Documente Academic

Documente Profesional

Documente Cultură

Carbon Steel, Stainless Steel, and Cast Iron Materials Guide

Încărcat de

Thomas Costa0 evaluări0% au considerat acest document util (0 voturi)

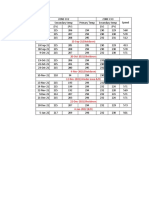

204 vizualizări7 paginiThe document provides specifications for various types of castings and steels, listing the Korean (KS), American (ASTM), German (DIN), and Japanese (JIS) standards as well as the minimum tensile strength and hardness for each grade. Specifications are given for grades of gray iron, ductile iron, carbon steel, stainless steel, bronze, phosphor bronze, leaded tin bronze, carbon steel for machinery, chromium molybdenum steels, rolled steel for general structure, carbon steel pipes, and stainless steel bars.

Descriere originală:

não sei do que se trata

Titlu original

Steel Comparison Table

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThe document provides specifications for various types of castings and steels, listing the Korean (KS), American (ASTM), German (DIN), and Japanese (JIS) standards as well as the minimum tensile strength and hardness for each grade. Specifications are given for grades of gray iron, ductile iron, carbon steel, stainless steel, bronze, phosphor bronze, leaded tin bronze, carbon steel for machinery, chromium molybdenum steels, rolled steel for general structure, carbon steel pipes, and stainless steel bars.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

204 vizualizări7 paginiCarbon Steel, Stainless Steel, and Cast Iron Materials Guide

Încărcat de

Thomas CostaThe document provides specifications for various types of castings and steels, listing the Korean (KS), American (ASTM), German (DIN), and Japanese (JIS) standards as well as the minimum tensile strength and hardness for each grade. Specifications are given for grades of gray iron, ductile iron, carbon steel, stainless steel, bronze, phosphor bronze, leaded tin bronze, carbon steel for machinery, chromium molybdenum steels, rolled steel for general structure, carbon steel pipes, and stainless steel bars.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 7

Structure

11. Carbon Steel Pipes for Ordinary Pipings

12. Stainless Steel Bars

13. Stainless Steel Pipes

1. Gray Iron Castings (KS D 4301)

Tensile Strength

KS ASTM DIN JIS HB

(KG-F/mm2)

241 and

19 and above

below

223 and

17 and above

GC150 below

A48-CL20 GG15 FC150

(ex-GC15) 212 and

15 and above

below

201 and

13 and above

below

255 and

24 and above

below

235 and

22 and above

GC200 below

A48-CL30 GG20 FC200

(ex-GC20) 223 and

20 and above

below

217 and

17 and above

below

269 and

28 and above

below

248 and

26 and above

GC250 below

A48-CL35 GG25 FC250

(ex-GC25) 241 and

25 and above

below

229 and

22 and above

below

269 and

31 and above

below

GC300 262 and

A48-CL40 GG30 FC300 30 and above

(ex-GC30) below

248 and

27 and above

below

2. Spheroidal Graphite (Ductile) Iron Castings (KS D 4302)

KS ASTM DIN JIS Tensile Strength HB

GCD400

201 and

(ex- A536-60-40-18 GGG-40 FCD40 40 and above

below

GCD40)

GCD450

(ex- A536-65-45-12 - FCD45 45 and above 143~217

GCD45)

GCD500

(ex- - GGG-50 FCD50 50 and above 170~241

GCD50)

GCD600 A536-80-55-06 GGG-60 FCD60 60 and above 192~269

(ex-

GCD60)

3. Carbon Steel Castings (KS D 4101)

KS ASTM DIN JIS Tensile Strength HB

SC410

A27-60-30 GS 38 SC42 42 and above -

(ex-SC42)

SC450

A27-65-35 GS 45 SC46 46 and above -

(ex-SC46)

SC480

A27-70-36 GS 52 SC49 49 and above -

(ex-SC49)

4. Stainless Steel Castings (KS D 4103)

KS ASTM DIN JIS Tensile Strength HB

163 ~

SSC1 A743-CA15 G-X12-Cr14 SCS1 55 and above

229

170 ~

SSC2 A743-CA40 G-X20-Cr14 SCS2 60 and above

235

170 ~

SSC11 - X8CrNi-Mo-275 SCS11 60 and above

235

183 and

SSC13 A743-CF-8 G-X6Cr-Ni-1809 SCS13 45 and above

below

183 and

SSC14 A743-CF8M G-X6Cr-NiMo-1810 SCS14 45 and above

below

183 and

SSC16 A743-CF3M X2CrNi-Mo-1810 SCS16 40 and above

below

183 and

SSC21 A743-CF8C G-X7Cr-NiNb-1809 SCS21 49 and above

below

5. Bronze Castings (KS D 6010)

KS ASTM DIN JIS Tensile Strength HB

BC2 B584-C903 - BC2 25 and above -

G-CuSn10Zn

BC3 B584-C905 BC3 25 and above -

(1705-73)

BC6 B584-C836 G-CuSn- 5ZnPb BC6 20 and above -

6. Phosphor Bronze Castings (KS D 6010)

KS ASTM DIN JIS Tensile Strength HB

60 and

PBC2 B505-907 G-CuSn-5ZnPb PBC2 20 and above

above

7. Leaded Tin Bronze Castings (KS D 6011)

KS ASTM DIN JIS Tensile Strength HB

60 and

LBC3 B584-937 G-CuPb10Sn LBC3 -

above

55 and

LBC4 B584-938 G-CuPb15Sn LBC4 -

above

8. Carbon Steel for Machine Structural Use (KS D 3752)

KS ASTM DIN JIS Tensile Strength HB

137 ~

SM30C A108-1030 - S30C 48 and above

197

149 ~

SM34C A108-1035 - S35C 52 and above

207

167 ~

SM45C A108-1045 - S45C 58 and above

229

9. Chromium Molybdenum Steels (KS D 3711)

KS ASTM DIN JIS Tensile Strength HB

262 ~

SCM420 - - SCM420 95 and above

352

34CrMo4 269 ~

SCM435 A322-4137 SCM435 95 and above

(1.7220) 331

42CrMo4 285 ~

SCM440 A322-4140 SCM440 100 and above

(1.7225) 352

10. Rolled Steel for Gerneral Structure (KS D 3503)

KS ASTM DIN JIS Tensile Strength HB

SS400

A283 - Gr .D - SS41 41 - 52 -

(ex-SS41)

11. Carbon Steel Pipes for Ordinary Pipings (KS D 3507)

KS ASTM DIN JIS Tensile Strength HB

St - 33 - 1

SPP A53 - Gr .F SGP1 30 and above -

(1.0033)

12. Stainless Steel Bars (KS D 3706)

KS ASTM DIN JIS Tensile Strength HB

X5CrNi-1809 187 and

STS304 A276-304 SUS304 53 and above

(1.4301) below

X2CrNi-1809 187 and

STS304L A276-304L SUS304L 49 and above

(1.4306) below

X5CrNi-Mo-1810 187 and

STS316 A276-316 SUS316 53 and above

(1.4401) below

X2CrNi-Mo-1810 187 and

STS316L A276-316L SUS316L 49 and above

(1.4401) below

X10CrNi-Ti-1809 187 and

STS321 A276-321 SUS321 53 and above

(1.4401) below

277 and

STS329J1 A240-329 - SUS329J1 60 and above

below

X15Cr13 170 and

STS403 A276-403 SUS403 60 and above

(1.4024) below

STS410 ANSI 410 SUS410

159 and

STS416 A582-416 - SUS413 55 and above

below

X20Cr13 192 and

STS420J1 A582-420 SUS420J1 65 and above

(1.401) below

217 and

STS420J2 - - SUS420J2 75 and above

below

X22CrNi17 229 and

STS431 A276-431 SUS431 80 and above

(1.4301) below

13. Stainless Steel Pipes (KS D 3576)

KS ASTM DIN JIS Tensile Strength HB

X5CrNi-1809

STS304TP A312-TP304 SUS304TP 53 and above -

(1.4301)

STS304LTP A312-TP304L - SUS304LTP 49 and above -

STS316TP A312-TP316 - SUS316TP 53 and above -

STS316LTP A312-TP316L - SUS316LTP 49 and above -

Comparison

Below is a table comparing steel grades from different grading systems.

Comparison of steel grades by chemistry[1][2]

EN steel SAE BS

EN steel name UNS DIN UNI JIS

number grade 970

Carbon steels

040A1

5

1.1141 CK15 080M C15 S15

C15D

1.0401 1018 C15 15 C16 S15CK

C18D

1.0453 C16.8 080A1 1C15 S15C

5

EN3B

060A4

1.0503 C45 7 C45

1.1191 CK45 080A4 1C45 S45C

C45 1045

1.1193 CF45 6 C46 S48C

1.1194 CQ45 080M C43

46

212M

1.0726 35S20 1140/11 35S20

40

1.0727 45S20 46 45S20

En8M

230M

1.0715 9SMn28 CF9SMn28 SUM 25

11SMn37 1215 07

1.0736 9SMn36 CF9SMn36 SUM 22

En1A

230M SUM

CF9SMnPb2

07 22L

1.0718 11SMnPb30 9SMnPb28 9

12L14 Leade SUM

1.0737 11SMnPb37 9SMnPb36 CF9SMnPb3

d 23L

6

En1A SUM

Leade 24L

d

Alloy steels

SCM

708A3 420

25CrMo4 25CrMo4

0 SCM

1.7218 4130 GS- (KB)

CDS1 430

25CrMo4 30CrMo4

10 SCCrM

1

708M

SCM

40

440

708A4 41CrMo4

1.7223 41CrMo4 SCM

2 38CrMo4

1.7225 4140/41 42CrMo4 440H

42CrMo4 709M (KB)

1.7227 42 42CrMoS4 SNB 7

40 G40 CrMo4

1.3563 43CrMo4 SCM

En19 42CrMo4

4M

En19

SCM 4

C

35NiCrMo6 SNCM

34CrNiMo6 817M

1.6582 (KB) 447

34CrNiMo6 4340 40NiCrMo8- 40

1.6562 40NiCrMo7 SNB24-

4 En24

(KB) 1-5

805A2

1.6543 21NiCrMo22 0 SNCM

20NiCrMo2-2 8620 20NiCrMo2

1.6523 21NiCrMo2 805M 200 (H)

20

Stainless steels

1.4310[cit

ation needed] X10CrNi18-8 301 S30100

1.4318[cit

ation needed] X2CrNiN18-7 301LN

303S

X10CrNiS18 31 X10CrNiS18 SUS

1.4305 X8CrNiS18-9 303 S30300

-9 En58 -09 303

M

304S

15

304S SUS

X5CrNi18-9

16 304

X2CrNi19-11 X5CrNi18- X5CrNi18-

1.4301 304 S30400 304S SUS

X2CrNi18-10 10 10

18 304-

XCrNi19-9

304S CSP

25

En58E

304S SUS304

1.4306 X2CrNi19-11 304L S30403

11 L

1.4311[cit X2CrNiN18- 304LN S30453

ation needed]

10

[cit

1.4948

ation needed] X6CrNi18-11 304H S30409

1.4303[cit

ation needed] X5CrNi18-12 305 S30500

X5CrNiMo1

316S

7 12 2 X5CrNiMo1

29

X5CrNiMo17- X5CrNiMo1 7 12 SUS

316S

1.4401 12-2 7 13 3 X5CrNiMo1 316

316 S31600 31

1.4436 X5CrNiMo18- X5CrNiMo 7 13 SUS316

316S

14-3 19 11 X8CrNiMo1 TP

33

X5CrNiMo 7 13

En58J

18 11

X2CrNiMo17- 316S SUS316

1.4404 316L S31603

12-2 11 L

1.4406[cit X2CrNiMoN1

ation needed]

7-12-2

316LN S31653

1.4429[cit X2CrNiMoN1

ation needed]

7-13-3

X6CrNiMoT 320S

1.4571 316Ti S31635

i17-12 33

1.4438[cit X2CrNiMo18-

ation needed] 317L S31703

15-4

X6CrNiTi18 321S

1.4541 321 S32100 SUS321

-10 31

1.4878[cit X12CrNiTi18-

ation needed] 321H S32109

9

1.4512[cit

ation needed] X6CrTi12 409 S40900

410 S41000

430S

1.4016 430 S43000 X6Cr17 SUS430

17

440A S44002

1.4112[cit

ation needed] 440B S44003

1.4125[cit X105CrMo1 SUS440

ation needed] 440C S44004

7 C

X14CrMoS1 SUS430

1.4104 430F S44020

7 F

1.4539[cit X1NiCrMoCu N0890

ation needed] 904L

25-20-5 4

1.4547[cit X1CrNiMoCu

ation needed] S31254

N20-18-7

Tool steels

T3010 X100CrMoV X100CrMo

1.2363 X100CrMoV5 A-2 [3] BA 2 SKD 12

2 51 V5-1 KU

T3010

A-3

3[4]

T3010

A-4

4[5]

T3010

A-6

6[6]

T3010

A-7

7[7]

T3010

A-8

8[8]

T3010

A-9

9[9]

X153CrMoV1 X153CrMoV X155CrVM

1.2379 D-2 BD 2 SKD 11

2 12-1 o12-1

95MnWCr-5

1.2510 O-1 100MnCrW4 Bo 1

KU

S-ar putea să vă placă și

- Material Conversion TableDocument3 paginiMaterial Conversion TableJose Lorenzo ToralÎncă nu există evaluări

- Material Conversion Table: 1. Gray Iron Castings (KS D 4301)Document3 paginiMaterial Conversion Table: 1. Gray Iron Castings (KS D 4301)Kang Kawe Waone SetiaoneÎncă nu există evaluări

- Material Conversion Table GuideDocument1 paginăMaterial Conversion Table GuideUgiezRagielÎncă nu există evaluări

- Material Conversion TableDocument1 paginăMaterial Conversion TableravikumarangÎncă nu există evaluări

- Bending Stress4Document1 paginăBending Stress4MayurÎncă nu există evaluări

- Material Conversion TableDocument3 paginiMaterial Conversion TableNo PersonÎncă nu există evaluări

- BTS Power Saving FeatureDocument534 paginiBTS Power Saving Featureyousef shabanÎncă nu există evaluări

- Is: 2062-1981 Mild SteelDocument2 paginiIs: 2062-1981 Mild Steelsuresh kumarÎncă nu există evaluări

- DIN 51825 German Grease Classification System PDFDocument1 paginăDIN 51825 German Grease Classification System PDFFelipeSantiagoÎncă nu există evaluări

- DIN 51825 German Grease Classification SystemDocument1 paginăDIN 51825 German Grease Classification SystemLuis M. ChamosoÎncă nu există evaluări

- DIN 51825 German Grease Classification System PDFDocument1 paginăDIN 51825 German Grease Classification System PDFsoumya ghoshÎncă nu există evaluări

- DIN 51825 German Grease Classification System PDFDocument1 paginăDIN 51825 German Grease Classification System PDFsoumya ghoshÎncă nu există evaluări

- SBCG/CGR Campo Grande, Brazil Voryrwy24: .Ceiling - RequiredDocument1 paginăSBCG/CGR Campo Grande, Brazil Voryrwy24: .Ceiling - RequiredIury AlencarÎncă nu există evaluări

- Jeppview For Windows: List of Pages in This Trip KitDocument18 paginiJeppview For Windows: List of Pages in This Trip KitМистермарк МистерклимюкÎncă nu există evaluări

- SPARK B02 METAL DECKING CuttingList - BinderDocument8 paginiSPARK B02 METAL DECKING CuttingList - BinderArif ParvejÎncă nu există evaluări

- Cire Non Controlé AWADocument22 paginiCire Non Controlé AWApaternedjamoÎncă nu există evaluări

- Krell Ksa100 Eur 1989Document7 paginiKrell Ksa100 Eur 1989DC project remixÎncă nu există evaluări

- Manhours Calculations MBDocument129 paginiManhours Calculations MBTalal Ahmed Khan100% (2)

- Transactions Tue Sep 21 2021 11 - 03 - 58 GMT+0700 (Western Indonesia Time)Document3 paginiTransactions Tue Sep 21 2021 11 - 03 - 58 GMT+0700 (Western Indonesia Time)Adrian PradiptaÎncă nu există evaluări

- Line 2 ObservationDocument4 paginiLine 2 ObservationSHANTANU PATHAKÎncă nu există evaluări

- 3a25 - Rev - 26 Cessna 340 TcdsDocument28 pagini3a25 - Rev - 26 Cessna 340 TcdsElmer Villegas0% (2)

- FAA Type Certificate Data Sheet for Textron Aviation Cessna 320 Series AircraftDocument28 paginiFAA Type Certificate Data Sheet for Textron Aviation Cessna 320 Series AircraftElmer VillegasÎncă nu există evaluări

- F240 Load Diagrams & SpecsDocument32 paginiF240 Load Diagrams & SpecsJuan Carlos Torres MartinezÎncă nu există evaluări

- Daily Ericson 2G 3G Fully Down Sites On Oct 26, 2020 @15 00Document8 paginiDaily Ericson 2G 3G Fully Down Sites On Oct 26, 2020 @15 00AnleyÎncă nu există evaluări

- Heidenhain Basic ProgrammingDocument110 paginiHeidenhain Basic ProgrammingSyed Qadir100% (3)

- Site ID Region SWAP/NSB Technology Power Source 2G BTS StatusDocument14 paginiSite ID Region SWAP/NSB Technology Power Source 2G BTS StatusAnleyÎncă nu există evaluări

- PVCPressPipeSteelA 24Document1 paginăPVCPressPipeSteelA 24Mustafa AlluhaibiÎncă nu există evaluări

- Shearwalls Chgeck MH CompoundDocument6 paginiShearwalls Chgeck MH CompoundAtul ShrivastavaÎncă nu există evaluări

- Q235 Steel, Q235A Q235B Q235C Q235D Specification, Chemical Composition, Properties & EquivalentDocument4 paginiQ235 Steel, Q235A Q235B Q235C Q235D Specification, Chemical Composition, Properties & EquivalentWaqas WaqasÎncă nu există evaluări

- Select 410nimo ApDocument1 paginăSelect 410nimo ApJuan Carlos RodriguezÎncă nu există evaluări

- 21 12 18 Updation of SBOQ RatesDocument4 pagini21 12 18 Updation of SBOQ Ratesnk229330Încă nu există evaluări

- Minfm2460 Bs 1452 Grade 220 BarDocument1 paginăMinfm2460 Bs 1452 Grade 220 BarFadyÎncă nu există evaluări

- Browse top selling home accessoriesDocument64 paginiBrowse top selling home accessoriesAndreea CarabusÎncă nu există evaluări

- Concrete Column Design SummaryDocument12 paginiConcrete Column Design SummaryRoy PangribÎncă nu există evaluări

- 05.-462-1624 Lines GP-Pilot (Front)Document4 pagini05.-462-1624 Lines GP-Pilot (Front)Teobaldo Silva CascaÎncă nu există evaluări

- Summer RSC Date Sheet 1Document128 paginiSummer RSC Date Sheet 1Daksh RaoÎncă nu există evaluări

- Lifting Lug Type2 H150x150 150kN Khoet Lo Xoay 90 DoDocument16 paginiLifting Lug Type2 H150x150 150kN Khoet Lo Xoay 90 Doduy quang NguyenÎncă nu există evaluări

- 90 degree beam connection analysisDocument18 pagini90 degree beam connection analysisduy quang NguyenÎncă nu există evaluări

- CS, LAS N SS Steel Requirements FinalDocument11 paginiCS, LAS N SS Steel Requirements FinalJahanvi BaruiÎncă nu există evaluări

- Daily Ericsoon 2G 3G Fully Down Sites On July 14,2020 AfternoonDocument10 paginiDaily Ericsoon 2G 3G Fully Down Sites On July 14,2020 AfternoonAnleyÎncă nu există evaluări

- Bim Color Coding: Projection CUT StructureDocument4 paginiBim Color Coding: Projection CUT StructureJohnzen LukeÎncă nu există evaluări

- Bar Bending ScheduleDocument25 paginiBar Bending ScheduleSreekanth Sattiraju100% (1)

- Calculation SheetDocument1 paginăCalculation SheetFazri CMEÎncă nu există evaluări

- Axis Product Catalog: Earthing & Lightning Protection SystemsDocument68 paginiAxis Product Catalog: Earthing & Lightning Protection Systemsaminchhipa6892Încă nu există evaluări

- Schedule of Rates: For The Year 2021-22Document288 paginiSchedule of Rates: For The Year 2021-22vikramjeet singhÎncă nu există evaluări

- 127 Building Spec PDFDocument132 pagini127 Building Spec PDFvzagkas100% (1)

- EARTHING and LightningDocument68 paginiEARTHING and LightningAshish SutharÎncă nu există evaluări

- LV.22.05.066 - Cty LS - Da Lotte Mall - L11.2 (Aquarium)Document7 paginiLV.22.05.066 - Cty LS - Da Lotte Mall - L11.2 (Aquarium)HungPhanÎncă nu există evaluări

- 2022-06-27-060218 CM Task Work Export (1-577)Document104 pagini2022-06-27-060218 CM Task Work Export (1-577)Oladimeji AladerokunÎncă nu există evaluări

- RECTANGULAR DUCT CONSTRUCTION TABLESDocument4 paginiRECTANGULAR DUCT CONSTRUCTION TABLESrehan khanÎncă nu există evaluări

- Cat Cs 563D Katalog Rezervnih DijelovaDocument365 paginiCat Cs 563D Katalog Rezervnih Dijelovadjordjes123Încă nu există evaluări

- Line List - Methanol SkidDocument3 paginiLine List - Methanol Skidbmanojkumar16Încă nu există evaluări

- Lifting Lug H150x150 150kN Khoet Lo Xoay 90 Do Type2.IdeaConDocument20 paginiLifting Lug H150x150 150kN Khoet Lo Xoay 90 Do Type2.IdeaConduy quang NguyenÎncă nu există evaluări

- LGBaramullaDocument34 paginiLGBaramullaashuar143119Încă nu există evaluări

- Internal Pressure Design of Pipeline SystemsDocument8 paginiInternal Pressure Design of Pipeline Systemsmavis sika okyereÎncă nu există evaluări

- Tracking Sheet For Civil Material Used at SiteDocument64 paginiTracking Sheet For Civil Material Used at SiteSovan PramanickÎncă nu există evaluări

- Middle Bridge - RCPT SummaryDocument1 paginăMiddle Bridge - RCPT Summarymcwong_98Încă nu există evaluări

- Painting Color Scheme for FPSO HullDocument8 paginiPainting Color Scheme for FPSO HullThomas CostaÎncă nu există evaluări

- Guide For Ergonomic Notations - ABSDocument74 paginiGuide For Ergonomic Notations - ABSrzepedacÎncă nu există evaluări

- I-et-3010.93-1351-956-Ovx-002 - 0 - Requirement and Scheme of Anti-Rust & Paint For Steel OutfittingDocument14 paginiI-et-3010.93-1351-956-Ovx-002 - 0 - Requirement and Scheme of Anti-Rust & Paint For Steel OutfittingThomas CostaÎncă nu există evaluări

- Master resume templateDocument1 paginăMaster resume templateThomas CostaÎncă nu există evaluări

- TCI-link FittingsDocument24 paginiTCI-link FittingsOresteHernandezÎncă nu există evaluări

- Armor PDFDocument7 paginiArmor PDFChristian N KarisoÎncă nu există evaluări

- Aircraft Materials, Processes and Hardware PDFDocument189 paginiAircraft Materials, Processes and Hardware PDFregina marie100% (1)

- Hot Rolled Vs Cold RolledDocument3 paginiHot Rolled Vs Cold RolledstephanieÎncă nu există evaluări

- Harris Brazing MaterialsDocument3 paginiHarris Brazing MaterialsfontyflockÎncă nu există evaluări

- Clamp EMC 29Document46 paginiClamp EMC 29ecolomboeÎncă nu există evaluări

- GMA welding proceduresDocument5 paginiGMA welding proceduresKirinSirÎncă nu există evaluări

- Wheel Hub Design DocumentationDocument4 paginiWheel Hub Design DocumentationPratikRoyÎncă nu există evaluări

- Design Guide - Sheet Metal Fabrication PDFDocument12 paginiDesign Guide - Sheet Metal Fabrication PDFŽeljko StefanovićÎncă nu există evaluări

- Welding ElectrodesDocument19 paginiWelding Electrodesraju100% (1)

- Erdemir Product Catalogue 2017Document334 paginiErdemir Product Catalogue 2017Burak Kececi0% (1)

- Steel Sheet, Zinc-Aluminum-Magnesium Alloy-Coated by The Hot-Dip ProcessDocument3 paginiSteel Sheet, Zinc-Aluminum-Magnesium Alloy-Coated by The Hot-Dip ProcessMohammed KhalidÎncă nu există evaluări

- B PDFDocument127 paginiB PDFshri mayuramÎncă nu există evaluări

- 1.chapter 01 Structure of MetalsDocument40 pagini1.chapter 01 Structure of MetalsmuhammadÎncă nu există evaluări

- Capacitación Ingeniería: Clase 4 Normas Calidades AceroDocument18 paginiCapacitación Ingeniería: Clase 4 Normas Calidades AcerogeracuajinaiÎncă nu există evaluări

- American Welding Soceity 5.9Document33 paginiAmerican Welding Soceity 5.9Hư VôÎncă nu există evaluări

- Model Questions On TransformersDocument7 paginiModel Questions On TransformersfotickÎncă nu există evaluări

- 2.4-p1-p71 VerticalDocument7 pagini2.4-p1-p71 VerticalFernando PerdomoÎncă nu există evaluări

- MetalJacket Overview CapabilitiesDocument17 paginiMetalJacket Overview CapabilitiesRajaSekarsajjaÎncă nu există evaluări

- Corrosion Resistance of Nickel and Nickel Containing Alloys in Caustic Soda and Other AlkaliesDocument42 paginiCorrosion Resistance of Nickel and Nickel Containing Alloys in Caustic Soda and Other AlkaliesrickrobbinsÎncă nu există evaluări

- Api 661Document6 paginiApi 661margarelliÎncă nu există evaluări

- Katalog Baja GRPDocument35 paginiKatalog Baja GRPYasinta PurnamasariÎncă nu există evaluări

- A 960 - 02 Qtk2mc0wmkeDocument9 paginiA 960 - 02 Qtk2mc0wmkesachinguptachdÎncă nu există evaluări

- Distek EPA ArticleDocument5 paginiDistek EPA ArticleNagendra KumarÎncă nu există evaluări

- Aeroshell FLUID 41 1Document2 paginiAeroshell FLUID 41 1Hugo SalazarÎncă nu există evaluări

- Metallography and Heat Treatment - Lab ReportDocument14 paginiMetallography and Heat Treatment - Lab ReportBrendan Jones0% (1)

- Materials Used in Process PlantsDocument8 paginiMaterials Used in Process PlantsEhtisham AndrAbiÎncă nu există evaluări

- Aryl Halide and Vinyl HalideDocument67 paginiAryl Halide and Vinyl HalideAhmadBadruzzamanShuib100% (1)

- General Chemistry Reference Sheet GuideDocument5 paginiGeneral Chemistry Reference Sheet Guidedadadabababa100% (8)