Documente Academic

Documente Profesional

Documente Cultură

Manual Gyplacc

Încărcat de

Edwin Alfredth PoquiomaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Manual Gyplacc

Încărcat de

Edwin Alfredth PoquiomaDrepturi de autor:

Formate disponibile

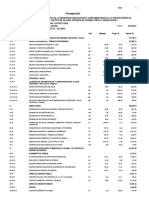

DISEÑO DE MUROS EN VOLADIZO

W= 700 Kg/m2 1.- Calculo del esfuerzo activo

Angulo del Talud

8

cos( ) cos 2 ( ) cos 2 ( )

Tg(θ)= 0 º= 0.0000 rad Ka cos( )

471.53 cos( ) cos 2 ( ) cos 2 ( )

altura de sobrecarga Ka1= 0.39046

hs/c= 0.388889 m 11 Ka2= 0.34697

e muro= 0.2 7 0 2.- Calculo del esfuerzo pasivo

Altura del talud 0.30 1 cos( ) cos 2 ( ) cos 2 ( )

htd= 0 Kp cos( )

cos( ) cos 2

( ) cos 2

( )

Coeficente de friccion

Kp= 2.88206

u= 0.55 γs= 1.80 t/m3

u= 0.55 Φ= 26 º

h1= 4.02 m

6

f cm= 1.4

f cp = 1.7

w= 300 Kg/m2

10

1 2 3 6.04 m 3.- Verificacion por deslizamiento y volteo 4. EVALUACION SIN SOBRECARGA

Peso Brazo Mact Fact= 12.11 tn

f'c= 210 kg/cm2 1 1317.60 2.03 2679.12 Fres= 31.97 tn FSD= 2.64 > 1.50 OK!

Fy= 4200 Kg/cm2 5 2 3952.80 2.25 8893.80 Mact= 25.32 tn-m

γs= 1.60 t/m3 γc= 2400 Kg/m3 h2= 1.47 m 3 0.00 2.40 0.00 Mres= 126.64 tn-m FSV= 5.00 > 1.75 OK!

Φ= 29.00 º Φv= 3/4 γs= 1.60 t/m3 4 6468.00 2.45 15846.60

Φ= 29 º 5 5880.00 3.65 21462.00 q1= 7.91 tn/m2 < 9 tn/m2

h3= 1.47 m 9 6 18090.00 3.65 66028.50 q2= 8.70 tn/m2 < 9 tn/m2

FSD= 1.50 7 0.00 4.07 0.00

FSV= 1.75 8 1750.00 3.65 6387.50

9 4531.78 0.96 4369.21

10 586.07 0.98 572.45

4 t= 0.55 m 11 471.53 2.175 1025.58

σt= 0.90 Kg/cm2 Total 43,047.77 127,264.77

Wtotal= 43.05 tn

Fact= 13.73 tn

1.90 0.20 0.30 0.00 2.50 Fres= 35.02 tn FSD= 2.55 > 1.50 OK!

Mact= 30.28 tn-m

B= 4.90 m Mres= 135.36 tn-m FSV= 4.47 > 1.75 OK!

5.- Presión sobre el terreno

Xo= 2.44 e= 0.009 < 0.81666667

OK!

B = 0.8166667

6

q1= 8.88 tn/m2 < 9 tn/m2

Ok!

q2= 8.69 tn/m2 < 9 tn/m2

6.- Diseño de la pantalla

0 0.27 tn/m2 Acero vertical

Ast1 Ast2 d= 0.45 calculado Ø = 0.9

d= 0.45 m Asuminos

M= 19.92 tn-m ITERANDO

Mu= 1.7 x 19.92 = 33.87 tn-m a= 4.30 cm a calculado= 4.9 cm

As = 20.91 cm2

As= 21.07 cm2

19.78 6.78 Tn-m Amin= 8.10 cm2 As = 21.07 cm2 OK! n= 7 s= 13.53 cm

3.52 3.47 m Usar Φ 3/4 @ 14 cm

23.3

3.10 tn/m2

Mu = 3.38 Mu = 23.30 1.84

0.86 Acero Horizontal Usar Φ 3/8

11.15 tn-m 13.73 tn-m Superior t1= 30 cm As= 7.5 cm2/m

4.90 tn-m Ast1= 5.000 Usar Φ 3/8 @ 14.25 cm

1.27 m Ast2= 2.500 Usar Φ 3/8 @ 28.50 cm

6.25 tn-m Central tm= 40 cm As= 10.0 cm2/m

1.09 m Ast1= 6.667 Usar Φ 3/8 @ 10.69 cm

3.57 tn/m2 Ast2= 3.333 Usar Φ 3/8 @ 21.38 cm

Mu= 19.92

7.64 tn-m 1.11 Inferior t2= 50 cm As= 10.0 cm2/m

4.90 tn-m Mact= 30.28 2.05 tn-m Ast1= 6.667 Usar Φ 3/8 @ 10.69 cm

0.26 m 0.27 m 3.88 tn/m2 Ast2= 3.333 Usar Φ 3/8 @ 21.38 cm

10.18 0 7.- Diseño de la zapata

Zapata Posterior

8.69 tn/m2 L= 2.50 m

qb= 8.79 tn/m d= 0.47 m fev = 1.35

wu= 16.25 tn/m

8.88 tn/m2 13.73 Mu= 1.77 tn-m As= 0.99 cm2 As = 8.50 cm2

Amin= 8.50 cm2 Usar Φ 5/8 @ 23.29 cm

Zapata anterior

wpp = 1.32 tn/m d= 0.47

wu max = 13.91 tn/m

Mu= 25.11 tn-m a= 2.30 cm a calculado= 3.4 cm

As= 14.42 cm2 As = 14.42 cm2 Usar Φ 5/8 @ 13.72 cm

Amin= 8.50 cm2

S-ar putea să vă placă și

- Manual Técnico GYPLACDocument42 paginiManual Técnico GYPLACtuto333100% (7)

- Manual Técnico GYPLACDocument42 paginiManual Técnico GYPLACtuto333100% (7)

- Manual de Seguridad y Salud en El Trabajo Sector Construccion - SunafilDocument119 paginiManual de Seguridad y Salud en El Trabajo Sector Construccion - SunafilEdwin Alfredth PoquiomaÎncă nu există evaluări

- Curso Obras HidráulicasDocument347 paginiCurso Obras HidráulicasFrancisco Ruiz100% (1)

- Test de PercolacionDocument3 paginiTest de PercolacionBraulio Rodriguez CarriónÎncă nu există evaluări

- Tablas y Cuadros FinalDocument30 paginiTablas y Cuadros FinalEdwin Alfredth PoquiomaÎncă nu există evaluări

- Fta Las Malvinas PDFDocument54 paginiFta Las Malvinas PDFEdwin Alfredth PoquiomaÎncă nu există evaluări

- Pres Tramo IIDocument3 paginiPres Tramo IIEdwin Alfredth PoquiomaÎncă nu există evaluări

- Cuota Familiar BetaniaDocument39 paginiCuota Familiar BetaniaEdwin Alfredth PoquiomaÎncă nu există evaluări

- Cuota Familiar BetaniaDocument39 paginiCuota Familiar BetaniaEdwin Alfredth PoquiomaÎncă nu există evaluări

- Fta Las Malvinas PDFDocument54 paginiFta Las Malvinas PDFEdwin Alfredth PoquiomaÎncă nu există evaluări

- Silabo Ppco 2019Document8 paginiSilabo Ppco 2019Edwin Alfredth PoquiomaÎncă nu există evaluări

- Pre Supuesto Client Ear Quite CDocument2 paginiPre Supuesto Client Ear Quite CEdwin Alfredth PoquiomaÎncă nu există evaluări

- SEGUNDO Modulo Edwin Poquioma MamaniDocument2 paginiSEGUNDO Modulo Edwin Poquioma MamaniEdwin Alfredth PoquiomaÎncă nu există evaluări

- Curso Obras HidráulicasDocument89 paginiCurso Obras HidráulicasEdwin Alfredth PoquiomaÎncă nu există evaluări

- Alcantarilla Rocafuerte 01 PDFDocument3 paginiAlcantarilla Rocafuerte 01 PDFEdwin Alfredth Poquioma100% (1)

- MEMORIA DESC PoderDocument3 paginiMEMORIA DESC PoderEdwin Alfredth PoquiomaÎncă nu există evaluări

- Precio Particular in Sumo Tipov Tipo 2Document5 paginiPrecio Particular in Sumo Tipov Tipo 2Edwin Alfredth PoquiomaÎncă nu există evaluări

- Guia de Relleno Sanitario ManualDocument87 paginiGuia de Relleno Sanitario Manualoscarvidal.aÎncă nu există evaluări

- Aguas Residuales PDFDocument6 paginiAguas Residuales PDFEdwin Alfredth PoquiomaÎncă nu există evaluări

- Chema AceleranteDocument2 paginiChema AceleranteSandra G. Martínez PariÎncă nu există evaluări

- Pre Supuesto Client eDocument26 paginiPre Supuesto Client eEdwin Alfredth PoquiomaÎncă nu există evaluări

- Encuesta Socioeconómica - Polideportivo UNIADocument3 paginiEncuesta Socioeconómica - Polideportivo UNIAEdwin Alfredth PoquiomaÎncă nu există evaluări

- Técnicas de ReconocimientoDocument9 paginiTécnicas de ReconocimientoEdwin Alfredth PoquiomaÎncă nu există evaluări

- Separadore 3 SDocument22 paginiSeparadore 3 SEdwin Alfredth PoquiomaÎncă nu există evaluări

- DS005-2014 E.010 PDFDocument1 paginăDS005-2014 E.010 PDFEdwin Alfredth PoquiomaÎncă nu există evaluări

- Diagrama EspectralDocument3 paginiDiagrama EspectralEdwin Alfredth PoquiomaÎncă nu există evaluări

- Metano PDFDocument4 paginiMetano PDFEdwin Alfredth PoquiomaÎncă nu există evaluări

- FibrablokDocument10 paginiFibrablokSara ArceÎncă nu există evaluări