Documente Academic

Documente Profesional

Documente Cultură

Astm A436

Încărcat de

PaulaErikaMATitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Astm A436

Încărcat de

PaulaErikaMADrepturi de autor:

Formate disponibile

Designation: A 436 – 84 (Reapproved 1997)e1

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Specification for

Austenitic Gray Iron Castings1

This standard is issued under the fixed designation A 436; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e1 NOTE—Keywords were added editorially in September 1997.

1. Scope 3.1.8 If different preparation for delivery requirements are

1.1 This specification covers austenitic gray iron castings needed (see 15.1).

that are used primarily for their resistance to heat, corrosion, 4. Materials and Manufacture

and wear. Austenitic gray iron is characterized by uniformly

distributed graphite flakes, some carbides, and the presence of 4.1 Melting may be done in any furnace that produces

sufficient alloy content to produce an austenitic structure. castings meeting the chemical compositions and mechanical

1.2 The values stated in inch-pound units are to be regarded properties outlined in this specification. These include cupolas,

as the standard. air furnaces, electric furnaces, crucible furnaces, etc.

4.2 By agreement between the manufacturer and the pur-

2. Referenced Documents chaser, the castings may be stress relieved by heating to and

2.1 ASTM Standards: holding in the temperature range from 1150 to 1200°F (620 to

E 30 Test Methods for Chemical Analysis of Steel, Cast 650°C) for not less than 1 nor more than 2 h/in. of thickness in

Iron, Open-Hearth Iron, and Wrought Iron2 the thickest section. Heating and cooling shall be uniform and

E 59 Practice for Sampling Steel and Iron for Determination shall be not more than 400°F (222°C)/h for castings less than

of Chemical Composition2 1 in. in maximum thickness, nor more than 400°F/h divided by

E 94 Guide for Radiographic Testing3 the maximum section thickness in inches for thicker castings.

E 165 Test Method for Liquid Penetrant Examination3 During the cooling cycle, castings may be cooled in still air

E 351 Test Methods for Chemical Analysis of Cast Iron— after the temperature has dropped to 600°F (315°C).

All Types2 4.3 If the manufacturer can demonstrate that another treat-

E 433 Reference Photographs for Liquid Penetrant Inspec- ment provides satisfactory stress relief, it may be used by

tion3 agreement between the manufacturer and the purchaser.

E 446 Reference Radiographs for Steel Castings Up to 2 in. 4.4 Whenever dimensional changes in high-temperature

(51 mm) in Thickness3 service are a problem, by agreement between the manufacturer

and the purchaser, the castings may be stabilized by heating at

3. Ordering Information 1600°F (870°C) for 1 h/in. of section, for a minimum of 1 h.

3.1 Orders for material to this specification shall include the Otherwise, the austenite that is supersaturated with respect to

following information: carbon may reject carbon during service and produce dimen-

3.1.1 ASTM designation and date of issue, sional changes.

3.1.2 Type of austenitic gray iron required (see 5.1), 4.5 By agreement between the manufacturer and the pur-

3.1.3 Heat treatment required (see 4.2 through 4.5), chaser, castings with chilled edges or excessive carbides may

3.1.4 If repair of castings is permitted (see 4.6), be annealed at 1750 to 1900°F (955 to 1040°C) for 1⁄2to 5 h,

3.1.5 Size and number of test bars required (see 11 through followed by uniform cooling, preferably in still air.

8.4 and 12.1), 4.6 Castings shall not be repaired by welding, plugging, or

3.1.6 If special tests are required (see Section 7 and 9.1), other methods without written permission from the purchaser.

3.1.7 If certification is required (see 14.1), and 5. Chemical Composition

5.1 Many combinations of alloys can be used to obtain an

1

This specification is under the jurisdiction of ASTM Committee A-4 on Iron austenitic gray iron. This specification includes only the six

Castings and is the direct responsibility of Subcommittee A04.01 on Gray Iron types defined by the chemical composition limits specified in

Castings. Table 1.

Current edition approved Jan. 27, 1984. Published May 1984. Originally

published as A 436–59 T. Last previous edition A 436–78.

5.2 The chemical analysis for total carbon shall be made on

2

Annual Book of ASTM Standards, Vol 03.05. chilled cast pencil-type specimens or from thin wafers approxi-

3

Annual Book of ASTM Standards, Vol 03.03. mately 1⁄32 in. (0.8 mm) thick cut from test coupons. Drillings

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

A 436

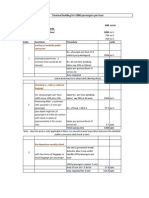

TABLE 1 Chemical Requirements

Element Composition, %

Type 1 Type 1b Type 2 Type 2b Type 3 Type 4 Type 5 Type 6

Carbon, total, max 3.00 3.00 3.00 3.00 2.60 2.60 2.40 3.00

Silicon 1.00–2.80 1.00–2.80 1.00–2.80 1.00–2.80 1.00–2.00 5.00–6.00 1.00–2.00 1.50–2.50

Manganese 0.5–1.5 0.5–1.5 0.5–1.5 0.5–1.5 0.5–1.5 0.5–1.5 0.5–1.5 0.5–1.5

Nickel 13.50–17.50 13.50–17.50 18.00–22.00 18.00–22.00 28.00–32.00 29.00–32.00 34.00–36.00 18.00–22.00

Copper 5.50–7.50 5.50–7.50 0.50 max 0.50 max 0.50 max 0.50 max 0.50 max 3.50–5.50

Chromium 1.5–2.5 2.50–3.50 1.5–2.5 3.00–6.00A 2.50–3.50 4.50–5.50 0.10 max 1.00–2.00

Sulfur, max 0.12 0.12 0.12 0.12 0.12 0.12 0.12 0.12

Molybdenum, max ... ... ... ... ... ... ... 1.00

A

Where some machining is required, the 3.00–4.00 % chromium range is recommended.

are not reliable because of the probable loss of graphite. is expressed, the manufacturer shall make the choice. The test

5.3 Drillings taken from test coupons, broken test speci- bars shall be cast in open molds made of suitable core sand

mens, or castings shall conform to the requirements for with a minimum of 1 1⁄2 in. (38 mm) of sand on all sides and

chemical composition as given in Table 1. Sampling shall be bottom of the 1⁄2-in. (13-mm) and 1-in. (25-mm) sizes, and 3 in.

conducted in accordance with Practice E 59 and chemical (76 mm) of sand for the 3-in. test bar.

analysis in accordance with Test Methods E 351 and Methods 8.2 By agreement between the manufacturer and the pur-

E 30. Test Methods E 30 should only be used for analyzing chaser, the 1-in. (25-mm) keel block shown in Fig. 2 may be

those elements for which specific coverage is not provided for used. It shall be an open mold made of suitable core sand with

in Test Methods E 351. a minimum of 11⁄2 in. (38 mm) of sand on all sides and bottom.

5.4 Spectrometric techniques may also be used for analysis, 8.3 It is recommended that test bars be poured immediately

but should a dispute arise concerning chemical composition, after the castings and from the same ladle of metal. If castings

chemical analyses determined by Test Methods E 351 and are to be heat treated, test bars shall be included in the same

Methods E 30 shall be used for referee analysis. furnace load.

8.4 By agreement between the manufacturer and the pur-

6. Mechanical Properties chaser, tension test specimens may be cut directly from

6.1 Although these irons are not used primarily for their centrifugal or other permanent mold castings. The location and

strength, the tensile strength and Brinell hardness are indicative orientation of such tension test specimens cut from castings

of the correct metallurgical structure. The six types shall shall be specified as agreed upon by the manufacturer and the

conform to the requirements given in Table 2. purchaser.

7. Magnetic Property Requirements 9. Workmanship, Finish, and Appearance

7.1 A convenient shop test for differentiating the various 9.1 The castings shall conform substantially to the dimen-

types of austenitic gray iron is based on the fact that a ground sions on the drawings furnished by the purchaser, or if no

face of either the test bars or the castings of Types 1, 2, and 4 drawing has been provided, to the dimensions predicated by

will not attract a small steel horseshoe-type magnet, that is the pattern supplied by the purchaser. The castings shall be free

normally attracted to steel. Types 1b, 2b, 3, and 5 may be of injurious defects. Surfaces of the castings shall be free of

attracted to a magnet. This nonmagnetic test is a convenient burnt-on sand and shall be reasonably smooth. In other

qualitative test only for Types 1, 2, and 4 and shall not be used respects, the castings shall conform to whatever points may be

as a basis for acceptance. In the event that nonmagnetic specifically agreed upon between the manufacturer and the

castings are specified, the magnetic permeability test shall be purchaser.

used. The specific test conditions and magnetic permeability 10. Tension Test Specimens

limits shall be agreed upon between the manufacturer and the

purchaser. 10.1 The round tension test specimen with 2-in. or 50-mm

gage length shown in Fig. 3 shall be used, except when the

NOTE 1—Alnico magnets should not be used. 1⁄2-in. (13-mm) “Y” block is used or when specimens are cut

from castings under 3⁄4-in. (19.0-mm) thickness. In these cases,

8. Test Bars

either of the test specimens shown in Fig. 4 shall be satisfac-

8.1 The separately cast test bars from which tension test tory.

specimens are to be machined shall be cast to the size and

shape shown in Fig. 1. The size of bar cast to represent the 11. Number of Test

casting shall be at the option of the purchaser. In case no option 11.1 The number of test bars cast shall be agreed upon by

TABLE 2 Mechanical Requirements

Type 1 Type 1b Type 2 Type 2b Type 3 Type 4 Type 5 Type 6

Tensile strength, min, ksi (MPa) 25 (172) 30 (207) 25 (172) 30 (207) 25 (172) 25 (172) 20 (138) 25 (172)

Brinell hardness (3000 kg) 131 183 149 212 118 174 171 248 118 159 149 212 99 124 124 174

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

A 436

“Y” Block Size

Dimensions For Castings of Thickness Less For Castings of Thickness 1⁄2 in. For Castings of Thickness of

than 1⁄2 in. (13 mm) (13 mm) to 11⁄2 in. (38 mm) 11⁄2 in. (38 mm) and Over

in. mm in. mm in. mm

A ⁄

12 13 1 25 3 75

B 15⁄8 40 21⁄8 54 5 125

C 2 50 3 75 4 100

D 4 100 6 150 8 200

E 7 175 7 175 7 175

approx approx approx approx approx approx

NOTE—1⁄16 in. 5 1.6 mm; 1⁄8 in. 5 3.2 mm.

FIG. 1 “Y” Blocks for Test Coupons

Metric Equivalents

in. mm in. mm

0.005 0.13 0.50 12.7

0.01 2.5 2 50.8

1⁄8 3.2 21⁄4 57.2

3⁄8 9.5

NOTE—The gage length and fillets shall be as shown but the ends may

be of any shape to fit the holders of the testing machine in such a way that

the load shall be axial. The reduced section shall have a gradual taper from

the ends toward the center, with the ends 0.003 to 0.005 in. (0.08 to 0.13

Metric Equivalents mm) larger in diameter than the center.

in. ⁄

12 1 11⁄2 2 FIG. 3 Standard Round Tension Test Specimen with 2-in. or

mm 13 25 38 51 50-mm Gage Length

NOTE—The length of the keel block shall be 6 in. (152 mm). penetrant inspection may be set up by mutual agreement

FIG. 2 Keel Block for Test Coupons

between the manufacturer and the purchaser.

12.2 Radiography, when required, shall be in accordance

the manufacturer and the purchaser. with Guide E 94 and Reference Radiographs E 446.

11.2 One tension test shall be made from sections cut from 12.3 Liquid penetrant inspection, when required, shall be in

the test bars as shown in Fig. 5. If any tension test specimen accordance with Test Method E 165 and Reference Photo-

shows obvious defects, another may be cut from the same test graphs E 433.

bar or from another test bar representing the same metal.

13. Responsibility for Inspection

12. Other Tests 13.1 Unless otherwise specified in the contract or purchase

12.1 Hydrostatic tests for pressure castings, fracture tests, order, the manufacturer is responsible for the performance of

microstructure standards, radiography standards, and liquid all inspection requirements as specified herein. Except as

3

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

A 436

Metric Equivalents

in. mm in. mm

0.005 0.13 1.0 25.4

0.007 0.18 11⁄4 31.8

0.252 6.40 1.4 35.6

0.357 9.07 13⁄4 44.4

NOTE 1—If desired, the length of the reduced section may be increased

to accommodate an extensometer.

FIG. 4 Examples of Small-Size Specimens Proportional to

Standard 1⁄2-in. (12.7-mm) Round Specimen

otherwise specified in the contract or order, the manufacturer

may use his own or any other facilities suitable for the

performance of the inspection requirements specified herein,

unless disapproved by the purchaser. The purchaser reserves

the right to perform any of the inspections set forth in the

specification where such inspections are deemed necessary to

assure supplies and services conform to the prescribed require-

ments.

14. Waiving of Inspection by Agreement

14.1 When agreed upon in writing by the purchaser and the

supplier, a certification shall be made the basis of acceptance of

the material. This shall consist of a copy of the manufacturer’s

test report or a statement by the supplier, accompanied by a

copy of the test results, that the material has been sampled,

tested, and inspected in accordance with the provisions of the

specification specified. Each certification so furnished shall be

signed by an authorized agent of the supplier or manufacturer.

15. Preparation for Delivery

FIG. 5 Sectioning Procedure for “Y” Blocks

15.1 Unless otherwise specified in the contract or purchase

order, cleaning, preservation, and packaging of castings shall

be in accordance with the manufacturer’s commercial practice.

Packing and marking shall also be adequate to ensure accep- 16. Keywords

tance and safe delivery by the carrier for the mode of 16.1 austenitic; gray iron castings; high-nickel

transportation employed.

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every five years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your

views known to the ASTM Committee on Standards, 100 Barr Harbor Drive, West Conshohocken, PA 19428.

COPYRIGHT American Society for Testing and Materials

Licensed by Information Handling Services

S-ar putea să vă placă și

- ASTM A747-Standard-Specification-For-Steel-Castings-Stainless-Precipitation-Hardening PDFDocument4 paginiASTM A747-Standard-Specification-For-Steel-Castings-Stainless-Precipitation-Hardening PDFRaul Dela Rosa Malanog100% (1)

- Astm A 297Document3 paginiAstm A 297friasdelacruz50% (2)

- Astm A485Document4 paginiAstm A485Vikash YadavÎncă nu există evaluări

- A299 A299m (2001) Standard Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Si PDFDocument2 paginiA299 A299m (2001) Standard Specification For Pressure Vessel Plates, Carbon Steel, Manganese-Si PDFGagan SinghÎncă nu există evaluări

- ASTMDocument10 paginiASTMDenisse LeinesÎncă nu există evaluări

- Astm A 1011M PDFDocument8 paginiAstm A 1011M PDFJuan CarlosÎncă nu există evaluări

- Astm A109Document9 paginiAstm A109banglvhÎncă nu există evaluări

- Astm A217 A217m 2010 PDFDocument4 paginiAstm A217 A217m 2010 PDFPedro SilvaÎncă nu există evaluări

- ASTM A580 2006 Standard Specification For Stainless Steel WireDocument5 paginiASTM A580 2006 Standard Specification For Stainless Steel WireEidrish Shaikh100% (2)

- A0487 - A0487m-93r12 Esp de MaterialDocument6 paginiA0487 - A0487m-93r12 Esp de MaterialIvan AlanizÎncă nu există evaluări

- ASTM A705 Standard Specification For Age Hardening Stainless Steel ForgingsDocument7 paginiASTM A705 Standard Specification For Age Hardening Stainless Steel ForgingsJuan Luis FerretÎncă nu există evaluări

- Astm A314 PDFDocument3 paginiAstm A314 PDFMatyash MatyashÎncă nu există evaluări

- A941-13b Standard Terminology Relating To Steel, Stainless Steel, Related Alloys, and FerroalloysDocument8 paginiA941-13b Standard Terminology Relating To Steel, Stainless Steel, Related Alloys, and FerroalloysChuthaÎncă nu există evaluări

- A 487Document6 paginiA 487arockia1977100% (2)

- Astm b169Document4 paginiAstm b169ANIL100% (1)

- Steel Bars, Alloys, For NitridingDocument2 paginiSteel Bars, Alloys, For Nitridingruben carcamoÎncă nu există evaluări

- Astm A297Document3 paginiAstm A297rams789Încă nu există evaluări

- Astm A747Document4 paginiAstm A747Srinivasan KrishnamoorthyÎncă nu există evaluări

- Astm A1008 12aDocument9 paginiAstm A1008 12aAleks SenaÎncă nu există evaluări

- Astm A352Document5 paginiAstm A352depeche1modeÎncă nu există evaluări

- Astm A48-A48m-03Document6 paginiAstm A48-A48m-03kimolocknarÎncă nu există evaluări

- A434Document3 paginiA434alirioÎncă nu există evaluări

- A176Document2 paginiA176Claudenir AlvesÎncă nu există evaluări

- Astm A1016Document11 paginiAstm A1016chandimadissanayaka100% (2)

- Astm A420a420m-16Document6 paginiAstm A420a420m-16arcadiosco100% (1)

- Astm F467Document6 paginiAstm F467MuhammadYusronAlfanyÎncă nu există evaluări

- Astm A351-A351mDocument7 paginiAstm A351-A351mJose Gregorio RodriguezÎncă nu există evaluări

- A834Document4 paginiA834mithileshÎncă nu există evaluări

- Astm A217-A217m 2010Document4 paginiAstm A217-A217m 2010rcfrcf279Încă nu există evaluări

- Aerospace CustomersDocument3 paginiAerospace CustomersSinan YıldızÎncă nu există evaluări

- Steel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements ForDocument31 paginiSteel, Sheet, Carbon, Structural, and High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled, General Requirements Foralucard375Încă nu există evaluări

- Astm A1039-A1039m-2004Document7 paginiAstm A1039-A1039m-2004Jorge Toribio0% (1)

- Astm A351Document5 paginiAstm A351Srinivasan KrishnamoorthyÎncă nu există evaluări

- Astm A743 PDFDocument6 paginiAstm A743 PDFzafarbadal100% (2)

- Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing For General ServiceDocument7 paginiSeamless and Welded Ferritic and Martensitic Stainless Steel Tubing For General ServicedgkmurtiÎncă nu există evaluări

- Astm B163 PDFDocument12 paginiAstm B163 PDFSuellen FerreiraÎncă nu există evaluări

- Aerospace Material SpecificationDocument6 paginiAerospace Material SpecificationadiÎncă nu există evaluări

- ASTM B188-2002 Tubos de CobreDocument10 paginiASTM B188-2002 Tubos de Cobrelinealmen100% (1)

- Astm B164 1998 PDFDocument9 paginiAstm B164 1998 PDFel_apache10Încă nu există evaluări

- Astm E689Document2 paginiAstm E689Jegan Sudharsan0% (1)

- A653a653m-18 1.06 PDFDocument13 paginiA653a653m-18 1.06 PDFist93993Încă nu există evaluări

- ASTM A681-08 - Standard Specification For Tool Steels AlloyDocument14 paginiASTM A681-08 - Standard Specification For Tool Steels Alloyhand42100% (1)

- Astm A293-2022Document10 paginiAstm A293-2022CarlosÎncă nu există evaluări

- Additive Manufacturing Stainless Steel Alloy (UNS S31603) With Powder Bed FusionDocument9 paginiAdditive Manufacturing Stainless Steel Alloy (UNS S31603) With Powder Bed FusionRaj Rajesh100% (1)

- A327A327M-11 Standard Test Methods For Impact Testing of Cast IronsDocument4 paginiA327A327M-11 Standard Test Methods For Impact Testing of Cast IronsjuegyiÎncă nu există evaluări

- A 958 - A 958M - 17Document5 paginiA 958 - A 958M - 17Eddie Michael67% (3)

- SA487Document6 paginiSA487verito09Încă nu există evaluări

- Astm A47 - A47m 99 PDFDocument5 paginiAstm A47 - A47m 99 PDFJavier Ricardo Romero BohorquezÎncă nu există evaluări

- Steel, Sheet and Strip, Heavy-Thickness Coils, Hot-Rolled, Carbon, Commercial, Drawing, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthDocument8 paginiSteel, Sheet and Strip, Heavy-Thickness Coils, Hot-Rolled, Carbon, Commercial, Drawing, Structural, High-Strength Low-Alloy, High-Strength Low-Alloy With Improved Formability, and Ultra-High StrengthIsaac ZTÎncă nu există evaluări

- Aisi 4340 Alloy Steel (Uns g43400)Document4 paginiAisi 4340 Alloy Steel (Uns g43400)LamhotFernandoSihombingÎncă nu există evaluări

- ASTM B846 19a Standard Terminology For Copper and Copper AlloysDocument18 paginiASTM B846 19a Standard Terminology For Copper and Copper AlloysRasim Göker Işık100% (1)

- Specification For General Requirements For Steel Plates For Pressure VesselsDocument34 paginiSpecification For General Requirements For Steel Plates For Pressure Vesselsedisson_barreraÎncă nu există evaluări

- Astm A 743 PDFDocument8 paginiAstm A 743 PDFWill MottaÎncă nu există evaluări

- Specification For Carbon Steel Forgings For Piping ApplicationsDocument10 paginiSpecification For Carbon Steel Forgings For Piping ApplicationsMauricio Esteban Fernandez RamirezÎncă nu există evaluări

- Austenitic Gray Iron Castings: Standard Specification ForDocument5 paginiAustenitic Gray Iron Castings: Standard Specification ForTushar RanpiseÎncă nu există evaluări

- Austenitic Gray Iron Castings: Standard Specification ForDocument5 paginiAustenitic Gray Iron Castings: Standard Specification ForDarwin DarmawanÎncă nu există evaluări

- A436-2020 Standard Specification For Austenitic Gray Iron CastingsDocument5 paginiA436-2020 Standard Specification For Austenitic Gray Iron CastingsPablo C. T.Încă nu există evaluări

- Astm A439-83-2004Document6 paginiAstm A439-83-2004NadhiraÎncă nu există evaluări

- Austenitic Ductile Iron Castings: Standard Specification ForDocument6 paginiAustenitic Ductile Iron Castings: Standard Specification ForDarwin DarmawanÎncă nu există evaluări

- MSC-MEPC.6-Circ.21 As at 31 October 2023Document61 paginiMSC-MEPC.6-Circ.21 As at 31 October 2023nedaldahha27Încă nu există evaluări

- Affidavit of SeparationDocument1 paginăAffidavit of SeparationRaysunArellano100% (9)

- Question Paper Code:: (10×2 20 Marks)Document2 paginiQuestion Paper Code:: (10×2 20 Marks)Umesh Harihara sudan0% (1)

- Huawei Videoconferencing MCU VP9600 Series Data SheetDocument2 paginiHuawei Videoconferencing MCU VP9600 Series Data SheetIsaac PiresÎncă nu există evaluări

- West Visayas State University (CHECKLIST FOR FS)Document3 paginiWest Visayas State University (CHECKLIST FOR FS)Nichole Manalo - PoticarÎncă nu există evaluări

- APEX Forms Sergei MartensDocument17 paginiAPEX Forms Sergei MartensIPlayingGames 301Încă nu există evaluări

- AIPT 2021 GuidelineDocument4 paginiAIPT 2021 GuidelineThsavi WijayasingheÎncă nu există evaluări

- Atf Fire Research Laboratory - Technical Bulletin 02 0Document7 paginiAtf Fire Research Laboratory - Technical Bulletin 02 0Mauricio Gallego GilÎncă nu există evaluări

- Guide Item Dota 2Document11 paginiGuide Item Dota 2YogaWijayaÎncă nu există evaluări

- (NewResultBD - Com) Mymensingh Board JSC Scholarship Result 2019Document80 pagini(NewResultBD - Com) Mymensingh Board JSC Scholarship Result 2019rthedthbdeth100% (1)

- Christian Borch & Gernot Bohme & Olafur Eliasson & Juhani Pallasmaa - Architectural Atmospheres-BirkhauserDocument112 paginiChristian Borch & Gernot Bohme & Olafur Eliasson & Juhani Pallasmaa - Architectural Atmospheres-BirkhauserAja100% (1)

- Bus Terminal Building AreasDocument3 paginiBus Terminal Building AreasRohit Kashyap100% (1)

- FAR MpsDocument2 paginiFAR MpsJENNIFER YBAÑEZÎncă nu există evaluări

- A Psychological Crusade by Fernando Sorrentino - Text 7Document2 paginiA Psychological Crusade by Fernando Sorrentino - Text 7Donnie DominguezÎncă nu există evaluări

- Article 124-133Document14 paginiArticle 124-133andresjosejrÎncă nu există evaluări

- Infor LN Baan - Debugging The BshellDocument26 paginiInfor LN Baan - Debugging The BshellShiva KumarÎncă nu există evaluări

- Pineapple Working PaperDocument57 paginiPineapple Working PaperAnonymous EAineTiz100% (7)

- Case Study 1 - Whirlpool Reverser Logistics - With New Rubric - Winter 2022Document4 paginiCase Study 1 - Whirlpool Reverser Logistics - With New Rubric - Winter 2022ShravanÎncă nu există evaluări

- Solution ManualDocument40 paginiSolution Manualkhaled_behery9934100% (1)

- Nclex PogiDocument8 paginiNclex Pogijackyd5Încă nu există evaluări

- The Wilderness - Chennai TimesDocument1 paginăThe Wilderness - Chennai TimesNaveenÎncă nu există evaluări

- Natural Resources of Arunachal PradeshDocument7 paginiNatural Resources of Arunachal PradeshshivarathordiviyapurÎncă nu există evaluări

- Way of St. LouiseDocument18 paginiWay of St. LouiseMaryann GuevaradcÎncă nu există evaluări

- Some FactsDocument36 paginiSome Factsapi-281629019Încă nu există evaluări

- ShowBoats International (May 2016)Document186 paginiShowBoats International (May 2016)LelosPinelos123100% (1)

- Ernieta - Entrep Survey Act.Document6 paginiErnieta - Entrep Survey Act.Nichole John ErnietaÎncă nu există evaluări

- FAN XR UP1 - E7Document26 paginiFAN XR UP1 - E7Mathieu MaesÎncă nu există evaluări

- Fujiwheel CatalogDocument16 paginiFujiwheel CatalogKhaeri El BarbasyÎncă nu există evaluări

- Climate Change Forests and Forest Management An O-Wageningen University and Research 481068Document145 paginiClimate Change Forests and Forest Management An O-Wageningen University and Research 481068gulnuromar034Încă nu există evaluări

- Time Value of Money PDFDocument4 paginiTime Value of Money PDFCalvin SandiÎncă nu există evaluări