Documente Academic

Documente Profesional

Documente Cultură

Patient Grounding Module

Încărcat de

Oliver HermosaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Patient Grounding Module

Încărcat de

Oliver HermosaDrepturi de autor:

Formate disponibile

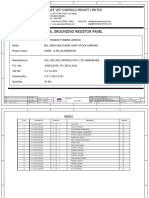

TECHNICAL SPECIFICATIONS

PATIENT GROUND MODULE (PGM)

Medical Division of Bender Inc.

ISOLATED POWER SYSTEMS EQUIPMENT

1 APPLICABLE STANDARDS

These requirements cover accessories for Isolated Power Systems. The Patient Ground Module

shall consist of multiple ground jacks and bus bars of a type and configuration as per contract

documents.

The equipment must satisfy the requirements imposed, but are not necessarily limited to the following:

Article 300 - Wiring Methods of the National Electric Code, NFPA 70

Standard for Cabinets and Boxes, UL 50

Standard for Wire Connectors and Soldering Lugs for Use with Copper Conductors, UL 486A

Standard for Attachment Plugs and Receptacles, UL 498

Standard for Metallic Outlet Boxes, UL 514A

Standard for Nonmetallic Outlet Boxes, Flush Device Boxes, and Covers, UL 14C

Standard for Terminal Blocks, UL 1059

These Codes and Standards identify the requirements for UL Recognized components, provide the

guidelines for adequate wire bending space, enclosure, strength, rigidity and minimum thickness and

identify constraints such as those that pertain to the installation of conductors with other systems.

2 PRODUCT

This section imposes additional constraints on the product addressing such topics as construction

details, size, operator interface, and component performance.

2.1 ENCLOSURE

2.1.1 Backbox

Shall be flush or surface mounted as indicated on the contract documents. Flush mounted units

shall be fabricated from 16GA galvanized sheet steel. Surface mounted units shall be 16GA

galvanized sheet steel and shall have a finish coat of hospital ivory, epoxy enamel. The

dimensions of the backbox shall be 8"W x 8"H x 4"D or 12"W x 8"H x 4"D or 18"W x 8"H x 4"D or

standard electrical gang wall box, with or without plaster ring, supplied by the contractor.

2.1.2 Face Plate

Shall be fabricated from 14GA Type 304 Stainless Steel, with #4 brushed finish. The face plate

for flush mounted units extends 1" on all sides of the backbox. For surface mounted units, the

face plate shall exactly match the dimensions of the backbox. The face plate shall be attached to

the backbox by means of four (4)#10-32 x 1" Stainless Steel Truss Head Phillips machine

screws.

Face plates for standard electrical gang wall boxes shall have a wall plate fabricated from Type

304 Stainless Steel, with a #4 brushed finish and attached to the wall box as required.

Page 1 of 4 Rev 2 - 2004 LST

TECHNICAL SPECIFICATIONS

PATIENT GROUND MODULE (PGM)

Medical Division of Bender Inc.

ISOLATED POWER SYSTEMS EQUIPMENT (Continued)

2.2 COMPONENTS

2.2.1 Ground Jacks

Shall be UL listed for hospital application as well as green in color and provide in quantities in

accordance with the contract drawings.

2.2.2 Ground Bus (Optional)

Shall contain a minimum of nineteen (19) #14-4 screw connections for the attachment of

grounding conductors. It shall have at least one (1) #4-2/0 lug for the system grounding

conductor. A Chicago style bus assembly constructed from 1/4" thick copper shall be available

as an option.

3 INSTALLATION

Type XHHW wire with crosslinked polyethylene insulation and a dielectric constant of 3.5 or less shall be

used.

As necessary, special instructions shall be provided for field assembly, mounting and wiring of the

equipment. They shall be part of a documentation package which includes three (3) sets of Operation and

Maintenance manuals. These manuals shall include written instructions on the care and maintenance of

the system, spare parts lists and certified “as built” drawings for the material furnished to the facility.

Included will be an electrical schematic, an interconnection diagram, an overall outline dimensional

drawing, and a LIM User Manual.

3.1 Installation Areas

3.1.1 Install the Patient Ground Module as shown on the contract drawings.

3.1.2 Use stranded green insulated copper wires for the grounding conductors and size them as

indicated on the contract drawings.

3.1.3 Install the grounding conductor in conduit from each Patient Ground Module to the reference

ground bus in the Isolated Power Panel. Run each grounding conductor directly back to the

reference ground bus in a radial arrangement; do not daisy chain conductors from module to

module.

3.1.4 Install the grounding conductors in a conduit to the ground bus in the Patient Ground Module

from the following locations:

♦ nurse call stations

♦ physiological monitor outlet

♦ elapsed time clock and control station

♦ code blue station

♦ medical gas piping at outlets

♦ hemodialysis water outlets

♦ any other metal objects which may become electrified, either accidentally or

intentionally, and then come in contact with the patient or hospital staff.

Page 2 of 4 Rev 2 - 2004 LST

TECHNICAL SPECIFICATIONS

PATIENT GROUND MODULE (PGM)

Medical Division of Bender Inc.

ISOLATED POWER SYSTEMS EQUIPMENT (Continued)

3.1.5 For Isolated Power Systems using a Master Ground Module, install grounding conductor in

conduit from each Patient Ground Module to the Master Ground Module. Run each grounding

conductor directly back to the ground bus in a radial arrangement; do not daisy chain conductors

from module to module.

3.1.6 Install grounding conductor in a conduit from the Master Ground Module to the reference

ground bus in the Isolated Power Panel that provides power to those areas.

4 TESTING & CERTIFICATION

In conjunction with being sold and installed as part of a complete Isolated Power System, an engineer or

senior technician shall be provided by the manufacturer for final testing and acceptance of

the Isolated Power System. Consult factory for complete testing and certification procedures.

5 TRAINING

In conjuntion with being sold and installed as part of a complete Isolated Power System and as required,

training shall be provided for the hospital maintenance and medical staff covering the correct operation

and routine testing of the Isolated Power System. Consult factory for complete training procedures.

6 ACCEPTABLE MANUFACTURERS

The equipment shall be provided by ISOTROL SYSTEMS or other approved supplier. Other suppliers

seeking approval shall submit proof of their ability to comply with the requirements set forth in this

specification.

7 APPROVAL SUBMITTALS

As part of the approval process, potential suppliers shall submit pertinent descriptive catalog literature.

The following shop drawings shall also be submitted: a) Dimensional data, b) Transformer data, c) Line

Isolation Monitor (LIM) details and performance data, d) Product specifications from the manufacturer, and

e) Load center construction details including method of mounting, type of circuit breaker, current capacity,

etc.

8 ADDRESS OF MANUFACTURER

ISOTROL SYSTEMS From USA, Canada and Mexico:

Medical Division of Bender Inc. Phone: 800-833-6834

700 Fox Chase

Coatesville, PA 19320 USA All other countries:

Phone: 610-383-9655

Fax: 610-383-7100

Page 3 of 4 Rev 2 - 2004 LST

TECHNICAL SPECIFICATIONS

PATIENT GROUND MODULE (PGM)

Medical Division of Bender Inc.

Notes:

Page 4 of 4 Rev 2 - 2004 LST

S-ar putea să vă placă și

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsDe la Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsEvaluare: 4 din 5 stele4/5 (1)

- Process Industry Practices Electrical: Pip Elsmc14 Low-Voltage Switch Rack SpecificationDocument16 paginiProcess Industry Practices Electrical: Pip Elsmc14 Low-Voltage Switch Rack SpecificationSujita SahÎncă nu există evaluări

- SECTION 16450 Grounding Part 1 - GeneralDocument8 paginiSECTION 16450 Grounding Part 1 - Generalno nameÎncă nu există evaluări

- DC Polarization CellDocument13 paginiDC Polarization CelliyyaniÎncă nu există evaluări

- Materials System SpecificationDocument9 paginiMaterials System SpecificationHatemS.MashaGbehÎncă nu există evaluări

- June 30, 2010Document41 paginiJune 30, 2010TTPL ProjectsÎncă nu există evaluări

- Pre-Installation Manual: Standard Frequency Series GeneratorsDocument20 paginiPre-Installation Manual: Standard Frequency Series GeneratorsLuis Fernando Garcia SÎncă nu există evaluări

- 56-SDMS, Specs For 13.8KV Unit Substation PDFDocument14 pagini56-SDMS, Specs For 13.8KV Unit Substation PDFA. Hassan100% (1)

- 14-SAMSS-534 Oh TransformerDocument8 pagini14-SAMSS-534 Oh TransformerHatemS.MashaGbehÎncă nu există evaluări

- Materials System SpecificationDocument5 paginiMaterials System SpecificationFlorante NoblezaÎncă nu există evaluări

- 16 Samss 510Document11 pagini16 Samss 510HatemS.MashaGbehÎncă nu există evaluări

- Spec Sub-Distributions PanelsDocument11 paginiSpec Sub-Distributions PanelsDolyÎncă nu există evaluări

- Bus Duct Technical SpecificationsDocument15 paginiBus Duct Technical SpecificationsAshish Mulik100% (1)

- 4.VFD Spec. Rev.1Document35 pagini4.VFD Spec. Rev.1wado11100% (1)

- 16 Samss 515Document5 pagini16 Samss 515HatemS.MashaGbehÎncă nu există evaluări

- June 30, 2010Document41 paginiJune 30, 2010mohamedÎncă nu există evaluări

- Mil STD 220Document29 paginiMil STD 220Adriana FerreiraÎncă nu există evaluări

- PowlVac 5-15kV Metal-Clad Switchgear Guide Specification v7Document8 paginiPowlVac 5-15kV Metal-Clad Switchgear Guide Specification v7ahmadgce04Încă nu există evaluări

- 16 Samss 523Document10 pagini16 Samss 523Eagle SpiritÎncă nu există evaluări

- Bechtel Limited: Engineering Guide Instruction 3DG-E23E-00100 D.C. Supply Units (Batteries & Battery Chargers)Document11 paginiBechtel Limited: Engineering Guide Instruction 3DG-E23E-00100 D.C. Supply Units (Batteries & Battery Chargers)mohammadkassarÎncă nu există evaluări

- CSC XxxxixDocument10 paginiCSC XxxxixAshish bhattÎncă nu există evaluări

- 002 - HCM-Q202C344-Vung Tau, DMT Factory-Spec - 20200629 - R0Document16 pagini002 - HCM-Q202C344-Vung Tau, DMT Factory-Spec - 20200629 - R0Nguyễn Huy HoàngÎncă nu există evaluări

- Specification No: ELRS /SPEC/ SI /0015: Government of IndiaDocument12 paginiSpecification No: ELRS /SPEC/ SI /0015: Government of Indiavikas katiyarÎncă nu există evaluări

- Lighting SystemDocument10 paginiLighting SystemJyoti ShekharÎncă nu există evaluări

- Panel Boards SpecificationDocument16 paginiPanel Boards SpecificationAhmad DagamsehÎncă nu există evaluări

- Small Power Distribution BoardsDocument6 paginiSmall Power Distribution BoardsSARAVANAÎncă nu există evaluări

- Sedecal HF Series X-Ray Generator - Service ManualDocument427 paginiSedecal HF Series X-Ray Generator - Service ManualDante Nuevo95% (38)

- (India) PVT LTD: FJ5705 1/6 - SS 75 6008/I 140597101Document22 pagini(India) PVT LTD: FJ5705 1/6 - SS 75 6008/I 140597101netsavy71Încă nu există evaluări

- Process Industry Practices Electrical: Pip Elswc03 600 Volt Power and Control CableDocument7 paginiProcess Industry Practices Electrical: Pip Elswc03 600 Volt Power and Control Cablemariannel perezÎncă nu există evaluări

- 111 - 198, 120, 60, 30 & 9 KV Gapless Surge ArrestorsDocument12 pagini111 - 198, 120, 60, 30 & 9 KV Gapless Surge Arrestorsjagadeesh_kumar_20Încă nu există evaluări

- 1017 EL DBS 101 - Rev.1Document22 pagini1017 EL DBS 101 - Rev.1c prakashÎncă nu există evaluări

- 14 Samss 533 PDFDocument14 pagini14 Samss 533 PDFMudabbir HussainÎncă nu există evaluări

- Design and Fabrication of High-Resistance Grounding Systems (1000 Volts or Below)Document14 paginiDesign and Fabrication of High-Resistance Grounding Systems (1000 Volts or Below)vladimir rosas ayalaÎncă nu există evaluări

- Spec MDBDocument16 paginiSpec MDBDolyÎncă nu există evaluări

- NPS - 003 - 007 Tech Specs On 66kV and 132kV Discs and ESDocument39 paginiNPS - 003 - 007 Tech Specs On 66kV and 132kV Discs and ESandcrisdanmatÎncă nu există evaluări

- ELSHT01Document10 paginiELSHT01Ariel Anibal Aparicio100% (1)

- Metal-Enclosed Medium Voltage Power Factor Correction SystemDocument16 paginiMetal-Enclosed Medium Voltage Power Factor Correction SystemYigit SarıkayaÎncă nu există evaluări

- مواصفات شركه الكهرباء السعوديهDocument24 paginiمواصفات شركه الكهرباء السعوديهahmedÎncă nu există evaluări

- 16 Samss 520Document11 pagini16 Samss 520HatemS.MashaGbehÎncă nu există evaluări

- Check The Source To Verify That This Is The Current Version Before UseDocument31 paginiCheck The Source To Verify That This Is The Current Version Before Useketab_doostÎncă nu există evaluări

- Electrical Requirements For Health Care FacilitiesDocument53 paginiElectrical Requirements For Health Care FacilitiescvevasÎncă nu există evaluări

- 50-TMSS-01 (Rev 01)Document17 pagini50-TMSS-01 (Rev 01)GardellÎncă nu există evaluări

- 44AD0600-00-E.02-0002-A4 - Rev 0 - Standard Specification For LCSDocument5 pagini44AD0600-00-E.02-0002-A4 - Rev 0 - Standard Specification For LCSAvinash ShuklaÎncă nu există evaluări

- Well-Site Power Supply and Distribution System User ManualDocument17 paginiWell-Site Power Supply and Distribution System User ManualAhmedÎncă nu există evaluări

- 31 TMSS 01 Rev01 PDFDocument29 pagini31 TMSS 01 Rev01 PDFFazleMasoodÎncă nu există evaluări

- Grounding StandardDocument85 paginiGrounding Standardflake03Încă nu există evaluări

- Technical Data Book of NGRDocument54 paginiTechnical Data Book of NGRAlind Dubey0% (1)

- Guide To Commercial Installations: Part 1: Type B Distribution Boards and The RegulationsDocument24 paginiGuide To Commercial Installations: Part 1: Type B Distribution Boards and The RegulationsspartanÎncă nu există evaluări

- VFD SystemDocument17 paginiVFD SystemVahidJamÎncă nu există evaluări

- National Grid Design Handbook dh01Document26 paginiNational Grid Design Handbook dh01akmezim100% (2)

- Specification of 11kv SF6 Insulated Ring Main UnitsDocument8 paginiSpecification of 11kv SF6 Insulated Ring Main UnitsGAGANÎncă nu există evaluări

- Materials System SpecificationDocument6 paginiMaterials System SpecificationCherukunnon JubuÎncă nu există evaluări

- 52TMSS01R0Document29 pagini52TMSS01R0Orcun CalayÎncă nu există evaluări

- SECTION 16312 Unit Substation, SecondaryDocument9 paginiSECTION 16312 Unit Substation, Secondaryno nameÎncă nu există evaluări

- 1-) 52-TMSS-01-Rev.00Document29 pagini1-) 52-TMSS-01-Rev.00Orcun CalayÎncă nu există evaluări

- Protection Principle and Technology of the VSC-Based DC GridDe la EverandProtection Principle and Technology of the VSC-Based DC GridÎncă nu există evaluări

- Protection of Substation Critical Equipment Against Intentional Electromagnetic ThreatsDe la EverandProtection of Substation Critical Equipment Against Intentional Electromagnetic ThreatsÎncă nu există evaluări

- Schneider (1000A) Bus DuctDocument342 paginiSchneider (1000A) Bus DuctOliver HermosaÎncă nu există evaluări

- Turn StilDocument3 paginiTurn StilOliver HermosaÎncă nu există evaluări

- HV Sheath Voltage Calculation - SampleDocument8 paginiHV Sheath Voltage Calculation - SampleOliver HermosaÎncă nu există evaluări

- Panel Wiring Cable SpecsDocument8 paginiPanel Wiring Cable SpecsOliver HermosaÎncă nu există evaluări

- Copper Bus Bar Ampacity - TablesDocument4 paginiCopper Bus Bar Ampacity - TablesOliver HermosaÎncă nu există evaluări

- Paul Gill - Eqpt Maint & TestingDocument1 paginăPaul Gill - Eqpt Maint & TestingOliver HermosaÎncă nu există evaluări

- 3PH Electric Chain Hoist ManualDocument48 pagini3PH Electric Chain Hoist ManualOliver HermosaÎncă nu există evaluări

- Cutler Hammer Bus DuctsDocument28 paginiCutler Hammer Bus DuctsOliver HermosaÎncă nu există evaluări

- Non-Segregated Phase Bus Duct BR en 6 2012Document8 paginiNon-Segregated Phase Bus Duct BR en 6 2012Aziddin GadingÎncă nu există evaluări

- Eaton Nonsegregated BusductDocument28 paginiEaton Nonsegregated BusducthanythekingÎncă nu există evaluări

- Canalis KSDocument36 paginiCanalis KSrubysultanaÎncă nu există evaluări

- Farnell SS Cable TiesDocument5 paginiFarnell SS Cable TiesOliver HermosaÎncă nu există evaluări

- Canalis KSDocument36 paginiCanalis KSrubysultanaÎncă nu există evaluări

- Pipeline Protection TechnicalDocument4 paginiPipeline Protection TechnicalOliver HermosaÎncă nu există evaluări

- Apollo Swing GateDocument25 paginiApollo Swing GateOliver HermosaÎncă nu există evaluări

- Apollo Swing GateDocument25 paginiApollo Swing GateOliver HermosaÎncă nu există evaluări

- Manual Intelligent Barriers Instruction: Pdf 文件使用 "Pdffactory Pro" 试用版本创建Document14 paginiManual Intelligent Barriers Instruction: Pdf 文件使用 "Pdffactory Pro" 试用版本创建Oliver HermosaÎncă nu există evaluări

- Cannon Cable PrinterDocument6 paginiCannon Cable PrinterOliver HermosaÎncă nu există evaluări

- Steel Conduit Install Guide PDFDocument32 paginiSteel Conduit Install Guide PDFOliver Hermosa100% (1)

- Steel Conduit Install GuideDocument7 paginiSteel Conduit Install GuideOliver HermosaÎncă nu există evaluări

- Thermal ImagerDocument46 paginiThermal ImagerOliver HermosaÎncă nu există evaluări

- Thermal Imager PDFDocument24 paginiThermal Imager PDFOliver HermosaÎncă nu există evaluări

- Stauff Surface Cable ClampsDocument54 paginiStauff Surface Cable ClampsOliver HermosaÎncă nu există evaluări

- Tyco Plastic ConduitsDocument6 paginiTyco Plastic ConduitsOliver HermosaÎncă nu există evaluări

- Cannon Cable Printer PDFDocument2 paginiCannon Cable Printer PDFOliver HermosaÎncă nu există evaluări

- Caddy Electrical Fixings PDFDocument2 paginiCaddy Electrical Fixings PDFOliver HermosaÎncă nu există evaluări

- Caddy Electrical FixingsDocument36 paginiCaddy Electrical FixingsOliver HermosaÎncă nu există evaluări

- Cable Gland Size TableDocument1 paginăCable Gland Size TableOliver HermosaÎncă nu există evaluări

- Caddy Pyramid Pipe SupportsDocument12 paginiCaddy Pyramid Pipe SupportsOliver HermosaÎncă nu există evaluări

- Bentel by Tyco Fire Catalgoye PDFDocument36 paginiBentel by Tyco Fire Catalgoye PDFOliver HermosaÎncă nu există evaluări

- Kumar 2015Document6 paginiKumar 2015Tio SÎncă nu există evaluări

- Leaflet UPS DPH-200-500-600kVA en V2-1Document2 paginiLeaflet UPS DPH-200-500-600kVA en V2-1Karina SolisÎncă nu există evaluări

- String Box LT - 1500V - SB-24-LT04-1500VDocument3 paginiString Box LT - 1500V - SB-24-LT04-1500VAgostino MilaneseÎncă nu există evaluări

- 4 Transmission Structures Fact SheetDocument10 pagini4 Transmission Structures Fact SheetmanikandanÎncă nu există evaluări

- 621 Generator On-Line Over and Under Excitation IssuesDocument26 pagini621 Generator On-Line Over and Under Excitation Issueswoop100% (1)

- Introduction To The Computer 1Document10 paginiIntroduction To The Computer 1Eric Leo AsiamahÎncă nu există evaluări

- TVSS (Transient Voltage Surge Suppression) What Is It and Why All of A Sudden Do We Need It?Document12 paginiTVSS (Transient Voltage Surge Suppression) What Is It and Why All of A Sudden Do We Need It?Jecer Casipong NuruddinÎncă nu există evaluări

- SK720 ManualDocument43 paginiSK720 ManualrandyromÎncă nu există evaluări

- Is 13529 1992Document9 paginiIs 13529 1992Arjun M KumarÎncă nu există evaluări

- st-200 ProDocument132 paginist-200 ProAndres TapiaÎncă nu există evaluări

- TC-2450 Equipment Case User's Manual ISI-4421-0061 Rev BDocument16 paginiTC-2450 Equipment Case User's Manual ISI-4421-0061 Rev BPeter BoongÎncă nu există evaluări

- Electricity ExamDocument4 paginiElectricity Examjorolan.annabelleÎncă nu există evaluări

- Ink Viscosity Tester KVST-12 Operation Manual: Serial No.Document10 paginiInk Viscosity Tester KVST-12 Operation Manual: Serial No.liebofreakÎncă nu există evaluări

- Caterpillar RC1000 Containerized Diesel Generator SetDocument4 paginiCaterpillar RC1000 Containerized Diesel Generator SetMacAllister MachineryÎncă nu există evaluări

- Iitians PaceDocument8 paginiIitians PaceAditya DevÎncă nu există evaluări

- Contain CeDocument4 paginiContain CenageshÎncă nu există evaluări

- Slide 2 Photovoltaic System 4Document71 paginiSlide 2 Photovoltaic System 4Chea LichhingÎncă nu există evaluări

- SolderDocument13 paginiSolderBalaji N MuthuramanÎncă nu există evaluări

- At Command ManualDocument38 paginiAt Command ManualOpulens KeyÎncă nu există evaluări

- LEvitonDocument2 paginiLEvitonAndres Barbosa LargoÎncă nu există evaluări

- Swe1003 Digital-logic-And-microprocessor Eth 1.0 37 Swe1003Document5 paginiSwe1003 Digital-logic-And-microprocessor Eth 1.0 37 Swe1003ROHITH RJ 20MIS0324Încă nu există evaluări

- DCCDocument35 paginiDCCkhushbu patelÎncă nu există evaluări

- Simulation Paper 8Document8 paginiSimulation Paper 8Sandip KumarÎncă nu există evaluări

- Design and Performance Analysis of Digital Integrator of A Multi-Channel Microwave RadiometerDocument6 paginiDesign and Performance Analysis of Digital Integrator of A Multi-Channel Microwave RadiometerJoh IgnacioÎncă nu există evaluări

- Gekko DSDocument2 paginiGekko DSAnte NekicÎncă nu există evaluări

- NGR - Ninh Hoa - R#0Document18 paginiNGR - Ninh Hoa - R#0trungtruc nguyenÎncă nu există evaluări

- Calibration Check List For Fresenius Medical CareDocument3 paginiCalibration Check List For Fresenius Medical CareAntra NovalÎncă nu există evaluări

- Circuits Module 03Document19 paginiCircuits Module 03Glenn VirreyÎncă nu există evaluări

- BZX55CV24Document4 paginiBZX55CV24kcraussÎncă nu există evaluări

- 5.2.1.7 Lab - Viewing The Switch MAC Address TableDocument4 pagini5.2.1.7 Lab - Viewing The Switch MAC Address TableMarc WallinÎncă nu există evaluări