Documente Academic

Documente Profesional

Documente Cultură

Ultima MM

Încărcat de

gass2Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ultima MM

Încărcat de

gass2Drepturi de autor:

Formate disponibile

Maintenance Manual

ULTIMA

CUTTING PLOTTER

MUTOH EUROPE N.V. AP-74050, Rev.: 1.1

2 AP-74050, Rev : 1.1

COPYRIGHT NOTICE

COPYRIGHT © 2003 Mutoh Europe N.V. all rights reserved.

This document may not be reproduced by means, in whole or in part, without written permission of the

copyright owner.

This document is furnished to support the Mutoh Ultima Multi-purpose cutting plotter (SC-850D and SC-

1400D). In consideration of the furnishing of the information contained in this document, the party to whom it

is given assumes its custody and control and agrees to the following :

The information herein contained is given in confidence, and any part thereof shall not be copied or

reproduced without written consent of Mutoh Europe N.V.

This document or the contents herein under no circumstances, shall be used in the manufacture or

reproduction of the article shown and delivery of this document shall not constitute any right or license to do

so.

March 2003

Published: Mutoh Europe N.V., Archimedesstraat 13, B-8400 Oostende, BELGIUM

FCC WARNING

This equipment complies with the requirements for a class A computing device in the FCC rules, part 15,

subpart J.

Operation of this device in a residential area may interfere with television or operating utilities.

Cutters generate weak radio signals and may interfere with television reception and utilities. If the cutter

does interfere with radio or TV reception, try the following :

Change the direction of your radio and TV reception antenna or feeder.

Change the direction of the cutter.

Move either the cutter or the receiving antenna so that there is more distance between them.

Be sure the cutter and the receiving antenna are on separate power lines.

.

3 AP-74050, Rev : 1.1

4 AP-74050, Rev : 1.1

TABLE OF CONTENTS

1. SPECIFICATIONS..........................................................................................................................9

1.1. EMC statement for CE Marking ...............................................................................................9

1.2. Important note ...........................................................................................................................9

1.3. Specifications of the Ultima Cutting Plotter ...........................................................................10

1.4. Ultima cutting plotter, environment........................................................................................11

1.5. Function keys ..........................................................................................................................12

2. SYSTEM BLOCK DIAGRAM .....................................................................................................15

2.1. Block diagram SC-850D.........................................................................................................15

2.2. Block diagram SC-1400D.......................................................................................................16

3. INTERFACES ...............................................................................................................................17

3.1. Serial interface RS-232C (standard) .......................................................................................17

3.1.1. RS-232 pin configuration.................................................................................................18

3.1.2. Serial cable configuration ................................................................................................18

3.2. USB interface..........................................................................................................................19

3.2.1. USB pin configuration .....................................................................................................19

4. TROUBLESHOOTING.................................................................................................................21

4.1. Recoverable errors ..................................................................................................................21

4.2. Unrecoverable errors...............................................................................................................22

4.3. Problem symptoms and suggested actions..............................................................................23

4.3.1. Processor errors................................................................................................................23

4.3.4. E-pos errors ......................................................................................................................24

4.3.5. Other errors ......................................................................................................................24

5. DIAGNOSTIC Mode.....................................................................................................................27

5.1. How to get in Diagnostic Mode? ............................................................................................27

5.2. How to leave in Diagnostic Mode?.........................................................................................27

5.3 Diagnostic Menu – menu overview .........................................................................................28

5.3.1 Factory default ..................................................................................................................28

5.3.2 EPOS readout....................................................................................................................29

5.3.3 Setting plot ........................................................................................................................30

5.3.4 Serial Number ...................................................................................................................31

5.3.5 Robot 2 test .......................................................................................................................32

5.3.6 Set Accuracy .....................................................................................................................33

5.3.7 Robot 1 test .......................................................................................................................34

5.3.8 Calibrate E-pos..................................................................................................................35

5.3.9 Measure Y .........................................................................................................................39

5.3.10 Penforce check ................................................................................................................40

5.3.11 Panel test 2 ......................................................................................................................41

5.3.12 Panel test 1 ......................................................................................................................42

5.3.13 Actuator write .................................................................................................................43

5.3.14 Sensor readout.................................................................................................................44

5.3.15 Quality Test.....................................................................................................................45

5.3.16 Update firmware keyboard..............................................................................................46

5.3.17 Aging...............................................................................................................................47

5 AP-74050, Rev : 1.1

5.4 Diagnostic mode – Error ..........................................................................................................48

5.4.1 How to get in diagnostic mode. ........................................................................................48

5.4.2 How to leave diagnostic mode ..........................................................................................48

5.5 Ultima shortcut key combinations. ..........................................................................................49

6. PARTS REPLACEMENT AND ADJUSTMENT ........................................................................51

6.1. Maintenance access table for parts replacement .....................................................................51

6.2. Mechanical parts .....................................................................................................................52

6.2.1. Covers Left : removal and installation.............................................................................52

6.2.2. Cover Right : removal and installation ............................................................................53

6.2.3. PCB box: open and close .................................................................................................54

6.2.4. Keyboard: removal and installation .................................................................................55

6.2.5. Y-rail Cover : removal and installation............................................................................55

6.2.6. Front Paper Sensor : removal and installation .................................................................55

6.2.7. Rear Paper Sensor : removal and installation ..................................................................56

6.2.8. Cutting Head : removal and installation ..........................................................................56

6.2.9. Grid Rollers : removal and installation ............................................................................58

6.2.10. Y-drive belt (long) : removal and installation................................................................59

6.2.9. Pressure roller pressure adjustment..................................................................................62

6.3. Electronical parts.....................................................................................................................63

6.3.1. Main PC board : removal and installation .......................................................................63

6.3.2. Head board installation ....................................................................................................65

6.3.3. Power supply board : removal and installation................................................................66

6.3.4. Power supply output connections ....................................................................................66

6.3.5. X-motor and drive belt : removal and installation ...........................................................67

6.3.6. Y-motor and drive belt : removal and installation ...........................................................68

6.3.7. Head flex cable : removal and installation.......................................................................69

6.3.8. Pressure roller UP/DOWN sensor : removal and installation..........................................70

6.3.9. Fan motors : removal and installation..............................................................................71

6.4. How to correctly install new firmware ...................................................................................72

6.4.1. Installation of new firmware with the USB cable............................................................72

6.4.2. Installation of new firmware with the serial cable...........................................................74

6.4.3. Installation of new firmware a flash card.........................................................................75

6.5. Performing a code update .......................................................................................................76

6.6. When you shut down the Ultima outside the critical section..................................................77

6.7. When you shut down the Ultima inside the critical section....................................................79

6.8. How to perform a parameter backup.......................................................................................80

6.8.1. Saving the settings onto the parameter backup card ........................................................80

6.8.2. Saving the settings from the parameter backup card onto the board ...............................81

6.9 Offset adjustment .....................................................................................................................82

7. JIG TOOL LIST.............................................................................................................................83

7.1. Jig tool list...............................................................................................................................83

7.2. Special glue .............................................................................................................................83

8. PARTS LISTS Ultima ...................................................................................................................85

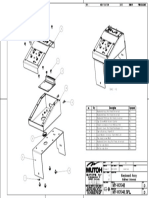

8.1. Body and Covers.....................................................................................................................85

8.2. Keyboard Assy........................................................................................................................86

8.3. Aging Level.............................................................................................................................87

8.4. Penhead Assy ..........................................................................................................................88

6 AP-74050, Rev : 1.1

8.5. Cutter holder assy....................................................................................................................89

8.6. Laser-Epos Assy Penhead.......................................................................................................90

8.7. Base plate assy ........................................................................................................................91

8.8. Base assy .................................................................................................................................92

8.9. Mechanicals final assy ............................................................................................................93

8.10. Suction tube assy...................................................................................................................94

8.11. Lever assy .............................................................................................................................95

8.12. XY-motor assy ......................................................................................................................96

8.13. Belt-cam ................................................................................................................................97

8.14. Y-drive pulley .......................................................................................................................98

8.15. Y-return pulley assy ..............................................................................................................99

8.16. X-motor pulley assy ............................................................................................................100

8.17. Y-motor pulley assy ............................................................................................................101

8.18. XY assy ...............................................................................................................................102

8.19. X-rail assy ...........................................................................................................................103

8.20. Bearing holder assy.............................................................................................................104

8.21. Y-rail assy ...........................................................................................................................105

8.22. Pressure Roller assy ............................................................................................................106

8.23. Paper sensors assy...............................................................................................................107

8.24. Left end plate assy...............................................................................................................108

8.25. Right end plate assy ............................................................................................................109

7 AP-74050, Rev : 1.1

8 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

1. SPECIFICATIONS

1.1. EMC STATEMENT FOR CE MARKING

Important :

• This is a Class A product approved for industrial environments. In a domestic

environment this product may cause radio interference in which case you may

be required to take adequate measures.

1.2. IMPORTANT NOTE

Technical problems and maintenance, which require the cutter to be opened, can only be done by qualified

personnel who were trained to repair this type of machine.

Unauthorized removing of covers and/or overruling safety locks can be dangerous and will result in your

guarantee becoming void.

Important :

• Details of this product and this manual are protected by copyright held by

this company and except for legitimate use by individuals, may not be

copied, reproduced or distributed in whole or in part.

• Details contained in this manual may be subject to future alteration without

notice.

• Details contained in this manual are believed to be correct but please contact

this company or your dealer if you suspect an error or if a point is not clear.

• In no event will this company be responsible for the consequences of using

this product or this manual.

9 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

1.3. SPECIFICATIONS OF THE ULTIMA CUTTING PLOTTER

Specifications ULTIMA SC-850D ULTIMA SC-1400D

Max. Media Width 850 (roll & sheet) 1400 (roll & sheet)

Cutting Range 100-630 (Left border 10 mm/ right 100-1200 (Left border 10 mm/ right

border 10 mm) border 10 mm)

Max. Media Thickness 1.0 mm

Applicable Tool Cutter / ink pen / ball point / ceramic / fibre / pressurised ball point

Drive Mechanism Friction

Cutting Principle Drag

Mechanical Resolution 0.005 mm

Accuracy 0.15 % of distance moved or ± 0.25 mm (whichever is greater)

Repeatability (mm/m) 0.25 0.25

No. of Pressure Rollers 2 3

Knives 30° / 45° / 60°

Speed 100 – 1000 mm/s axial (1414 mm/s diagonal)

Acceleration Max. 3 G (tool up & down) / Automatic control, speed linked to media width

Tool Up / Down Cycles 40 per second

Cutting Force Range 20 – 450 g (stepwise adjustable)

Interface (standard) RS-232 & USB

Input Buffer (standard) 6 MB

Roll support system + Media Standard (included)

collection basket

Automatic Take-up system Optional

Graphic language MH-GL/2 (HP-GL/2 compatible)

Configurable Origin Yes

Offset adjustment Yes (0 – 1 mm)

Auto Sheet Off Function + Yes

Replot Function

Alignment Feature for Integrated Laser-Alignment Tool

contour cutting

Keyboard with LCD-Display Detachable with 4 lines, 16 character/line LCD

Power requirements AC 100/120 V, AC 220/240 V

10 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

1.4. ULTIMA CUTTING PLOTTER, ENVIRONMENT

The location where you set up your equipment is very important. Please see to it that it meets following

conditions :

• Power supply of 100 to 120 VAC 50/60 Hz or 200 to 240 VAC 50/60 Hz.

• Ambient conditions :

o Operating environment

Temperature : 5 °C to 30 °C

Humidity : 35 % - 75 % non-condensation

o Recommended environment

Temperature : room temperature 16 °C to 25 °C

Humidity : 50 % to 65 % non-condensation

o Variation rate

Temperature : 2 °C per hour

Humidity : 5 % per hour

o Storage environment

Temperature : 0 °C to 50 °C

• Please protect your cutter from moisture, dust, draughts and direct sunlight. It is best to keep your

machine away from open windows and air-conditioners.

• See to it that there is an adequate space around the cutter so that ventilation is not obstructed.

• Avoid unnecessary vibrations and set up your cutter on a level surface.

• When selecting a place for your cutter, leave at least 90 cm in front and 90 cm at the rear.

11 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

1.5. FUNCTION KEYS

Using the control panel, you can access different modes and alter several settings, in order to fine-tune the

cutter to match all your needs.

1) CANCEL : The [CANCEL] key is controlling the cancel function. By pressing the

[CANCEL] key, instead of confirmation you will keep the previous setting.

By pressing the [CANCEL] key you can clear all received data.

2) EXIT : The [EXIT] key cancels the changes made in the setting. You will return

to the previous menu.

Press the [EXIT] key in normal mode to perform a shut off.

3) ENTER : Press the [ENTER] key to select a menu.

Press the [ENTER] key to confirm the changes made to the setting.

4) READY / PAUSE : Press the [READY/PAUSE] key to set the cutter “READY or PAUSE”

5) UP : Press the [UP] key to increase the value of the setting.

Press the [UP] key to select a parameter in the menu.

6) DOWN : Press the [DOWN] key to decrease the value of the setting.

Press the [DOWN] key to select a parameter in the menu.

7) PRESETS : Change the user (there are maximum 32 users), each user has his own

set of settings, that are saved when the machine is shut down.

8) ORIGIN : Press the [ORIGIN] key to change the origin.

9) TEST : Press the [TEST] key to choose one of the testplots to plot.

10) CONTOUR CUTTING : Press the [CONTOUR CUTTING] key to start an auto/manual aligning

procedure.

11) SPEED : Press the [SPEED] key to change the value of the speed.

12) FORCE : Press the [FORCE] key to change the value of the force.

12 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

13) OFFSET : Press the [OFFSET] key to change the value of the offset.

14) TOOL : Press the [TOOL] key to change the tool type.

15) Take-up / Sheet / Roll : Press the [TUSR] key to select the loaded media.

16) ARROW-KEY : Press the [ARROW] key for manual movement of the tool head.

13 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

14 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

2. SYSTEM BLOCK DIAGRAM

2.1. BLOCK DIAGRAM SC-850D

15 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

2.2. BLOCK DIAGRAM SC-1400D

16 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

3. INTERFACES

3.1. SERIAL INTERFACE RS-232C (STANDARD)

1) Baud rate (software selectable)

• 9600 bps

• 4800 bps

• 2400 bps

• 1200 bps

2) Data length (software selectable)

• 7 bits

• 8 bits

3) Stop bits (software selectable)

• 1 bit

• 2 bits

4) Parity (software selectable)

• Odd

• Even

• None

5) Error detection

• Parity error

• Framing error

• Overrun error

6) External connector

• DB-9F

7) RS-232C driver / receiver IC

• HIN 238CP

17 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

3.1.1. RS-232 pin configuration

PIN # SIGNAL Abbr. Signal direction

2 Receive date RXFPC IN

3 Transmit data TX2PC OUT

4 GND

5 Data terminal ready DTR OUT

8 Clear to send CTS IN

3.1.2. Serial cable configuration

Computer side : DB-25F Cutter side : DB-9M

Pin Nr: 25F Pin Nr: 9M

FRAME Shielding wire FRAME

2 ←→ 2

3 ←→ 3

5+6 ←→ 4

7 ←→ 5

20 ←→ 6+8

Cable length: 3 meter

18 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

3.2. USB INTERFACE

The used UND interface in the Ultima cutting plotter is the USB version 1.1. Standard in the box is a double-

shielded USB cable with a length of 5m.

3.2.1. USB pin configuration

PIN # SIGNAL

1 VUSB → NC

2 - DATA

3 + DATA

4 GND

19 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

20 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

4. TROUBLESHOOTING

When errors occur during cutting or after powering on the machine, some messages may appear on the

display to inform you about the kind of error.

4.1. RECOVERABLE ERRORS

Recoverable errors are mostly related to communication problems or user mistakes.

In this section you will find a summary of problems that might occur during day-to-day use of your cutter and

some hints how to determine the cause of the problem.

1) Power switch is turned ON, but the cutter does not operate.

• Is the power cable connected to the cutter ?

• Is the cutter connected to a power outlet with the specified voltage ?

2) Media is loaded, but the cutter does not operate.

• Is the media hold lever lowered ?

• Is the media properly loaded ?

• Are the paper sensors clean ?

3) Data is being sent from the computer, but the cutter does not react.

• Is there a proper interface cable connected ?

• Is the cutter in ON-LINE mode ?

• Do the interface conditions on the host computer match those set on the cutter ?

4) Data is sent from the computer but errors occur on the cutter’s side.

• Are the output settings correct on the host computer and in the cutting software ?

• Do the interface conditions on the host computer match those set on the cutter ?

• Does the command mode on the host computer match the command mode on the cutter ?

5) Some parts of the design are not well cut.

• Check whether the knife tip is not clogged with material residues.

• Examine the knife blade with a magnifier to see if the tip is not damaged or broken.

• Perform the offset adjustment routine to check cutting quality.

• Perform the internal test cut and check its quality

21 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

4.2. UNRECOVERABLE ERRORS

The machine will stop working when an unrecoverable error occurs.

To clear the error message, the machine needs to be powered OFF and ON again. (Wait ± 7 seconds

between power OFF/ON).

Refer to the following chart for error code explanation :

NOYENCODER : No Y encoder, check connectors or call service.

YPOSENCTURN : Y+ encoder turn, check connectors or call service.

YNEGENCTURN : Y- encoder turn, check connectors or call service.

YXSWAPPED : YX are swapped, check connectors or call service.

NOXENCODER : No X encoder, check connectors or call service.

XPOSENCTURN : X+ encoder turn, check connectors or call service

XNEGENCTURN : X- encoder turn, check connectors or call service.

XYSWAPPED : XY are swapped, check connectors or call service.

YPOSERROR : X position error, PWM switched off as a safety.

XPOSERROR : Y position error, PWM switched off as a safety.

ZPOSERROR : Z position error, PWM switched off as a safety.

DRAMERROR0 : MEMORY size allocation error

DRAMERROR1 : MEMORY allocation lower limit error

DRAMERROR2 : MEMORY allocation upper limit error

GENYENCODER : General Y encoder failure, PWM switched off as a safety.

GENXENCODER : General X encoder failure, PWM switched off as a safety.

SERIALOFW : Serial Buffer Overflow Error.

VECTOROFW : Vector Buffer Overflow Error.

SERVOOFW : Servo Buffer Overflow Error.

NOZENCODER : No Z encoder, check connectors or call service.

ZPOSENCTURN : Z+ encoder turn, check connectors or call service

ZNEGENCTURN : Z- encoder turn, check connectors or call service.

GENZENCODER : General Z encoder failure, PWM switched off as a safety.

RAMCARDAAAA : RamCard Error while writing 'AAAA' code.

RAMCARD5555 : RamCard Error while writing '5555' code.

UNDEFCARD : Undefined card inserted.

UNDEFCARDWP : Undefined card inserted and write protected.

CORRUPTFCCA : Corrupt 'FCCA' code, Flash incorrectly loaded.

Communication errors are caused by a problem in the communication between the cutter and the host

computer. They can be caused by errors related to the communication conditions, errors due to a defective

handshake or command format errors in the ESCAPE sequences.

KEYB_COMM_CHECKSUM : KEYB communication checksum problem

UART1_COMM_ERROR : UART1 communication error

UART2_COMM_ERROR : UART2 communication error

UART2_SENDTOKEYB_ERROR : UART2 send to keyb problem

Language errors occur when command data entered from the host computer does not match the data

format of the command mode currently activated on the cutter’s side. The error can be caused by a

difference in command type or by a syntax error.

PGTOOSHORT : PG error : Media too short to perform a 'PG;'.

PGM0TOOSHORT : PG Mode 0 Error : Media too short to perform a 'PG;'.

PGM1TOOSHORT : PG Mode 1 Error : Media too short to perform a 'PG;'.

PGM2TOOSHORT : PG Mode 2 Error : Media too short to perform a 'PG;'.

DRAWERROR00 : Out of limit error, vector has been clipped.

22 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

4.3. PROBLEM SYMPTOMS AND SUGGESTED ACTIONS

4.3.1. Processor errors

PROBLEM SYMPTOM POSSIBLE CAUSE SUGGESTED ACTIONS

• Error code 0 • Poor connection between • Check cable and connection

• Watch dog timeout main and terminal board. • Replace mainboard

• Bus trap error • Mainboard failure

• Address trap error

• Illegal instruction (MC68020)

• Zero divide

• General processor failure

• Interrupt failure

• 1010 CPU failure

• 1111 CPU failure

• DRAM error

• SRAM error

• Extended RAM error • Poor extended RAM • Check connection

connection • Replace extended RAM

• Bad extended RAM

4.3.2. X-Y servo errors

PROBLEM SYMPTOM POSSIBLE CAUSE SUGGESTED ACTIONS

• OUT of SYNC X • Defective motor / encoder • Replace motor / encoder

• OUT of SYNC Y • Loose drive pulley • Fix pulley or replace motor /

• X position Timeout • Failure in drive circuit encoder

• Y position Timeout • Poor connection of motor/ • Replace main PC board

• X over current encoder • Check cables and

• Y over current • Too much friction in X or Y connections

• X overload axis • Check X and Y movement

• Y overload

• X Encoder fail

• Y Encoder fail

• Encoder failure

• Driver failure

4.3.3. Cutting head errors

PROBLEM SYMPTOM POSSIBLE CAUSE SUGGESTED ACTIONS

• Position Timeout Moving Coil • Blade is too far out • Check knife holder

(MC) • Sheet off mechanism blocks • Check blade depth

• OVER CURRENT Moving Coil UP/DOWN movement • Check sheet off mechanism

(MC) • Head flex cable bad or poor • Check connections or replace

• A/D failure Moving Coil (MC) connection head flex cable

• Bad cutting head • Replace cutting head

• Failure in drive circuit • Replace main PC board

23 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

4.3.4. E-pos errors

PROBLEM SYMPTOM POSSIBLE CAUSE SUGGESTED ACTIONS

Problem with the E-pos system Laser not working Check connection

Sensor not working Replace head

Laser damaged

Sensor damaged

4.3.5. Other errors

PROBLEM SYMPTOM POSSIBLE CAUSE SUGGESTED ACTIONS

• System is dead : • Power failure • Check power cord

• No movement • Defective power supply (P/S) • Check wall outlet

• No LED’s lighted • Defective mainboard • Check fuse on P/S

• Check LEDs on P/S

• Replace P/S

• Replace mainboard

• Display lighted but no • Defective mainboard • Replace mainboard

movement of the motors and • Poor connection between • Check cable connections

cutting head. main and terminal board

• Plotter does not pre-feed • Pressure roller lever is not • Lower the lever

media. DOWN • Check the lever sensor

• Bad lever sensor • Load media properly

• Both media sensors are not • Clean or replace media

covered sensors

• Media sensors dusty or bad

• Illegal mainboard revision • Mainboard version is not • Use correct mainboard

compatible

• Wrong mainboard • Mainboard is not compatible • Use correct mainboard

• Plotter has pre-feeded media • Plotter is OFF-line • Put plotter in ON-line

but does not respond to data • Interface cable not connected • Check interface cable

or bad • Check plotter driver

• Wrong plotter driver • Check interface parameters

• Wrong interface parameters • Check port or replace main

• Bad interface port PC board

• Plotter is responding to data, • Wrong interface parameters • Check interface parameters

but error messages appear on • Wrong cable configuration • Check interface cable

the display.

• Plotter is cutting but quality is • Blade worn or broken • Replace blade

not acceptable • Blade is not turning smooth • Check or replace knife holder

• Offset is not correct • Perform offset procedure

• Blade is too far out • Adjust knife depth

• Cutting force is too high • Reduce cutting force

• Cutting mat worn • Replace cutting mat

• Wrong plotter driver • Select correct plotter driver

• Play on cutting head • Check or replace cutting head

• Drive belt tension not correct • Check or adjust belt tensions

• X or Y motor defective • Replace X or Y motor

24 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

PROBLEM SYMPTOM POSSIBLE CAUSE SUGGESTED ACTIONS

• Media tracking problems • Media is not loaded straight in • Load media as described in

• Media skews during cutting or the machine the User’s Guide

loading. • Grid rollers dirty • Clean grid rollers

• Grid rollers or pressure rollers • Replace grid rollers or

worn pressure rollers

• Speed or acceleration too • Decrease

high • Cutting speed

• Pressure roller pressure not • Pen/UP speed

correct • Cutting acceleration

• Media backing is very slippery • Pen/UP acceleration

(Teflon based) • Adjust pressure roller

pressure

• Change media type or

decrease speed acceleration

25 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

26 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5. DIAGNOSTIC MODE

5.1. HOW TO GET IN DIAGNOSTIC MODE?

To go in Diagnostic Mode, please follow the instructions mentioned below.

Step 1: Power ON the Ultima cutting plotter.

Notes :

Let the unit perform the initialise routine (determination of left and right borders). In case

media is loaded media will also be measured.

Step 2: Press the [PRESETS], [ORIGIN], [CONTOUR CUTTING] and [TEST] key simultaneously.

Step 3: The Ultima cutting plotter will enter the Diagnostic Mode. The display on the Operation Panel

shows following message:

Diagnostics Mode

is entered

Press any key

Step 4: Press any key.

5.2. HOW TO LEAVE IN DIAGNOSTIC MODE?

To leave the Diagnostic Mode, please follow the instructions mentioned below.

Step 1: Press the [PRESETS], [ORIGIN], [CONTOUR CUTTING] and [TEST] key simultaneously.

Step 2: The Ultima cutting plotter will leave the Diagnostic Mode. The display on the Operation Panel

shows following message:

Diagnostics Mode

is leaved

Press any key

Step 3: Press any key.

27 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3 DIAGNOSTIC MENU – MENU OVERVIEW

5.3.1 Factory default

To set the values of the machine back to factory default, please follow the instructions below.

Step 1: Go into Diagnostic Mode.

Step 2: Press the [TEST] key.

Step 3: By pressing the [UP] or [DOWN] key select “Factory default”. The display on the Operation

Panel will show the following message.

Diagnostics :

Factory default

Choose item

Step 4: Press the [ENTER] key. Values are set to factory default, a double beep will sound. The display

will show the following message :

DIAGNOSTIC MODE

PRESS TEST

BUTTON TO SELECT

AN ITEM

28 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.2 EPOS readout

To check the photodiode of the Ultima cutting plotter, please follow the instructions below.

Step 1: Go into Diagnostic Mode.

Step 2: Press the [ENTER] key.

Step 3: By pressing the [UP] or [DOWN] key select “EPOS readout”. The display on the Operation Panel

will show the following message.

Diagnostics :

Epos Readout

Choose item

Step 4: Press the [ENTER] key. The display will show the following message:

Photodiode

ACD value :

***

Change the value

Step 5: By covering or uncovering the front sensor, the display will show the relative status of the

sensor.

Step 6: Press the [ENTER] key to exit the “EPOS readout menu”

29 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.3 Setting plot

To make a setting plot, please follow the instructions below.

Step 1: Perform a “Factory default” in Diagnostic mode.

Step 2: Install a pen.

Step 3: Press the [TOOL] key and select “pen tool”.

Step 4: Install media.

Step 5: Go into Diagnostic Mode.

Step 6: Press the [TEST] key.

Step 7: By pressing the [UP] or [DOWN] key select “Settings plot”.

Step 8: Press the [ENTER] key. The Laser will light up. The display will show the following message :

Step 9: The Ultima cutting plotter will draw the settings plot.

30 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.4 Serial Number

Only to be used during production of the unit.

31 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.5 Robot 2 test

To perform a Robot 2 Test, please follow the instructions below.

Step 1: Go into Diagnostic Mode.

Step 2: Load media.

Step 3: Install a knife.

Step 4: Press the [TEST] key.

Step 5: By pressing the [UP] or [DOWN] key select “Robot 2 Test”. The display on the Operation Panel

will show the following message.

Diagnostics :

Robot 2 Test

Choose item

Step 6: Press the [ENTER] key. The Ultima cutting plotter will cut a picture. Check the patterns.

Especially look for good quality of the corners and easy weeding. If this is not the case, readjust

the Ultima cutting plotter.

32 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.6 Set Accuracy

To check the accuracy of the Ultima cutting plotter, please follow the instructions below.

Step 1: Go into Diagnostic Mode.

Step 2: Press the [TEST] key.

Step 3: By pressing the [UP] or [DOWN] key select “Set accuracy”. The display on the Operation Panel

will show the following message.

Diagnostics :

Set accuracy

Choose item

Step 4: Press the [ENTER] key. The display will show the following message :

Set real X value

Ref : 20000

Val : 20000

UP/DOWN & ENTER

Step 5: By pressing the [ARROW] keys change the X value by steps of 10 digits.

By pressing the [UP] or [DOWN] key change the X value accurately.

Step 6: Press the [ENTER] key. The display will show the following message :

Set real Y value

Ref : 20000

Val : 20000

UP/DOWN & ENTER

Step 7: By pressing the [ARROW] keys change the Y value by steps of 10 digits.

By pressing the [UP] or [DOWN] key change the Y value accurately.

Step 8: Press the [ENTER] key to exit the “Set accuracy” menu.

33 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.7 Robot 1 test

To perform a Robot 1 Test, please follow the instructions below.

Step 1: Go into Diagnostic Mode.

Step 2: Load media.

Step 3: Install a knife.

Step 4: Press the [TEST] key.

Step 5: By pressing the [UP] or [DOWN] key select “Robot 1 Test”. The display on the Operation Panel

will show the following message.

Diagnostics :

Robot 1 Test

Choose item

Step 6: Press the [ENTER] key. The Ultima cutting plotter will cut a picture. Check the patterns.

Especially look for good quality of the corners and easy weeding. If this is not the case, readjust

the Ultima cutting plotter.

34 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.8 Calibrate E-pos

During calibration the distance between the laser and the pen/knife is measured (and stored).

Measurement can be done in two ways, namely:

¾ Automatic calibration

¾ Manual calibration (with knife)

¾ Manual calibration (with pen)

It is possible to check visually the calibration by using the ‘Calibration with pre-drawn sample square’.

1. Automatic calibration

To calibrate the E-pos system using the ‘Automatic calibration’, please follow the instructions mentioned

below.

Step 1 : Install a knife.

Step 2 : Press the [TOOL] key and select ‘knife’.

Step 3 : Install a black vinyl.

Step 4 : Press the [TEST] key.

Step 5 : By pressing the [UP] or [DOWN] key select ‘EPOS align tune --> automatic. The Display on the

Operation Panel will show the following message.

Testplot

EPOS align tune

→ automatic

Choose testfile

Step 6 : Press the [ENTER] key. The Ultima cutting plotter will cut a square. After cutting following

message will appear.

Measure box is

cut please

Weed out and

Press a button

Step 7 : Peel of the box cut by the Ultima cutting plotter.

Step 8 : Press the [ENTER] key.

Step 9 : The laser of the Ultima cutting plotter will measure the box. The distance between laser and

knife is calculated and stored.

Step 10 : Calibration of the E-pos system with the ‘automatic calibration’ method is done. Following

message will appear.

EPOS

Calibration

done

35 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

2. Manual calibration with knife

To calibrate the E-pos system using the ‘manual calibration’, please follow the instructions mentioned below.

Step 1 : Install a knife.

Step 2 : Press the [TOOL] key and select ‘knife’.

Step 3 : Install a black vinyl.

Step 4 : First set the ORIGIN in the middle of the media.

¾ Press the [Origin] key.

¾ Select ‘Manual’.

¾ Use the [ARROW] keys to position the tool head in the middle of the media.

¾ Press the [ENTER] key to confirm.

Step 5 : Press the [TEST] key.

Step 6 : By pressing the [UP] or [DOWN] key select ‘EPOS align tune --> manual’. The Display on the

Operation Panel will show the following message.

Testplot

EPOS align tune

→ manual

Choose testfile

Step 7 : Press the [ENTER] key. The Ultima cutting plotter will start cutting two square boxes. After

drawing following message will appear.

Measure box is

cut please

Weed out and

Press a button

Step 8 : Peel of the boxes cut by the Ultima cutting plotter.

Step 9 : Press the [ENTER] key.

Step 10 : The Ultima cutting plotter will move the laser to the point where both squares touch. Following

message will appear.

* Epos Calibrate. *

Please move

laser pointer to

Cross and enter

Step 11 : If necessary, use the [ARROW] keys to position the laser exactly onto the point where both

squares touch. Do not keep the [ARROW] keys pressed, pressing the keys only causes one

movement.

Step 12 : Press the [ENTER] key to confirm the position of the laser. The distance between laser and knife

is calculated and stored.

Step 13 : Calibration of the E-pos system with the ‘manual calibration’ method is done.

36 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

3. Manual calibration with pen

To calibrate the E-pos system using the ‘manual calibration’, please follow the instructions mentioned below.

Step 1 : Install a pen.

Step 2 : Press the [TOOL] key and select ‘pen’.

Step 3 : Install an A4-format paper.

Step 4 : First set the ORIGIN in the middle of the media.

¾ Press the [Origin] key.

¾ Select ‘Manual’.

¾ Use the [ARROW] keys to position the tool head in the middle of the media.

¾ Press the [ENTER] key to confirm.

Step 5 : Press the [TEST] key.

Step 6 : By pressing the [UP] or [DOWN] key select ‘EPOS align tune --> manual’. The Display on the

Operation Panel will show the following message.

Testplot

EPOS align tune

→ manual

Choose testfile

Step 7 : Press the [ENTER] key. The Ultima cutting plotter will start drawing a cross.

Step 8 : The Ultima cutting plotter will move the laser to the point where both lines intersect. Following

message will appear.

* Epos Calibrate. *

Please move

laser pointer to

Cross and enter

Step 9 : If necessary, use the [ARROW] keys to position the laser exactly onto the point where both lines

intersect. Do not keep the [ARROW] keys pressed, pressing the keys only causes one

movement.

Step 10 : Press the [ENTER] key to confirm the position of the laser. The distance between laser and knife

is calculated and stored.

Step 11 : Calibration of the E-pos system with the ‘manual calibration’ method is done.

37 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

4. Visual check of the calibration

It is possible to check the calibration of the Ultima cutting plotter by using the calibration with pre-drawn

sample square’ method. To check the calibration, please follow the instructions mentioned below.

Before performing a ‘calibration with pre-drawn sample square’ make sure to have the files ‘kot.eps’.

Step 1 : Prepare your printer to ‘Ready-to-print’.

Step 2 : Import the kot.eps file and RIP this file.

Step 3 : Print out the ripped kot.eps file.

Step 4 : Power ON the Ultima cutting plotter and install a pen.

Step 5 : Load the printed output into the Ultima cutting plotter.

Step 6 : By pressing the [UP] or [DOWN] key select ‘EPOS alignment --> test plot’. The Display on the

Operation Panel will show the following message.

Testplot

EPOS alignment

→ test plot

Choose testfile

Step 7 : Press the [ENTER] key. The laser of the Ultima cutting plotter will measure the box and will start

(re)drawing the diagonals and the small rectangle.

Step 8 : Check if the drawn lines are well positioned according to the printed lines.

38 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.9 Measure Y

To measure the height difference in the Y direction of the Ultima cutting plotter, please follow the instructions

below.

Step 1: Go into Diagnostic Mode.

Step 2: Press the [TEST] key.

Step 3: By pressing the [UP] or [DOWN] key select “Measure Y”. The display on the Operation Panel

will show the following message.

Diagnostics :

Measure Y

Choose item

Step 4: Press the [ENTER] key. The display will show the following message :

Measure drum

Please wait

While Ultima

Is measuring

Measure drum

Max : 0

Delta : 18

U/D & ENTER

Step 5: Press the [UP] or [DOWN] key to change the value.

Step 6: Press the [ENTER] key to exit the “Measure Y” menu.

39 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.10 Penforce check

To check the penforce of the Ultima cutting plotter, please follow the instructions below.

Step 1: Install media.

Step 2: Install the measure-equipment.

Step 3: Go into Diagnostic Mode.

Step 4: Press the [TEST] key.

Step 5: By pressing the [UP] or [DOWN] key select “Penforce check”. The display on the Operation

Panel will show the following message.

Diagnostics :

Penforce check

Choose item

Step 6: Press the [ENTER] key. The display will show the following message :

Penforce check

Current force :

100.000000

UP/DOWN & ENTER

Step 7: Check the measured value with the displayed value.

Step 8: By pressing the [UP] or [DOWN] key change the value of the display to the corresponding

measured value.

Step 9: Press the [ENTER] key to exit the “Keyboard LED’s” menu.

40 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.11 Panel test 2

To check the buttons of the Ultima cutting plotter, please follow the instructions below.

Step 1: Go into Diagnostic Mode.

Step 2: Press the [TEST] key.

Step 3: By pressing the [UP] or [DOWN] key select “Panel test 2”. The display on the Operation Panel

will show the following message.

Diagnostics :

Panel test 2

Choose item

Step 4: Press the [ENTER] key. The display will show the following message :

Keyboard LED’s

→ SHEET LED

MU/MD = change

ENTER = exit

Step 5: By pressing the [UP] or [DOWN] key select a LED. In normal condition the LED displayed will

light up on the operation panel.

Step 6: Press the [ENTER] key to exit the “Keyboard LED’s” menu.

41 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.12 Panel test 1

To check the buttons of the Ultima cutting plotter, please follow the instructions below.

Step 1: Go into Diagnostic Mode.

Step 2: Press the [TEST] key.

Step 3: By pressing the [UP] or [DOWN] key select “Panel test 1”. The display on the Operation Panel

will show the following message.

Diagnostics :

Panel test 1

Choose item

Step 4: Press the [ENTER] key. The display will show the following message :

Keyboard check

→ No button

Press 3 times

ENTER to cancel

Step 5: Press a key. The display will show the selected button.

Step 6: Press three times the [ENTER] key to exit the “Panel test 1” menu.

42 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.13 Actuator write

To check the buzzer, LED’s, sheet-off knife or laser of the Ultima cutting plotter, please follow the instructions

below.

Step 1: Go into Diagnostic Mode.

Step 2: Press the [TEST] key.

Step 3: By pressing the [UP] or [DOWN] key select “Actuator write”. The display on the Operation Panel

will show the following message.

Diagnostics :

Actuator write

Choose item

Step 4: Press the [ENTER] key. The display will show the following message :

Actuator write

Mainboard LED’s :

OFF

U/D & ARROW U/D

Step 5: Press the [ARROW] key change the status of the item.

Step 6: Press the [UP] or [DOWN] key select buzzer, LED’s, sheet-off knife or laser.

Step 7: Press the [ENTER] key to exit the “Actuator write” menu.

43 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.14 Sensor readout

To check the sensors of the Ultima cutting plotter, please follow the instructions below.

Step 1: Go into Diagnostic Mode.

Step 2: Press the [TEST] key.

Step 3: By pressing the [UP] or [DOWN] key select “Sensor readout”. The display on the Operation

Panel will show the following message.

Diagnostics :

Sensor readout

Choose item

Step 4: Press the [ENTER] key. The display will show the following message :

Sensor Read

X front sensor :

OFF

Change the value

Step 5: By covering or uncovering the front sensor, the display will show the relative status of the

sensor.

Step 6: By pressing the [UP] or [DOWN] key select the newt sensor test. Sensors to be checked are :

• “X rear sensor” = to check the X rear sensor → cover or uncover the rear sensor

• “Lever sensor” = to check the lever sensor → detect up or down position of the Lever

• “Y flap sensor” = to check the position-sensor of the pressure rollers → moves head above

the pressure rollers.

Step 7: Press the [ENTER] key to exit the “Sensor readout” menu.

44 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.15 Quality Test

To perform a Quality Test, please follow the instructions below.

Step 1: Go into Diagnostic Mode.

Step 2: Load media.

Step 3: Install a knife.

Step 4: Press the [TEST] key.

Step 5: By pressing the [UP] or [DOWN] key select “Quality Test”. The display on the Operation Panel

will show the following message.

Diagnostics :

Quality Test

Choose item

Step 6: Press the [ENTER] key. The Ultima cutting plotter will cut a picture. Check the patterns.

Especially look for good quality of the corners and easy weeding. If this is not the case, readjust

the Ultima cutting plotter.

45 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.16 Update firmware keyboard

Notes :

Please perform this function after a firmware upgrading. Without this procedure, the

panel keyboard remains in the old firmware version.

To perform an update firmware keyboard, please follow the instructions mentioned below.

Step 1: Go into Diagnostic Mode.

Step 2: Press the [TEST] key.

Step 3: By pressing the [UP] or [DOWN] key select “Update Firmware keyboard”. The display on the

Operation Panel will show the following message.

Diagnostics

Update Firmware

keyboard

Choose item

Step 4: Press the [ENTER] key. The display on the Operation Panel will show the following message.

Code Update

Please wait …

Step 5: After approximately 45 second a beep will sound and following message appears (short) on the

display.

Mutoh Europe NV

Version ***

Initializing

Please wait

Step 6: The keyboard has been updated and reset.

Step 7: You will automatically enter the Normal Mode.

46 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.3.17 Aging

To check the movement of the Head and Grid Rollers please follow the instructions below.

Step 1: Go into Diagnostic Mode.

Step 2: Press the [TEST] key.

Step 3: By pressing the [UP] or [DOWN] key select “Aging”. The display on the Operation Panel will

show the following message.

Diagnostics :

Aging

Choose item

Step 4: Press the [ENTER] key. The Head will start to move. The display will show the following

message :

Smooting

Page Length

VS/ZF Settings

Emulation

Step 5: To stop the movements pres the [TEST] key. The display on the Operation Panel will show the

following message.

Diagnostics :

Aging

Choose item

Step 6: Press the [ENTER] key. The machine will stop all movements. The display will show the

following message :

Smooting

Page Length

VS/ZF Settings

Emulation

Step 7: Load media and repeat step 1 to 7 to check the movement of the grid rollers

47 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.4 DIAGNOSTIC MODE – ERROR

In case you cannot power ON the Ultima cutting plotter normally, you are unable to enter Diagnostic Mode.

If this is the case, please follow the instructions mentioned below to enter Diagnostic Mode.

Notes :

Only a small amount of tests can be performed in this diagnostic mode.

5.4.1 How to get in diagnostic mode.

Step 1: Power ON the Ultima cutter plotter.

Notes :

Don’t let the machine complete his start up.

Step 2: Press the [TEST] and [PRESETS] key simultaneously when following screen is displayed.

VERSION ID

*********************

SR V *.**

Date Hour

Step 3: The Ultima cutting plotter will enter the Diagnostic Mode. The display on the Operation Panel

shows following message.

DIAGNOSTIC MODE

PRESS TEST

BUTTON TO SELECT

AN ITEM

Step 4: Press the [TEST[ key to start the several tests.

5.4.2 How to leave diagnostic mode

Step 1: The machine needs to be powered “OFF” and “ON” again. (Wait ± 7 seconds between power

OFF/ON)

48 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

5.5 ULTIMA SHORTCUT KEY COMBINATIONS.

PRESETS+ORIGIN+TEST+CONTOUR CUTTING: Enter/Leave diagnostic mode.

PRESETS + ORIGIN + SPEED + FORCE: Update the keyboard firmware.

TEST + COUNTOUR CUTTING + OFFSET + TOOL: Reset the keyboard.

ORIGIN + RIGHT: Activate sheet off knife.

ORIGIN + LEFT: Deactivate sheet off knife.

TEST + LEFT: Set laser LED on.

TEST + RIGHT: Set laser LED off.

CONTOUR + (UP or DOWN or LEFT or RIGHT): EPOS line search for maximum 4 cm.

CONTOUR + TEST + RIGHT: Scan a postnet code from left to right.

CONTOUR + TEST + UP: Scan a postnet code from down to up.

PRESETS + TEST: Startup in diagnostic (combination works only at

startup when firmware version is showed).

49 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

50 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

6. PARTS REPLACEMENT AND

ADJUSTMENT

6.1. MAINTENANCE ACCESS TABLE FOR PARTS

REPLACEMENT

Removal of the following cover gives access to the following part or mechanical adjustment :

COVER Gives access to

Left cover Y-axis return pulley assy

Y-axis drive belt tension adjustment

Right cover Y-motor

Y-drive pulley assy

Y-drive belt (short) tension adjustment

Pressure roller UP/DOWN sensor

Pressure roller UP/DOWN mechanism

Keyboard assy

Y-rail cover Pressure roller assy

Y-rail assy

Penhead flex cable assy

Pressure roller pressure adjustment

PCB-box Main/driver board assy

Power supply board assy

X-motor assy

X-drive belt tension adjustment

Fan motor

Grid cover Grid rollers

Paper sensors

Head cover E-pos system

Coil

Cutter holder

51 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

6.2. MECHANICAL PARTS

6.2.1. Covers Left : removal and installation

Step 1: Remove the two screws at the bottom of the cover.

Step 2: Remove the two screws at the inside of the cover.

Step 3: Remove the cover by pulling the cover carefully up at the bottom.

Notes :

To reinstall Left Cover perform above steps in reversed order.

52 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

6.2.2. Cover Right : removal and installation

Step 1: Remove the two screws at the bottom of the cover.

Step 2: Remove the two screws at the inside of the cover.

Step 3: Remove the cover by pulling the cover carefully up at the bottom.

Notes :

To reinstall the Right Cover perform above steps in reversed order.

53 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

6.2.3. PCB box: open and close

Step 1: Remove the Conveyor System

a. Remove the Conveyor Rollers.

b. Loosen the three screws at the Left Conveyor Support System.

c. Loosen the three screws at the Right Conveyor Support System.

d. Remove the Conveyor System.

Step 2: Remove the three screws at the rear of the PCB Box.

Step 3: Remove the three screws at the front of the PCB Box.

Step 4: The PCB box will turn open.

Notes :

Close the PCB box by performing the above steps in reversed order.

54 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

6.2.4. Keyboard: removal and installation

Step 1: Disconnect the Keyboard Cable.

Step 2: Remove the Keyboard.

Notes :

To reinstall the Panel perform above steps in reversed order.

6.2.5. Y-rail Cover : removal and installation

Step 1: Remove the Keyboard. (Please refer to 6.2.4. Keyboard)

Step 2: Remove the two screws at the rear of the Y-rail Cover.

Step 3: Remove the two screws at the front of the Y-rail Cover.

Step 4: Remove the Y-rail Cover.

Notes :

To reinstall the Y-rail Cover perform above steps in reversed order.

6.2.6. Front Paper Sensor : removal and installation

Step 1: Remove the Left Cover. (Please refer to 6.2.1. Cover Left)

Step 2: Remove the Right Cover. (Please refer to 6.2.2. Cover Right)

Step 3: Remove the two screws at the left side of the Front Cover.

Step 4: Remove the two screws at the right side of the Front Cover.

Step 5: Open the PCB box (Please refer to 6.2.3. PCB box).

Step 6: Pull out the Front Plate.

Step 7: Loosen the screw, disconnect connector (F) and remove the Front Paper Sensor.

Notes :

To reinstall the Front Paper Sensor perform above steps in reversed order.

55 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

6.2.7. Rear Paper Sensor : removal and installation

Step 1: Remove the Left Cover. (Please refer to 6.2.1. Cover Left)

Step 2: Remove the Right Cover. (Please refer to 6.2.2. Cover Right)

Step 3: Remove the two screws at the left side of the Rear Cover.

Step 4: Remove the two screws at the right side of the Rear Cover.

Step 5: Open the PCB box (Please refer to 6.2.3. PCB box).

Step 6: Pull out the Rear Plate.

Step 7: Loosen the screw, disconnect connector (R) and remove the Rear Paper Sensor.

Notes :

To reinstall the Rear Paper Sensor perform above steps in reversed order.

6.2.8. Cutting Head : removal and installation

Step 1: Remove the Y-rail Cover. (Please refer to 6.2.5. Y-rail Cover)

Step 2: Remove the head cover by removing the two screws in the front of the cover.

Step 3: The head cover can be removed by sliding upwards.

Step 4: Open the 2 white connectors by sliding them to the front and pull away the 2 flex cables from the

connectors.

Step 5: Remove the head PCB on top of the head by 2 screws ‘C’ (Please refer to picture mentioned

below) and lay it somewhere on the Y-rail where the flex cable cannot be damaged.

56 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

Step 6: Remove screw ‘A’ that fix the cutting head to the drive belt.

It is strongly recommended to use a magnetised –screwdriver in order not to drop the screw

inside the head.

Step 7: Remove screw ‘B’ on the top of the head and slide away the blade spring.

Notes :

To reinstall the cutting head perform above steps in reversed order.

Caution :

After replacement of the cutting head the following electronically adjustments have to be

performed :

Cutting mat height measurement

Adjusting the sheeting off system

Pen force calibration

57 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

6.2.9. Grid Rollers : removal and installation

Step 1: Remove the Left Cover. (Please refer to 6.2.1. Left Cover)

Step 2: Remove the Right Cover. (Please refer to 6.2.2. Right Cover)

Step 3: Remove the Y-rail Cover. (Please refer to 6.2.5. Y-rail Cover)

Step 4: Unscrew the two screws from the X-motor a few turns and remove the X-drive belt.

Step 5: Unscrew all the grid rollers (with 1.5mm hex-key) and pull out gently the shaft out of the

machine. In this way every grid roller can be removed from the shaft.

Caution :

Never replace only one grid roller but always the whole set. Replacement of only one

grid roller may result in noticeable deviation of media tracking!

Before unscrewing the grid rollers, mark the position of every roller on the shaft. This

will simplify the reinstallation.

NEVER unscrew or change the position of the bearing blocks on the X-rail as this will

result in misalignment of the grid roller shaft!

Notes :

To reinstall the grid rollers perform above steps in reversed order.

Caution :

After reinstallation of the grid rollers, the X-drive belt tension should be adjusted (Please

refer to the adjustment of the X-drive belt).

58 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

6.2.10. Y-drive belt (long) : removal and installation

Step 1: Remove the Left Cover (Please refer to 6.2.1. Left Cover).

Step 2: Remove the Right Cover (Please refer to 6.2.2. Right Cover).

Step 3: Remove the Y-rail Cover (Please refer to 6.2.5. Y-rail Cover).

Step 4: Remove the cutting head.

Step 5: On the left hand side of the machine, unscrew both screws #5 (2) ± 5 turns in order to get the

tension of the belt (Please refer to picture mentioned below).

Step 6: Remove two screws #4 and one plate #3 from the belt connection assy and pull the belt

complete out of the Y-rail. (Please refer to the picture on the next page.)

(1) Y-drive belt (long) : Installation and adjustment.

Step 1: Hold the belt in front of the machine and push one end trough the slit of the right side plate.

Turn the belt around the pulley and push it in the second slit to enter the slide at the back of the

Y-rail.

Push it as far as it goes and then use a flash light and look into the slit at the left side of the

machine.

With a pair of tweezers try to grab the belt and pull it through the slit.

Turn the belt around the return pulley and push it through the front slit to arrive at the starting

point of the belt again.

59 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

Step 2: Close the belt with the connection plate assy and be sure that all the teeth of the connection

plate are used to hold the belt.

Step 3: Turn the 2 screws on the return pulley an equal amount of turns in CW (Clockwise direction) in

order to get a little tension on the belt.

Step 4: Install the cutting head (Please refer to 6.2.8. Cutting head).

Step 5: Move the head manually from the left to the right and look for the tracking of the belt on the

return pulley.

If the belt moves upwards, turn the top screw CW or the bottom screw CCW (counter-clockwise).

If the belt moves downwards, turn the top screw CCW or the bottom screw CW.

The target is that the tension of the belt stays stable at the surface of the return pulley on the

complete range of the cutting head.

Step 6: Similar to step 5 check the track of the belt on the drive pulley.

If the belt moves upwards turn the screw 9 (Please refer to the picture mentioned below) CW.

If the belt moves downward turn screw 9 CCW.

60 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

Caution :

Pay attention to the tension on the belt during this alignment.

The tension should stay between acceptable values (Please refer to step 7).

Step 7: Move the head to the right end of the Y-rail and measure with a bar tension gauge (range : 500g,

MUTOH Part# JD-41446B) the tension of the belt in the middle of the Y-rail (Please refer to

picture mentioned below).

Push the belt with the bar tension gauge (with steel belt tension attachment MUTOH part# JD-

41565) to touch the rail and release gently the pressure on the gauge.

The movement that the belt starts to release from the rail is the moment of reading the value on

the bar tension gauge.

The values are different for each size machine :

SC-850D SC-1400D

180 ± 5 g 125 ± 5 g

The tension can be adjusted by turning the screws on the return pulley CW for more tension and CCW for

less tension.

Caution :

While adjusting the tension, keep on checking the track of the belt on the return pulley

(Please refer to step 5).

61 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

6.2.9. Pressure roller pressure adjustment

Step 1: Switch off the machine and place the pressure rollers on top of a grid roller.

Step 2: Remove the Y-rail Cover (Please refer to 6.2.5. Y-rail Cover).

Step 3: Take a piece of polyester film of ± 300 cm long, 2.5 mm wide (12” X 1”) and put it between the

grid roller and the pressure roller (Please refer to the picture mentioned below).

Attach the bar tension gauge (range 5 kg, MUTOH Part# JD-41446C) to the pressure roller shaft

with a piece of rope or with the pressure measurement attachment JD-41563 and pull

simultaneously the film and the tension gauge under 90° angle.

The moment that the film is slipping between the rollers is the moment to read the value on the

tension gage.

The value should be 3.5 kg ± 0.1 kg.

To adjust the pressure, change the spring tension by turning the nuts A (Please refer to the

figure mentioned below) CW to increase or CCW to decrease the pressure on the rollers.

62 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

6.3. ELECTRONICAL PARTS

6.3.1. Main PC board : removal and installation

N° Description N° Description N° Description

1 Serial port 7 Flex cable 2 head 13 Fan 1

2 Keyboard cable connector 8 Front paper sensor 14 Fan 2

3 USB port 9 Rear paper sensor 15 Motor X

4 Flash card connector 10 Cover sensor (not used) 16 Motor Y

5 Encoder X 11 Lever sensor 17 Power connector

6 Encoder Y 12 DIP switch

Step 1 : Open the PCB box (Please refer to 6.2.3. PCB box).

Step 2 : Remove the protection cap.

Step 3 : Unplug all the connectors, remove all screws from the board and remove the board. Do not

forget to remove the screws from the parallel and serial communication connector.

Notes :

Pay attention to the position of all connectors and the proper place of all the cables.

This will simplify the installation.

To reinstall the Main PC board perform above steps in reversed order.

63 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

Notes :

Please note that the connector of the Cover Sensor (J6) is not used.

<

64 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

6.3.2. Head board installation

To install the Head Board, please follow the instructions mentioned below.

Important :

Before working on a machine, always power OFF the unit and pull out the power

supply cable. Otherwise you may suffer an electric shock.

Step 1: Disconnect the Keyboard Cable.

Step 2: Remove the Operation Panel.

Step 3: Remove the two screws at the rear of the Y-rail Cover.

Step 4: Remove the two screws at the front of the Y-rail Cover.

Step 5: Remove the Y-rail Cover.

Step 6: Remove the head cover by removing the screw in the middle of the cover and unscrew the

bottom screw a few turns. The head cover can be removed by sliding upwards.

Step 7: Remove the connectors. Remove the 2 screws on top of the Head board and remove the Head

Board

Step 8: Install the new Head Board. Reconnect the connectors.

Connections on the New Head Board

65 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

Notes :

Please note that the flex head cable connection is made onto the second connector on

the new Head Board.

6.3.3. Power supply board : removal and installation

Step 1: Open the PCB box (Please refer to 6.2.3.PCB box).

Step 2: Remove the protection cap.

Step 3: Remove the connectors and the screw from the grounding wire and remove the board.

Notes :

To reinstall the board perform above steps in reversed order.

6.3.4. Power supply output connections

PIN SIGNAL COLOUR PIN SIGNAL COLOUR

1 + 5V Red 7 FG Green

2 + 5V Red 8 - 12V Blue

3 SG Black 9 AG Black

4 SG Black 10 + 12Vb Orange

5 + 12Va Orange 11 PG1 Black

6 + 40V Yellow 12 PG2 Black

66 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

6.3.5. X-motor and drive belt : removal and installation

Step 1: Remove the right cover (Please refer to 6.2.2. Right Cover).

Step 2: Open the PCB box (Please refer to 6.2.3.PCB box).

Step 3: Remove the X-motor connector and the X-encoder connector from the Main PCB.

Step 4: Remove the screws from the X-motor and remove the belt and the motor.

Notes :

To reinstall the x-motor perform above steps in reversed order.

(1) X-drive belt : Tension adjustment.

Step 1: From the side of the PCB box, attach a piece of rope (or the pressure measurement attachment

JD-41563) around the motor body as close as possible to the side plate.

Step 2: Be sure that the motor screws are not fixed and pull the bar tension gauge (range 5kg, MUTOH

part# JD-41446C) downwards for 3.75 kg ± 0.05 kg.

Turn manually the grid shaft a few turns and fix the motor screws.

67 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

6.3.6. Y-motor and drive belt : removal and installation

Step 1: Remove the right cover (Please refer to 6.2.2. Right Cover) and open the PCB box (Please refer

to 6.2.3.PCB box). If the drive belt needs to be removed, remove the left cover too (Please refer

to 6.2.1. Left Cover).

Step 2: Remove the Y-motor connector and the Y-encoder connector from the mainboard and pull the

cables out of the PCB box.

Step 3: Remove the 2 screws from the Y-motor and remove the motor.

Notes :

To reinstall the Y-motor perform above steps in reversed order and perform the belt

tension adjustment. (Please refer to point 1) Y-motor and drive belt mentioned below).

Step 4: (Drive belt removal only)

Release the tension on the Y-drive belt (long) (Please refer to 6.2.8 Y-drive belt (long) step 3).

Remove the screw on top of the pulley shaft (Please refer to screw 9 on figure 6.2.8. Y-drive belt

(long) 1) Y-drive belt (long) step 3) and remove the pulley assy from the bracket. If not possible,

the Y-drive belt (long) needs to get more play by turning the screws of the return pulley CCW.

Now the Y-belt (short) can be removed.

(1) Y-motor and drive belt : installation and adjustment.

Step 1: Install the Y-drive belt (short) by performing the above steps in reverse order.

Step 2: Turn in the screws from the Y-motor a few turns, but do not fix them.

Step 3: Attach the bar tension gauge (range 5 kg, MUTOH part# JD-41446C) to the motor shaft (use a

piece of rope or pressure measurement attachment JD-41563) and pull for 3.5 kg ± 0.05 kg.

While pulling the gauge, move the cutting head manually left and right a few times before fixing

the motor screws.

68 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter

6.3.7. Head flex cable : removal and installation

Step 1: Remove the Y-rail cover (Please refer to 6.2.5 Y-rail cover).

Step 2: Remove the head cover by removing the screw in the middle of the cover and unscrew the

bottom screw a few turns. The head cover can be removed by sliding upwards.

Step 3: Open the 2 white connectors by sliding them to the front and pull away the 2 flex cables from the

connectors. Remove the head PCB on top of the head by 2 screws and lay it somewhere on the

Y-rail where the flex cable cannot be harmed.

Step 4: Open the PCB box (Please refer to 6.2.3. PCB box).

Step 5: Remove the flex cable from the terminal board.

Step 6: Remove the right cover (Please refer to 6.2.2. Right Cover) and open the cable guides that

holding the flex cable.

Step 7: Remove the flex cable.

Notes :

Pay attention to the position of the cable in the way that it is guided all through the

machine.

This will simplify the installation.

Notes :

To reinstall the head flex cable perform above steps in reversed order.

69 AP-74050, Rev : 1.1

Maintenance Manual – Ultima Cutting Plotter