Documente Academic

Documente Profesional

Documente Cultură

Concrete Technology Lec01: Compressive & Tensile Stress

Încărcat de

faizanDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Concrete Technology Lec01: Compressive & Tensile Stress

Încărcat de

faizanDrepturi de autor:

Formate disponibile

CONCRETE TECHNOLOGY

Lec#01

CONCRETE:

Concrete is a composite material wherein a binding material mixed in water on

solidification binds the inert particles of well graded fine and coarse aggregate.

Freshly prepared concrete till it has not yet set is called wet or green

concrete.

After it has thoroughly set and fully hardened it is called set or just concrete.

Concrete = Cement + Sand (Fine Aggregate) + Stone ballast/gravel (Coarse

aggregate) + Water

CLASSIFICATION:

Based on cementing material used, Concretes are classified as lime concrete and

cement concrete.

1) Lime concrete: It is a mixture of lime mortar and coarse aggregate. In lime

concrete, lime is used as a binding material, but this type of concrete is not

used nowadays because the setting time is very slow as it requires CO2 for

hardening and gains strength in time greater than the time in which cement

concrete gains same value of strength. Also, it takes a long time to cure

which is very time consuming and uneconomical.

2) Cement Concrete: It is a composite material wherein a paste of cement,

made with water, on solidification binds firmly together the various particles

of inert materials like sand and stone ballast. The inert materials called

“aggregate” is well graded in size from fine sand to pebbles or stone ballast

or brick ballast.

Cement concrete is an extremely versatile material of construction which is

used for variety of works ranging from small drains and cottages to massive

bridges and dams. Cement concrete is quite strong in compression but weak

in tension. To make good this deficiency of concrete, steel bars

(reinforcement) are embedded in concrete which is known as reinforced

cement concrete (R.C.C). Concrete without reinforcement is known as plain

cement concrete (P.C.C).

COMPRESSIVE & TENSILE STRESS:

The two basic types of physical stress are compressive stress and tensile

stress. Consider a length of material, be it a stone slab, steel bar, or piece of

lumber. If one were to hold each end of the material and squeeze, one would

exert compressive force.

If, however, one were to pull outward (as though one were trying to stretch

the material), one would exert tensile force.

SELECTION OF MATERIAL

Concrete forming materials should be carefully selected to get quality

concrete:

1) Cement: Normally ordinary Portland cement satisfying requirements of

Indian standard institution is used. However, for special condition the

type of cement suiting the requirement to be used.

Cement being hygroscopic, attracts moisture quickly and sets. So, storage

of cement should be carefully attended and no set or partially set cement

should be used.

2) Fine aggregates: Sand is commonly used as fine aggregate in cement

concrete. Particles of fine aggregate range from 4.75mm to 0.15mm in

size.

3) Coarse aggregates: Those aggregates whose particle size is bigger than

4.75mm and less than 7.5mm are called coarse aggregates. Usually stone

ballast, gravel and brick ballast are used as coarse aggregates.

4) Water: Only good clean water should be used for making concrete. It

should be free from silt, salt or any organic matter. The most suitable

water for concrete preparation is the drinking water.

S-ar putea să vă placă și

- Solution of Estimation in Building ConstructionDocument24 paginiSolution of Estimation in Building Constructionfaizan83% (6)

- Solution of Estimation in Building ConstructionDocument24 paginiSolution of Estimation in Building Constructionfaizan83% (6)

- Estimating Construction Cost by PurefoyDocument614 paginiEstimating Construction Cost by Purefoyfaizan100% (1)

- BPO2-Module 9 PROJECT PLANDocument16 paginiBPO2-Module 9 PROJECT PLANJudame Charo ZozobradoÎncă nu există evaluări

- DEALERS WITH INTERSTATE SALES AND EXPORTS UNDER RS. 3 CROREDocument567 paginiDEALERS WITH INTERSTATE SALES AND EXPORTS UNDER RS. 3 CRORETanmoy RoyÎncă nu există evaluări

- Xypex Chemical Corporation WaterproofingDocument292 paginiXypex Chemical Corporation WaterproofingalbijayÎncă nu există evaluări

- Cs15 Gas Tank Cleaning Degassing 1997Document12 paginiCs15 Gas Tank Cleaning Degassing 1997kirandevi1981100% (2)

- Hoarding Guide 2020Document46 paginiHoarding Guide 2020Mohammed HafizÎncă nu există evaluări

- Technical Report PDFDocument184 paginiTechnical Report PDFSrinivasan RajenderanÎncă nu există evaluări

- HW03 5ad S19 PDFDocument2 paginiHW03 5ad S19 PDFbobÎncă nu există evaluări

- Long Working Time Epoxy MortarDocument1 paginăLong Working Time Epoxy MortarbradleyrobinsonÎncă nu există evaluări

- 09 - TDS - Masterflow 928T PDFDocument5 pagini09 - TDS - Masterflow 928T PDFGibbs PerÎncă nu există evaluări

- Renderoc PlugDocument3 paginiRenderoc Plugtalatzahoor100% (1)

- Tankguard Brochure - tcm189 1612Document8 paginiTankguard Brochure - tcm189 1612RomankoÎncă nu există evaluări

- ConcreteDocument3 paginiConcreteTran DtrungÎncă nu există evaluări

- Anquamine 731Document4 paginiAnquamine 731Cloudy DayÎncă nu există evaluări

- ECMALON - High Performance ResinsDocument5 paginiECMALON - High Performance ResinsNagendra GuptaÎncă nu există evaluări

- High Solid PU Dispersion FormulationDocument3 paginiHigh Solid PU Dispersion FormulationBudhi NuryantoÎncă nu există evaluări

- Liquid Applied Waterproofing - ProtectowrapDocument3 paginiLiquid Applied Waterproofing - ProtectowrapYndia SorianoÎncă nu există evaluări

- ABC Tile Adhesive Heavy DutyDocument1 paginăABC Tile Adhesive Heavy DutyMark GoducoÎncă nu există evaluări

- Baker Distributing Company ProfileDocument8 paginiBaker Distributing Company ProfiledodgeraganÎncă nu există evaluări

- Dinesh Chandran K.P, Head - Technical Services and R&D Ultratech Cement Limited, Building Products Division, MumbaiDocument7 paginiDinesh Chandran K.P, Head - Technical Services and R&D Ultratech Cement Limited, Building Products Division, MumbaiRabish AÎncă nu există evaluări

- Laboratory Test Report Checklist (IGG)Document1 paginăLaboratory Test Report Checklist (IGG)huasÎncă nu există evaluări

- Masterflow 928 Spec PDFDocument8 paginiMasterflow 928 Spec PDFDavid Toyohashi BioGenÎncă nu există evaluări

- Brochure Defoamers MM NADocument2 paginiBrochure Defoamers MM NAWilder Atalaya ChavezÎncă nu există evaluări

- Determining Surface: Strength of ConcreteDocument5 paginiDetermining Surface: Strength of ConcreteAlonsoHernandezÎncă nu există evaluări

- Protect PRODUCTS From NATURE So That, PRODUCT Protects You From NATUREDocument14 paginiProtect PRODUCTS From NATURE So That, PRODUCT Protects You From NATUREannayya.chandrashekar Civil EngineerÎncă nu există evaluări

- Standards PDFDocument10 paginiStandards PDFbadrudinÎncă nu există evaluări

- 003 FAIRMATE - Construction ChemicalsDocument8 pagini003 FAIRMATE - Construction Chemicalsfairmatechemical100% (1)

- Waterproofing Admixture PDFDocument2 paginiWaterproofing Admixture PDFSegun100% (1)

- Report On Crystaline WaterproofingDocument11 paginiReport On Crystaline WaterproofingAnkita Baban GavadeÎncă nu există evaluări

- Tile Laying LeafletDocument1 paginăTile Laying LeafletniroÎncă nu există evaluări

- Mapefloor Installation Manual-EN PDFDocument24 paginiMapefloor Installation Manual-EN PDFYatsen Jepthe Maldonado SotoÎncă nu există evaluări

- M Seal Epoxy PuttyDocument2 paginiM Seal Epoxy PuttyvineetthesupermanÎncă nu există evaluări

- Recent Progress in Concrete-Polymer CompositesDocument10 paginiRecent Progress in Concrete-Polymer Compositesswathi1105Încă nu există evaluări

- Comparing IS codes for concrete materialsDocument2 paginiComparing IS codes for concrete materialsShyam SundarÎncă nu există evaluări

- Shrinkage Compensating Admixtures by Sunanda CoatingsDocument2 paginiShrinkage Compensating Admixtures by Sunanda Coatingss.skumar10% (1)

- BPD Master Catalogue-2Document18 paginiBPD Master Catalogue-2Dr. Manamohan R KalgalÎncă nu există evaluări

- IMC Product ListDocument4 paginiIMC Product ListjosebejoyÎncă nu există evaluări

- Pull-Off Test Report - PUB Pedestrian Bridge ProjectDocument1 paginăPull-Off Test Report - PUB Pedestrian Bridge ProjectErin Williams100% (1)

- NDT On Concrete Pull Off Test: by Subhodeep Neogi Sai Prakash VaddiDocument12 paginiNDT On Concrete Pull Off Test: by Subhodeep Neogi Sai Prakash VaddiManish Mittal100% (1)

- High Performance Premium Tile AdhesivesDocument6 paginiHigh Performance Premium Tile Adhesivesshreekumar_scdlÎncă nu există evaluări

- Formulation Techniques Using Feve Resins in Waterborne and HighDocument10 paginiFormulation Techniques Using Feve Resins in Waterborne and HighManuel ChireÎncă nu există evaluări

- AF Vandex Crystalline Technology Sales 2018 09Document30 paginiAF Vandex Crystalline Technology Sales 2018 09chowki yashwanthÎncă nu există evaluări

- Selection and Specification of Resin FloorsDocument24 paginiSelection and Specification of Resin FloorshotalamÎncă nu există evaluări

- Water Retaining Conc RepairDocument48 paginiWater Retaining Conc Repairanele_amisÎncă nu există evaluări

- AdmixtureDocument6 paginiAdmixtureDunvillÎncă nu există evaluări

- Types of AdmixturesDocument3 paginiTypes of AdmixturesvanamgouthamÎncă nu există evaluări

- W.P.T. - Penetron ChemicalsDocument30 paginiW.P.T. - Penetron ChemicalsguptasonsonÎncă nu există evaluări

- Chemical Bonding Agents and MortarsDocument14 paginiChemical Bonding Agents and MortarsakurilÎncă nu există evaluări

- Disclosure To Promote The Right To InformationDocument18 paginiDisclosure To Promote The Right To Informationsudhir5441Încă nu există evaluări

- Fibre Reinforced Concrete - PPTXDocument32 paginiFibre Reinforced Concrete - PPTXEr Anindya GhoshÎncă nu există evaluări

- Sika Tilling SystemsDocument32 paginiSika Tilling SystemsEduardo Rojas100% (1)

- Sikagard - 550 W ElasticDocument4 paginiSikagard - 550 W ElasticAndrei GheoÎncă nu există evaluări

- Effect of sand fineness on concrete propertiesDocument8 paginiEffect of sand fineness on concrete propertiesRamBinodSharmaÎncă nu există evaluări

- Curing In-Place ConcreteDocument2 paginiCuring In-Place ConcreteaaÎncă nu există evaluări

- MS 14 - Internal Waterproofing PDFDocument3 paginiMS 14 - Internal Waterproofing PDFsullamsÎncă nu există evaluări

- Dry Mix Conc ProposalDocument2 paginiDry Mix Conc Proposalnishat meghnaÎncă nu există evaluări

- Masterroc® FLC 100 (Formerly Known As Meyco® Flowcable)Document2 paginiMasterroc® FLC 100 (Formerly Known As Meyco® Flowcable)Ryan LasacaÎncă nu există evaluări

- Mechanical Properties of Concrete Incorporating High Volumes of Fly Ash From Sources in The U.S.Document10 paginiMechanical Properties of Concrete Incorporating High Volumes of Fly Ash From Sources in The U.S.Afifah FauziÎncă nu există evaluări

- ConcreteDocument23 paginiConcreteHein ZanÎncă nu există evaluări

- Dr. C. D. Modhera - Day 3 - Session 1Document93 paginiDr. C. D. Modhera - Day 3 - Session 1mbgfknjhgfÎncă nu există evaluări

- Introduction of Cement: When Was Cement Begin?Document11 paginiIntroduction of Cement: When Was Cement Begin?مايف سعدونÎncă nu există evaluări

- Cement Concrete: CE 2330 Jul - Nov 2017 IIT TirupatiDocument77 paginiCement Concrete: CE 2330 Jul - Nov 2017 IIT TirupatiUmar AlamÎncă nu există evaluări

- Carbonation of Flyash ConcretDocument6 paginiCarbonation of Flyash ConcretAnshul SoniÎncă nu există evaluări

- 5 - Building MaterialsDocument86 pagini5 - Building MaterialsZynb AlhlalÎncă nu există evaluări

- Admixtures: Classification of ConcreteDocument13 paginiAdmixtures: Classification of ConcreteDrGanesh Kame100% (1)

- Engineering Materials by S. Singh PDFDocument264 paginiEngineering Materials by S. Singh PDFfaizan76% (17)

- Assgt No 2Document8 paginiAssgt No 2faizanÎncă nu există evaluări

- Types of Slope InstabilityDocument32 paginiTypes of Slope InstabilityfaizanÎncă nu există evaluări

- CE240 Lect W031 Consistency AtterberglinmitsDocument35 paginiCE240 Lect W031 Consistency AtterberglinmitsAdron LimÎncă nu există evaluări

- RRTIG AttbDocument4 paginiRRTIG AttbfaizanÎncă nu există evaluări

- AA Holtz & Kovacs - An Introduction To Geotechnical Engineering PDFDocument746 paginiAA Holtz & Kovacs - An Introduction To Geotechnical Engineering PDFwarlockall100% (1)

- Lecture1428371514 PDFDocument123 paginiLecture1428371514 PDFabimanaÎncă nu există evaluări

- AA Holtz & Kovacs - An Introduction To Geotechnical EngineeringDocument23 paginiAA Holtz & Kovacs - An Introduction To Geotechnical EngineeringfaizanÎncă nu există evaluări

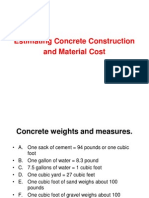

- Estimating Concrete Material Fuller MethodDocument17 paginiEstimating Concrete Material Fuller MethodOliver BrownÎncă nu există evaluări

- Managing Risks in Construction WorkDocument80 paginiManaging Risks in Construction WorkfaizanÎncă nu există evaluări

- Project Risk ManagementDocument56 paginiProject Risk Managementianvlynch100% (1)

- Risk ResponseDocument4 paginiRisk ResponseAbdighaniMOGoudÎncă nu există evaluări

- Calibration of A Pressure GaugeDocument6 paginiCalibration of A Pressure GaugeThapelo100% (2)

- RT 50Document2 paginiRT 50valentin prouteauÎncă nu există evaluări

- BRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualDocument28 paginiBRAY SERIES 4X HIGH PERFORMANCE BRAY-McCANNLOCK VALVES - Technical ManualLuis Daniel ContrerasÎncă nu există evaluări

- Bel Adv Details For Senior Assistant Engineer Posts - Jobalertshub 2Document5 paginiBel Adv Details For Senior Assistant Engineer Posts - Jobalertshub 2Palani AppanÎncă nu există evaluări

- DiGas 4000 Light E 08.02Document2 paginiDiGas 4000 Light E 08.02manit1963Încă nu există evaluări

- CRCM Manual 2 9 16Document33 paginiCRCM Manual 2 9 16Kamagara Roland AndrewÎncă nu există evaluări

- Transmission ErrorDocument7 paginiTransmission ErrorTapas JenaÎncă nu există evaluări

- SYMAP UsersManual E PDFDocument98 paginiSYMAP UsersManual E PDFRafaqatAliÎncă nu există evaluări

- International Tubulars MSDS RegisterDocument4 paginiInternational Tubulars MSDS RegisterMuhammad SuhaibÎncă nu există evaluări

- Grove GMK 4080Document6 paginiGrove GMK 4080Deiver BarrazaÎncă nu există evaluări

- Bots and Automation Over Twitter During The U.S. Election: CompropDocument5 paginiBots and Automation Over Twitter During The U.S. Election: CompropRaninha MoraisÎncă nu există evaluări

- Optimal Design & Operation of RO Systems 3-Day SeminarDocument10 paginiOptimal Design & Operation of RO Systems 3-Day SeminarasankandessÎncă nu există evaluări

- Explorador Ww90j6410cwec Version 02Document13 paginiExplorador Ww90j6410cwec Version 02Cristi PopescuÎncă nu există evaluări

- Sensotronic Brake ControlDocument20 paginiSensotronic Brake ControlShubhankar Banerjee100% (1)

- 350q-5 Operation ManualDocument97 pagini350q-5 Operation ManualCesar Mora100% (2)

- Ahmed Mohammed EL Desouky 2007Document8 paginiAhmed Mohammed EL Desouky 2007Hazem MohamedÎncă nu există evaluări

- BlowersDocument58 paginiBlowersmahmad61100% (1)

- Proposed Rule: Domestic Mail Manual: Domestic Mailing Services New StandardsDocument45 paginiProposed Rule: Domestic Mail Manual: Domestic Mailing Services New StandardsJustia.comÎncă nu există evaluări

- Aviation Week & Space Technology - September 22, 2014 USADocument60 paginiAviation Week & Space Technology - September 22, 2014 USAJohn David Hoyos MarmolejoÎncă nu există evaluări

- LB2 UC30 Data Sheet enUS 80218564235Document5 paginiLB2 UC30 Data Sheet enUS 80218564235Ahmed ShawkyÎncă nu există evaluări

- 1329804769qno 5,6,7Document94 pagini1329804769qno 5,6,7Aman MishraÎncă nu există evaluări

- LMS Adaptive FiltersDocument14 paginiLMS Adaptive FiltersalialibabaÎncă nu există evaluări

- Indian Standards As On 17.01.2004 LatestDocument19 paginiIndian Standards As On 17.01.2004 LatestSaravana KumarÎncă nu există evaluări

- Formulation - Beton - Dreux - Gorisse Good - Fr.enDocument9 paginiFormulation - Beton - Dreux - Gorisse Good - Fr.enRabnawaz ImamÎncă nu există evaluări

- Us01cphy02 Unit 1 2014 THPDocument18 paginiUs01cphy02 Unit 1 2014 THPapi-264723824Încă nu există evaluări