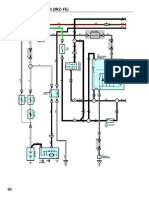

- Starting and Ignition (3RZ-FE)Document4 paginiStarting and Ignition (3RZ-FE)Esteban Lefont100% (1)

- Crop Production and Management-Solved ExercisesDocument4 paginiCrop Production and Management-Solved ExercisesSbs ReddyÎncă nu există evaluări

- Construction Machines & Equipment GuideDocument48 paginiConstruction Machines & Equipment GuideKlemen KavčičÎncă nu există evaluări

- TSEK36 Labmanual 2009 SE v1Document47 paginiTSEK36 Labmanual 2009 SE v1Syamak KashfolayatÎncă nu există evaluări

- Royal Military College of Science - Cranfield University: ReliabilityDocument4 paginiRoyal Military College of Science - Cranfield University: ReliabilitySanjay MehrishiÎncă nu există evaluări

- Heat Setting Fabrics for Dimensional StabilityDocument5 paginiHeat Setting Fabrics for Dimensional StabilityFathi MustafaÎncă nu există evaluări

- PQC and DLC AnalysisDocument6 paginiPQC and DLC AnalysisLalkiran VaddeÎncă nu există evaluări

- Oaj Issue2 Kazan FinalDocument9 paginiOaj Issue2 Kazan FinalfcordÎncă nu există evaluări

- 2 - Introduction To The ME Engine PDFDocument14 pagini2 - Introduction To The ME Engine PDFVikash Khaliyav Yadav50% (2)

- LG gr-349 389 SQF PDFDocument41 paginiLG gr-349 389 SQF PDFionagyb100% (1)

- Accordion Fold Book: by Diane Weintraub and Kathy MillerDocument2 paginiAccordion Fold Book: by Diane Weintraub and Kathy Millerapi-25909634Încă nu există evaluări

- Pressure Test CertificateDocument1 paginăPressure Test CertificateSopi LabuÎncă nu există evaluări

- 4812159895Document642 pagini4812159895El Aleman0% (1)

- Standard Bearhawk Fuselage Tube Inventory ListDocument1 paginăStandard Bearhawk Fuselage Tube Inventory ListdiegoalnsÎncă nu există evaluări

- Jit and Lean OperationsDocument8 paginiJit and Lean OperationsIvyJoyce100% (1)

- CDX mp30Document48 paginiCDX mp30sonicman23Încă nu există evaluări

- Appliances Picture Flashcards by Learnwell OyDocument7 paginiAppliances Picture Flashcards by Learnwell OyVeronicaGelfgren100% (3)

- En The New Polo 1.0 TSI, Petrol Engine 85 KW Six-Speed Manual GearboxDocument1 paginăEn The New Polo 1.0 TSI, Petrol Engine 85 KW Six-Speed Manual GearboxrobbertmdÎncă nu există evaluări

- Esaote P80i User Manual PDFDocument50 paginiEsaote P80i User Manual PDFJ NarvaezÎncă nu există evaluări

- HeinDocument4 paginiHeinRam BabuÎncă nu există evaluări