Documente Academic

Documente Profesional

Documente Cultură

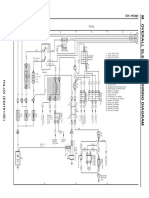

Pm-Drg-Ly26 11092-M-01 Isometric Drawing Rev. D 2010 - Internal Painting Option - A3 Discharge Line

Încărcat de

LEE JHONTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pm-Drg-Ly26 11092-M-01 Isometric Drawing Rev. D 2010 - Internal Painting Option - A3 Discharge Line

Încărcat de

LEE JHONDrepturi de autor:

Formate disponibile

Pipe size Class Item Gasket Bolt Size Bolt

Fro

Item

& Gm G- ec

ap

in inch Rating Qty -30 304 a nk pip weld

5 e to T "

3 nd

ove e a

N 12 300 38 SS Inner & outer R 46 1-1/8 x 170 16 pip em Piec

8 300 39 SS Inner & outer R 7/8 x 140 12 3" TP R

5 e

47 TPm Te

8 1500 40 R50 Soft Iron 48 1-5/8 x 320 12 06

5 fro

6 1500 41 R50 Soft Iron 49 1-3/8 x 265 12 m G-3 3"

Fro

4 1500 42 R50 Soft Iron 50 1-1/4 x 200 8 BILL OF MATERIALS

3 1500 43 R50 Soft Iron 51 1-1/8 x 267 8

3 1500 R50 Soft Iron 1-1/8 x 180 8 06 475 ITEM QUANTITY UNIT SIZE RATING DESCRIPTION

43 52 07 1

80 PIPES

2 1500 44 R50 Soft Iron 53 7/8 x 260 8 088 G-3

10 2

6 v. =

.=

1 m Ele 1

2 1500 R50 Soft Iron 7/8 x 146 8 v Fro 43 7 569 CL

44 54 Ele 5 2 20 meters 8" Sch 120 Pipe A-106 Gr B SMLS

305 52

795 CL 3

12 14 4

305

"-E 1

114

8" -3 5 2 meters 4" Sch 80 Pipe A-106 Gr B SMLS

I-3 1**

6

12

BPR0 E-W 14

334

0

121

103 10

172 7 22 meters 3" Sch 80 Pipe A-106 Gr B SMLS

-G 12 2 AG FITTINGS

-8" 3" UG

116

0

-31

28 1 OC

) 2"x 7 86 8

- WI P S-0 y Z 37 2 9 3 pcs 8x4x8 Sch 120 8x4x8 Reducing Tee A-234 Gr WPB

1 03E l i e d b LVE

A

5 7 19

upp C V 5 2 26 14 10 3 pcs 3" Sch 80 3" Equal Tee A-234 Gr WPB

( S AY AR 2" 0

530 W

YAR 2"x4

"

3"x 7 26 43 320 11

114

2

4" 4"x

305 8"x 59 18 43 12 7 pcs 8" Sch 120 90° LR Elbow BW A-234 Gr WPBB

2405

FE 7 3" 27 114 13 3 pcs 4" Sch 80 90° LR Elbow A-234 Gr B

119

16 2"x 27 44 14 5 pcs 3" Sch 80 90° LR Elbow A-234 Gr B

305

-0 1

PS 18 44 54 15

152 2 61 50

42 26 54

12 40 25

16 1 pcs 8"x4" Sch 120 8"x4" Conc Reducer BW A-234 Gr B

43

60 17 1 pcs 4"x3" Sch 80 4"x3" Conc Reducer BW A-234 Gr B

152

48 18

FCV9 36

156 124 27 18 3 pcs 3"x2" Sch 80 3"x2" Conc Reducer BW A-234 Gr B

356

44 51

13 19 1 pcs 3" Sch 80 3" Pipe Cap

50 53 43

110 42 0 20

4"x 5 25 26 345

1630

21 3 pcs 4"x1" 6000#FS 4"x1" Threadolet A181 Gr 1

3"

103E-WI-31**-4"-E12

5 156 9 22

102 5 FLANGES

17 4" 23 5 pcs 8" 1500# RTJ WN Flange Sch 120 bore A-105 Gr 2 ASME B16.5

895

24

34 26

P 25 25 9 pcs 4" 1500# RTJ WN Flange Sch 80 bore A-105 Gr 2 ASME B16.5

78I8 25

43 114 13 PI

356

42

36

787 26 10 pcs 3" 1500# RTJ WN Flange Sch 80 bore A-105 Gr 2 ASME B16.5

152

42 9

58 27 3 pcs 2" 1500# RF WN Flange Sch 80 bore A-105 Gr 2 ASME B16.5

152

50 7 58

P 51

21 78I9 50 25 28

FC 43 21

119V 14 5

114

7 58 152 42 29

26

21

50 30

13

31

3"

485

PS- 600 33 23

03 40 PS- VALVES

48 04

23 Ele 32 1 pcs 8" 1500# ASME 1500 RTJ Flg Swing Check Valve A216-WCB Disc & seat 13% CR B16.34 API 600

5 40 v.

48 103 = 1 33 2 pcs 8" 1500# ASME 1500 RTJ FLG Ball Valve CS A216 WCB Trim 13% CR Ball A105 Gear operated

152 8"

25

57

TP E-G 055 34 2 pcs 4" 1500# ASME 1500 RTJ FLG Ball Valve CS A216 WCB Trim 13% CR Ball A105 Gear operated

156 103E-WI-31**-3"-E12

950

-30 82

Fro 42 25

7 2 8 ( 35

300 1545

Dis

m G

From G-306

50 42 5 TP2 36 2 pcs 3" 1500# ASME 1500 RTJ Check Valve, Duocheck II

-30 9 750

o C

cha

4 & 50 f W onn rge C 37 2 pcs 3" 1500# ASME 1500 RTJ FLG Ball Valve CS A216 WCBTrim 13%CR Ball A105 Gear operated

34 I P ect ) L

G-3 25 ump to GASKETS AND

356

23

05 42 25 Dis 3" 38

TP4 cha Fla

Exi Con 40 207 42 rge nge

sti nec 48 3

05 1200 0 50 39

From G-307

ng t t 50 40 7 pcs 8" 1500# R50 Gasket RTJ Octagonal Ring, Soft Iron.Max 90 BHN ASME B16.20

8

TP "Fla o 12

400

305 915 Dra

in 41

nge 105 p

305

CL 4 3" v. = 3" m Pum 42 9 pcs 4" 1500# R39 Gasket RTJ Octagonal Ring, Soft Iron.Max 90 BHN ASME B16.20

12 7

Ele 40 Ele ro 43 9 pcs 3" 1500# R35 Gasket RTJ Octagonal Ring, Soft Iron.Max 90 BHN ASME B16.20

103 v= 12" 2 48

e,

pip ce 14 F

E-W 105 x8" g 3" e Pie 37 26 44 3 pcs 2" 1500# R24 Gasket RTJ Octagonal Ring, Soft Iron.Max 90 BHN ASME B16.20

I-1 915 40 23 tin Te

xis ual 43

305

330 STUD BOLTS

2 ut ell Eq 52

-12 48 40 2 C

3 ta

TP d ins 26 3" 45

"-G 23 48

3

305

12

an TP 43

1915

12 33

52 46

305

3 AG

200

47

2 UG AG 48 84 pcs 1 5/8 8"1500# Stud Bolt 1 5/8 x 320mm A-193 Gr B7,2 Hex Nuts A-194 Gr2H

-E1 540 a nk

12

2 -8" oT UG 49

127 T

2

305

17

12 I-3 3" 50 72 pcs 1 1/4 4"1500# Stud Bolt 1 1/4 x 200mm A-193 Gr B7,2 Hex Nuts A-194 Gr 2H

8" E -W 95

PS-

10 3 16 10 ied 51 16 pcs 1 1/8 3"1500# Stud Bolt 1 1/8 x 267mm A-193 Gr B7,2 Hex Nuts A-194 Gr 2H

burrve

0 7

150 2 2 7 e

0 86 3" pip se 52 40 pcs 1 1/8 3"1500# Stud Bolt 1 1/8 x 180mm A-193 Gr B7,2 Hex Nuts A-194 Gr 2H

305 8" ep to ump

305 680 m

m d rse 53 8 pcs 7/8 2"1500# Stud Bolt 7/8 x 260mm A-193 Gr B7,2 Hex Nuts A-194 Gr 2H

163

5 7000mm wate 54 16 pcs 7/8 2"1500# Stud Bolt 7/8 x 146mm A-193 Gr B7,2 Hex Nuts A-194 Gr 2H

65 drain DRAIN WATER SUMP

as 55

11

14

4

56

114

14 INSTRUMENTS

57 1 pcs 4" 1500# FCV 1197 Flow control valve

114 58 3 pcs 1/2" 6000# PI-787/PI-788/PI-789 0-5000 PSI 1/2" NPT pressure indicator

59 1 pcs 2" 1500# BPCV 1210 1500 RTJ Back Pressure Control Valve, Yarway

114

425 60 1 pcs 4" 1500# FCV 1249 1500 RTJ Flow control valve 4"x4"x2", Yarway Arc Valve

5 61 1 set 8" 1500# FE-1197 Orifice plate and flange, Model 1495 and 1496 Rosemount

TIE-IN POINT INSTRUCTIONS

TP 1 Connect to 6" 1500# Flange of WI Pump Suction

TP 2 Connect to 4" 1500# Flange of WI Pump Discharge

TP 3 Cut existing 3" pipe and install Equal Tee Piece Legend: Reference Drawing NOTES:

TP 4 Connect to existing 8" 1500# Flange Existing AG

01. All dimensions are in millimeters unless otherwise noted.

TP 5 Remove 3" pipe cap and weld pipe Existing UG LY26/11092-I-001 02. Grade elevation = 105000mm.

TP 6 Remove 12" pipe cap and weld elbow piece Above Ground 103E-CL-39683 03. Verify all dimensions prior to fabrication of piping spools.

Under Ground ZUEITINA OIL COMPANY

TP 7 Cover with 8" blind flange 103E-CL-39749 04. Gaskets to be suitable for produced water.

DESIGN PRESSURE: 2000 PSI / 138 bar RADIOGRAPHY: 100 % 103E-CL-39676 05. All wetted parts on valves to be made of Super Duplex Alloy.

OPERATING PRESSURE: 1500 PSI /103 bar STRESS RELIEF: 3/4" WT & more 103E-DA-3397 06. Pipes internally epoxy coated according to specification GES X04.

07. For coating purposes on site additional flange connections might be required.

TEST PRESSURE: 3000 PSI /207 bar RATING: 1500#

DESIGN TEMPERATURE:

OPERATING TEMPERATURE:

200 F / 93°C INSULATION:

0-50 °C amb MEDIUM:

N/A

Produced Water

08.

09.

Item 60: Flow Control Valve.

ALL UNDER GROUND PIPES WILL BE WRAPPED.

V A L U E

VAOS

A D D E D O I L F I E L D S E R V I C E S

S-ar putea să vă placă și

- Piping Stress Analysis and Design Training CoursesDocument1 paginăPiping Stress Analysis and Design Training CoursesMeena RezkallahÎncă nu există evaluări

- Province Tanger Assilah AR A3Document1 paginăProvince Tanger Assilah AR A3Abdellah MarniÎncă nu există evaluări

- Province Tanger Assilah AR A3Document1 paginăProvince Tanger Assilah AR A3Abdellah MarniÎncă nu există evaluări

- 1 Toyota Fortuner (Cont. Next Page) : Starting Power SourceDocument2 pagini1 Toyota Fortuner (Cont. Next Page) : Starting Power Sourcealexander pintoÎncă nu există evaluări

- 1 Toyota Fortuner (Cont. Next Page) : Starting Power SourceDocument2 pagini1 Toyota Fortuner (Cont. Next Page) : Starting Power Sourcealexander pintoÎncă nu există evaluări

- Overall Electrical Wiring Diagram for the Toyota FortunerDocument2 paginiOverall Electrical Wiring Diagram for the Toyota Fortuneralexander pintoÎncă nu există evaluări

- Ingeniería Toyota 08Document2 paginiIngeniería Toyota 08alexander pintoÎncă nu există evaluări

- 1 1 PDFDocument2 pagini1 1 PDFMarcio Soraia ZopiÎncă nu există evaluări

- Toyota Hilux - Full Motores CheckDocument2 paginiToyota Hilux - Full Motores CheckVallejos FranzÎncă nu există evaluări

- Toyota Hilux - Full Motores CheckDocument2 paginiToyota Hilux - Full Motores CheckDanilo PierreÎncă nu există evaluări

- Overall Electrical Wiring Diagram for Toyota HiluxDocument2 paginiOverall Electrical Wiring Diagram for Toyota HiluxDanilo PierreÎncă nu există evaluări

- Toyota Hilux - Full Motores CheckDocument2 paginiToyota Hilux - Full Motores CheckJoycee Lázaro Reyes0% (1)

- 1 Hilux (Cont. Next Page) : Starting Power SourceDocument2 pagini1 Hilux (Cont. Next Page) : Starting Power SourcewilderÎncă nu există evaluări

- HW 2Document2 paginiHW 2김가온Încă nu există evaluări

- Ukupna Netto Površina / Summ Net Area Brutto Površina / Summ Gross AreaDocument1 paginăUkupna Netto Površina / Summ Net Area Brutto Površina / Summ Gross AreaVuk VusovicÎncă nu există evaluări

- MONTHLY MONITORINGDocument17 paginiMONTHLY MONITORINGRisali AddiniÎncă nu există evaluări

- F122 76-10526-Detail Design: Fire Protection Services - Ground Level PlanDocument1 paginăF122 76-10526-Detail Design: Fire Protection Services - Ground Level PlanMazen IsmailÎncă nu există evaluări

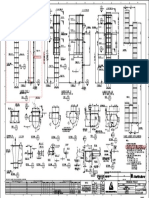

- 560 000 ST S 004 - 0 - EscalerVerticalDocument1 pagină560 000 ST S 004 - 0 - EscalerVerticalRenzo Amiquero CrispinÎncă nu există evaluări

- Circuit Descriptions: Test PointDocument2 paginiCircuit Descriptions: Test PointRM EletronicaÎncă nu există evaluări

- Mazowe DevelopmentDocument1 paginăMazowe DevelopmentRodney ZephaniaÎncă nu există evaluări

- Steeldeck 3F PDFDocument1 paginăSteeldeck 3F PDFlouie n. gustoÎncă nu există evaluări

- Steeldeck 3F PDFDocument1 paginăSteeldeck 3F PDFlouie n. gustoÎncă nu există evaluări

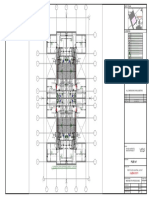

- Total Parking 11 Parkings: Setback OutlineDocument1 paginăTotal Parking 11 Parkings: Setback Outlinehanim MohamedÎncă nu există evaluări

- Site Layout FO KIK-CCTV-ARIF - New Rev4Document1 paginăSite Layout FO KIK-CCTV-ARIF - New Rev4Adi PriyapurnatamaÎncă nu există evaluări

- Scubber Seal Tank (6a25-T12) 12kl-MasterDocument2 paginiScubber Seal Tank (6a25-T12) 12kl-MasterJayan VKÎncă nu există evaluări

- Thermadyne-Catalog CigweldDocument292 paginiThermadyne-Catalog CigweldUmmi Rahmatul IstiqomahÎncă nu există evaluări

- SM 1Document87 paginiSM 1Gilberto BerdealÎncă nu există evaluări

- Brake Abs SystemDocument5 paginiBrake Abs SystemHENRY HERRERA100% (1)

- This Map Shows The Location of Dropped Kerbs Within The City Centre, To Assist in Journey Planning For Visitors. Visitor Information: 01273 290337Document1 paginăThis Map Shows The Location of Dropped Kerbs Within The City Centre, To Assist in Journey Planning For Visitors. Visitor Information: 01273 290337Fer GarciaÎncă nu există evaluări

- November - 2022 - 14097631 - 2022 - 12 - 19 - 21 - 33Document27 paginiNovember - 2022 - 14097631 - 2022 - 12 - 19 - 21 - 33Sudha ManiÎncă nu există evaluări

- Kip D 1001071709 003 PDFDocument1 paginăKip D 1001071709 003 PDFHisham AfzalÎncă nu există evaluări

- Sector Huancapata 03Document1 paginăSector Huancapata 03Carlos BustamanteÎncă nu există evaluări

- Clearing and Grubbing 052622Document1 paginăClearing and Grubbing 052622CCDC PTP MabalacatÎncă nu există evaluări

- M Overall Electrical Wiring Diagram: 2005 HIGHLANDER (EWD592U)Document67 paginiM Overall Electrical Wiring Diagram: 2005 HIGHLANDER (EWD592U)Meng HortÎncă nu există evaluări

- Cartridge List by FamilyDocument10 paginiCartridge List by Familydomi3316Încă nu există evaluări

- EPA Intranet Memo on Internal Testing ResultsDocument5 paginiEPA Intranet Memo on Internal Testing ResultsxdslÎncă nu există evaluări

- Circular Canvas: User ManualDocument23 paginiCircular Canvas: User ManualBerry BlueÎncă nu există evaluări

- Circular Canvas: Manuel D'UtilisationDocument23 paginiCircular Canvas: Manuel D'UtilisationjeanluluÎncă nu există evaluări

- Francais Circular CanvasDocument23 paginiFrancais Circular CanvasZiyad Ait allaÎncă nu există evaluări

- Baja Sae ResultsDocument3 paginiBaja Sae ResultsAkash Pavan100% (1)

- 1TR-FE WiringDocument4 pagini1TR-FE WiringoretuertoyanapaÎncă nu există evaluări

- Ilide - Info Caterpillar Gas Engine 3516 Schematic Diagram PRDocument2 paginiIlide - Info Caterpillar Gas Engine 3516 Schematic Diagram PRTamÎncă nu există evaluări

- P-12 POI P-11: Ubicación GeneralDocument1 paginăP-12 POI P-11: Ubicación GeneraledulinlinÎncă nu există evaluări

- CR FT Labels Lot 2.8.16Document20 paginiCR FT Labels Lot 2.8.16Sathiya SeelanÎncă nu există evaluări

- Mur-Sd-Th-4f-Ee-03-002 First Floor Lighting Layout-Ff LightingDocument1 paginăMur-Sd-Th-4f-Ee-03-002 First Floor Lighting Layout-Ff Lightingcarrei JohnÎncă nu există evaluări

- Bp Aciprisprince R4.00+ EP070+ PlatforDocument1 paginăBp Aciprisprince R4.00+ EP070+ PlatforBogdan ParaschivÎncă nu există evaluări

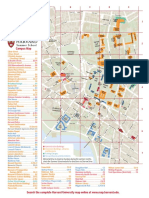

- Campus MapDocument1 paginăCampus MapCretu NicolaeÎncă nu există evaluări

- Amato Habanera Double Bass and Piano PDFDocument2 paginiAmato Habanera Double Bass and Piano PDFJuan Patricio SaenzÎncă nu există evaluări

- Hilux PDFDocument6 paginiHilux PDFEuler De Souza Silva CarvalhoÎncă nu există evaluări

- Texas House District 121Document1 paginăTexas House District 121Texas Public RadioÎncă nu există evaluări

- Brgy. Santa Clara: STA. 31+320.00 MatchlineDocument1 paginăBrgy. Santa Clara: STA. 31+320.00 Matchline020898Încă nu există evaluări

- Western Adventure LoopDocument4 paginiWestern Adventure Loopanon_275937008Încă nu există evaluări

- Lands Op en To Public Hunting Lap Eer County: LegendDocument1 paginăLands Op en To Public Hunting Lap Eer County: LegendChris LeidleinÎncă nu există evaluări

- SM 1Document115 paginiSM 1Anthonio Jesús Lezkano MÎncă nu există evaluări

- MDF304 Cory Pattern Letter A4Document45 paginiMDF304 Cory Pattern Letter A4BeaÎncă nu există evaluări

- Midas MD-TV29399 Con UOC TMPA8879CSN Diagrama PDFDocument3 paginiMidas MD-TV29399 Con UOC TMPA8879CSN Diagrama PDFOdaliz EspinozaÎncă nu există evaluări

- SITEPLANDocument1 paginăSITEPLANnadia haniÎncă nu există evaluări

- Bus Control: AGC VT CSDocument3 paginiBus Control: AGC VT CSTecnico GenioÎncă nu există evaluări

- Irrigation Plan SymbolsDocument4 paginiIrrigation Plan SymbolsZai Unn100% (2)

- Válvula Diafragma para Controlar de NívelDocument4 paginiVálvula Diafragma para Controlar de NívelRouberioRolimÎncă nu există evaluări

- Pneumatic Three Axis Tipper Lifts VehiclesDocument14 paginiPneumatic Three Axis Tipper Lifts Vehiclesn_amarsinh9938Încă nu există evaluări

- Volvo BL 71 6 SteeringDocument29 paginiVolvo BL 71 6 SteeringVygintas Balcius100% (2)

- BFE Installation-Operation-Maintenance Manual PDFDocument48 paginiBFE Installation-Operation-Maintenance Manual PDFErcan Yilmaz0% (1)

- Instrument Air Dryer Sizing Calculation FactorsDocument1 paginăInstrument Air Dryer Sizing Calculation FactorsAravind Kannan100% (2)

- Condensate TankDocument2 paginiCondensate TankvpjagannaathÎncă nu există evaluări

- Evaporator and Condensers TypesDocument4 paginiEvaporator and Condensers TypesOwais SiddiquiÎncă nu există evaluări

- Centrifugal PumpsDocument24 paginiCentrifugal PumpsHari Babu DharmavarapuÎncă nu există evaluări

- BTG ValvesDocument20 paginiBTG ValvesShivakumarÎncă nu există evaluări

- Valve HandbookDocument52 paginiValve Handbookshivam100% (1)

- Bomba de Engranajes Catalogo JOYANGDocument8 paginiBomba de Engranajes Catalogo JOYANGlizbethdiosesÎncă nu există evaluări

- API Specification 12B: Specification For Bolted Tanks For Storage of Production LiquidsDocument3 paginiAPI Specification 12B: Specification For Bolted Tanks For Storage of Production LiquidsArthamigas RamdaniÎncă nu există evaluări

- Gear Pump Datasheets 1Document12 paginiGear Pump Datasheets 1MauliÎncă nu există evaluări

- Line Sizing1Document20 paginiLine Sizing1Srihari KodimelaÎncă nu există evaluări

- KBMG Series Side Pocket MandrelsDocument2 paginiKBMG Series Side Pocket Mandrelsبلال حسينيÎncă nu există evaluări

- Heat Exchanger SpecificationsDocument1 paginăHeat Exchanger SpecificationsPankaj PandeyÎncă nu există evaluări

- Cañerias Del EnfriadorDocument4 paginiCañerias Del EnfriadorAlex BravoÎncă nu există evaluări

- Conversion Table From Inches To MillimetersDocument4 paginiConversion Table From Inches To MillimetersZeljko KukicÎncă nu există evaluări

- BeltingDocument2 paginiBeltingandirahmantanjungÎncă nu există evaluări

- Sizing & Selection: Control Valve Noise PredictionDocument5 paginiSizing & Selection: Control Valve Noise PredictionsnamprogÎncă nu există evaluări

- Fluid Flow MeasurementDocument5 paginiFluid Flow MeasurementKarla MaalihanÎncă nu există evaluări

- Boiler Feed and Pump Sizing - C-B and Grundfos July 2016Document63 paginiBoiler Feed and Pump Sizing - C-B and Grundfos July 2016Jose Lorenzo Toral100% (2)

- Piping Presentation L & TDocument61 paginiPiping Presentation L & TBukti SiahaanÎncă nu există evaluări

- Isa-S75 01 PDFDocument52 paginiIsa-S75 01 PDFOSIIQPGRIS100% (2)

- Waterhammer Potential in Pumps and SystemsDocument16 paginiWaterhammer Potential in Pumps and Systemseuric82Încă nu există evaluări

- Astral Aquasafe Price List Dt. 05th May 2018.Document8 paginiAstral Aquasafe Price List Dt. 05th May 2018.PGHOSH11Încă nu există evaluări

- Diaz Bendo Lipana FinalDocument73 paginiDiaz Bendo Lipana FinalAries Villegas MontabonÎncă nu există evaluări

- BKH / Bkhp420 2-Way Ball Valve Stainless Steel: Available Sizes ConnectionsDocument4 paginiBKH / Bkhp420 2-Way Ball Valve Stainless Steel: Available Sizes ConnectionsManikandan MÎncă nu există evaluări

- PLANO Hidraulico 325C PDFDocument2 paginiPLANO Hidraulico 325C PDFRamón Hugo EspinozaÎncă nu există evaluări