Documente Academic

Documente Profesional

Documente Cultură

2300series View

Încărcat de

Emmanuel Ber STitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2300series View

Încărcat de

Emmanuel Ber SDrepturi de autor:

Formate disponibile

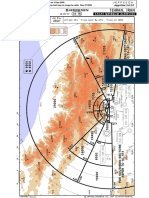

FSXA Quick Selection Chart

0 10 20 30 40 50 60 70 80 90

4000

LEGEND 15000

bard

14000

Contact Warren 3500

13000

12000

3000

FSXA-3830 11000

10000

2500

FSXA-2530 9000

Capacity (gpm)

8000

2000

FSXA-2030 7000

6000

1500

5000

FSXA-1250

4000

1000

3000

FSXA-655

500 2000

1000

FSXA-360

0 0

0 200 400 600 800 1000 1200 1400

Differential Pressure (psid)

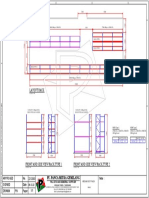

Approximate Dimensions

FSXA MOTOR

PUMP SUCTION DISCH. HP RPM FRAME C CP HA HB HC HD HG HL HM HO HT X Y Z HL1 PH DH W

SIZE

360* 21/2” - 300# 2” - 600# 100 1750 405TS 351/8” 377/16” 21” 601/4” 779/16” 131/2” 3” 171/2” 241/4” 171/2” 5” 11/2” 51/2” 33/4” 265/8” 101/2” * N/A

655* 4” - 300# 3” - 600# 200 1750 447TS 43 /8” 47 /4”

7 3

23” 74 /4” 96 /8” 15 /2”

1 5 1

4” 23 /16” 27 /16” 20 /4”

5 9 1

5” 1 /8”

7

6 /4”

3

5” 349/16” 111/2” * N/A

1250 6” - 300# 4” - 600# 250 1750 447TS 437/8” 551/4” 23” 961/2” 1041/8” 17” 4” 245/8” 291/16” 23” 5” 21/4” 83/4” 61/4” 377/8” 13” * 1

/16”

2030 8” - 300# 6” - 600# 400 1750 5010S 583/4” 6315/16” 26” 122” 12711/16” 211/2” 6” 283/8” 365/16” 28” 5” 25/8” 91/2” 71/2” 431/2” 151/2” * 13/16”

2530 10” - 300# 8” - 600# 600 1150 6809L 751/2” 78” 34” 1501/2” 1581/2” 241/2” 6” 341/4” 431/2” 325/8” 5” 33/8” 113/8” 83/4” 531/2” 181/2” * 113/16”

3830 12” - 300# 10” - 600# 1000 1150 6811L 85 /2” 87 /8”

1 1

34” 166 /8” 177 /8” 29 /2”

3 5 1

8” 40” 48 /2” 38 /2”

1 1

5” 3 /4”

3

12 /2” 10 /4” 62”

1 1

21 /2”

1

* 57/16”

* Pump Size #360 & #655 do not have Gear Housing Foot. Dimensions not to be used for construction purposes. * To be determined by customer.

CL PUMP

CLMOTOR & BASE

DISCHARGE HC

FLANGE

X HL CP C

HT

Warren Pumps

CLEARANCE HL1

REQUIRED FOR

REMOVAL OF ROTOR SUCTION

FLANGE

HO

Z

DH

HM

FSXA 2300 Series

Heavy-Duty, High Pressure Screw Pumps

PH

HD

W

Y HG

HA HB

Warren Pumps Inc. • 82 Bridges Ave. • PO Box 969 • Warren, MA 01083-0969 USA

Two-Screw Team

Allweiler Houttuin IMO Pump Warren Pumps

Ph. 413-436-7711 • Fax 413-436-5605 • www.warrenpumps.com • email: warrensales@colfaxcorp.com WP 4/02 5M

FSXA 2300 Series

Heavy-Duty, High Pressure Screw Pumps

• Capacities to 3500 GPM+

Body

• Discharge pressures to 1400 PSI The solid cast body is generously ribbed and has thick cross

• Viscosities from .5 cst sections for pipeline pressures and rigidity. The suction flow

Permanently Timed Back Pull Out passage is designed to provide a constant area from the flange

Factory performed timing is easily repeated Rotor removes for inspection or repair without opening to the screw entrance allowing for the best NPSH

with Warren’s method of gear and screw disturbing piping or driver. One-craft capabilities of any similarly sized pump.

Advantages synchronization. maintenance.

• Very high efficiencies

• Rugged body and rotor design Wear Protection

• Excellent performance on both To insure long life in tough services, the critical pumping

low and high viscosity fluids surfaces are coated. The body bore can be coated with an

(.05 – 10,000 cst) electrolytically applied industrial hard chrome. The screws

• Double helical timing gears can have a variety of OD coatings with hardness in excess of

minimize rotor wear by maintaining 60 (Rockwell C). Nitriding and other coating combinations

axial alignment, and also provide torque are added features that, when combined with the chrome

load capacities lined bore, have proven to be the best wear protection in the

• Long service intervals industry.

Applications

• Crude Oil Pipelines or Platforms –

transfer and gathering

• Gas Turbine Fuel Pumps or

Burner Feed Pumps – fuel oils

and naphtha

• Petroleum Transport – barge and

tanker loading/unloading, tank

farms

Bearings

Options Radial loading is handled by heavy-duty roller

• Iron or Cast Steel Casing bearings at five locations that are sized to

• Chrome Plated Bores handle maximum loads. They are oil

• Hard Fused Coating on Rotors lubricated and are sealed off from the

• Hardened Timing Gears

pumpage by internal mechanical seals, which Integral Screw and Shaft

are under suction pressure only. The heavy- Each rotor is of an integral design, meaning that the entire

• External Seal Lubrication duty double row thrust bearing locks the drive screw and shaft is machined out of one piece of material,

• General Compliance with API676 shaft in position axially. This is one of the only allowing for maximum rigidity and stiffness. This minimizes

six bearing twin screw pump designs in the shaft deflection, an important consideration in high-pressure

world and is a result of more than 50 years pumps.

of experience in high pressure applications.

Hardened Steel

Double Helical Timing Gears

Hardened steel double helical timing gears are used to

prevent metal-to-metal contact between the meshed rotating

screws. The clearance between the pumping screws results in High Efficiency Screw Profile

longer pump life and higher average efficiencies over the life Having mastered the manufacture of pumping screws, the 2300

of the pump. Series can come in a variety of screw pitches, and combined

with the “QNS” screw profile offers the highest efficiency twin

The double helical concept allows for multiple tooth screw pump in the industry. This has been accomplished as a

engagement and maintains precision screw clearances. result of over 50 years of factory testing and field performance.

Typical crude oil pipeline pump with Both are features that commonly used spur-type gears cannot

natural gas engine drive. provide.

S-ar putea să vă placă și

- 3.5 5.0 Ton at 600mm Load Center: SH1F4-1 / 13 Apr. '10Document30 pagini3.5 5.0 Ton at 600mm Load Center: SH1F4-1 / 13 Apr. '10JulianoÎncă nu există evaluări

- Forklift NISSAN Model W1F4A40UDocument12 paginiForklift NISSAN Model W1F4A40UfitriÎncă nu există evaluări

- Site Plan + Luas - 230426 - 223115Document1 paginăSite Plan + Luas - 230426 - 223115J.T HalohoÎncă nu există evaluări

- 00 - Commissary ELEC Rev 00-E-3Document1 pagină00 - Commissary ELEC Rev 00-E-3edmar jay conchadaÎncă nu există evaluări

- PARAN3E ExerciseNo2 Layout1Document1 paginăPARAN3E ExerciseNo2 Layout1Mickaela Kassandra ParanÎncă nu există evaluări

- Minimum Melting Time-Current Characteristic Curves: SMD Fuse Units-S&C Standard SpeedDocument1 paginăMinimum Melting Time-Current Characteristic Curves: SMD Fuse Units-S&C Standard SpeedRafaelo09Încă nu există evaluări

- OIIIDocument28 paginiOIIISeyi WilliamsÎncă nu există evaluări

- 165 6 2Document1 pagină165 6 2Carlos A. Carpio CárdenasÎncă nu există evaluări

- 165 6 PDFDocument1 pagină165 6 PDFGonzalo Peñafiel CondoriÎncă nu există evaluări

- 2016CT Compressor Specs at GlanceDocument4 pagini2016CT Compressor Specs at GlanceabsahkahÎncă nu există evaluări

- Office A1 PDFDocument1 paginăOffice A1 PDFalfredo agsunodÎncă nu există evaluări

- Technical Analysis - Charts, Trends & Patterns: Presented by Jayanthi Premkumar 0991014Document26 paginiTechnical Analysis - Charts, Trends & Patterns: Presented by Jayanthi Premkumar 0991014ruckumaaluÎncă nu există evaluări

- Rehab Kantor PPT DjarumDocument52 paginiRehab Kantor PPT Djarumbambang trk20Încă nu există evaluări

- P2 PlanDocument1 paginăP2 PlanFrancis Lloyd MalganaÎncă nu există evaluări

- E1 Sample Working DrawingDocument1 paginăE1 Sample Working DrawingjasonÎncă nu există evaluări

- First Floor Lighting Layout Second Lighting Layout: Cyrus Construction Development GroupDocument1 paginăFirst Floor Lighting Layout Second Lighting Layout: Cyrus Construction Development GroupCyrus RivasÎncă nu există evaluări

- Kolkata 700 001 7, Hare StreetDocument1 paginăKolkata 700 001 7, Hare Streetkoushik42000Încă nu există evaluări

- B C Location Map Vicinity MapDocument1 paginăB C Location Map Vicinity MapJOHN MICHAEL MADLAINGÎncă nu există evaluări

- 0 MergedDocument10 pagini0 MergedRicky Martin ZiliwuÎncă nu există evaluări

- BHADBHUT BARRAGE PLAN 46 TO 90-ModelDocument1 paginăBHADBHUT BARRAGE PLAN 46 TO 90-ModelNishant SarrafÎncă nu există evaluări

- Sukhani GA With Levels PDFDocument1 paginăSukhani GA With Levels PDFHimal KafleÎncă nu există evaluări

- TCC Number 450 8 PDFDocument1 paginăTCC Number 450 8 PDFjavier jimenez rodriguezÎncă nu există evaluări

- Total Clearing Time-Current Characteristic Curves: Fault Tamer Fuse LimitersDocument1 paginăTotal Clearing Time-Current Characteristic Curves: Fault Tamer Fuse LimitersStoner WddÎncă nu există evaluări

- Total Clearing Time-Current Characteristic Curves: Smu Fuse Units For Voltage-Transformer Applications-S&C Standard SpeedDocument1 paginăTotal Clearing Time-Current Characteristic Curves: Smu Fuse Units For Voltage-Transformer Applications-S&C Standard SpeedObed GarcíaÎncă nu există evaluări

- Minimum Melting Time-Current Characteristic CurvesDocument1 paginăMinimum Melting Time-Current Characteristic CurvesObed GarcíaÎncă nu există evaluări

- DGTWWSpring2021Engine SpecsAtAGlanceDocument3 paginiDGTWWSpring2021Engine SpecsAtAGlanceMohamed HamdallahÎncă nu există evaluări

- WaddDocument29 paginiWaddReanaldy Ibrahim Masudi PutraÎncă nu există evaluări

- Asrama Mess4Document1 paginăAsrama Mess4Rustandi KartikoÎncă nu există evaluări

- Legend:: Reflected Ceiling PlanDocument1 paginăLegend:: Reflected Ceiling PlanJoane ColipanoÎncă nu există evaluări

- ESTRADADocument1 paginăESTRADABryan Rudolph PascualÎncă nu există evaluări

- GIORDANO HOUSE - 2120320 - DenahDocument3 paginiGIORDANO HOUSE - 2120320 - DenahBintang Murnadi HanantoÎncă nu există evaluări

- Multiples of Ground Fault Pickup SettingDocument1 paginăMultiples of Ground Fault Pickup SettingjosehenriquezsotoÎncă nu există evaluări

- Arabian Construction Company: Ruwais Igd 4Th NGL Train Project - Civil & BuildingsDocument1 paginăArabian Construction Company: Ruwais Igd 4Th NGL Train Project - Civil & BuildingsJule Lobres0% (1)

- Rop Sinaw Cable & Water Line RouteDocument1 paginăRop Sinaw Cable & Water Line RouteAkbar DahriÎncă nu există evaluări

- Ground Floor Plan - 1St Floor PlanDocument1 paginăGround Floor Plan - 1St Floor Plankrisna kingÎncă nu există evaluări

- Camp-12-Model LatestDocument1 paginăCamp-12-Model Latestsiva ganesanÎncă nu există evaluări

- Ground Floor 1Document1 paginăGround Floor 1Daniel OkerekeÎncă nu există evaluări

- Available Three-Phase Symmetrical Short-Circuit Current (Kiloamps)Document1 paginăAvailable Three-Phase Symmetrical Short-Circuit Current (Kiloamps)jurica_2006Încă nu există evaluări

- Available Three-Phase Symmetrical Short-Circuit Current (Kiloamps)Document1 paginăAvailable Three-Phase Symmetrical Short-Circuit Current (Kiloamps)Amr AhmedÎncă nu există evaluări

- Wadd ChartDocument39 paginiWadd ChartIlhamÎncă nu există evaluări

- Final ProjectDocument1 paginăFinal ProjectIsraelÎncă nu există evaluări

- Ge Tey3100 MCB ManualDocument1 paginăGe Tey3100 MCB ManualPrathap KumarÎncă nu există evaluări

- A4 Sample Working DrawingDocument1 paginăA4 Sample Working DrawingjasonÎncă nu există evaluări

- Kerja-Kerja Menaiktaraf Sistem Takungan Air Mentah Di Mukasauk Loji Rawatan Air (Lra) Kina Benuwa, Wilayah Persekutuan LabuanDocument1 paginăKerja-Kerja Menaiktaraf Sistem Takungan Air Mentah Di Mukasauk Loji Rawatan Air (Lra) Kina Benuwa, Wilayah Persekutuan LabuanFarith AkbarÎncă nu există evaluări

- Denah LT - Dasar Kitchen CikarangDocument1 paginăDenah LT - Dasar Kitchen Cikarangbss kateringÎncă nu există evaluări

- A B C D F e A B C D F e A B C D F eDocument1 paginăA B C D F e A B C D F e A B C D F eLhewiz BrionesÎncă nu există evaluări

- A301 Section Aa and BBDocument1 paginăA301 Section Aa and BBDavidson DavidÎncă nu există evaluări

- 2212003-Medium Duty-R1Document1 pagină2212003-Medium Duty-R1benyamin okiÎncă nu există evaluări

- Lower Ground Upper Ground: CR LanaiDocument1 paginăLower Ground Upper Ground: CR LanaiBethoven KhoÎncă nu există evaluări

- Nivafer Layout PDFDocument1 paginăNivafer Layout PDFOdubiyi AdewaleÎncă nu există evaluări

- 3 Bedroom Floor Plan (Back)Document1 pagină3 Bedroom Floor Plan (Back)Sodiq ShittuÎncă nu există evaluări

- Uas Utilitas GedungDocument2 paginiUas Utilitas GedungRoihatul JannahÎncă nu există evaluări

- DES-101B: Multiple of Trip Rating PlugDocument1 paginăDES-101B: Multiple of Trip Rating Plugjurica_2006Încă nu există evaluări

- Ges 6194 PDFDocument2 paginiGes 6194 PDFjurica_2006Încă nu există evaluări

- Typ.2Nd, 3Rd & 4Th Floor Power Layout: Scale 1:100 MDocument1 paginăTyp.2Nd, 3Rd & 4Th Floor Power Layout: Scale 1:100 MAnne PierreÎncă nu există evaluări

- SectionDocument1 paginăSectionShalom loisÎncă nu există evaluări

- OSHYIYEDocument1 paginăOSHYIYENana BarimaÎncă nu există evaluări

- Warren FSXB Series Spec SheetDocument3 paginiWarren FSXB Series Spec SheetEmmanuel Ber SÎncă nu există evaluări

- ASME Pressure Vessels Basic CalculationsDocument23 paginiASME Pressure Vessels Basic Calculationsdhasdj100% (17)

- Heat Transfer and Friction in Rectangular Duct With Pin-Fin ArraysDocument7 paginiHeat Transfer and Friction in Rectangular Duct With Pin-Fin ArraysEmmanuel Ber SÎncă nu există evaluări

- Heat Transfer and Friction in Rectangular Duct With Pin-Fin ArraysDocument7 paginiHeat Transfer and Friction in Rectangular Duct With Pin-Fin ArraysEmmanuel Ber SÎncă nu există evaluări

- 2061-MIX-001 Rev1Document2 pagini2061-MIX-001 Rev1Emmanuel Ber SÎncă nu există evaluări

- Nuevo Documento de Microsoft WordDocument1 paginăNuevo Documento de Microsoft WordEmmanuel Ber SÎncă nu există evaluări

- API 12N - Práctica Recomendada para La Op'n, Prueba y Mantto. de Arrestadores de FlamaDocument13 paginiAPI 12N - Práctica Recomendada para La Op'n, Prueba y Mantto. de Arrestadores de FlamaEmmanuel Ber SÎncă nu există evaluări

- Seam Join FactorDocument3 paginiSeam Join FactorEmmanuel Ber SÎncă nu există evaluări

- Datos Cruciales BarcoDocument1 paginăDatos Cruciales BarcoEmmanuel Ber SÎncă nu există evaluări

- Datos Cruciales BarcoDocument1 paginăDatos Cruciales BarcoEmmanuel Ber SÎncă nu există evaluări

- Preparing, Cleaning, and Evaluating Corrosion Test SpecimensDocument8 paginiPreparing, Cleaning, and Evaluating Corrosion Test SpecimensLê CôngÎncă nu există evaluări

- Crude Oil Gathering SystemDocument31 paginiCrude Oil Gathering SystemMohanad HussienÎncă nu există evaluări

- GenChem2 Q3 Module1A Properties of Matter and Intermolecular Forces of Attraction v4Document22 paginiGenChem2 Q3 Module1A Properties of Matter and Intermolecular Forces of Attraction v4Junelle Ramos Aquino100% (1)

- Glinka Problems in General Chemistry MirDocument290 paginiGlinka Problems in General Chemistry MirMaurizio D'IppolitoÎncă nu există evaluări

- Theories of FailureDocument77 paginiTheories of FailureAnonymous 6HADGUEXDÎncă nu există evaluări

- Geo-Synthetics: Specifications For Railway SectorDocument51 paginiGeo-Synthetics: Specifications For Railway SectorVISHWAJITÎncă nu există evaluări

- Chem Is Try Lab 2019Document8 paginiChem Is Try Lab 2019leah phoÎncă nu există evaluări

- Heat Transfer Operations Lab Report: Engr. M. Akmal RanaDocument4 paginiHeat Transfer Operations Lab Report: Engr. M. Akmal RanaUmair farooqÎncă nu există evaluări

- Eco Friendly Vat DyeingDocument27 paginiEco Friendly Vat Dyeingnagpal_aakash100% (1)

- Sensitometry: Describing Photographic PerformanceDocument55 paginiSensitometry: Describing Photographic PerformanceilloÎncă nu există evaluări

- Konelab 20Document2 paginiKonelab 20mrashrafi100% (1)

- Basics in Process Design - 2006 PDFDocument30 paginiBasics in Process Design - 2006 PDFSamuel OnyewuenyiÎncă nu există evaluări

- The Presentation ON: Satus of The PSF Plant OperationDocument24 paginiThe Presentation ON: Satus of The PSF Plant OperationKaushik SinghaÎncă nu există evaluări

- General Chemistry 2 Quarter 4 - Week 4 Module 4: PH of Buffer SolutionsDocument12 paginiGeneral Chemistry 2 Quarter 4 - Week 4 Module 4: PH of Buffer SolutionsHazel EncarnacionÎncă nu există evaluări

- Chapter 3Document3 paginiChapter 3Quennie Dhea AdanzaÎncă nu există evaluări

- Chapter 6 Powerpoint IIDocument34 paginiChapter 6 Powerpoint IIhdavey100% (1)

- Analytica Chimica Acta: Jacopo La Nasa, Francesca Modugno, Matteo Aloisi, Anna Lluveras-Tenorio, Ilaria BonaduceDocument8 paginiAnalytica Chimica Acta: Jacopo La Nasa, Francesca Modugno, Matteo Aloisi, Anna Lluveras-Tenorio, Ilaria Bonaducejuanda.scienceÎncă nu există evaluări

- Group A Rawat Lab Presentation FinalDocument96 paginiGroup A Rawat Lab Presentation Finalumair100% (3)

- ASTM GradesDocument4 paginiASTM GradesSaurabh MundheÎncă nu există evaluări

- Aderco Marine - Global Energy Sulphur Cap 2020 - v03Document24 paginiAderco Marine - Global Energy Sulphur Cap 2020 - v03Saw Win0% (1)

- Sizing of LPG Air Mix System (24mmbtu 60B-40P, 50psig)Document1 paginăSizing of LPG Air Mix System (24mmbtu 60B-40P, 50psig)ekabudiartiÎncă nu există evaluări

- Organic Syntheses Collective Volume 6Document1.299 paginiOrganic Syntheses Collective Volume 6caltexas100% (2)

- Ventilation Rates - ASHRAE 62.1-2013-2Document4 paginiVentilation Rates - ASHRAE 62.1-2013-2Mohammed Abdul MoiedÎncă nu există evaluări

- Endosimbiose e A Origem Dos PlastídeosDocument9 paginiEndosimbiose e A Origem Dos PlastídeosegpereiraÎncă nu există evaluări

- Enen 619-03 Final Research ProjectDocument26 paginiEnen 619-03 Final Research ProjectSalman NoorÎncă nu există evaluări

- Gadus s2 v220 2Document3 paginiGadus s2 v220 2ThinhÎncă nu există evaluări

- Well LoggingDocument57 paginiWell LoggingLaura DemarchÎncă nu există evaluări

- Zangar C Water Percolation 5 Water OcrDocument86 paginiZangar C Water Percolation 5 Water Ocrreem.ranoom.moonÎncă nu există evaluări

- Pressure Drop CalculationDocument13 paginiPressure Drop CalculationknsaravanaÎncă nu există evaluări

- Handbook of Fat ReplacersDocument295 paginiHandbook of Fat Replacersgoldennanuk100% (1)