Documente Academic

Documente Profesional

Documente Cultură

Experimental Investigation and Analysis A Mechanical Properties of Hybrid Polymer Composite Plates

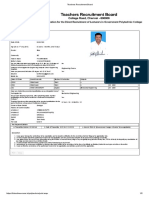

Încărcat de

Karthik SubramaniDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Experimental Investigation and Analysis A Mechanical Properties of Hybrid Polymer Composite Plates

Încărcat de

Karthik SubramaniDrepturi de autor:

Formate disponibile

International Journal of Engineering Trends and Technology (IJETT) – Volume 9 Number 8 - Mar 2014

Experimental Investigation and Analysis a

Mechanical Properties of Hybrid Polymer

Composite Plates

R.Sakthivela*, D.Rajendranb

* Corresponding author

a

P.G Scholar, Jayaram college of engineering college of technology ,Trichy - 621014

b

Supervisor and Faculty Member, Jayaram college of engineering college of technology ,Trichy - 621014

ABSTRACT woven fiber glass hybrid composites. In this hybrid

composite laminates banana-glass-banana (BGB) and

The hybrids composite has emerged and have the glass-banana-glass (GBG) exhibit higher mechanical

potential reinforcement material for composites and thus properties due to chemical treatment to natural fibers. So,

gain attraction by many researchers. This is mainly due to the hybrid composite material shows the highest

their applicable benefits have they offer low density, low mechanical properties. This High performance hybrid

cost, renewable, biodegradability and environmentally composite material has extensive engineering applications

harmless and also comparable mechanical properties with such as transport industry, aeronautics, naval, automotive

synthetic fiber composites. In the project natural fiber and industries.

glass hybrid composites were fabricated by using epoxy

resin combination of hand lay-up method and cold press

method. Specimen was cut from the fabricated laminate Keywords: Hybrid composites, mechanical properties,

according to the ASTM standard for different experiments epoxy, hand layup.

for tensile test, flexural text, and impact test. A significant

improvement in tensile strength was indicated by the

1.INTRODUCTION as natural fibres from a vast number of plants.However,

since the last decade, a great deal of emphasis has been

In recent years, polymeric based focused on the development and application of natural fibre

composites materials are being used in many application reinforced composite material in many industries. Needless

such as automotive, sporting goods, marine, electrical, to say, due to relatively high cost of synthetic fibres such as,

industrial, construction, household appliances, etc. glass, plastic, carbon and Kevlar used in fibre reinforced

Polymeric composites have high strength and stiffness, composite, and the health hazards of asbestos fibres, it

light weight, and high corrosion resistance. Natural fibres becomes necessary to explore natural fibre, like banana

are available in abundance in nature and can be used to fibres.

reinforce polymers to obtain light and strong materials. The The natural fiber present important advantages such

information on the usage of banana fibre in reinforcing as low density, appropriate stiffness, mechanical properties

polymers is limited in the literature. In dynamic with high disposability and renewability. In this project are

mechanical analysis, have investigated banana fibre used the natural fibre of banana. Moreover, these banana

reinforced polyester composites and found that the fiber are recycle and biodegradable.. Banana fiber, a lingo-

optimum content of banana fibre is 40%. The analysis of cellulosic fiber, obtained from the pseudo-stem of banana

tensile, flexural, and impact properties of these composites plant (Musa sepientum), is a bast fiber with relatively good

revealed that composites with good strength could be mechanical properties. In tropical countries like India,

successfully developed using banana fibre as the fibrous plants are available in abundance and some of them

reinforcing agent. The source of banana fibre is the waste like banana are agricultural crops. Banana fiber at present is

banana trunk or stems which are abundant in many places a waste product of banana cultivation. Hence, without any

in the world. additional cost input, banana fiber can be obtained for

Nature continues to provide mankind generously industrial purposes. Banana fiber is found to be good

with all kinds of rich resources in plentiful abundance, such reinforcement in polypropylene resin. The properties of the

composites are strongly influenced by the fiber length

ISSN: 2231-5381 http://www.ijettjournal.org Page 407

International Journal of Engineering Trends and Technology (IJETT) – Volume 9 Number 8 - Mar 2014

Table 1 composites.

Comparison between natural and glass fibres

Natural fibres Glass fibres

iii. Polymer Matrix Composites

Density Low Twice that of natural fibres

Cost Low Low, but higher than NF Polymeric matrix composites are the most

Renewability Yes No

commonly used matrix materials. The reasons for this are

Recyclability Yes No

Energy consumption Low High

two-fold. In general the mechanical properties of polymers

Distribution Wide wide are inadequate for many structural purposes. In particular

CO2 neutral Yes No their strength and stiffness are low compared to metals and

Abrasion to machines No Yes ceramics. By reinforcing other materials with polymers

Health risk when inhaled No Yes these difficulties can be overcome. Secondly high pressure

Disposal Biodegradable Not biodegradable and high temperature are not required in the processing of

polymer matrix composites. For this reason polymer

composites developed rapidly and became popular for

1.2 OBJECTIVES structural applications with no time. Polymer composites

are used because overall properties of the composites are

Keeping in view the above mentioned knowledge superior to those of the individual polymers.

gaps, the following objectives were chosen for the present 2. EXPERIMENTAL

research project work. 2.1 MATERIALS AND METHODS

a) Fabrication of a new class of epoxy based hybrid THE MATRIX

composites reinforced with oriented glass fibers and The materials used for matrix are epoxy,

banana fibers. unsaturated polyester and vinyl ester. Epoxy resins are the

b) Evaluation of mechanical properties such as most common matrices for high performance advanced

tensile strength, flexural strength and micro hardness for polymer composites, but they are also inherently brittle

these composites. because of their high degree of cross linking. The densely

c) To study the influence of fiber parameters such as cross linked structures are the basis of superior mechanical

fiber and fiber loading on the mechanical behaviour of the properties such as high modulus, high fracture strength,

composites. and solvent resistance. However, these materials are

irreversively damaged by high stresses due to the

TYPES OF COMPOSITE MATERIALS formation and propagation of cracks. These lead to

dangerous loss in the load-carrying capacity of polymeric

Broadly, composite materials can be structural engineering materials. Currently the unsaturated

classified into three groups on the basis of matrix polyesters are the most widely used polymer in

material. They are construction [6].

i. Metal Matrix Composites (MMC) HARDENER

ii. Ceramic Matrix Composites (CMC) A substance of mixture added to a plastic

iii. Polymer Matrix Composites (PMC) composition to take part in and promote or control the

curing action, also a substance added to control the degree

i. Metal matrix composites of hardness of the cured film. See also curing agents,

Higher specific modulus, higher specific strength, catalyst and cross-linking [6].

better properties at elevated temperatures and lower All working times (pot life) are based upon an

coefficient of thermal expansion are the advantages of optimum working temperature of about 80 degrees F.

metal Matrix Composites over monolithic metals. Because temperatures variations will greatly affect curing times,

of these attributes metal matrix composites are under and when below 65F can sometimes double curing times.

consideration for wide range of applications viz. Other factors that affect epoxy curing can be moisture and

combustion chamber nozzle (in rocket, space shuttle), humidity, as well as the thickness of lamination.

housings, tubing, cables, heat exchangers, structural GLASS FIBERS

members etc. The most common reinforcement for the polymer matrix

ii. Ceramic matrix Composites composites is a glass fiber. Most of the fibers are based on

One of the main objectives in producing ceramic silica (sio2), with addition of oxides of ca, b, na, fe, and al.

matrix composites is to increase the toughness. Naturally it the glass fibers are divided into three classes -- e-glass, s-

is hoped and indeed often found that there is a concomitant glass and c-glass. the e-glass is designated for electrical

improvement in strength and stiffness of ceramic matrix use and the s-glass for high strength.

ISSN: 2231-5381 http://www.ijettjournal.org Page 408

International Journal of Engineering Trends and Technology (IJETT) – Volume 9 Number 8 - Mar 2014

the fiber and make it suitable for spinning. The

concentrations used were 0.5%, 1%, 1.5% weight/volume.

Treatment was done with sample: liquor ratio of

1:30.Standard procedure used in the institute is as

follows[5]. In the present study 200 grams of banana fibres

were used per concentration. Since the NaOH used was

1:30 total solution used in each case was 6 litres. For

preparation of NaOH solution, 1% NaOH solution was

used [11].

Fibre-cell-OH + NaOH Fibre cell-O-Na+ + H2O + impurities

Fig 1 Glass fiber

The Researchers now a days developed

equipment to make the glass fiber dust in to powder or

particle cullet either by calcinations and pulverization or

by pyrolysis. This enabled the company to re-use the fiber

dust as glassmaking material.

This chapter details the materials used and methodologies

adopted during the fabrication, sample preparation,

mechanical testing and characterization of the hybrid Fig 2 Chemical reaction

composites. The raw materials used in the study are: Alkaline treatment of banana fibers protocol

i) Epoxy resin

ii) Banana Fiber

Weigh out required quantity of banana fibers

iii) Glass Fiber (S-Glass)

iv) Hardener

Epoxy resin Check out specific gravity of required conc. Of NaOH

Epoxy resins are available in liquid and solid forms

and are cured into the finished plastics by a catalyst. They

are cured at room temperatures as well as elevated

Take NaOH in a glass beaker (1:30 ratio) 4 gm fibre: 120

temperatures of about 2750C. The erosion resin of grade

ml NaOH

LY-556 was used of density 1.1-1.2gm/cc at 298K. It

having the following outstanding properties has been used

as the matrix material.

Add 1-2 drops of wetting agent i.e. auxypon

a) Excellent adhesion to different materials.

b) High resistance to chemical and atmospheric

attack. High dimensional stability.

Mix the solution properly with the help of a glass rod

c) Free from internal stresses.

d) Excellent mechanical and electrical properties.

Odourless, tasteless and completely nontoxic.

Add fibers in a beaker such that fibers are immersed in the

Negligible shrinkage.

solution completely

2.2 Banana fiber and Alkali treatment

Banana fiber is a natural fiber with relatively

good mechanic properties. The diminutive second-

Keep it for ½ hr. Swirl the solution intermediately

generation Mercedes-Benz A-Class designed the spare tire

recess covered with a composite material, polypropylene

thermoplastic with embedded banana fibers, abaca, with

Wash out the fibers with warm water 4-5 times

high tensile strength and rot-resistant. It can withstand

stone strikes and exposure to the environment, such as

ultraviolet from the sun, water, some chemicals. Using

Wash the fibers with distilled water

abaca fiber is saving energy because conventional glass

fibers production requires 60% more energy than this

natural fiber[11].

Sodium Hydroxide (NaOH) treatment removes Dry the fibers at room temperature on a blotting paper.

impurities from the fiber surface, Banana fiber sample

were treated with three different conc. of NaOH to soften Fig 3 Treatment of banana fiber

ISSN: 2231-5381 http://www.ijettjournal.org Page 409

International Journal of Engineering Trends and Technology (IJETT) – Volume 9 Number 8 - Mar 2014

Table 2

Tensile strength 48 Mpa

Properties of Banana fiber

PROPERTIES BANANA FIBER

Compressive strength 103 Mpa

Cellulose % 63–64

Moisture content % 10-11 (a) Description of hand layup technique

Matrixes/Resins are impregnated by hand into fibers

Density (kg/m3) 1350

which are in the form of chopped strand mat woven,

knitted, stitched or bonded fabrics. This is usually

Flexural modulus (GPa) 2-5 accomplished by rollers or brushes, with an increasing use

of nip-roller type impregnators for forcing resin into the

Lumen size (mm) 5 fabrics by means of rotating rollers and a bath of resin.

Laminates are left to cure under standard atmospheric

Tensile strength (MPa) 54 conditions [2].

Young’s modulus (GPa) 3.4878

Glass fibers are among the most versatile

industrial materials known today. They are readily

produced from raw materials, which are available in

virtually unlimited supply. All glass fibers described in this

article are de-rived from compositions containing silica.

They exhibit useful bulk properties such as hardness,

transparency, resistance to chemical attack, stability, and

inertness, as well as desirable fiber properties such as Fig 5 Hand layup technique

strength, flexibility, and stiffness. Glass fibers are used in

the Manufacture of structural composites, printed circuit

boards and a wide range of special-purpose products[2][3]. (b) Materials Options

Resins: Epoxy, polyester, vinyl ester, phenolic and any

other resin.

Fibers: Glass, Carbon, Aramid and any other

reinforcement, although heavy aramid fabrics can be

difficult to wet-out by hand.

Cores: Any core materials can be used provided that

should be compatible with resin system, i.e. polystyrene

core cannot be used with polyester or vinylester resin

system.

(c) Advantages

Fig 4 Methodology

i) Low capital Investment.

Table 3

ii) Simple principles to fabricate the part.

S-glass fibers properties iii) Low cost tooling, if room-temperature cure resins are

used.

Value in metric unit iv) Wide choice of suppliers and material types.

Density 1.8×103 Kg/m3

The banana fiber and glass which is taken as

Tensile modulus 5.5 Gpa

reinforcement in this study is collected from local sources.

Compressive modulus 6.9 Gpa The epoxy resin and the hardener are supplied. Wooden

moulds having were first manufactured for composite

ISSN: 2231-5381 http://www.ijettjournal.org Page 410

International Journal of Engineering Trends and Technology (IJETT) – Volume 9 Number 8 - Mar 2014

fabrication. The banana fiber and S- Glass fibers are mixed continue to hardened after it has gelled, until, at some time

with epoxy resin by simple mechanical stirring and the later. It has obtained maximum hardness and all its

mixture was poured into various moulds, keeping in view properties. This reaction itself is accompanied by the

the requirements of various testing conditions and generation of exothermic heat, which, in turn speed up the

characterization standards. The composite samples of nine reaction. This whole process is known as ‘Curing’ of the

different compositions (S-1 to S-4) are prepared. The resins.

composite samples S-1 to S-4 are prepared in three Curing at high temperature has the added

different percentages of Glass and banana fibers (15 wt % advantage that it actually increases the end mechanical

and 30 wt %). properties of the material. And many resin systems will not

reach their ultimate mechanical properties unless the resin

is given this ‘Postcure’. This posture process involves

increasing the laminate temperature after the initial room

Table 4 temperature cure, which increase the amount of cross

Classifications of glass fibers linking of the molecules that can take place. To some

degree this posture will occur naturally at warm room

TypesOf Glass Area Of Specification temperatures, but higher properties and shorter posture

times will be obtained if elevated temperatures are used.

Application

Table 5

S –glass Tensile strength High strength Designation of Composites

E –glass Electrical High electrical resistivity REINFORCEMENT

C –glass Chemical High corrosion resistance MATRIX SYNTHETIC NATURAL

S-GLASS FIBER BANANA

This is done while keeping the epoxy content at a FIBER

fixed percentage (i.e. 50 and60 wt %).Same lengths of

banana fiber are used, while keeping the length of the glass S1 YELLOW 50 % 20% 30 %

fiber constant. The detailed composition and designation of

composites are shown in Table 5. S2 BLUE 60 % 20 % 20 %

A releasing agent is used on the mould release S3 GREEN 50 % 25 % 25 %

sheets to facilitate easy removal of the composite from the

S4 RED 60 % 25 % 15 %

mould after curing. The entrapped air bubbles (if any) are

removed carefully with a sliding roller and the mould is

closed for curing at a temperature of 30°C for 24 h at a

constant load of 50 kg. After curing, the specimens of

suitable dimension are cut using a diamond cutter for

mechanical tests as per the ASTM standards. The

composition and designation of the composites prepared

for this study are listed in the following table. The samples

have been prepared by varying the fiber length and fiber

loading for the two fibers[2][3]][4].

Fig 6 Fiber and Resin layer

Fig 7 Fabricated specimens

On addition to hardener the resin will begin to

become more viscous until it’s not at all liquid and has lost

its ability to flow. This is ‘Gel Point’ the resin will

ISSN: 2231-5381 http://www.ijettjournal.org Page 411

International Journal of Engineering Trends and Technology (IJETT) – Volume 9 Number 8 - Mar 2014

3. RESULTS AND DISCUSSION 3.2 FLEXURAL STRENGTH (ASTM D-790)

3.1 TENSILE TEST (ASTM D-638) Flexural strength, also known as modulus of

rupture, bend strength, or fracture strength a mechanical

The ability to resist breaking under tensile stress parameter for brittle material, is defined as a material's

is one of the most important and widely measured ability to resist deformation under load. The transverse

properties of materials used in structural applications. bending test is most frequently employed, in which a rod

specimen having either a circular or rectangular cross-

The force per unit area (MPa or psi) required to break a section is bent until fracture using a three point flexural

material in such a manner is the ultimate tensile test technique.

strength or tensile strength at break. Tensile properties

indicate how the material will react to forces being applied The flexural strength represents the highest stress

in tension. A tensile test is a fundamental mechanical test experienced within the material at its moment of rupture. It

where a carefully prepared specimen is loaded in a very is measured in terms of stress, here given the

controlled manner while measuring the applied load and symbol .When an object formed of a single material, like

the elongation of the specimen over some distance. Tensile a wooden beam or a steel rod, is bending, it experiences a

tests are used to determine the modulus of elasticity, elastic range of stresses across its depth. At the edge of the object

limit, elongation, proportional limit, and reduction in area, on the inside of the bend (concave face) the stress will be

tensile strength, yield point, yield strength and other tensile at its maximum compressive stress value. At the outside of

properties. the bend (convex face) the stress will be at its maximum

tensile value. These inner and outer edges of the beam or

rod are known as the 'extreme fibers'. Most materials fail

under tensile stress before they fail under compressive

stress, so the maximum tensile stress value that can be

sustained before the beam or rod fails is its flexural

strength.

Fig 8 Tensile Strength Fig 9 Tensile Strength

Table 6 Table 7

TENSILE STRENGTH FLEXURAL STRENGTH

TENSILE FLEXURAL

LENGTH WIDTH THICKNESS SPAN

STRENGTH BREADTH THICKNESS STRENGTH

S.NO LENGTH

mm mm mm S.NO mm mm

MPa mm

Mpa

1 50 12.50 4.00 54.15

1 100 27 4 163.1

2 50 12.60 3.40 27.27

2 100 26.80 3.20 133.16

3 50 12.90 3.80 51.80

3 100 27.60 3.80 116.67

4 50 12.60 3.90 33.30

4 100 26.80 3.80 120.15

ISSN: 2231-5381 http://www.ijettjournal.org Page 412

International Journal of Engineering Trends and Technology (IJETT) – Volume 9 Number 8 - Mar 2014

3.3. CHARPY IMPACT (ASTM D-256)

The Charpy impact test, also known as

the Charpy v-notch test, is a standardized high strain-rate

test which determines the amount of energy absorbed by a

material during fracture. This absorbed energy is a

measure of a given material's toughness and acts as a tool

to study temperature-dependent ductile-brittle transition. It

is widely applied in industry, since it is easy to prepare and

conduct and results can be obtained quickly and cheaply. A

major disadvantage is that all results are only comparative.

The apparatus consists of a pendulum axe swinging at a

notched sample of material.

The energy transferred to the material can

be inferred by comparing the difference in the height of the Fig 10 Results of Tensile Test

hammer before and after a big fracture. The notch in the

sample affects the results of the impact test, thus it is

necessary for the notch to be of regular dimensions and

geometry. The size of the sample can also affect results,

since the dimensions determine whether or not the material

is in plane strain.

Impact strength = E/t×1000

‘E’- Energy used to break (J)

‘t’ – Thickness in mm

Table 8

CHARPY IMPACT STRENGTH

ENERGY Fig 11 Results of Charpy Test

IMPACT

BREADTH THICKNESS USED TO

STRENGTH

S.N BREAK

180 163.1

mm mm

FLEXURAL STRENGTH

(J/mm) 160

(J) 133.16

140

116.67 120.15

120

100

1 10 4.00 2 10

Mpa

80

60

40

2 10 3.40 2 11.76 20

0

SPECIMEN-1 SPECIMEN-2 SPECIMEN-3 SPECIMEN 4

3 10 3.80 2 10.52 TEST SPECIMEN

4 10 3.90 2 10.25

Fig 12 Results of Flexural Test

ISSN: 2231-5381 http://www.ijettjournal.org Page 413

International Journal of Engineering Trends and Technology (IJETT) – Volume 9 Number 8 - Mar 2014

4. CONCLUSIONS flexural properties increasing volume fraction of fiber

A new type of fiber reinforcement composite was percent. Glass fiber dust is so voluminous that it cannot be

experimentally investigated. re-used as glass making material without treatment. It has

been disposed of by land filling as industrial waste.

However, regarding the glass fiber dust as an important

Chemical treatment like NaOH will increases the resource for glassmaking the company decided to recycle

flexural strength of the fiber up to 20-30% and removes the it.

moisture content of the fiber.

The future scope of the project is extended by doing the

The mechanical properties of banana and glass fiber and experimental analysis on different proportion of coupling

reinforced epoxy hybrid composites have been agents and the fiber content in the samples and performs

investigated. The tensile strength and flexural strength the mechanical and thermal properties test on the

increases with increasing fibre volume fraction. Among all specimen. And also implementation of eco-friendly fibers

the hybrid fibre composites tested, banana reinforced in the automotive parts like car panels, bumper etc.

epoxy hybrid composites registered the highest mechanical Through implementing this fiber we can achieve light

properties whereas glass and banana fiber composites weight and structural component in automotive parts,

showed the highest. which in turn fuel efficiency is increased.

The mechanical properties of the natural fibre and

synthetic fiber platescom-posites tested were found to

compare favourably with the corresponding tensile and

[8] Ashby M. F. Engineering materials and processes: Desk

Reference. 2013 pp-2239-2243

REFERENCES [12] Sapuan, S.M., Leenie, A., Harimi, M., Beng, Y.K., Mechanical

[1] Satyanarayana K. G, Sukumaran K, Mukherjee P. S, Pavithran properties of woven banana fiber reinforced epoxy composites,

C and Pillai S. G. K, “Natural-Poymer Fiber Composites”,nd 2006, 27, 689–693.

[13] SamratMukhopadhyay, Raul Fangueiro and Vijay Shivankar,

Concrete Journal of Composites, 12(2), 1990, pp. 117-136.

[2] Yang G. C, Zeng H. M, Jian, N. B and Li, J. J. Properties of Variability of Tensile Properties of Fibers from Pseudostem of

banana/ glass fiber reinforced PVC hybrid composites. Plastics Banana Plant, Textile Research Journal 2009, 79, 387-393.

[14] Malik P. K. Fiber reinforced Composites: Materials,

Industry, 1: (1996), pp 79-81.

[3] Kalaprasad G, Joseph K. and Thomas S. Influence of short Manufacturing and Design.

glass fiber addition on the mechanical properties of banana [15] S. Joseph, M.S. Sreekala, P. Koshy, Z. Oommen, and S.

Thomas, Comparing the mechanical properties of banana

reinforced LDPE composites, J. Comp. Matter, 31: (1997), pp

509-526. fibre reinforced phenol formaldehyde and glass fibre

[4] Chawla K. K. Composite Materials: Science and Engineering: reinforced phenol formaldehyde composites., Composite

science and technology, 62,1857-1 868 (2002)

Springer, 1998.

[5] Kutz M. Mechanical Engineers Handbook, Third Edition, John [16] S. Joseph and Sabu Thomas, Effect of environmental ageing

Wiley and Sons Inc., Hoboken, New Jersey, 2000. on the mechanical properties of banana fibre reinforced PF

composites, Journal of Applied Polymer Sciences (In press)

[6] Nabi Saheib D, Jog J. P, natural fiber polymer composites: A

review, Advances in polymer technology, 18(4), (2004), pp

351-363. [17] S. Joseph, M.S Sreekala, G. Groeninckx and Sabu Thomas,

Dynamic mechanical analysis of banana fibre, glass fiber and

[7] S. M. Sapuan, Leenie A, Harimi M, Beng YK. “Mechanical

properties of woven banana fiber reinforced, epoxy hybrid fibre reinforced phenol formaldehyde composites,

composites”. Materials and Design (2006); 27(8):689–93. Composites (communicated)

[9] Satyanarayana K. G, Sukumaran K, Kulkarni A. G, Pillai S. G.

K, and Rohatgi P. “Fabrication and Properties-Reinforced

Polyester of Nat Composites”, Journal of - 333Composites,. [18] D. Chandramohan1& ,K. Marimuthu .A REVIEW ON

17(4) NATURAL FIBERS Vol8 Issue2 August 2011.

[10] Krevelen D.W. Properties of Polymers: Their correlation with [19] Z. Salleh, M. N. Berhan, Koay Mei Hyie, and D. H. Isaac.

chemical structure; their numerical estimation and prediction Cold-pressed and Fibreglass Hybrid Composites Laminates:

from additive group contributions: Elsevier, 2009. Effect of Fibre Types, World Academy of Science,

[11] M. Thiruchitrambalam, A.Alavudeen, A.Athijayamani Engineering and Technology 71 2012.

N.Venkateshwaran And A.Elaya Perumal.Improving [20] Madhukiran.J, Dr. S. Srinivasa Rao, Madhusudan.S .

mechanical properties of banana/kenaf polyester hybrid Fabrication and Testing of Natural Fiber Reinforced

composites using sodium laulryl sulfate treatment. Materials Hybrid Composites Banana/Pineapple Vol. 3, Issue. 4, July-

Physics and august. 2013 pp-2239-2243

Mechanics 8 (2009) 165-173.

ISSN: 2231-5381 http://www.ijettjournal.org Page 414

S-ar putea să vă placă și

- RCC Beam Design AS CodeDocument1 paginăRCC Beam Design AS CodeGaurav BhabadÎncă nu există evaluări

- Tribology of Graphene: Simulation Methods, Preparation Methods, and Their ApplicationsDe la EverandTribology of Graphene: Simulation Methods, Preparation Methods, and Their ApplicationsEvaluare: 5 din 5 stele5/5 (1)

- Development of ASTM Test Methods For FRP Composite Materials - Overview and Transverse ShearDocument8 paginiDevelopment of ASTM Test Methods For FRP Composite Materials - Overview and Transverse ShearGregory Simmon100% (1)

- Studies On Mechanical and Flexural Strength of Carbon Nano Tube Reinforced With Hemp Vinyl Ester Carbon Fiber Laminated Hybrid Composite-IJRASETDocument12 paginiStudies On Mechanical and Flexural Strength of Carbon Nano Tube Reinforced With Hemp Vinyl Ester Carbon Fiber Laminated Hybrid Composite-IJRASETIJRASETPublications100% (1)

- Investigation of Mechanical Properties of Corn Fiber Reinforced With Biodegradable ResinDocument4 paginiInvestigation of Mechanical Properties of Corn Fiber Reinforced With Biodegradable ResinRaja SajinÎncă nu există evaluări

- CSWIP Welding Inspection Notes and Questions PDFDocument115 paginiCSWIP Welding Inspection Notes and Questions PDFrahim_335162856100% (3)

- QCP KOC-VME 1221006120-PART 1 Rev 3Document49 paginiQCP KOC-VME 1221006120-PART 1 Rev 3Alireza Golpesar100% (1)

- Introduction To MaintenanceDocument77 paginiIntroduction To MaintenanceKarthik SubramaniÎncă nu există evaluări

- IK Module 6 Easa Part 66Document246 paginiIK Module 6 Easa Part 66Hamzeh Al-Qaisi100% (1)

- Fracture Mechanics - 2nd Ed - Solution ManualDocument120 paginiFracture Mechanics - 2nd Ed - Solution ManualMahesh Raja50% (2)

- PD5091-Product Lifecycle ManagementDocument8 paginiPD5091-Product Lifecycle ManagementKarthik Subramani67% (3)

- Ashirvad Pipes Pvt. LTD., Bangalore: Test Report of CPVC Pipes As Per Is 15778Document7 paginiAshirvad Pipes Pvt. LTD., Bangalore: Test Report of CPVC Pipes As Per Is 15778mohd shiraz100% (1)

- Strain Based Design of PipelineDocument137 paginiStrain Based Design of PipelinejangdiniÎncă nu există evaluări

- Journalnx ADocument4 paginiJournalnx AJournalNX - a Multidisciplinary Peer Reviewed JournalÎncă nu există evaluări

- 1 s2.0 S0301679X23007661 MainDocument33 pagini1 s2.0 S0301679X23007661 Main32216116Încă nu există evaluări

- Chand Gude 2021Document26 paginiChand Gude 2021Aruya VasyaÎncă nu există evaluări

- PC 26291Document21 paginiPC 26291rara flemishÎncă nu există evaluări

- Lobo 2021Document8 paginiLobo 2021Yerco muñozÎncă nu există evaluări

- Experimental Study On Retrofitted RC T-BEAM Using FRPDocument5 paginiExperimental Study On Retrofitted RC T-BEAM Using FRPInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- 1 s2.0 S2214785322016662 MainDocument7 pagini1 s2.0 S2214785322016662 MainAmitabh RaviÎncă nu există evaluări

- Ijme Iccrest P114Document7 paginiIjme Iccrest P114eshuÎncă nu există evaluări

- Manufacturing and Mechanical Properties Testing of Hybrid Natural Fibre Reinforced Polymer CompositesDocument9 paginiManufacturing and Mechanical Properties Testing of Hybrid Natural Fibre Reinforced Polymer CompositesIJRASETPublicationsÎncă nu există evaluări

- Composites Part B: Adewale George Adeniyi, Damilola Victoria Onifade, Joshua O. Ighalo, Akorede Samson AdeoyeDocument10 paginiComposites Part B: Adewale George Adeniyi, Damilola Victoria Onifade, Joshua O. Ighalo, Akorede Samson AdeoyeClaudia UngureanuÎncă nu există evaluări

- Studyofmechanical Properties of The Composite Material Produced From The Wastage of Plastic and Coconut FiberDocument6 paginiStudyofmechanical Properties of The Composite Material Produced From The Wastage of Plastic and Coconut FiberLOINI IIPUMBUÎncă nu există evaluări

- Mechanical Properties of Natural Cellulose Fibers Reinforced PolymerDocument8 paginiMechanical Properties of Natural Cellulose Fibers Reinforced Polymernurshiyama89Încă nu există evaluări

- Effect of Micro-Crystalline Cellulose Particles On MechanicalDocument15 paginiEffect of Micro-Crystalline Cellulose Particles On MechanicalZohaib Iqbal BajwaÎncă nu există evaluări

- Fig 1: Fiber Reinforced Polymer CompositesDocument23 paginiFig 1: Fiber Reinforced Polymer CompositesanonymousÎncă nu există evaluări

- Deepa Materials Today ProceedingsDocument8 paginiDeepa Materials Today ProceedingsAmitTelangÎncă nu există evaluări

- Effects of Jute Fabric Structures On The Performance of Jute-Reinforced Polypropylene CompositesDocument9 paginiEffects of Jute Fabric Structures On The Performance of Jute-Reinforced Polypropylene CompositesabiliovieiraÎncă nu există evaluări

- Hybrid and Synthetic FRP Composites Under Different StrainDocument23 paginiHybrid and Synthetic FRP Composites Under Different Strainviscairsyad96Încă nu există evaluări

- Uma Revisão Sobre Compósitos Híbridos Reforçados Com Fibra Natural - Tratamentos Químicos, Métodos de Fabricação e Aplicações PotenciaisDocument8 paginiUma Revisão Sobre Compósitos Híbridos Reforçados Com Fibra Natural - Tratamentos Químicos, Métodos de Fabricação e Aplicações PotenciaisMariana DiasÎncă nu există evaluări

- Polymers 14 02043 v2Document22 paginiPolymers 14 02043 v2Brinsi AnwerÎncă nu există evaluări

- Composites Fibre CoconutDocument9 paginiComposites Fibre CoconutmajmateusÎncă nu există evaluări

- Pillai Hoc College of Engineering and Technology Rasayani - 410207Document6 paginiPillai Hoc College of Engineering and Technology Rasayani - 410207Pranit Malkar ArtÎncă nu există evaluări

- AdvancedSustainableSystems 2022 Maiti SustainableFiberReinforcedCompositesAReviewDocument34 paginiAdvancedSustainableSystems 2022 Maiti SustainableFiberReinforcedCompositesAReviewHasan MazharulÎncă nu există evaluări

- A Study On Different Compositions of Epoxy Resin Reinforced With Natural Fibers and Glass FiberDocument3 paginiA Study On Different Compositions of Epoxy Resin Reinforced With Natural Fibers and Glass FibersriyajambukarÎncă nu există evaluări

- Irjet V6i10132Document9 paginiIrjet V6i10132Echebiri CollinsÎncă nu există evaluări

- Kenaf Fiber ApperDocument6 paginiKenaf Fiber ApperDr. R. Sathish KumarÎncă nu există evaluări

- 1 s2.0 S2238785423000066 MainDocument15 pagini1 s2.0 S2238785423000066 MainPratul DesouzaÎncă nu există evaluări

- ChaptersDocument123 paginiChaptersMuhammad Mostafizur RahmanÎncă nu există evaluări

- A Review On Mechanical Properties of GFRP With Different Filler MaterialsDocument4 paginiA Review On Mechanical Properties of GFRP With Different Filler MaterialsAnonymous kw8Yrp0R5rÎncă nu există evaluări

- JCM-published PaperDocument22 paginiJCM-published Paperdharani kumarÎncă nu există evaluări

- Phase 1 PresentationDocument16 paginiPhase 1 Presentationpiyush kumarÎncă nu există evaluări

- Mechanical and Thermal Characterization of Coir/ Hemp/polyester Hybrid Composite For Lightweight ApplicationsDocument12 paginiMechanical and Thermal Characterization of Coir/ Hemp/polyester Hybrid Composite For Lightweight Applicationsgp rajeshÎncă nu există evaluări

- Composites JuteDocument7 paginiComposites JuteRAKESH THURPATIÎncă nu există evaluări

- Mechanical Properties of Silanized Jute-Polypropylene CompositesDocument6 paginiMechanical Properties of Silanized Jute-Polypropylene CompositesJuan Camilo Pedraza OrtizÎncă nu există evaluări

- Mechanical Properties of A Polyester Fibreglass CompositeDocument6 paginiMechanical Properties of A Polyester Fibreglass CompositeJeff Zaraki MbogneÎncă nu există evaluări

- Composites Part B: Kin-Tak Lau, Pui-Yan Hung, Min-Hao Zhu, David HuiDocument12 paginiComposites Part B: Kin-Tak Lau, Pui-Yan Hung, Min-Hao Zhu, David HuiDANIELA OCACIONÎncă nu există evaluări

- 20 Jahre IAP BiobasedComposites Ganster ErdmannDocument9 pagini20 Jahre IAP BiobasedComposites Ganster ErdmannAnupat PotisatityuenyongÎncă nu există evaluări

- Additives Used in Natural Fibre Reinforced Polymer 2022 Materials Today ProDocument8 paginiAdditives Used in Natural Fibre Reinforced Polymer 2022 Materials Today Prodeepali boradeÎncă nu există evaluări

- Study On Mechanical Behaviour of Sugarcane Bagasse Fiber Reinforced Polymer Matrix CompositesDocument9 paginiStudy On Mechanical Behaviour of Sugarcane Bagasse Fiber Reinforced Polymer Matrix CompositesYasir Aneuk WeldingÎncă nu există evaluări

- Micromachines 13 01875Document14 paginiMicromachines 13 01875ภัทรพล ธีรพงศ์ภักดีÎncă nu există evaluări

- Synthesis, Characterization and Finite Element Analysis of Polypropylene Composite Reinforced by Jute and Carbon Fiber - 2023Document8 paginiSynthesis, Characterization and Finite Element Analysis of Polypropylene Composite Reinforced by Jute and Carbon Fiber - 2023bakhrul ilmiÎncă nu există evaluări

- ST MTDocument13 paginiST MTAsep Aby SaputraÎncă nu există evaluări

- Advanced Sustainable Systems - 2022 - Maiti - Sustainable Fiber Reinforced Composites A ReviewDocument33 paginiAdvanced Sustainable Systems - 2022 - Maiti - Sustainable Fiber Reinforced Composites A Reviewchatgpt51023Încă nu există evaluări

- Vidya Bharathi 2021 IOP Conf. Ser. Mater. Sci. Eng. 1055 012024Document9 paginiVidya Bharathi 2021 IOP Conf. Ser. Mater. Sci. Eng. 1055 012024Prof L. OblisamyÎncă nu există evaluări

- Materials Today: Proceedings: R. Girimurugan, Pon - Maheskumar, Gyanaranjan Sahoo, A. Sivalingam, S. MayakannanDocument6 paginiMaterials Today: Proceedings: R. Girimurugan, Pon - Maheskumar, Gyanaranjan Sahoo, A. Sivalingam, S. MayakannanraulÎncă nu există evaluări

- Paper 2Document6 paginiPaper 2diliph.21.bemeÎncă nu există evaluări

- Materials Today: Proceedings: Balu Maloth, N.V. Srinivasulu, R. RajendraDocument6 paginiMaterials Today: Proceedings: Balu Maloth, N.V. Srinivasulu, R. RajendraJúlia NogueiraÎncă nu există evaluări

- MaterialstodayroceedingDocument6 paginiMaterialstodayroceedingvenomÎncă nu există evaluări

- Corbin 2018 IOP Conf. Ser. Mater. Sci. Eng. 406 012016Document12 paginiCorbin 2018 IOP Conf. Ser. Mater. Sci. Eng. 406 012016adonaies19Încă nu există evaluări

- Materials Today: Proceedings: K. Balasubramanian, N. Rajeswari, R. VishvakDocument5 paginiMaterials Today: Proceedings: K. Balasubramanian, N. Rajeswari, R. VishvakedmealemÎncă nu există evaluări

- Mechanical Testing and Microstructure Characterization of Glass Fiber Reinforced Isophthalic Polyester CompositesDocument10 paginiMechanical Testing and Microstructure Characterization of Glass Fiber Reinforced Isophthalic Polyester Compositespinkan25Încă nu există evaluări

- Nallusamy 2017 IOP Conf. Ser. Mater. Sci. Eng. 225 012283 PDFDocument10 paginiNallusamy 2017 IOP Conf. Ser. Mater. Sci. Eng. 225 012283 PDFSayan RakshitÎncă nu există evaluări

- Materials Today: Proceedings: Jonathan B. Dawit, Hirpa G. Lemu, Yohannes Regassa, Adugna D. AkessaDocument6 paginiMaterials Today: Proceedings: Jonathan B. Dawit, Hirpa G. Lemu, Yohannes Regassa, Adugna D. AkessaHelmi ChaâbeneÎncă nu există evaluări

- Mechanical Characterization of MMT Nano Clay/Epoxy/ Basalt Fiber CompositesDocument6 paginiMechanical Characterization of MMT Nano Clay/Epoxy/ Basalt Fiber CompositesArpan BhandariÎncă nu există evaluări

- Mechanical Engg. Minor ProjectDocument14 paginiMechanical Engg. Minor ProjectParas Thakur50% (2)

- Characterization of Natural Reinforcements and Their CompositesDocument18 paginiCharacterization of Natural Reinforcements and Their CompositesspawnmeaddowÎncă nu există evaluări

- A Review On The Degradability of Polymeric Composites Based On Natural Fibres PDFDocument19 paginiA Review On The Degradability of Polymeric Composites Based On Natural Fibres PDFThiago SantosÎncă nu există evaluări

- A Study On Effect of Variation of Thickness On Tensile Properties of Hybrid Polymer Composites (Glassfibre-Carbonfibre-Graphite) and GFRP CompositesDocument10 paginiA Study On Effect of Variation of Thickness On Tensile Properties of Hybrid Polymer Composites (Glassfibre-Carbonfibre-Graphite) and GFRP CompositesfullaÎncă nu există evaluări

- Design of Hydraulic and Pneumatic Systems - QPDocument11 paginiDesign of Hydraulic and Pneumatic Systems - QPKarthik SubramaniÎncă nu există evaluări

- Hydraulics and Pneumatics: Varun Pratap SinghDocument38 paginiHydraulics and Pneumatics: Varun Pratap SinghKarthik SubramaniÎncă nu există evaluări

- DislocationMotion STR Recovery Ch7Document40 paginiDislocationMotion STR Recovery Ch7Karthik SubramaniÎncă nu există evaluări

- Maintenance Engineering - VijayaragavanDocument6 paginiMaintenance Engineering - VijayaragavanKarthik SubramaniÎncă nu există evaluări

- B.e.cseDocument107 paginiB.e.cseSangeetha ShankaranÎncă nu există evaluări

- Ch3 AxisymmDocument2 paginiCh3 AxisymmKarthik SubramaniÎncă nu există evaluări

- Cs8383 Oops Lab ManualDocument81 paginiCs8383 Oops Lab ManualKarthik Subramani83% (12)

- Project Helmet UseDocument5 paginiProject Helmet UseKarthik SubramaniÎncă nu există evaluări

- A Non-Linear Orthotropic Hydrocode Model For Ultra-High Molecular Weight PolyetheleneDocument13 paginiA Non-Linear Orthotropic Hydrocode Model For Ultra-High Molecular Weight PolyetheleneAkash VineetÎncă nu există evaluări

- Astm A 447-2011Document4 paginiAstm A 447-2011Vk Rai100% (1)

- UTJ5 UTR5 Brochure Web en 201803Document5 paginiUTJ5 UTR5 Brochure Web en 201803Lina Ricse CaballeroÎncă nu există evaluări

- AT-3046 To 3054Document9 paginiAT-3046 To 3054mechtek 19Încă nu există evaluări

- Strength of Materials 2020 by S K MondalDocument493 paginiStrength of Materials 2020 by S K MondalSanjb MitraÎncă nu există evaluări

- Din 1Document1 paginăDin 1ttpatelÎncă nu există evaluări

- Specification For Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsDocument4 paginiSpecification For Copper-Silicon Alloy Plate, Sheet, Strip, and Rolled Bar For General Purposes and Pressure VesselsJolettitoÎncă nu există evaluări

- Flexural Behavior of High-Strength Concrete Beams Confined With Stirrups in Pure Bending ZoneDocument7 paginiFlexural Behavior of High-Strength Concrete Beams Confined With Stirrups in Pure Bending ZoneAdnane OURABAHÎncă nu există evaluări

- Prepared By: Engr. Marianne Kriscel Jean T. Dejarlo, CE, SEDocument40 paginiPrepared By: Engr. Marianne Kriscel Jean T. Dejarlo, CE, SEKhaycee DejarloÎncă nu există evaluări

- !2011 AISI S905 Test Methods For Mech Fas CFS Connections PDFDocument25 pagini!2011 AISI S905 Test Methods For Mech Fas CFS Connections PDFmabuhamdÎncă nu există evaluări

- Bruhn 73 C4Document28 paginiBruhn 73 C4brhÎncă nu există evaluări

- CMT Reviewer Part 2Document26 paginiCMT Reviewer Part 2erwinandal9Încă nu există evaluări

- Research ArticleDocument11 paginiResearch ArticleVashishth KushwahaÎncă nu există evaluări

- Flat Slab Design - Engineering DissertationsDocument34 paginiFlat Slab Design - Engineering DissertationsBobby LupangoÎncă nu există evaluări

- 3RD Sem - MT LabDocument81 pagini3RD Sem - MT Labnitrovert80% (5)

- ms264 (High Strength Steel)Document18 paginims264 (High Strength Steel)Enrique Maya VisuetÎncă nu există evaluări

- Fangming Heng Thesis 2015Document147 paginiFangming Heng Thesis 2015keanshengÎncă nu există evaluări

- Cramer J., Empelmann 2021 Simulation of Crack Propagation in Reinforced Concrete ElementsDocument20 paginiCramer J., Empelmann 2021 Simulation of Crack Propagation in Reinforced Concrete Elementsdmt7nzztcmÎncă nu există evaluări

- 2648Document30 pagini2648anandakoeÎncă nu există evaluări

- Moaveni Engineering Fundamentals 5e SI Chapter 03 PDFDocument113 paginiMoaveni Engineering Fundamentals 5e SI Chapter 03 PDFJoselitoÎncă nu există evaluări

- MSE 212 Material Science Lab Experiment (3) : Tensile Test: Submitted byDocument13 paginiMSE 212 Material Science Lab Experiment (3) : Tensile Test: Submitted byRewanÎncă nu există evaluări

- Design Fundamentals-FullDocument64 paginiDesign Fundamentals-FullNishant DeyÎncă nu există evaluări