Documente Academic

Documente Profesional

Documente Cultură

Process Modeling, Simulation, and Control For Chemical Engineers 2nd Ed (McGraw-Hill Chemical Engineering Series) - William L. Luyben

Încărcat de

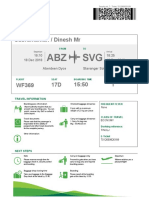

Dinesh KumarTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Process Modeling, Simulation, and Control For Chemical Engineers 2nd Ed (McGraw-Hill Chemical Engineering Series) - William L. Luyben

Încărcat de

Dinesh KumarDrepturi de autor:

Formate disponibile

out.fm Seite 1 Donnerstag, 16.

April 2015 7:35 07

Instructions for use

Micro handpieces

92-020 | 92-021 | 92-112

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US 0123

Handpiece 92

out.fm Seite 2 Donnerstag, 16. April 2015 7:35 07

2 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 3 Donnerstag, 16. April 2015 7:35 07

Table of contents

Table of contents

1 Introduction .................................................................................................... 5

1.1 Information about these instructions for use................................. 5

1.2 Typographical conventions ............................................................. 5

1.3 General conditions............................................................................ 6

2 Safety ............................................................................................................... 7

2.1 Intended use...................................................................................... 7

2.2 General warnings .............................................................................. 8

3 Overview........................................................................................................10

3.1 Overview of micro handpiece ........................................................10

3.2 Scope of delivery.............................................................................11

3.3 Pictograms.......................................................................................11

3.4 System overview .............................................................................12

4 Transport and storage..................................................................................13

5 Operation ......................................................................................................14

5.1 Preparing for treatment .................................................................15

5.1.1 Connecting the micro handpiece to the ultrasonic generator.............15

5.1.2 Functional testing .................................................................................................17

5.2 Starting treatment ..........................................................................18

5.3 Ending treatment............................................................................21

5.3.1 Disconnecting the micro handpiece from the ultrasonic generator..21

6 Reprocessing .................................................................................................23

6.1 Disassembling the micro handpiece .............................................23

6.2 Manually pre-cleaning the micro handpiece ................................24

6.3 Automatically clean and disinfect the micro handpiece .............25

6.4 Reassembling the micro handpiece ..............................................26

6.5 Sterilizing the micro handpiece.....................................................27

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 3

out.fm Seite 4 Donnerstag, 16. April 2015 7:35 07

Table of contents

7 Preventive maintenance ..............................................................................28

7.1 Faults................................................................................................28

7.2 Safety check.....................................................................................29

7.3 Preventive maintenance ................................................................29

7.4 Repairs .............................................................................................29

8 Disposal .........................................................................................................31

9 Technical data ...............................................................................................32

Index ..............................................................................................................33

4 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 5 Donnerstag, 16. April 2015 7:35 07

Introduction

Information about these instructions for use

1 Introduction

1.1 Information about these instructions for use

These instructions for use are intended to help you use the Micro handpiece in an op-

timum manner. Assembly and disassembly of the Micro handpiece and reprocessing

after use are described in detail. Medical application is not described. Find out about

the medical applications and their side effects. The relevant information can be found

in the specialist literature.

These instructions for use are included with the Micro handpiece. Please read the in-

structions for use completely before using the Micro handpiece. Please keep these in-

structions for use for future reference.

The Micro handpiece is only approved for use with a Söring ultrasonic generator and

Söring accessories. Please also observe the instructions for use for the ultrasonic gen-

erator and the accessories that are used.

If you have further questions on the content of these instructions for use or use of the

Micro handpiece, please contact Söring GmbH (contact data on back page) or an au-

thorized distributor.

1.2 Typographical conventions

In these instructions for use, warnings are indicated by a signal word. Hazards are cat-

egorized into hazard levels with consequences of differing severity.

Signal word Consequences

The consequences are death or severe injury.

The consequences may be death or severe injury.

The consequences may be minor injury.

This could result in material damage.

All warning information is structured according to the same model. The source of the

hazard is stated after the signal word. Then the effects of the hazard and its conse-

quences are described. Finally the steps that must be taken to eliminate the hazard

are given.

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 5

out.fm Seite 6 Donnerstag, 16. April 2015 7:35 07

Introduction

General conditions

1.3 General conditions

Ensure that the following conditions are met when working with the Micro hand-

piece:

The instructions for use must be read before the Micro handpiece can be used.

The Micro handpiece must be processed according to the instructions given in

these instructions for use before it can be used for the first time (see Chapter ”Re-

processing” on page 23).

Report any recurring faults or problems to Söring GmbH or an authorized distrib-

utor.

Söring GmbH does not accept liability for any damage or personal injury arising from:

Modification or manipulation of the Micro handpiece

Improper use

Use of an unauthorized ultrasonic generator

Use of accessories other than the recommended ones

Improper handling

Non-compliance with these instructions for use

1.4

6 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 7 Donnerstag, 16. April 2015 7:35 07

Safety

Intended use

2 Safety

2.1 Intended use

The micro handpiece is intended solely for use on the central nervous system, in neu-

rosurgery and in spine surgery on humans. The micro handpiece is used for selective

dissection of tissue. Intracranial tumours (e.g. meningeomas, gilomas, neurinomas) in-

tracranial metastases as well as spinal soft tissue (intradural extramedullary tumors,

intradural intramedullary tumors and extradural tumors) may be treated.

The micro handpiece is not intended for use directly on the eye or circulatory system.

For the desired tissue effect to be achieved with the micro handpiece, sufficient irriga-

tion solution must be used. Only physiological saline solution or Ringer's solution is

approved as an irrigation solution.

As no definitive information is available for the treatment of at risk patients – primar-

ily pregnant women and hemophiliacs as well as infants and children up to 13 years

of age – the attending surgeon must weigh the risks of the treatment particularly

carefully against the benefits.

In each case, the surgeon providing treatment is responsible for weighing the risks of

treatment against the benefits.

The micro handpiece may only be used in medical procedures and operating rooms.

In close vicinity to the operating field, the atmosphere must not be oxygen enriched

nor must there be any danger of explosion.

Only qualified surgeons may operate on patients with the micro handpiece.

Any other use of the micro handpiece in accordance with the intended use – e.g. for

operation and reprocessing – is only permitted for qualified specialists such as oper-

ating room staff and sterilization department staff possessing the required education,

training or knowledge as well as sufficient experience.

In general, the micro handpiece may only be used by individuals properly instructed

in its handling. The manufacturer or a person authorized by the operator must pro-

vide instruction in the handling of the micro handpiece with the help of these instruc-

tions for use.

The micro handpiece is authorized for use with the following Söring ultrasonic gener-

ators only:

SONOCA 300

SONOCA 400

Under normal conditions, the micro handpiece is intended for use of no longer than

60 minutes in total.

The specified ambient temperature, relative humidity and air pressure conditions

must be maintained at all times during operation as well as during transport and stor-

age.

Any use other than that specified is considered to be improper use.

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 7

out.fm Seite 8 Donnerstag, 16. April 2015 7:35 07

Safety

General warnings

2.2 General warnings

Electromagnetic fields

Electromagnetic fields, such as those generated by a magnetic resonance tomograph,

can influence the function of the micro handpiece and cause severe injury to patients.

Do not use the micro handpiece in the area of influence of electromagnetic fields.

Ensure electromagnetic compatibility of other electrical devices.

Only use medical electrical devices that have a CE mark with identification num-

ber of the notified body.

Contaminated micro handpiece

Use of a contaminated micro handpiece may result in life-threatening infections in

both patients and users.

Only use a sterile micro handpiece.

Only use a sterile instrument cable.

Only use a sterile double tubing from undamaged packaging.

Damaged instrument cable

Damaged insulation on the instrument cable may cause electric shock and result in

severe injury or death.

Check the instrument cable for damage.

If the instrument cable is damaged, immediately switch off the power supply (or

do not switch it on).

Replace the instrument cable if damaged.

Only use an undamaged instrument cable.

8 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 9 Donnerstag, 16. April 2015 7:35 07

Safety

General warnings

Incorrect accessories

Use of unauthorized accessories may lead to malfunction and cause severe injury to

patients as well as operators.

Only use approved accessories (see catalogue or our website: www.soering.com).

Use outside of the specified ambient conditions

Use of the micro handpiece outside the specified ambient temperature, relative hu-

midity and air pressure conditions can have incalculable consequences.

When operating the micro handpiece, ensure that the specified ambient condi-

tions are maintained.

During transport and storage, ensure that the specified ambient conditions are

maintained.

Treatment of at risk patients

The treatment of at risk patients may lead to death or severe injury. At risk patients in-

clude pregnant women, hemophiliacs as well as infants and children up 13 years of

age.

Weigh the medical benefits of the treatment against the risks.

Prior to beginning treatment, ensure that all measures for lessening risks have

been taken.

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 9

out.fm Seite 10 Donnerstag, 16. April 2015 7:35 07

Overview

Overview of micro handpiece

3 Overview

3.1 Overview of micro handpiece

1 2

3

5

6

8 7

Fig. 3.1 Micro handpiece

1 Sonotrode 5 Luer lock port for the aspiration

2 Cover (disposable accessory) 6 Luer lock port for the irrigation

3 Nose cone 7 Connector socket for the instrument cable

4 Handpiece body with ultrasonic transducer 8 Type designation and serial number

1

2

Fig. 3.2 Individual parts of micro handpiece

1 Cover (disposable accessory) 3 Handpiece body with ultrasonic transducer

2 Nose cone 4 Sonotrode

10 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 11 Donnerstag, 16. April 2015 7:35 07

Overview

Scope of delivery

3.2 Scope of delivery

The micro handpiece is delivered without other accessories.

For the use of the micro handpiece, the following accessories are necessary:

An instrument cable

A double tubing (disposable accessory)

Only use approved accessories. Approved accessories are listed in the catalogue.

For the latest information regarding accessories, please visit our website:

www.soering.com

3.3 Pictograms

In connection with the Micro handpiece, standardized symbols are used. In particular,

the packaging of the required accessories is marked with these symbols.

Pictogram Meaning

Indicates that the instructions for use must be read and followed.

Indicates a medical device of type BF (Body Floating).

Indicates a medical device with an article number in order to identify and re-

order it.

Indicates the batch of the medical device.

Indicates who is the manufacturer of the medical device.

Indicates when the medical device was manufactured.

Indicates the date until which the medical device may be used.

Indicates a medical device that may not be used if the packaging is damaged

or already open.

Indicates a medical device that has been sterilized with ethylene oxide.

Indicates a medical device that must be stored in a dry place and protected

from humidity.

Indicates a medical device that must be protected from sunlight and light

sources.

Indicates the temperature to which the medical device can be safely exposed.

Indicates a medical device that may not be reused and is only intended for

single use on an individual patient during a single treatment.

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 11

out.fm Seite 12 Donnerstag, 16. April 2015 7:35 07

Overview

System overview

3.4 System overview

The micro handpiece is connected to an ultrasonic generator with irrigation and aspi-

ration. A single foot switch on the ultrasonic generator is used for simultaneously acti-

vating the ultrasonic power as well as the irrigation and the aspiration.

INFORMATION

Fig. 3.3 Micro handpiece in the entire system

1 Ultrasonic generator 4 Micro handpiece

2 Double tubing (disposable accessory) 5 Cover (disposable accessory)

3 Instrument cable 6 Single foot switch

3.5

12 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 13 Donnerstag, 16. April 2015 7:35 07

Transport and storage

4 Transport and storage

For transport and storage of the Micro handpiece, use packaging which protects it

from damage and contamination.

Always store the sterilized Micro handpiece in sterile packaging in accordance with

ISO 11607.

The storage environment must be dry, clean and dust-free.

Storage temperature: between –25 °C and 70 °C (–13 °F and 158 °F).

Relative humidity: between 10 % and 95 %, non-condensing.

Air pressure: between 500 hPa and 1060 hPa (7.25 psi and 15.37 psi).

4.1

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 13

out.fm Seite 14 Donnerstag, 16. April 2015 7:35 07

Operation

5 Operation

Only qualified surgeons may operate on patients with the micro handpiece. Any

other use of the micro handpiece in accordance with the intended use is only permit-

ted for qualified specialists.

The surgeon providing treatment is responsible for weighing the risks of treatment

against the benefits.

Prior to the first treatment – and prior to any further treatment – the micro handpiece

and the instrument cable must be cleaned, disinfected and sterilized (see Chapter

”Reprocessing” on page 23).

Please also observe the instructions for use supplied with the ultrasonic generator.

They contain information regarding the assembly of the required accessories and the

connection of the micro handpiece to the ultrasonic generator.

Functional testing must always be performed on the ultrasonic generator with the

micro handpiece prior to treatment (see Chapter ”Functional testing” on page 17).

Please also observe the instructions for use supplied with the ultrasonic generator

when performing this test.

During the treatment keep a redundant system ready for use in case the first one fails.

After treatment, properly dispose of the double tubing. The micro handpiece and the

instrument cable must be reprocessed (see Chapter ”Reprocessing” on page 23).

14 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 15 Donnerstag, 16. April 2015 7:35 07

Operation

Preparing for treatment

5.1 Preparing for treatment

First the Micro handpiece must be connected to the ultrasonic generator. A visual in-

spection must then be performed. Finally, functional testing must be performed and

the power settings on the ultrasonic generator checked. Only then may treatment be

started.

5.1.1 Connecting the micro handpiece to the ultrasonic generator

Requirements

The micro handpiece is sterile.

The instrument cable is sterile.

An irrigation bottle, an aspiration canister and a sterile double tubing are at hand.

The ultrasonic generator is turned on.

Procedure

1. During a visual inspection, ensure that the handpiece body, the sonotrode and

the nose cone are in perfect condition.

2. Place the cover over the sonotrode and slide onto the nose cone.

Liquid on the contacts

The connector socket may melt due to liquid on the contacts of a connector socket or

the instrument cable. This leads to malfunctions of the micro handpiece and of the ul-

trasonic generator. Treatment must be performed with a redundant system, thereby

lengthening the treatment duration.

Make sure the contacts on the connector sockets and on the plugs are dry.

Observe the specified sequence of the steps so no liquid gets onto the contacts.

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 15

out.fm Seite 16 Donnerstag, 16. April 2015 7:35 07

Operation

Preparing for treatment

3. Insert the instrument cable plugs into the connector socket on the ultrasonic gen-

erator.

Heed the markings.

– The instrument cable engages in the connector socket.

4. Insert the instrument cable into the connector socket on the micro handpiece.

Heed the markings.

– The instrument cable engages in the connector socket.

– The OK indicator light on the ultrasonic generator lights.

5. Connect the double tubing with the luer lock ports of the micro handpiece.

Hand tighten only.

Observe the instructions for use of the ultrasonic generator for using the irriga-

tion bottle and the aspiration canister.

– The micro handpiece has been connected to the ultrasonic generator.

16 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 17 Donnerstag, 16. April 2015 7:35 07

Operation

Preparing for treatment

5.1.2 Functional testing

Functional testing must always be performed on the ultrasonic generator with the

micro handpiece prior to treatment. The irrigation function and the ultrasonic func-

tion are checked during the functional testing and the suctioning function.

Finally, the power settings on the ultrasonic generator must be checked and ad-

justed. The ultrasonic power as well as the aspiration capacity and the irrigation ca-

pacity must be ensured.

Requirements

The micro handpiece has reached the permissible temperature for use (between

10 °C and 40 °C (50 °F and 104 °F)).

The micro handpiece has been connected to the ultrasonic generator.

The OK indicator light on the ultrasonic generator lights.

Procedure

1. Press and hold the button on the ultrasonic generator for filling with irrigation so-

lution until irrigation solution exits from the sonotrode on the micro handpiece

and there is no more air trapped in the double tubing.

2. Ensure the connections between the double tubing and micro handpiece and be-

tween the double tubing and irrigation bottle do not leak.

3. Activate the micro handpiece with the foot switch and immerse the sonotrode in

sterile liquid.

– The sterile liquid begins to make a noise; this is a sign that ultrasonic power is

being supplied.

4. Release the foot switch.

– The aspiration pump continues to run for another 30 seconds.

5. As long as the aspiration pump continues to run, immerse the sonotrode in sterile

liquid again.

– The liquid is suctioned off which is visible in the transparent part of the double

tubing.

– Functional testing has been performed.

6. Check and adjust the power settings on the ultrasonic generator (irrigation capac-

ity, ultrasonic power and aspiration capacity).

– All power settings have been adjusted.

– Treatment can be carried out.

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 17

out.fm Seite 18 Donnerstag, 16. April 2015 7:35 07

Operation

Starting treatment

5.2 Starting treatment

A single foot switch on the ultrasonic generator is used for simultaneously activating

the ultrasonic power as well as the irrigation and the aspiration.

It is crucial for the treatment result that the power settings are correct. The tissue ef-

fect is controlled primarily with the ultrasonic power and the aspiration capacity. The

higher the ultrasonic power and the aspiration capacity is set, the stronger the tissue

effect.

Always begin the treatment with a low ultrasonic power to prevent an unintention-

ally strong effect. Then slowly increase the ultrasonic power.

For the desired tissue effect to be achieved with the micro handpiece, sufficient irriga-

tion solution must be used. Only physiological saline solution or Ringer's solution is

approved as an irrigation solution.

Only when sufficient irrigation solution is directed to the sonotrode tip will the so-

notrode tip not clog. Sufficient irrigation solution also prevents the micro handpiece

from becoming excessively hot when activated for a long time. Thus check the so-

notrode tip continuously over the course of the treatment to determine that it is

being supplied with sufficient irrigation solution. For the irrigation solution to be aspi-

rated again, the aspiration capacity must be set accordingly high.

Sufficient irrigation solution is important to achieve the desired tissue effect. How-

ever, too much irrigation solution can impair the view of the operating field. The irri-

gation solution must be aspirated.

Do not set the aspiration capacity too low. Instead, increase the irrigation capacity in

order to prevent the sonotrode and the double tubing from blocking.

Due to the friction heat, it is also crucial for the treatment result that the correct pres-

sure is applied to the tissue and the movement of the sonotrode tip is correct over

the tissue.

Always use the micro handpiece with care so the sonotrode is not damaged. Do not

bend the sonotrode or touch any metal objects with it.

Observe the course of the instrument cable and the double tube during the treat-

ment. The staff must not be impeded. They could fall and patients be injured by the

sudden movement from the fall.

18 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 19 Donnerstag, 16. April 2015 7:35 07

Operation

Starting treatment

Contaminated micro handpiece

Use of a contaminated micro handpiece may result in life-threatening infections in

both patients and users.

Only use a sterile micro handpiece.

Only use a sterile instrument cable.

Only use a sterile cover from undamaged packaging.

Only use a sterile double tubing from undamaged packaging.

Metal objects in the vicinity of the sonotrode

Contact of the sonotrode with metal objects can cause sparking. This may result in ex-

plosions and fires. The sonotrode can also be damaged, in turn leading to the possi-

bility of severe injury to patients.

Do not touch any metal objects with the sonotrode.

Do not use anaesthetic gas or oxygen in the immediate vicinity of the operating

field.

Do not use any explosive or flammable materials in the immediate vicinity of the

operating field.

Hot sonotrode

The sonotrode can heat up during the operation. Contact with the hot sonotrode can

damage tissue, even if the micro handpiece is not activated.

Do not touch tissue that is not to be operated on with the sonotrode.

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 19

out.fm Seite 20 Donnerstag, 16. April 2015 7:35 07

Operation

Starting treatment

Micro handpiece incorrectly set down

A micro handpiece that is not in use can be accidentally activated. If the micro hand-

piece is set down on a patient, this can result in severe injury to the patient due to ac-

cidental activation.

Always set an unused micro handpiece down on a utility table.

Never set the micro handpiece down on a patient when not in use.

Treatment without cover

The sonotrode can become hot during the treatment. The cover prevents direct con-

tact of the sonotrode edges with the surrounding tissue and directs the irrigation so-

lution to the sonotrode tip. If no cover is used, this can result in burning of the

surrounding tissue

Always use a cover.

Only touch the tissue with the sonotrode tip.

Never touch tissue with the sonotrode edge.

20 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 21 Donnerstag, 16. April 2015 7:35 07

Operation

Ending treatment

5.3 Ending treatment

After treatment the Micro handpiece must be disconnected from the ultrasonic gen-

erator and disassembled into its constituent parts. Disposable accessories must be

disposed of immediately.

The Micro handpiece and the instrument cable must then be reprocessed (see Chap-

ter ”Reprocessing” on page 23).

5.3.1 Disconnecting the micro handpiece from the ultrasonic generator

Requirements

The ultrasonic generator is switched off.

Procedure

1. Pull the cover off the nose cone and dispose of properly.

2. Disconnect the instrument cable from the micro handpiece.

To do this, only pull on the grip sleeve of the instrument cable.

3. Disconnect the instrument cable from the ultrasonic generator.

To do this, only pull on the grip sleeve of the instrument cable.

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 21

out.fm Seite 22 Donnerstag, 16. April 2015 7:35 07

Operation

Ending treatment

4. Disconnect the double tubing from the luer lock ports of the micro handpiece.

5. Disconnect the double tube from the ultrasonic generator and properly dispose

of it.

– The micro handpiece has been disconnected from the ultrasonic generator.

Do not allow any secretions or tissue residues to dry on the instrument. If the micro

handpiece cannot be disassembled and reprocessed immediately, place it in a closed

jar with cleaning and disinfectant solution. The jar protects the micro handpiece dur-

ing transport and prevents contamination of the environment.

You can completely immerse the micro handpiece in a cleaning or disinfectant solu-

tion. Do not use a physiological saline solution. Please observe the manufacturer's in-

formation regarding cleaning and disinfecting solution temperatures, contact times

and concentrations.

22 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 23 Donnerstag, 16. April 2015 7:35 07

Reprocessing

Disassembling the micro handpiece

6 Reprocessing

The Micro handpiece (handpiece body and mouthpiece) and the instrument cable

must be reprocessed after each treatment to prevent infections.

Reprocessing of the Micro handpiece and the instrument cable essentially consists of

three steps:

Cleaning

Disinfection

Sterilization

Only use disinfectants recommended by the Association for Applied Hygiene (VAH).

Also observe the guidelines of the Robert Koch Institute (RKI).

6.1 Disassembling the micro handpiece

Requirements

The micro handpiece has been disconnected from the ultrasonic generator.

Procedure

1. Unscrew the nose cone and remove from the sonotrode.

– The micro handpiece has now been disassembled into its two individual parts.

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 23

out.fm Seite 24 Donnerstag, 16. April 2015 7:35 07

Reprocessing

Manually pre-cleaning the micro handpiece

6.2 Manually pre-cleaning the micro handpiece

If the handpiece body, the nose cone or the instrument cable are heavily soiled, they

must be pre-cleaned manually.

The information in the table describes the reprocessing procedure recommended by

Söring for manual pre-cleaning. If you want to use other methods and parameters,

you can determine the material compatibility from the reprocessing procedure rec-

ommended by Söring.

Manual pre-cleaning Water type Temperature Process chemical Duration

In water bath Tap water Cold – > 1 minute

With brushes Tap water Cold Alkali > 2 minutes

With water jet Tap water Cold – 10 seconds

In ultrasonic bath Tap water Cold Alkali > 3 minutes

Requirements

The micro handpiece has now been disassembled into the handpiece body and

nose cone.

Procedure

1. Place the handpiece body, nose cone and instrument cable in a cold water bath

(see table).

If the water is too warm, residues can deposit on the individual parts.

2. Brush off visible dirt with a soft brush in the water bath with process chemicals

(see table).

3. Rinse out the nose cone with a water jet at a water pressure of 1.8 bar (26.11 psi)

(see table).

4. Clean the handpiece body, nose cone and instrument cable in the ultrasonic bath

with process chemical.

– The handpiece body and the nose cone of the micro handpiece and the instru-

ment cable are ready to be pre-cleaned manually and cleaned and disinfected

mechanically.

24 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 25 Donnerstag, 16. April 2015 7:35 07

Reprocessing

Automatically clean and disinfect the micro handpiece

6.3 Automatically clean and disinfect the micro handpiece

A washer-disinfector must be used for the cleaning and disinfection of the handpiece

body, the nose cone and the instrument cable.

The information in the table describes the reprocessing procedure validated by

Söring for the mechanical cleaning and disinfection. If you want to use another pro-

cess chemical, other methods or parameters, you can determine the material compat-

ibility from the reprocessing procedure validated by Söring.

For the validation, Neodisher Mediclean forte was used as the process chemical.

The reprocessing procedure recommended by Söring includes the following program

steps.

Program steps Water type Temperature Process chemical Duration

Pre-rinsing Tap water –

Cleaning Tap water 55 °C (131 °F) Alkali 10 minutes

Double neutralization Tap water –

Thermal disinfection VE water 93 °C (199.4 °F) – 5 minutes

Drying – > 90 °C (194 °F) – 40 minutes

Minimum requirement for the thermal disinfection: A0value > 3000.

Requirements

The handpiece body and the nose cone of the micro handpiece and the instru-

ment cable are ready to be cleaned and disinfected mechanically.

Procedure

1. Place the handpiece body and the connection cable in a suitable stainless steel

basket.

2. Load the stainless steel basket into the washer-disinfector.

Connect the luer lock ports on the micro handpiece to an irrigation device.

Make sure the lumens are clear and can be sufficiently flushed through.

3. Insert the nose cone on a flushing cannula of the washer-disinfector.

4. Clean and disinfect all individual parts in the washer-disinfector.

The cleaning and disinfection according to the reprocessing procedure validated

by Söring (see table) is recommended.

– The handpiece body and the nose cone of the micro handpiece and the instru-

ment cable have been automatically cleaned and disinfected.

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 25

out.fm Seite 26 Donnerstag, 16. April 2015 7:35 07

Reprocessing

Reassembling the micro handpiece

6.4 Reassembling the micro handpiece

Requirements

All individual parts of the micro handpiece and the instrument cable have been

automatically cleaned and disinfected and are dry.

Procedure

1. Perform a visual inspection to check that the handpiece body, the sonotrode and

the nose cone are not visibly damaged.

– The handpiece body, the sonotrode and the nose cone are in perfect condition.

2. Position the nose cone on the sonotrode and screw on tightly.

– The micro handpiece has now been reassembled.

26 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 27 Donnerstag, 16. April 2015 7:35 07

Reprocessing

Sterilizing the micro handpiece

6.5 Sterilizing the micro handpiece

A steam sterilizer and special packaging conforming to ISO 11607 must be used for

sterilizing the micro handpiece and the instrument cable.

The information in the table describes the reprocessing procedure validated by

Söring for the sterilization. For the validation, simple packaging was used. If you want

to use other methods and parameters, you can determine the material compatibility

from the reprocessing procedure validated by Söring.

Settings on the steam sterilizer Pressure Temperature Duration

Sterilization 3 bar (43.51 psi) 134 °C (273.2 °F) 3 minutes

Drying 10 minutes

Requirements

The micro handpiece and the instrument cable have been cleaned and disin-

fected.

The cleaned and disinfected micro handpiece has now been reassembled.

Procedure

1. Place the micro handpiece in packaging.

2. Place the instrument cable in different simple packaging.

3. Sterilize the packaged micro handpiece and the packaged instrument cable in a

steam sterilizer with a fractionated pre-vacuum.

4. Store the micro handpiece and the instrument cable in accordance with the in-

structions (see Chapter ”Transport and storage” on page 13).

– The micro handpiece and the instrument cable have now been sterilized and

can be used for treatment.

6.6

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 27

out.fm Seite 28 Donnerstag, 16. April 2015 7:35 07

Preventive maintenance

Faults

7 Preventive maintenance

The Micro handpiece undergoes natural wear due to thermal, chemical and mechani-

cal strain even if used according to its intended use and handled with care. This wear

has an effect on individual component service life. Regular maintenance of the Micro

handpiece lengthens the expected service life.

Maintenance of the Micro handpiece entails checking the condition of the Micro

handpiece and the extent of wear at regular intervals. A safety check must be per-

formed on the Micro handpiece once every 12 months.

You can remedy some faults occurring during use yourself. However, you must not

perform repairs yourself. You may only replace the mouthpiece yourself.

7.1 Faults

Use despite the presence of a fault

Use of the micro handpiece when a fault condition exists may lead to malfunction

and result in life-threatening injury to patients.

Immediately eliminate the cause of the fault.

Report any recurring faults to the manufacturer or an authorized distributor.

Fault Possible cause Remedy

A clanking noise can be heard The sonotrode is not firmly Send in the micro handpiece

when the micro handpiece is screwed to the ultrasonic for repair.

activated. transducer.

The micro handpiece is exces- Either the ultrasonic trans- Send in the micro handpiece

sively hot. ducer or the sonotrode is de- for repair.

fective.

The achieved tissue effect is The instrument cable is defec- Replace the instrument cable.

insufficient. tive.

Either the ultrasonic trans- Send in the micro handpiece

ducer or the sonotrode is de- for repair.

fective.

There is no irrigation solution. The roller clamp on the double Release the roller clamp on the

tubing is engaged. double tubing.

The irrigation bottle is empty. Use a new irrigation bottle.

The OK indicator light on the The instrument cable is defec- Replace the instrument cable.

ultrasonic generator is not lit. tive.

The ERROR indicator light on The micro handpiece is over- Wait for 10 seconds and acti-

the ultrasonic generator is lit. loaded or damaged. For safety vate the micro handpiece

The micro handpiece cannot purposes, the ultrasonic gen- again.

be activated. erator no longer outputs any If the fault persists, the micro

ultrasonic power. handpiece is defective and may

no longer be used.

28 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 29 Donnerstag, 16. April 2015 7:35 07

Preventive maintenance

Safety check

7.2 Safety check

A safety check must be performed on the Micro handpiece at least once every 12

months. The safety check may only be performed by competent individuals autho-

rized by the manufacturer using suitable measuring and testing devices. The type and

scope of the safety check are prescribed by the manufacturer. The procedure and re-

sults of this safety check must be recorded in a report.

7.3 Preventive maintenance

Regular maintenance of the Micro handpiece lengthens the expected service life. It is

recommended to perform preventive maintenance once every twelve months or

after 150 reprocessing cycles.

Preventive maintenance may only be performed by the manufacturer. Regular pre-

ventive maintenance preserves the leak-tightness of the handpiece body.

7.4 Repairs

Unauthorized repairs or modifications

Improper repairs, modifications and manipulations can lead to malfunctions and re-

sult in life-threatening injury to patients.

Only have repairs performed by the manufacturer or by qualified service person-

nel authorized or trained by the manufacturer.

Do not attempt to repair the micro handpiece yourself. You can only replace the nose

cone or a part of the nose cone yourself if it is visibly damaged or has been lost.

Please contact the manufacturer or an authorized distributor to order a new spare

part.

Spare part Article number

Titanium part of the nose cone including O-ring 612S0024

O-ring for the titanium part 510N0053

Plastic part of the nose cone including O-ring 612S0031

O-ring for the plastic part 510N0054

If you want to use a spare part, first mechanically clean and disinfect, then sterilize the

micro handpiece and the new spare part. After assembly, the micro handpiece must

be sterilized again.

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 29

out.fm Seite 30 Donnerstag, 16. April 2015 7:35 07

Preventive maintenance

Repairs

A defective micro handpiece can be sent to the manufacturer or an authorized dis-

tributor for inspection and repair. Also send the instrument cable along with the in-

strument if possible. Only send in a disinfected micro handpiece with certificate of

disinfection; otherwise additional costs will be incurred. Enclose a detailed error de-

scription that also notes the serial number of the micro handpiece.

If the micro handpiece is irreparable, please send it to the manufacturer, an autho-

rized distributor or a disposal company for proper disposal (see Chapter ”Disposal” on

page 31).

30 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 31 Donnerstag, 16. April 2015 7:35 07

Disposal

8 Disposal

As soon as the Micro handpiece or the instrument cable has reached the end of its

service life, it must be properly disposed of.

Contaminated Micro handpiece

An improperly disposed of contaminated Micro handpiece or instrument cable can

lead to life-threatening infections in people and damage to the environment.

Only a cleaned and disinfected Micro handpiece or instrument cable will be ac-

cepted for disposal.

Give the Micro handpiece or the instrument cable to a disposal company or send it to

the manufacturer or an authorized distributor.

8.1

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 31

out.fm Seite 32 Donnerstag, 16. April 2015 7:35 07

Technical data

9 Technical data

Micro handpiece

Materials: Titanium, plastic

Total length: 92-020: 222 mm

92-021: 285.5 mm

92-112: 296.5 mm

Working length: 92-020: 35 mm

92-021: 96.5 mm

92-112: 107.5 mm

Sonotrode tip diameter: 92-020: 2.0 mm

92-021: 2.0 mm

92-112: 2.3 mm

Irrigation: External

Aspiration: Interior

Weight: 92-020: 81 g

92-021: 82 g

92-112: 83 g

Working frequency: 35 kHz

Compatibility: SONOCA 300, SONOCA 400,

software version 4.53 and higher

Temperature: Operation: 10 °C to 40 °C (50 °F to 104 °F)

Transport and storage: –25 °C to 70 °C (–13 °F to 158 °F)

Relative humidity: Operation: 20 % to 80 %, non-condensing

Transport and storage: 10 % to 95 %, non-condensing

Air pressure: Operation: 700 hPa to 1060 hPa (10.15 psi to 15.37 psi)

Transport and storage: 500 hPa to 1060 hPa (7.25 psi to 15.37 psi)

Activation: Foot switch

Procedure time: During treatment:

Not more than 60 minutes in total

Classification: Type BF (in accordance with IEC 60601-1)

Class III (in accordance with the Medical Devices and Directive

93/42/EEC, Annex IX)

Annex I (German Ordinance on the Installation, Operation and

Use of Medical Products (MPBetreibV))

9.1

32 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 33 Donnerstag, 16. April 2015 7:35 07

Index

Index

A Double tubing 12

Accessories 11 connecting 15

improper 9

E

Activation 32 Electromagnetic compatibility 8

Ambient conditions 9, 32 Electromagnetic fields 8

Application, see Intended use End of service life, of the Micro handpiece 31

Article number 29

F

Assembly 26

Fail-safe operation 14

Association for Applied Hygiene (VAH) 23

Faults 28

At risk patients 7, 9 use despite 28

Autoclaving, see Sterilization Foot switch 12

C Functional testing, carrying out 17

Cavity, see Lumen H

Check Handling the Micro handpiece, conditions for 6

regular 29

safety 29 I

Classification 32 Instructions for use

for the Micro handpieces 5

Cleaning 24, 25

for the ultrasonic generator 5

Conditions, for handling the Micro handpiece 6

Instrument, see Micro handpiece

Connector socket 10

Instrument cable

Contamination, see Cleaning connecting 15

Cover 10, 12, 20 contaminated 8, 19

damaged 8

D disconnecting 21

Disassembly 23 Intended use 7

Disinfectants, recommended 23 L

Disinfection 25 Luer lock port 10

Disposal 31 Lumen 25

Disposal company 31

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 33

out.fm Seite 34 Donnerstag, 16. April 2015 7:35 07

Index

M Q

Magnetic fields 8 Qualification 7

Magnetic resonance tomograph 8

R

Micro handpiece Repair 29

assembling 26

automatic cleaning 25 Reprocessing 23

checking 29 prior to initial use 14

cleaning 24, 25 Reprocessing cycles 29

connecting 15

Robert Koch Institute (RKI) 23

contaminated 8, 19, 31

detaching 23 S

disassembling into individual parts 23

disconnecting 21 Safety check 29, see Safety check

disinfecting 25 Safety notice, see Warning

incorrectly set down 20

Scope of delivery 11

manually pre-cleaning 24

operating 14 Serial number 10

reassembling 26 Service life 28, 29

sterilizing 27

Signal word 5

Micro handpieces, overview of 10

Sonotrode 10, see Sonotrode, see Sonotrode

MRT 8 contaminated 8

hot 19

N

incorrectly fitted 28

Noise, clanking 28

Sonotrode tip 10

Nose cone 10, 29

Spare part 29

Numeric code, on the ultrasonic generator 28

Specialist staff, qualified 7

O Stainless steel basket 25, see Stainless steel basket,

O-ring 29 see Stainless steel basket

Operation 14 Steam sterilization, see Sterilization

Overview 10 Steam sterilizer 27

Sterilization 27

P

Packaging 13 Storage 13, see Storage

for sterilization 27

T

Pictogram Technical data 32

on the Micro handpiece 11

on the packaging 11 Transport 13

Power settings, checking 17 Treatment

benefits of 14

Pre-vacuum, fractionated 27 ending 21

Preventive maintenance 28, 29 preparing 15

risks of 14

Procedure time 32

starting 18

Purpose 7 tasks prior to 14, 15

Type designation 10

34 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 35 Donnerstag, 16. April 2015 7:35 07

Index

U V

Ultrasonic transducer 10, see Ultrasonic transducer, Visual inspection 15, 26

see Ultrasonic transducer, see Ultrasonic transdu-

cer W

Usage, see Intended use Warning 5

general 8

Use

intended 7 Washer-disinfector 25, see Washer-disinfector

of incorrect accessories 9 Wear 28

of the Micro handpiece 23

Working length 32

DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US | Micro handpieces 35

out.fm Seite 36 Donnerstag, 16. April 2015 7:35 07

Index

36 Micro handpieces | DocNr.: 03-2002_R02.01 | 16.04.2015 | en-US

out.fm Seite 37 Donnerstag, 16. April 2015 7:35 07

out.fm Seite 38 Donnerstag, 16. April 2015 7:35 07

Söring GmbH

Justus-von-Liebig-Ring 2

D-25451 Quickborn

Tel.: +49 (0)4106-6100-0

Fax: +49 (0)4106-6100-10 Content management

Email: info@soering.com ZINDEL AG

Internet: www.soering.com www.zindel.de

S-ar putea să vă placă și

- Models Statement PDocument3 paginiModels Statement PshakirÎncă nu există evaluări

- AspenAdvProcCtrlV12 0-InstDocument86 paginiAspenAdvProcCtrlV12 0-InstLaith HashimÎncă nu există evaluări

- Centrifugal CompressorDocument2 paginiCentrifugal CompressorAyman EsaÎncă nu există evaluări

- NTPC Project ReportDocument31 paginiNTPC Project ReportDeepak Ranjan ParidaÎncă nu există evaluări

- ZANDER Aufbereitungstechnik GMBHDocument393 paginiZANDER Aufbereitungstechnik GMBHdanenicÎncă nu există evaluări

- TeDocument67 paginiTeYudha Sanditya SaputraÎncă nu există evaluări

- Ic LabDocument19 paginiIc LabDanial Ali100% (1)

- Titanium FractionDocument9 paginiTitanium FractionAhmadÎncă nu există evaluări

- Piping Design - An Introduction For Non - Piping EngineersDocument5 paginiPiping Design - An Introduction For Non - Piping EngineersPRASANTH G KRISHNANÎncă nu există evaluări

- GST-250 PSI Vertical Storage Tanks: 1500 Gallons Through 20,000 GallonsDocument33 paginiGST-250 PSI Vertical Storage Tanks: 1500 Gallons Through 20,000 GallonsPham LanphuongÎncă nu există evaluări

- EDD Calibration TrimDocument23 paginiEDD Calibration TrimAnonymous cXjAZTÎncă nu există evaluări

- Asme Section I & Section Viii Fundamentals: Pdhonline Course M398 (3 PDH)Document59 paginiAsme Section I & Section Viii Fundamentals: Pdhonline Course M398 (3 PDH)vuchinhÎncă nu există evaluări

- 5HP PDFDocument76 pagini5HP PDFeduardomanuel3Încă nu există evaluări

- AutoclaveDocument5 paginiAutoclaveRahul KooraÎncă nu există evaluări

- Aspen Internet Process Manual2006 - 5-Usr PDFDocument18 paginiAspen Internet Process Manual2006 - 5-Usr PDFBabak Mirfendereski100% (1)

- SpiraxSarco B14 Condensate RecoveryDocument80 paginiSpiraxSarco B14 Condensate RecoveryGabriel BarbosaÎncă nu există evaluări

- Manual Del Usuario Pipe FlowDocument202 paginiManual Del Usuario Pipe FlowAlexis SalazarÎncă nu există evaluări

- Physical Quantity - DataDocument53 paginiPhysical Quantity - DataDeogratias LaurentÎncă nu există evaluări

- CH 5 Heat Exchanger Design MethodsDocument30 paginiCH 5 Heat Exchanger Design Methodsapi-3765936100% (1)

- GDN Service BrochureDocument8 paginiGDN Service BrochureAsim NajamÎncă nu există evaluări

- SterlingDocument11 paginiSterlingMohammed GomaaÎncă nu există evaluări

- HAZOP Study of A Fixed Bed Reactor For MTBE SyntheDocument8 paginiHAZOP Study of A Fixed Bed Reactor For MTBE SyntheVianka ArcheryÎncă nu există evaluări

- Simulationof Single Phase Full Bridge Converter Using PSPICEDocument10 paginiSimulationof Single Phase Full Bridge Converter Using PSPICEDhivya NÎncă nu există evaluări

- Chapter 5-Basic ThermodynamicDocument19 paginiChapter 5-Basic ThermodynamicjaechaosÎncă nu există evaluări

- 2VAA001693 en S Control NTDI01 Digital IO Termination UnitDocument35 pagini2VAA001693 en S Control NTDI01 Digital IO Termination Unitanbarasan0% (1)

- PHE Control Mechanism PDFDocument6 paginiPHE Control Mechanism PDFNaren VmdÎncă nu există evaluări

- Process Engineering Course by IfluidsDocument81 paginiProcess Engineering Course by IfluidsirfichemÎncă nu există evaluări

- Computer Aided Chemical Process Design: The Flowtran SystemDocument11 paginiComputer Aided Chemical Process Design: The Flowtran SystemMarcelo PerettiÎncă nu există evaluări

- Chemical Reactor Types: 1. Fundamental Types of Chemical Reactors 2. PFR Types and ConfigurationsDocument2 paginiChemical Reactor Types: 1. Fundamental Types of Chemical Reactors 2. PFR Types and ConfigurationsWancianSiaÎncă nu există evaluări

- Budinis S 2016 PHD Thesis PDFDocument372 paginiBudinis S 2016 PHD Thesis PDFw_sallumÎncă nu există evaluări

- DryingDocument54 paginiDryingShanthana LoshiniÎncă nu există evaluări

- v1.0 Rishabh Engineering CS 37 Piping Stress Analysis Horizontal HeaterDocument4 paginiv1.0 Rishabh Engineering CS 37 Piping Stress Analysis Horizontal HeaterJasonChong212Încă nu există evaluări

- Thermocompressors Preventative MaintenanceDocument4 paginiThermocompressors Preventative MaintenancealicardozoÎncă nu există evaluări

- R715-Refrigeration Laboratory UnitDocument3 paginiR715-Refrigeration Laboratory UnitSaud barqÎncă nu există evaluări

- Thermocompressors: Engineered For EfficiencyDocument4 paginiThermocompressors: Engineered For EfficiencyAmir AbbaszadehÎncă nu există evaluări

- Engineering Materials: Polymers, Ceramics and CompositesDocument11 paginiEngineering Materials: Polymers, Ceramics and Compositesvishalbhojak vishalbhojakÎncă nu există evaluări

- EEE231-E-I Lab ManualDocument120 paginiEEE231-E-I Lab ManualM Hamza TabassumÎncă nu există evaluări

- Thermocompressor PDFDocument4 paginiThermocompressor PDFYogesh GhanekarÎncă nu există evaluări

- A Brief CV of Aftab Ahmed MazariDocument6 paginiA Brief CV of Aftab Ahmed MazariAftab Ahmed Mazari100% (2)

- Penlon Prima 450 Anesthesia SystemDocument4 paginiPenlon Prima 450 Anesthesia SystemJoharÎncă nu există evaluări

- Experimental Process Technology Textbook Version 6Document116 paginiExperimental Process Technology Textbook Version 6Sara AlrubaiiÎncă nu există evaluări

- Acetic AnhydrideDocument5 paginiAcetic AnhydrideChern YuanÎncă nu există evaluări

- Tables of Piping Standards - PittsburghDocument166 paginiTables of Piping Standards - PittsburghzhangamecÎncă nu există evaluări

- Double Suction Centrifugal PumpDocument8 paginiDouble Suction Centrifugal PumpBilal WaseemÎncă nu există evaluări

- Best Practices For Steam Control Valve InstallationDocument4 paginiBest Practices For Steam Control Valve InstallationBen MusimaneÎncă nu există evaluări

- Automatic Control The Hidden TechnologyDocument13 paginiAutomatic Control The Hidden Technologye-barbas6378Încă nu există evaluări

- Im32q01c10 31eDocument362 paginiIm32q01c10 31eFarrukh MajeedÎncă nu există evaluări

- Basic Mechanical EngineeringDocument46 paginiBasic Mechanical EngineeringNguyễn Khánh Tùng100% (1)

- 1 CDB 4014 - Plant Design Project IDocument3 pagini1 CDB 4014 - Plant Design Project Iharvin95Încă nu există evaluări

- EHB en File 6.4.4-Back-PressureDocument3 paginiEHB en File 6.4.4-Back-PressureXpizmonÎncă nu există evaluări

- Chapter 3 SQCDocument22 paginiChapter 3 SQCShishir GyawaliÎncă nu există evaluări

- Temperature Control of Exothermic ReactionDocument8 paginiTemperature Control of Exothermic ReactionAhmad MuzammilÎncă nu există evaluări

- Unit Operation Laboratory ProtocolDocument73 paginiUnit Operation Laboratory ProtocolSreemoyee ChakrabortyÎncă nu există evaluări

- Error Function Table PDFDocument1 paginăError Function Table PDFPoulami Saanjhbati DasguptaÎncă nu există evaluări

- UserManual - UVx - 30258694 - D - En-1Document40 paginiUserManual - UVx - 30258694 - D - En-1andridert99Încă nu există evaluări

- 89228001EN Manual NIRS DS2500 AnalyzerDocument47 pagini89228001EN Manual NIRS DS2500 AnalyzerJordan DechevÎncă nu există evaluări

- Nirs Xds Smartprobe Analyzer: ManualDocument50 paginiNirs Xds Smartprobe Analyzer: ManualJonatan Dominguez PerezÎncă nu există evaluări

- Centrifuga-Thermo Scientific Heraeus Megafuge 16 - UserDocument52 paginiCentrifuga-Thermo Scientific Heraeus Megafuge 16 - UserPlaton JuanÎncă nu există evaluări

- Titan 3 Manual XDocument53 paginiTitan 3 Manual XfnsfashionltdÎncă nu există evaluări

- Sirosonic LDocument100 paginiSirosonic LAnonymous D8ay3BMJ5Încă nu există evaluări

- Line Sizing PresentationDocument26 paginiLine Sizing Presentationtagne simo rodrigueÎncă nu există evaluări

- Linear Algebra NotesDocument113 paginiLinear Algebra NotesMirza BasitÎncă nu există evaluări

- Part - 2 MAWP CalcuationDocument15 paginiPart - 2 MAWP CalcuationAbdul KharisÎncă nu există evaluări

- Dinesh Subramanian CV 190606Document8 paginiDinesh Subramanian CV 190606Dinesh KumarÎncă nu există evaluări

- Reliability by DesignDocument11 paginiReliability by DesignDinesh KumarÎncă nu există evaluări

- Ccreportexamplesai PDFDocument2 paginiCcreportexamplesai PDFDinesh KumarÎncă nu există evaluări

- Stavanger FlightDocument1 paginăStavanger FlightDinesh KumarÎncă nu există evaluări

- Methodology For Slug Catcher Sizing: MethodlogyDocument3 paginiMethodology For Slug Catcher Sizing: MethodlogyDinesh KumarÎncă nu există evaluări

- Naked Trading PlanDocument30 paginiNaked Trading PlanSrinivasan Rmasamy94% (31)

- Application Form 1164793051Document4 paginiApplication Form 1164793051Dinesh KumarÎncă nu există evaluări

- Dinesh ResumeDocument2 paginiDinesh ResumeDinesh KumarÎncă nu există evaluări

- Theory of Accounts On Business CombinationDocument2 paginiTheory of Accounts On Business CombinationheyÎncă nu există evaluări

- Sample UploadDocument14 paginiSample Uploadparsley_ly100% (6)

- Case Analysis of Vishal Jeet V. Union of India Trafficking of Women and ChildrenDocument7 paginiCase Analysis of Vishal Jeet V. Union of India Trafficking of Women and ChildrenTrishani NahaÎncă nu există evaluări

- Hedayati2014 Article BirdStrikeAnalysisOnATypicalHeDocument12 paginiHedayati2014 Article BirdStrikeAnalysisOnATypicalHeSharan KharthikÎncă nu există evaluări

- Apport D Un Fonds de Commerce en SocieteDocument28 paginiApport D Un Fonds de Commerce en SocieteJezebethÎncă nu există evaluări

- Human Evolution SE Skull Analysis GizmoDocument9 paginiHuman Evolution SE Skull Analysis GizmoTamia WashingtonÎncă nu există evaluări

- All Vaccinees Are Requested To Bring Certificate of Dose-II From COWIN Portal Alongwith Registered Mobile Number Before Proceeding For VaccinationDocument7 paginiAll Vaccinees Are Requested To Bring Certificate of Dose-II From COWIN Portal Alongwith Registered Mobile Number Before Proceeding For VaccinationRakesh KumarÎncă nu există evaluări

- Peseshet - The First Female Physician - (International Journal of Gynecology & Obstetrics, Vol. 32, Issue 3) (1990)Document1 paginăPeseshet - The First Female Physician - (International Journal of Gynecology & Obstetrics, Vol. 32, Issue 3) (1990)Kelly DIOGOÎncă nu există evaluări

- Web Script Ems Core 4 Hernandez - Gene Roy - 07!22!2020Document30 paginiWeb Script Ems Core 4 Hernandez - Gene Roy - 07!22!2020gene roy hernandezÎncă nu există evaluări

- Wax Depilation ManualDocument17 paginiWax Depilation ManualAmit Sharma100% (1)

- PCB Engraver Operator Manual PDFDocument41 paginiPCB Engraver Operator Manual PDFmyoshkeuÎncă nu există evaluări

- RA ELECTRONICSTECH CEBU Apr2019 PDFDocument12 paginiRA ELECTRONICSTECH CEBU Apr2019 PDFPhilBoardResultsÎncă nu există evaluări

- CHAPTER 3 Formwork Part 1Document39 paginiCHAPTER 3 Formwork Part 1nasÎncă nu există evaluări

- Raffles Hotel Jakarta Pricelist 2020Document2 paginiRaffles Hotel Jakarta Pricelist 2020kielachela aaÎncă nu există evaluări

- Akin To PityDocument356 paginiAkin To PityPaul StewartÎncă nu există evaluări

- Plumber (General) - II R1 07jan2016 PDFDocument18 paginiPlumber (General) - II R1 07jan2016 PDFykchandanÎncă nu există evaluări

- MODEL 1332 MODEL 1432: Slide LengthDocument8 paginiMODEL 1332 MODEL 1432: Slide LengthFabian FragosoÎncă nu există evaluări

- EC Type-Examination Certificate: Reg.-No.: 01/205/5192.02/18Document11 paginiEC Type-Examination Certificate: Reg.-No.: 01/205/5192.02/18Orlando Ortiz VillegasÎncă nu există evaluări

- HIPULSE U 80kVA 500kVA-Manual - V1.1Document157 paginiHIPULSE U 80kVA 500kVA-Manual - V1.1joseph mendezÎncă nu există evaluări

- B028-Sayli Kapse B029-Surya Teja B030-Taranum Kaur B032-Yashesh Kothari B034-Sathish Kumar B035-ManeeshDocument24 paginiB028-Sayli Kapse B029-Surya Teja B030-Taranum Kaur B032-Yashesh Kothari B034-Sathish Kumar B035-ManeeshTaranum RandhawaÎncă nu există evaluări

- Guia Laboratorio Refrigeración-2020Document84 paginiGuia Laboratorio Refrigeración-2020soniaÎncă nu există evaluări

- User'S Guide: 5. SpecificationsDocument8 paginiUser'S Guide: 5. SpecificationsNguyễn Xuân VĩÎncă nu există evaluări

- Complete Denture TechniquesDocument6 paginiComplete Denture TechniquesJohn Hyunuk ChoÎncă nu există evaluări

- Learners ' Health and Safety Practices and Their Academic PerformanceDocument10 paginiLearners ' Health and Safety Practices and Their Academic PerformanceHira SaddozaiÎncă nu există evaluări

- Mapagbigay PT1 Group1Document4 paginiMapagbigay PT1 Group1Hazel SarmientoÎncă nu există evaluări

- Service Manual - DM0412SDocument11 paginiService Manual - DM0412SStefan Jovanovic100% (1)

- Public Health Interventions: Applications For Public Health Nursing PracticeDocument249 paginiPublic Health Interventions: Applications For Public Health Nursing PracticeJemimah AdaclogÎncă nu există evaluări

- Narrative Pathophysiology of PregnancyDocument2 paginiNarrative Pathophysiology of PregnancyMarvin ChulyaoÎncă nu există evaluări

- Ens TecDocument28 paginiEns TecBorja CanalsÎncă nu există evaluări

- Stepanenko DermatologyDocument556 paginiStepanenko DermatologySanskar DeyÎncă nu există evaluări