Documente Academic

Documente Profesional

Documente Cultură

Mems Lecture Plan

Încărcat de

Mahesh Kumar K B0 evaluări0% au considerat acest document util (0 voturi)

49 vizualizări2 paginicv

Drepturi de autor

© © All Rights Reserved

Formate disponibile

XLSX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentcv

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLSX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

49 vizualizări2 paginiMems Lecture Plan

Încărcat de

Mahesh Kumar K Bcv

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLSX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

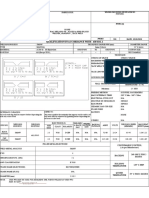

Lecture Plan - MEMS

Sl. Date &

Hr. Topics to be Covered

No Day

Module 1-- MEMS and Microsystems: MEMS as a micro

sensor,acutator, components of micro system, Intelligent mcro

system

1 Comparson between micro system and micro electronics.

Applications –Health care industry,aerospace industry, industral

products consumer products and tele communication.

Multidisciplinary nature of MEMS

Principles and examples of Micro sensors and micro actuators:

acoustic wave sensor, biomedical sensor, chemical sensors, optical

2 sensors, pressure sensors, thermal sensor, actuation using thermal

forces, shape memory alloys, piezo electric crystals and

electrostatic forces

3 Micro accelerometer –comb drives - Micro grippers –micro motors

4 Micro valves, micro pumps

Review of Mechanical concepts: Stress, Strain, Modulus of

5

Elasticity, yield strength, ultimate strength

6 General stress strain relations – compliance matrix.

7 Overview of commonly used mechanical structures in MEMS

- Beams, Cantilevers, Plates

8 Mechanical structures in MEMS - Beams, Cantilevers,

Plates,Diaphragms – Typical applications

Module 2-- Flexural beams: Types of Beams, longitudinal

9

strain under pure bending

10 Deflection of beams

11 Spring constant of cantilever –Intrinsic stresses

12 Actuation and Sensing techniques : Thermal sensors and actuators

13 Electrostatic sensors and actuators

14 Piezoelectric sensors and actuators

15 magnetic actuators

Module 3-- Scaling laws in miniaturization - scaling in geometry,

16

scaling in rigid body dynamics

17 Trimmer force scaling vector

18 scaling in electrostatic and electromagnetic forces

19 scaling in electricity and fluidic dynamics

20 scaling in heat conducting and heat convection.

21 Module 4--Materials for MEMS – Silicon

22 Silicon compounds – Silicon Nitride

23 Silicon Dioxide, Silicon carbide, Poly Silicon

24 GaAs , Silicon Piezo resistors

25 Polymers in MEMS – SU-8, PMMA, PDMS

26 Langmuir –Blodgett Films, Micro System fabrication

27 Photolithography – Ion implantation

28 Diffusion – Oxidation

29 Chemicalvapour deposition – Etching

30 Module 5--Overview of Micro manufacturing

Bulk micro manufacturing: overview of etching, isotopic and

31

ansotropic etching, wet etchants, etch stop, dry etchng

32 Surface micro machining: process, mechanical problems

33 LIGA process: process, materials, SLIGA process

34 Microstereo lithography

35 Microstereo lithography

36 Micro system Packaging

37 General considerations in packaging design

38 Levels of Micro system packaging: die level, device level, system level.

Module 6--Bonding techniques for MEMS : Surface bonding ,

39

Anodic bonding

40 Silicon - on - Insulator , wire bonding , Sealing

41 Assembly of micro systems

42 Overview of MEMS areas : RF MEMS, BioMEMS

43 MOEMS, NEMS

S-ar putea să vă placă și

- ECS&KTUDocument2 paginiECS&KTUVishnu Prasad MÎncă nu există evaluări

- Ec465 MemsDocument2 paginiEc465 MemsAnupriya T MÎncă nu există evaluări

- MemsDocument3 paginiMemssteve johnsÎncă nu există evaluări

- MEMSDocument1 paginăMEMSp.arunagiriÎncă nu există evaluări

- MEMS5Document35 paginiMEMS5sabitha sÎncă nu există evaluări

- MEMSDocument1 paginăMEMSAvinash VikramÎncă nu există evaluări

- For Questions, Notes, Syllabus & Results: Vl5091 Mems and NemsDocument1 paginăFor Questions, Notes, Syllabus & Results: Vl5091 Mems and Nemslakshmi sakthivelÎncă nu există evaluări

- MsmeDocument3 paginiMsmeJigneshkumar PatelÎncă nu există evaluări

- NUSRI-ME4200 (NUS-ME3281) - Module DescriptionDocument4 paginiNUSRI-ME4200 (NUS-ME3281) - Module DescriptionJiaÎncă nu există evaluări

- Slide Vi Cơ Đã G PDocument187 paginiSlide Vi Cơ Đã G PĐình Chiến PhạmÎncă nu există evaluări

- Vl5091-Mems and NemsDocument2 paginiVl5091-Mems and NemsPALANIVEL RAJAN0% (1)

- EC8001 SyllabusDocument1 paginăEC8001 SyllabusSarika AyyathuraiÎncă nu există evaluări

- Prepared By: Kiran WaliaDocument28 paginiPrepared By: Kiran WaliaAdityaÎncă nu există evaluări

- VL9266 MemsDocument1 paginăVL9266 MemskamarajvlsiÎncă nu există evaluări

- IV I Mech Mems (Open Elective-R13)Document2 paginiIV I Mech Mems (Open Elective-R13)Aboobakker SidhiqueÎncă nu există evaluări

- Working Principles of MicrosystemsDocument1 paginăWorking Principles of MicrosystemsAnkush KambleÎncă nu există evaluări

- MEMS Design Chap 1 - OVERVIEWDocument24 paginiMEMS Design Chap 1 - OVERVIEWvuonglupÎncă nu există evaluări

- Microelectromechanical Systems (MEMS) : AbstractDocument6 paginiMicroelectromechanical Systems (MEMS) : AbstractARVINDÎncă nu există evaluări

- SEM VII Syllabus B.E. 1Document1 paginăSEM VII Syllabus B.E. 1Nishikant KulkarniÎncă nu există evaluări

- MEMS Sensors PaperDocument5 paginiMEMS Sensors PaperM.Aimal KhiamÎncă nu există evaluări

- Working Principles of MicrosystemsDocument2 paginiWorking Principles of MicrosystemsAnkush KambleÎncă nu există evaluări

- MEMS & BIO-MEMS - Ch1Document70 paginiMEMS & BIO-MEMS - Ch1Adnan Ahmed100% (1)

- Mems QB 2016Document8 paginiMems QB 2016Manoj Kumar PasupathiÎncă nu există evaluări

- Mems and NemsDocument25 paginiMems and Nemsprasanthmct100% (5)

- 1.-Introduction To Microsystem Fabrication and IntegrationDocument44 pagini1.-Introduction To Microsystem Fabrication and IntegrationAlexander Martínez PasekÎncă nu există evaluări

- Che384t Jykim Mems v2 SubmitDocument24 paginiChe384t Jykim Mems v2 SubmitBhuvnesh BhambooÎncă nu există evaluări

- Lecture 1: MEMS Motivation: Prasanna S. Gandhi Assistant ProfessorDocument36 paginiLecture 1: MEMS Motivation: Prasanna S. Gandhi Assistant ProfessorAditya Narayan SahooÎncă nu există evaluări

- RAMDEOBABA Nagpur-79-80Document2 paginiRAMDEOBABA Nagpur-79-80muraliÎncă nu există evaluări

- An Introduction To MEMS Micro-Electromechanical Systems - MEMS IntroDocument55 paginiAn Introduction To MEMS Micro-Electromechanical Systems - MEMS Introyoucefblc99Încă nu există evaluări

- Mems SyllabusDocument2 paginiMems SyllabusSony RamaÎncă nu există evaluări

- Mechatronics Module 2-MemsDocument26 paginiMechatronics Module 2-MemsRahul DasÎncă nu există evaluări

- SYLLABUSDocument2 paginiSYLLABUSDr-Asit Kumar ParidaÎncă nu există evaluări

- MICRO ELECTRO MECHANICAL SYSTEM (MEMS) OverviewDocument6 paginiMICRO ELECTRO MECHANICAL SYSTEM (MEMS) OverviewvigneshgeminiÎncă nu există evaluări

- Mems in AutomtivesDocument16 paginiMems in AutomtivesVikas BohraÎncă nu există evaluări

- Applications of Mems in Robotics Using Psoc 5Document5 paginiApplications of Mems in Robotics Using Psoc 5Sathisha BMÎncă nu există evaluări

- BPUTSYLLABUSDocument2 paginiBPUTSYLLABUSshreetam beheraÎncă nu există evaluări

- Ice 4010: Micro Electro Mechanical Systems (Mems) : Lecture #02 History & Characteristics of MEMSDocument10 paginiIce 4010: Micro Electro Mechanical Systems (Mems) : Lecture #02 History & Characteristics of MEMSNAVEEN KUMAR S NÎncă nu există evaluări

- MEMS Accelerometers-KoncnaDocument17 paginiMEMS Accelerometers-KoncnaaryakushalÎncă nu există evaluări

- Recent Trends and Advancements in The Field of Micro Electrical and Mechanical Systems (Mems) TechnologyDocument10 paginiRecent Trends and Advancements in The Field of Micro Electrical and Mechanical Systems (Mems) TechnologyTJPRC PublicationsÎncă nu există evaluări

- Presented By: Nitish Ghosal Amit RaiDocument25 paginiPresented By: Nitish Ghosal Amit RainitishghosalÎncă nu există evaluări

- 15ME745 Smart Materials Module 4Document29 pagini15ME745 Smart Materials Module 4Yogananda Bangalore ShanthamurthyÎncă nu există evaluări

- MEMSDocument51 paginiMEMSHarshal YeoleÎncă nu există evaluări

- Chapter 1Document11 paginiChapter 1Senthilkumaar JSÎncă nu există evaluări

- MEMS Silicon-Based Microelectronics + Micromachining TechnologyDocument36 paginiMEMS Silicon-Based Microelectronics + Micromachining TechnologyJerry boyÎncă nu există evaluări

- Micro-Electro-Mechanical Systems: Presented by Rajan KumarDocument13 paginiMicro-Electro-Mechanical Systems: Presented by Rajan Kumarrajan2258Încă nu există evaluări

- Mems 1 Ktunotes - inDocument36 paginiMems 1 Ktunotes - inAlfin TomÎncă nu există evaluări

- Bio Mems Persentation by Prachi Gadge From VNIT (NIT) NagpurDocument24 paginiBio Mems Persentation by Prachi Gadge From VNIT (NIT) NagpurvnitstudentÎncă nu există evaluări

- 제02주차 Chapter01 미소전기기계시스템 (MEMS) 의 소개Document3 pagini제02주차 Chapter01 미소전기기계시스템 (MEMS) 의 소개K SiriusÎncă nu există evaluări

- Minal Zia (Project Work # 5)Document27 paginiMinal Zia (Project Work # 5)k shahÎncă nu există evaluări

- Review of MEMS Technology & Its Applications in Various FieldsDocument5 paginiReview of MEMS Technology & Its Applications in Various FieldsAnonymous kw8Yrp0R5rÎncă nu există evaluări

- MemsDocument16 paginiMemsDhanya Geethanjali SasidharanÎncă nu există evaluări

- 제1장 - 2 - MEMS 기초Document45 pagini제1장 - 2 - MEMS 기초2554759Încă nu există evaluări

- M. Sahith Chandan Roll. No: 05P71A0438 B.TECH 4/4 E.C.E Ph. No: 9985066696Document27 paginiM. Sahith Chandan Roll. No: 05P71A0438 B.TECH 4/4 E.C.E Ph. No: 9985066696D S RaoÎncă nu există evaluări

- MEMS TechnologyDocument22 paginiMEMS Technologyavishekghosh1985Încă nu există evaluări

- Mems NotesDocument104 paginiMems NotesPRATHAMESH KUMBHARÎncă nu există evaluări

- Bee026 MemsDocument49 paginiBee026 MemsRaviÎncă nu există evaluări

- Mems TPP PaperDocument5 paginiMems TPP PaperPreeti SheteÎncă nu există evaluări

- About Mems:: What Is MEMS Technology?Document14 paginiAbout Mems:: What Is MEMS Technology?ashabiaÎncă nu există evaluări

- Thyrocare Report 09 Oct 2019Document11 paginiThyrocare Report 09 Oct 2019Mahesh Kumar K B100% (4)

- AdvantagesDocument50 paginiAdvantagesMahesh Kumar K BÎncă nu există evaluări

- Initial Stability of Semi-Submersible Vessel During Floating Onload Without CargoDocument5 paginiInitial Stability of Semi-Submersible Vessel During Floating Onload Without CargoMahesh Kumar K BÎncă nu există evaluări

- Delftship ManualDocument110 paginiDelftship ManualMahesh Kumar K BÎncă nu există evaluări

- ICICI Amazon Nov 19Document3 paginiICICI Amazon Nov 19Mahesh Kumar K BÎncă nu există evaluări

- Updated 06-2019Document5 paginiUpdated 06-2019Mahesh Kumar K BÎncă nu există evaluări

- 09 Jan 20sample Welding Procedure by VishnuDocument1 pagină09 Jan 20sample Welding Procedure by VishnuMahesh Kumar K BÎncă nu există evaluări

- Offshore Platform DesignDocument43 paginiOffshore Platform Designsmvenkateswaran95% (20)

- Acfm and FMDDocument6 paginiAcfm and FMDMahesh Kumar K BÎncă nu există evaluări

- Determination of Reserve Strength Ratio For Offshore JacketsDocument3 paginiDetermination of Reserve Strength Ratio For Offshore Jacketsabhinavka123100% (1)

- Acfm and FMDDocument6 paginiAcfm and FMDMahesh Kumar K BÎncă nu există evaluări

- June 14, 2019 July 3, 2019: Credit Card StatementDocument4 paginiJune 14, 2019 July 3, 2019: Credit Card StatementMahesh Kumar K BÎncă nu există evaluări

- Medical CertificateDocument5 paginiMedical CertificateMahesh Kumar K BÎncă nu există evaluări

- Naval Architecture Syllabus PDFDocument8 paginiNaval Architecture Syllabus PDFMahesh Kumar K BÎncă nu există evaluări

- Are You Thereaa PDFDocument4 paginiAre You Thereaa PDFMahesh Kumar K BÎncă nu există evaluări

- Conditional FFU ClauseDocument1 paginăConditional FFU ClauseMahesh Kumar K BÎncă nu există evaluări

- THDocument3 paginiTHMahesh Kumar K BÎncă nu există evaluări

- Its Not That PDFDocument4 paginiIts Not That PDFMahesh Kumar K BÎncă nu există evaluări

- Are You Thereaa PDFDocument4 paginiAre You Thereaa PDFMahesh Kumar K BÎncă nu există evaluări

- Towing Plan-BES PioneerDocument1 paginăTowing Plan-BES PioneerMahesh Kumar K BÎncă nu există evaluări

- ONGC Format Mahesh Kumar K BDocument4 paginiONGC Format Mahesh Kumar K BMahesh Kumar K BÎncă nu există evaluări

- Naval Architecture SyllabusDocument8 paginiNaval Architecture SyllabusMahesh Kumar K BÎncă nu există evaluări

- Syllabus For S1 and S2 KTUmodified15.06.2016Document70 paginiSyllabus For S1 and S2 KTUmodified15.06.2016Mahesh Kumar K BÎncă nu există evaluări

- Degree AICTE ValidationDocument1 paginăDegree AICTE ValidationMahesh Kumar K BÎncă nu există evaluări

- Surveying Model QuestionDocument2 paginiSurveying Model QuestionMahesh Kumar K BÎncă nu există evaluări

- Wre Model Question PaperDocument1 paginăWre Model Question PaperMahesh Kumar K BÎncă nu există evaluări

- Types of Basic Mechanical and Non Mechanical Marine PropulsionDocument19 paginiTypes of Basic Mechanical and Non Mechanical Marine PropulsionMahesh Kumar K BÎncă nu există evaluări

- DDMCA Detailed Syllabii 3yearsDocument49 paginiDDMCA Detailed Syllabii 3yearsMahesh Kumar K BÎncă nu există evaluări

- Simpsons Rule NotesDocument3 paginiSimpsons Rule NotesSherwin Bonsol Arevalo100% (1)

- The Seven Keys To Effective Order Picking System DesignDocument3 paginiThe Seven Keys To Effective Order Picking System DesignpedrocaballeropedroÎncă nu există evaluări

- Deterioration of Concrete ImportantDocument32 paginiDeterioration of Concrete ImportantcuibaprauÎncă nu există evaluări

- Nitomortar TC2000 PDFDocument3 paginiNitomortar TC2000 PDFtalatzahoor100% (2)

- SS304 304L Data SheetDocument2 paginiSS304 304L Data SheetPrakash KumarÎncă nu există evaluări

- Staircase & Ramps Duration (DAYS) Appendix StaircaseDocument7 paginiStaircase & Ramps Duration (DAYS) Appendix StaircaseLai ChungyiÎncă nu există evaluări

- Structural Steel Sub-Grades JR, J0 and J2 Does It MatterDocument1 paginăStructural Steel Sub-Grades JR, J0 and J2 Does It MatterJafarÎncă nu există evaluări

- PolymersDocument44 paginiPolymersGail Rocx100% (1)

- Waterborne Paints DescriptionDocument3 paginiWaterborne Paints DescriptionChrysler Kane DepnagÎncă nu există evaluări

- Column Interaction DiagramDocument4 paginiColumn Interaction DiagramMario100% (1)

- Marshall TestDocument5 paginiMarshall TestZick Zickry50% (2)

- Background On Flexible Manufacturing SystemDocument4 paginiBackground On Flexible Manufacturing SystemRahapradÎncă nu există evaluări

- Standard Color CatalogueDocument4 paginiStandard Color CatalogueAnonymous SDeSP1Încă nu există evaluări

- Contect Prrson Remarks List of Industres (Other Than Pipe Mill) Working in Kutch AreaDocument3 paginiContect Prrson Remarks List of Industres (Other Than Pipe Mill) Working in Kutch AreaSrinivasan RajuÎncă nu există evaluări

- F3Document132 paginiF3Catalin OajdeaÎncă nu există evaluări

- Shear Capacities BrochureDocument16 paginiShear Capacities BrochureHugo RodriguezÎncă nu există evaluări

- 7 Tool Steels1Document12 pagini7 Tool Steels1ontc0109Încă nu există evaluări

- Material HandlingDocument15 paginiMaterial HandlingusamaÎncă nu există evaluări

- Me6403 Emm PDFDocument116 paginiMe6403 Emm PDFRAMESHKUMAR.S MCE-LECT/MECHÎncă nu există evaluări

- Renderoc HB40 NewDocument5 paginiRenderoc HB40 NewJayvee G. DignosÎncă nu există evaluări

- BT Hand Pallet Truck Product and Service Brochure PDFDocument8 paginiBT Hand Pallet Truck Product and Service Brochure PDFtintucinbÎncă nu există evaluări

- Flexible Manufacturing SystemDocument18 paginiFlexible Manufacturing SystemTp 10Încă nu există evaluări

- Fusealloy Fabrication Guidelines 2016Document25 paginiFusealloy Fabrication Guidelines 2016Vitor Rigueira de GodoyÎncă nu există evaluări

- Plastics: A Friend or Enemy of The EnvironmentDocument8 paginiPlastics: A Friend or Enemy of The EnvironmentRajarshi MitraÎncă nu există evaluări

- Data BuildingsDocument163 paginiData Buildingspabba shankarÎncă nu există evaluări

- Plastics in Automotive Engineering: Technical Solutions and TrendsDocument2 paginiPlastics in Automotive Engineering: Technical Solutions and TrendsMoHaN RaMaNaÎncă nu există evaluări

- Om-Chapter 3Document29 paginiOm-Chapter 3wubeÎncă nu există evaluări

- Basic Repair Kit 2010 JanDocument32 paginiBasic Repair Kit 2010 JanJhonathan CamposÎncă nu există evaluări

- ECE 693-001: Foundations of MEMS Technology: Rpandey@bama - Ua.eduDocument2 paginiECE 693-001: Foundations of MEMS Technology: Rpandey@bama - Ua.eduMukesh ParmarÎncă nu există evaluări

- Predavanje 4a-1 - Strain GaugesDocument3 paginiPredavanje 4a-1 - Strain Gaugesmis38Încă nu există evaluări

- Special Reinforced Concrete Shear Wall Design Based On ACI 318-05 / IBC 06Document2 paginiSpecial Reinforced Concrete Shear Wall Design Based On ACI 318-05 / IBC 06Muhammad Sajid0% (1)