Documente Academic

Documente Profesional

Documente Cultură

2B) Inlet Air Shut-Off Valve

Încărcat de

Mohamed HamedDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2B) Inlet Air Shut-Off Valve

Încărcat de

Mohamed HamedDrepturi de autor:

Formate disponibile

INLET SYSTEM

INLET AIR SHUT-OFF VALVE

DESCRIPTION

The inlet air shut-off valve uses a rotating ‘butterfly’ type valve to provide intake air shut-off and

employs a free-flow design which provides very low pressure drop, to avoid any loss in engine

shaft horsepower.

The valve actuator is pressurized to open the valve. Loss of air pressure causes the valve to

close via spring action. It is suitable for remote resetting or inclusion in automatic starting

sequences from pneumatic control systems. It also acts as a safety device to prevent engine

operation in the event of a broken pressure line or leaking connection.

Pneumatic Actuator

Minimum Actuation Pressure = 310 kPa (45 psi)

Recommended Actuation Pressure = 414 – 525

kPa (60 – 80 psi)

Maximum Actuation Pressure = 690 kPa (100

psi)

Butterfly Valve (Closed position)

Safety Control Operator

Adjustable Trip Pressure = 34 - 275 kPa (45 psi)

Maximum Pressure on Diaphragm = 1170 kPa

(100 psi)

INSTALLATION

The air flow direction is marked on the valve body and must be strictly adhered to.

Before installation, ensure that any packing material is blown well clear of all components.

The control pipework connections on the valve actuator are made with pipe thread fittings. 1/4"

o/d tubing is the minimum size recommended for air or gas, 5/16” o/d is the recommended

minimum for short lengths of lube oil line; while 3/8” o/d may be required for longer lengths

(especially in cold weather operation). Any scale, dirt, tubing chips, etc. must be removed from

the fitting and tubing before they are connected to the valve actuator. Ensure all tubing and hose

connections are tightened securely to avoid leakage and apply a good quality thread sealant (e.g.

Loctite Pipe Sealant) to the threaded pipe connections. This sealant must not be permitted to

enter the valve actuator passages.

Teflon thread sealing tape may be used, but the tape must not be applied in a manner that

enables shreds of tape to enter the valve actuator.

Copyright 2003 Issue 1

Pyroban Ltd, Endeavour Works, Dolphin Rd, Shoreham-by-Sea

West Sussex. BN43 6QG. United Kingdom.

Tel: +44(0) 1273 466200.

INLET SYSTEM

MAINTENANCE

Properly applied and installed, Intake Air Shut-off Valves require minimal maintenance. A careful

visual inspection of the valve must be carried out at monthly intervals.

An engine shutdown test must also be carried at monthly intervals to ensure correct valve

operation.

The valve ‘O’ ring(s) and valve shafts need not be serviced.

If it is necessary to replace the ‘O’ ring within the valve due to wear, damage or hardness:

i) Remove the valve actuator and rotate the disc through 180° from its normal closed

position.

ii) Remove the ‘O’ ring and replace.

iii) Reverse this sequence to re-assemble the valve.

Periodically, apply a suitable light grease (e.g. Dow Corning MS$ or equivalent) to the ‘O’ ring in

the periphery of the butterfly plate and to the mating conical surface inside the casting.

Copyright 2003 Issue 1

Pyroban Ltd, Endeavour Works, Dolphin Rd, Shoreham-by-Sea

West Sussex. BN43 6QG. United Kingdom.

Tel: +44(0) 1273 466200.

S-ar putea să vă placă și

- MODEL 5500 HYDRAULIC TUBING TONG OPERATIONS AND SERVICE MANUALDocument37 paginiMODEL 5500 HYDRAULIC TUBING TONG OPERATIONS AND SERVICE MANUALLucas Lewis0% (3)

- Balcrank 1130-001 Tiger PumpDocument8 paginiBalcrank 1130-001 Tiger PumpJoseph GeraciÎncă nu există evaluări

- SV250V 600 Operations Manual V1.3Document22 paginiSV250V 600 Operations Manual V1.3Giorgiana Rosu0% (1)

- SV110 Pump ManualDocument15 paginiSV110 Pump ManualFerenc-Jozsef Amik100% (1)

- 2D) SVG Inlet Valve SVG-12, SVG-9.5, SVG-4Document4 pagini2D) SVG Inlet Valve SVG-12, SVG-9.5, SVG-4Mohamed HamedÎncă nu există evaluări

- No Drip Atomizing Nozzle Installation & Maintenance: 11510 Goldcoast Drive Cincinnati, OH, USA 45249-1621Document2 paginiNo Drip Atomizing Nozzle Installation & Maintenance: 11510 Goldcoast Drive Cincinnati, OH, USA 45249-1621George MarkasÎncă nu există evaluări

- IR Turbine Power Starters TS700Document20 paginiIR Turbine Power Starters TS700andistwn99Încă nu există evaluări

- TYPE 330/340 Series Air Filter Regulator & Air Regulator: Installation, Operation, and Maintenance InstructionsDocument4 paginiTYPE 330/340 Series Air Filter Regulator & Air Regulator: Installation, Operation, and Maintenance InstructionsPeter RhoadsÎncă nu există evaluări

- 26850A005Document12 pagini26850A005Luciano AlencastroÎncă nu există evaluări

- CV1500 - Control Valves Installation and Operation ManualDocument16 paginiCV1500 - Control Valves Installation and Operation ManualMohammad Safdar SadatÎncă nu există evaluări

- Model Da8: (Formerly DA8/9) Direct-Acting, Positive Bias Differential Back Pressure RegulatorDocument18 paginiModel Da8: (Formerly DA8/9) Direct-Acting, Positive Bias Differential Back Pressure RegulatorBoubekeur HamegÎncă nu există evaluări

- 05-9040-269 ANGMC-6019-US Anderson Greenwood PDFDocument33 pagini05-9040-269 ANGMC-6019-US Anderson Greenwood PDFDIONNY VELASQUEZÎncă nu există evaluări

- ASC Air Starter ST700 SeriesDocument29 paginiASC Air Starter ST700 SeriesLeonid KolesnikovÎncă nu există evaluări

- Relief Valve 500 ES1196-1Document5 paginiRelief Valve 500 ES1196-1Jhon GuerreroÎncă nu există evaluări

- 873 400 Regulator Operation and Maintenance ManualDocument2 pagini873 400 Regulator Operation and Maintenance ManualHassan KhattabÎncă nu există evaluări

- Standard Gate Valves ManualDocument8 paginiStandard Gate Valves ManualmechanikyÎncă nu există evaluări

- Operating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasDocument20 paginiOperating and Maintenance Manual LPG: M-285 Rev. G P.D. Oscillating Piston Flowmeter 1 4D-MD LP GasCarlos RondonÎncă nu există evaluări

- Válve Relay Air Starters CAT E WaukeshaDocument8 paginiVálve Relay Air Starters CAT E WaukeshaJonatas Barbaglio Gomes PereiraÎncă nu există evaluări

- Bomba Myers D35-20DVDocument12 paginiBomba Myers D35-20DVdiroperacionesÎncă nu există evaluări

- Manual Arranque NeumaticoDocument52 paginiManual Arranque NeumaticoSabry Socarrás AarónÎncă nu există evaluări

- Operation and Maintenance: Model 873-400 RegulatorDocument2 paginiOperation and Maintenance: Model 873-400 Regulatorilham rusdyÎncă nu există evaluări

- Two Three Way Ball ValvesDocument6 paginiTwo Three Way Ball ValvesUzair AnsariÎncă nu există evaluări

- Jandy Check Valve Installation GuideDocument2 paginiJandy Check Valve Installation GuidejupodeÎncă nu există evaluări

- Operations-And Maintenance Instructions For FansDocument16 paginiOperations-And Maintenance Instructions For Fanskeyur1109Încă nu există evaluări

- Servo Electrohydraulic760 - CDS6541 - GDocument4 paginiServo Electrohydraulic760 - CDS6541 - GGuillermoÎncă nu există evaluări

- PVR-108-2 Fueling Model SheetDocument2 paginiPVR-108-2 Fueling Model SheetLetycia RosalesÎncă nu există evaluări

- ST900 Ed12Document28 paginiST900 Ed12moisesÎncă nu există evaluări

- 3-5400 Safety Relief Valves ManualDocument16 pagini3-5400 Safety Relief Valves ManualPrashant ChauhanÎncă nu există evaluări

- Swing-Flex Check Valve: Operation, Maintenance and Installation ManualDocument8 paginiSwing-Flex Check Valve: Operation, Maintenance and Installation ManualAhmed ShawkyÎncă nu există evaluări

- SuperSpool RCV Service Literature R434000181Document8 paginiSuperSpool RCV Service Literature R434000181Carlos Andrés CuelloÎncă nu există evaluări

- Anderson Greenwood - Pentair Series 400 Modulating Datasheet PDFDocument4 paginiAnderson Greenwood - Pentair Series 400 Modulating Datasheet PDFSARATH KRISHNAKUMARÎncă nu există evaluări

- Breathing Air Distribution System Technical Rescue Cart Instruction Manual - EN PDFDocument30 paginiBreathing Air Distribution System Technical Rescue Cart Instruction Manual - EN PDFSERGIOÎncă nu există evaluări

- 900 040 01Document8 pagini900 040 01Alessandra FloresfarÎncă nu există evaluări

- Catálogo Anderson Greenwood 400sDocument32 paginiCatálogo Anderson Greenwood 400sDaniela BeltranÎncă nu există evaluări

- 13 - SRK S-PlatformDocument46 pagini13 - SRK S-PlatformLassané KINDOÎncă nu există evaluări

- Pressure Relief Valves Operating Instructions: Supplemental ProtectionDocument2 paginiPressure Relief Valves Operating Instructions: Supplemental ProtectionlorenzoÎncă nu există evaluări

- SPM Full Bore Emergency Unloading Valve Manual PDFDocument9 paginiSPM Full Bore Emergency Unloading Valve Manual PDFPablo SotoÎncă nu există evaluări

- Es Acv 1116FMDocument4 paginiEs Acv 1116FMWattsÎncă nu există evaluări

- CVS Series 50 Chemical Injection Pump ManualDocument12 paginiCVS Series 50 Chemical Injection Pump Manualiqmpslab0% (1)

- A Coverage On Safety ValveDocument55 paginiA Coverage On Safety Valveagaurav2001100% (4)

- Engrasadora LINCOLNDocument8 paginiEngrasadora LINCOLNfernandojimenezdeÎncă nu există evaluări

- IOM 19 SeriesDocument6 paginiIOM 19 SeriesUmen AryanÎncă nu există evaluări

- HansenDocument4 paginiHansenBruna MacedoÎncă nu există evaluări

- Mooney Flowgrid Slam Shut 1 Inch Valve: GE Oil & GasDocument12 paginiMooney Flowgrid Slam Shut 1 Inch Valve: GE Oil & GasCarlos TarquinoÎncă nu există evaluări

- Mallard IOM Series 5600Document13 paginiMallard IOM Series 5600Nacho.pÎncă nu există evaluări

- FunctionalSafety V7666Document12 paginiFunctionalSafety V7666rufino.perea.2Încă nu există evaluări

- Bendix TC-2 Trailer Control Brake Valve: DescriptionDocument4 paginiBendix TC-2 Trailer Control Brake Valve: Descriptionjorge chavarriaÎncă nu există evaluări

- Catalog Functional Safety Solutions Asco en 5084612Document16 paginiCatalog Functional Safety Solutions Asco en 5084612alejomariana03Încă nu există evaluări

- OPERATING & SERVICE MANUAL AZ-1-107-NL SERIES PUMPDocument16 paginiOPERATING & SERVICE MANUAL AZ-1-107-NL SERIES PUMPREZA ASGARIÎncă nu există evaluări

- Kysor On/Off Rear Air Fan Drive: Installation - ServiceDocument12 paginiKysor On/Off Rear Air Fan Drive: Installation - ServiceeloyabnerÎncă nu există evaluări

- 755Document19 pagini755JOHNÎncă nu există evaluări

- FVCPDocument14 paginiFVCPmichaelxiaoÎncă nu există evaluări

- Compact Air Drive Ii: User'S ManualDocument20 paginiCompact Air Drive Ii: User'S ManualrossiÎncă nu există evaluări

- Operating and Maintenance Instructions For: Air Valve For Waste Water and Potable WaterDocument3 paginiOperating and Maintenance Instructions For: Air Valve For Waste Water and Potable WaterhoseyliauÎncă nu există evaluări

- Manual 1956 PN 09-1013 VF-61Document3 paginiManual 1956 PN 09-1013 VF-61fabiosparkÎncă nu există evaluări

- 45Kg Cylinder & Valve AssemblyDocument4 pagini45Kg Cylinder & Valve AssemblyRaju Saha100% (1)

- Hydroseal Series 3500 Pilot Operated Relief ValvesDocument8 paginiHydroseal Series 3500 Pilot Operated Relief Valvesprihartono_diasÎncă nu există evaluări

- !!!WARNING!!!Document6 pagini!!!WARNING!!!orlando montielÎncă nu există evaluări

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDe la EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsÎncă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Principles of Intrinsic SafetyDocument14 paginiPrinciples of Intrinsic SafetyMohamed HamedÎncă nu există evaluări

- 2I) ServicingDocument1 pagină2I) ServicingMohamed HamedÎncă nu există evaluări

- Lecture 10 - Ex NDocument11 paginiLecture 10 - Ex NMohamed HamedÎncă nu există evaluări

- Glanding: Glands Must Maintain Integrity of EnclosureDocument11 paginiGlanding: Glands Must Maintain Integrity of EnclosureMohamed HamedÎncă nu există evaluări

- Miscellaneous Items: Screw Secured Engine Oil Filler CapDocument1 paginăMiscellaneous Items: Screw Secured Engine Oil Filler CapMohamed HamedÎncă nu există evaluări

- Pre - Run Check ListDocument2 paginiPre - Run Check ListMohamed HamedÎncă nu există evaluări

- Lecture 09 - Ex PDocument8 paginiLecture 09 - Ex PMohamed HamedÎncă nu există evaluări

- JSA Form DraftDocument1 paginăJSA Form DraftMohamed HamedÎncă nu există evaluări

- 6F) Oil Pressure Gauge and Pipe Kit InstallationDocument1 pagină6F) Oil Pressure Gauge and Pipe Kit InstallationMohamed HamedÎncă nu există evaluări

- Apsey Application Form en r10 0Document3 paginiApsey Application Form en r10 0Mohamed HamedÎncă nu există evaluări

- Pyroban CDRom Installation & Technical ManualDocument10 paginiPyroban CDRom Installation & Technical ManualMohamed HamedÎncă nu există evaluări

- Hazard Identification Prompt CDocument2 paginiHazard Identification Prompt CMohamed HamedÎncă nu există evaluări

- 6E) Exhaust Gas Temperature Gauge InstallationDocument1 pagină6E) Exhaust Gas Temperature Gauge InstallationMohamed HamedÎncă nu există evaluări

- 6D) Coolant Temperature Gauge InstallationDocument1 pagină6D) Coolant Temperature Gauge InstallationMohamed HamedÎncă nu există evaluări

- Cooling Circuit Installation and MaintenanceDocument1 paginăCooling Circuit Installation and MaintenanceMohamed HamedÎncă nu există evaluări

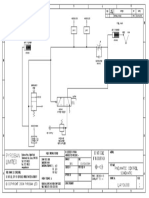

- Control SchematicDocument1 paginăControl SchematicMohamed HamedÎncă nu există evaluări

- Control Schematic PDFDocument1 paginăControl Schematic PDFMohamed HamedÎncă nu există evaluări

- Heat Rejection and Coolant NotesDocument1 paginăHeat Rejection and Coolant NotesMohamed HamedÎncă nu există evaluări

- K06952 BomDocument2 paginiK06952 BomMohamed HamedÎncă nu există evaluări

- 2G) SVF Inlet Oil ValveDocument1 pagină2G) SVF Inlet Oil ValveMohamed HamedÎncă nu există evaluări

- Heat Rejection and Coolant NotesDocument1 paginăHeat Rejection and Coolant NotesMohamed HamedÎncă nu există evaluări

- Field DataDocument1 paginăField DataMohamed HamedÎncă nu există evaluări

- Battery SpecsDocument2 paginiBattery SpecsAbraham SaucedoÎncă nu există evaluări

- Observe The Employee: Safe Act/ConditionDocument3 paginiObserve The Employee: Safe Act/ConditionMohamed HamedÎncă nu există evaluări

- Ensco Work Instruction and JSA ProceduresDocument18 paginiEnsco Work Instruction and JSA ProceduresMohamed HamedÎncă nu există evaluări

- Cleaning Galley Fryer WIDocument2 paginiCleaning Galley Fryer WIMohamed HamedÎncă nu există evaluări

- Cleaning Galley Fryer WIDocument2 paginiCleaning Galley Fryer WIMohamed HamedÎncă nu există evaluări

- Working With KnifesDocument2 paginiWorking With KnifesMohamed HamedÎncă nu există evaluări

- Nature of Acidity and Lime Requirement in Acid Soils of ManipurDocument8 paginiNature of Acidity and Lime Requirement in Acid Soils of ManipurIJASRETÎncă nu există evaluări

- 2 Interference in Spur GearsDocument2 pagini2 Interference in Spur Gearschris100% (1)

- Oksd Icwh 1993 RoisumDocument40 paginiOksd Icwh 1993 RoisumKamalam CloudsoftÎncă nu există evaluări

- Government Engineering College Surveying Lab ManualDocument26 paginiGovernment Engineering College Surveying Lab ManualNittin BhagatÎncă nu există evaluări

- CH (1) : Introduction: 1.1: Database Management SystemsDocument5 paginiCH (1) : Introduction: 1.1: Database Management SystemsaboalfotohÎncă nu există evaluări

- 3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFDocument6 pagini3RInternational Tetzner Model Based Pipeline LDS 07-2003 PDFRene ParedesÎncă nu există evaluări

- WPD Flotationdrying PDFDocument19 paginiWPD Flotationdrying PDFVvbjÎncă nu există evaluări

- CAD1 AssignmentDocument11 paginiCAD1 AssignmentJohn2jÎncă nu există evaluări

- Pen Holder SHSDocument16 paginiPen Holder SHSabhijeetbose1Încă nu există evaluări

- 49 CFR Ch. I (10-1-11 Edition) 173.318Document5 pagini49 CFR Ch. I (10-1-11 Edition) 173.318MauricioÎncă nu există evaluări

- EZ-THUMP™ Series: Portable Fault Location SystemsDocument2 paginiEZ-THUMP™ Series: Portable Fault Location Systemsriyad abdulhafeedÎncă nu există evaluări

- Hit-Re 500 With Hit-V Has RodsDocument3 paginiHit-Re 500 With Hit-V Has RodsMKÎncă nu există evaluări

- Dow Corning (R) 200 Fluid, 50 Cst.Document11 paginiDow Corning (R) 200 Fluid, 50 Cst.Sergio Gonzalez GuzmanÎncă nu există evaluări

- How To Install GmtsarDocument24 paginiHow To Install GmtsardedetmixÎncă nu există evaluări

- YCMOU-6th Semester Question Papers-7Document5 paginiYCMOU-6th Semester Question Papers-7phase_shekhar21Încă nu există evaluări

- Dewatering SystemDocument124 paginiDewatering SystemSpyros NannosÎncă nu există evaluări

- V8fr-Ii V8r7-IiDocument1 paginăV8fr-Ii V8r7-Iiaeroseb1Încă nu există evaluări

- Excellent Hex Key Wrench: English VersionDocument54 paginiExcellent Hex Key Wrench: English Versionmg pyaeÎncă nu există evaluări

- Assignment - Iv Examples of Design of Transformer: W 2 M 2 T W WDocument1 paginăAssignment - Iv Examples of Design of Transformer: W 2 M 2 T W Wiamketul6340Încă nu există evaluări

- Method Statement For Architecture Work (Drywall) : No. Work Sequence Good Practices Picture Tools RemarksDocument16 paginiMethod Statement For Architecture Work (Drywall) : No. Work Sequence Good Practices Picture Tools RemarksAn-an ChanÎncă nu există evaluări

- Luran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)Document3 paginiLuran S KR2868C: Acrylonitrile Styrene Acrylate / Polycarbonate (ASA/PC)rosebifÎncă nu există evaluări

- Magnum 3904 DatasheetDocument3 paginiMagnum 3904 DatasheetbobÎncă nu există evaluări

- Michelson Interferometer Na Lamp-1Document11 paginiMichelson Interferometer Na Lamp-1SOHINI KAYALÎncă nu există evaluări

- A Report On Workability of Fresh Concrete by Slump TestDocument5 paginiA Report On Workability of Fresh Concrete by Slump TestRishabhJain100% (1)

- Woodson Property Group's Conditional Use Permit ApplicationDocument108 paginiWoodson Property Group's Conditional Use Permit ApplicationShannon GeisenÎncă nu există evaluări

- Timing Chain Tensioner ResetDocument4 paginiTiming Chain Tensioner ResetHybrid RacingÎncă nu există evaluări

- How rock layers are formedDocument3 paginiHow rock layers are formedAlemar AllecerÎncă nu există evaluări

- Sallyport MBI Bifold BrochureDocument6 paginiSallyport MBI Bifold BrochureameraldaherÎncă nu există evaluări

- Aso Airfield Standards Quick ReferenceDocument66 paginiAso Airfield Standards Quick ReferenceRahul RanaÎncă nu există evaluări