Documente Academic

Documente Profesional

Documente Cultură

Hdpe Bps Sab355

Încărcat de

Benjamin Enmanuel Mango DDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Hdpe Bps Sab355

Încărcat de

Benjamin Enmanuel Mango DDrepturi de autor:

Formate disponibile

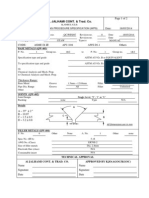

HDPE BPS

Date: 06 – Nov- 2009

HDPE BONDING PROCEDURE SPECIFICATION

ESPECIFICACION DEL PROCEDIMIENTO DE SOLDADURA HDPE N° 001

1. WELDING PROCESS: THERMO FUSION

PIPE CLASIFICATION (ASTM D3350) PIPE CLASIFICATION (ASTM D3350)

Type IPS Nominal Size Range 6” 12”

Grade PE3608 (PE 3408) Minimum Wall Size Range 0.736” 1.417”

Range Size 6” and 12” Actual OD Range 6.625” 12.750”

Range Rating DR 9 (Class 200 Actual ID Range 5.094” 9.803”

FM)

Color Black Weight Range 5.932 lbs/ft 21.97 lbs/ft

2. BASE MATERIAL

Material Properties Test Methods Units

Material Designation PPI/ASTM PE3408

Gell Clasification ASTM D3350 345464C

Density ASTM D1505 gm/cc 0.955 to 0.957

Flow Rate ASTM D12238 (190/21.6) gm/10 min. 0.08

Flexural Modulus, 2% Secant ASTNM D790 Psi >110,000

Tensite Strength @ Yield ASTM D638 Psi 3200

Carbon Black (UV Protection) ASTM D1603 % 2.0 to 2.5%

Hydrostatic Design Basis (HDB) @ 21C ASTM D2837 psi 1600

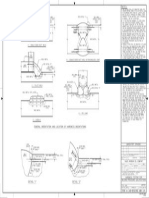

3. TECHNIQUE

1 Aligment / Alineamiento Fit/Check

2 Cleaning / Limpieza Cotton Rags

3 Temperature Heating / Temperatura Plato Calefactor 205-215°C

4 Inercial Pressure Bead Formation / Presion Inicial Rebarba P1

5 Wall Thickness / Espesor rebarba inicial Bead

6 Pressure Heating / Presion de Calentamiento P2

7 Time of Heating / Tiempo de Calentamiento T2

8 Time Requested Change Over / Tiempo Retiro Plato Calefactor T3

9 Time Bringing Up Pressure / Tiempo Incremento de Presion T4

10 Pressure Cooling / Presion de Enfriamiento P5

11 Time Cooling / Tiempo de Enfriamiento T5

4. EQUIPMENT AND BONDING PARAMETERS

D S Temp P1 Bead P2 T2 T3 T4 P5 T5

SDR

Maquina mm mm °C Bar mm bar sec sec sec bar Sec

1 TT SAB355 323 36 9 210 57.5 4.5 7 380 15 16 57.5 2400

Note: Our Parameters are in millimeters and bars, according the specification of the manuals, adding to obtain accurate estimates have had to

interpolate the parameters.

5. INSPECTION Use a visual inspection as indicated by the pipe provider to accept the joint

S-ar putea să vă placă și

- Guía de Evaluación AWS G1.10MDocument45 paginiGuía de Evaluación AWS G1.10MDaniel Jimenez100% (1)

- PFI ES 24 Pipe Bending and TollerancesDocument12 paginiPFI ES 24 Pipe Bending and TollerancesArcadio DuranÎncă nu există evaluări

- w Ab 036386 硬度检测点要求Document1 paginăw Ab 036386 硬度检测点要求essence1Încă nu există evaluări

- Welding Map Spool 3D - Sht4Document1 paginăWelding Map Spool 3D - Sht4Nguyễn Quốc PhượngÎncă nu există evaluări

- Welding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin JasmirDocument3 paginiWelding Process: Mma/Smaw TYPES: Manual: Preliminary Welding Procedure Specification (PWPS) Nama: Shah Nadzri Bin Jasmirshahaljawaie87100% (2)

- ITP Pipeline Truba MandiriDocument7 paginiITP Pipeline Truba MandiriFarhan100% (1)

- F1055 15708Document15 paginiF1055 15708Alejandro ValdesÎncă nu există evaluări

- Soldaduras Varios PDFDocument54 paginiSoldaduras Varios PDFCristhian AndresÎncă nu există evaluări

- Tabla de Torque - HdpeDocument3 paginiTabla de Torque - HdpeDevi SalcedoÎncă nu există evaluări

- Utoc Preliminary Wps Shell Project 270807 PDFDocument55 paginiUtoc Preliminary Wps Shell Project 270807 PDFErick HoganÎncă nu există evaluări

- Hot Tap ReportDocument2 paginiHot Tap ReportCak NhassÎncă nu există evaluări

- Bolt Torque Chart: ASTM A307Document5 paginiBolt Torque Chart: ASTM A307Leonardo Díaz Cerna100% (1)

- Normas DVS PDFDocument11 paginiNormas DVS PDFrodrigo diaz poblete100% (1)

- HDPE الوسايلDocument151 paginiHDPE الوسايلMohamed ElarabiÎncă nu există evaluări

- Welder Performance Qualification (WPQ)Document2 paginiWelder Performance Qualification (WPQ)alokbdasÎncă nu există evaluări

- Tn-38 Bolt Torque Flanged Joints (1) (1) Torque HDPEDocument37 paginiTn-38 Bolt Torque Flanged Joints (1) (1) Torque HDPEDarwin CornejoÎncă nu există evaluări

- Comparison Pe4710 Pe3608Document1 paginăComparison Pe4710 Pe3608Rene CALLIRI MAQUERAÎncă nu există evaluări

- Astm A270 PDFDocument1 paginăAstm A270 PDFgaminÎncă nu există evaluări

- TR 33 Generic Butt Fusion Joining Gas PipeDocument40 paginiTR 33 Generic Butt Fusion Joining Gas PipeRamonezeÎncă nu există evaluări

- PFI ES-03 Fabricating TolerancesDocument4 paginiPFI ES-03 Fabricating TolerancesAL DOMAÎncă nu există evaluări

- Figure 323.2 Asme b31.3Document1 paginăFigure 323.2 Asme b31.3Siddiqui Abdul KhaliqÎncă nu există evaluări

- Tabla de DVS 2212-1Document9 paginiTabla de DVS 2212-1percivalczÎncă nu există evaluări

- Pfi Es-3 2004Document2 paginiPfi Es-3 2004bayu212Încă nu există evaluări

- Drps Material Submittal 2Document160 paginiDrps Material Submittal 2soorajÎncă nu există evaluări

- Project:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportDocument4 paginiProject:OLMTP Project No:16-PSS-002 Client:ZKB-RELIABLE: Daily Welding Inspection ReportEngr Saeed AnwarÎncă nu există evaluări

- PQR For 32 MM PlateDocument1 paginăPQR For 32 MM PlateMuhammed MubeenÎncă nu există evaluări

- Wps For Aluminium WeldingDocument8 paginiWps For Aluminium WeldingMohammed MusaÎncă nu există evaluări

- Qw-482 Welding Procedure Specification (WPS)Document4 paginiQw-482 Welding Procedure Specification (WPS)Aldeline Sungahid100% (2)

- QW 483Document2 paginiQW 483delta lab sangliÎncă nu există evaluări

- PWPS WPS CAP 039 PQR 035Document15 paginiPWPS WPS CAP 039 PQR 035GOPINATH KRISHNAN NAIRÎncă nu există evaluări

- Installation of T1501 PIPE ProcedureDocument6 paginiInstallation of T1501 PIPE Procedure1339979Încă nu există evaluări

- PQR (Hdpe)Document3 paginiPQR (Hdpe)abdo elmokademÎncă nu există evaluări

- Welding Procedure Specification For GTAWDocument9 paginiWelding Procedure Specification For GTAWraja reyhanÎncă nu există evaluări

- 2.1 WPS - PipingDocument13 pagini2.1 WPS - PipingSheri DiĺlÎncă nu există evaluări

- Hdpe FieldDocument44 paginiHdpe Fieldwesqui100% (1)

- f2620 - Standar Practce For Heat Fusion Joining of Polyethylene PipeDocument21 paginif2620 - Standar Practce For Heat Fusion Joining of Polyethylene PipeDeyvi Vasquez PittmanÎncă nu există evaluări

- DVS 2207-5Document22 paginiDVS 2207-5OscarÎncă nu există evaluări

- Content of Standard 4S-10.02: FRP Pressure Pipe, Fittings and FlangesDocument24 paginiContent of Standard 4S-10.02: FRP Pressure Pipe, Fittings and FlangesJuan Ayala ValdebenitoÎncă nu există evaluări

- Wps A53 Gtaw R00Document2 paginiWps A53 Gtaw R00Richard PeriyanayagamÎncă nu există evaluări

- A545-736-11-42-DS-0034 - A - Flow TeeDocument2 paginiA545-736-11-42-DS-0034 - A - Flow TeeMurli ramchandranÎncă nu există evaluări

- ASTM D2657 - 07 Heat Fusion Joning HDPEDocument7 paginiASTM D2657 - 07 Heat Fusion Joning HDPEMarlon TurnerÎncă nu există evaluări

- Wqt-Visual-Mag - BS 2Document24 paginiWqt-Visual-Mag - BS 2KyÎncă nu există evaluări

- PFI ES-7 Min Spacing For WeldingDocument6 paginiPFI ES-7 Min Spacing For WeldingNguyen Anh TungÎncă nu există evaluări

- Welding Procecure SpecificationDocument9 paginiWelding Procecure SpecificationNwoha PeterÎncă nu există evaluări

- WPS Format For AWS D1.1 - WPS - SAWDocument1 paginăWPS Format For AWS D1.1 - WPS - SAWThe Welding Inspections CommunityÎncă nu există evaluări

- Step 3 Hydrotest Diagram Stage 1Document1 paginăStep 3 Hydrotest Diagram Stage 1mansih457100% (1)

- Prefabricacion y Montaje de Tuberias HDPE Por Electrofusion (Ingles)Document10 paginiPrefabricacion y Montaje de Tuberias HDPE Por Electrofusion (Ingles)Kike BúÎncă nu există evaluări

- Dvs 2207Document139 paginiDvs 2207Yen Belton Capcha CuyutupaÎncă nu există evaluări

- SMAW DuniDocument4 paginiSMAW DuniMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- WPS-Nozzle With Reinforcement Pad (CS-CS) .Document1 paginăWPS-Nozzle With Reinforcement Pad (CS-CS) .suria qaqcÎncă nu există evaluări

- Material Requisition For Bolt and Nuts-Rev0Document5 paginiMaterial Requisition For Bolt and Nuts-Rev0altipatlarÎncă nu există evaluări

- Flanges ANSI16 5###Document48 paginiFlanges ANSI16 5###kunal shahÎncă nu există evaluări

- MSS SP 97 01Document15 paginiMSS SP 97 01Allan SousaÎncă nu există evaluări

- Pull Off Test Report RefinaryDocument3 paginiPull Off Test Report RefinaryZaid Raslan AyoubÎncă nu există evaluări

- Astm D 3035 PDFDocument7 paginiAstm D 3035 PDFSushil GambhirÎncă nu există evaluări

- TN 46 Guidance Field Hydro Test Hdpe Pressure ConsiderationsDocument17 paginiTN 46 Guidance Field Hydro Test Hdpe Pressure ConsiderationsZohair AftabÎncă nu există evaluări

- Tips Wps FormatDocument5 paginiTips Wps FormatWaqas WaqasÎncă nu există evaluări

- Duraline - Ficha Técnica Tubería PEAD 4710 (Gas Natural)Document4 paginiDuraline - Ficha Técnica Tubería PEAD 4710 (Gas Natural)FrancoÎncă nu există evaluări

- Nylatron® 4.6 - BoedekerDocument6 paginiNylatron® 4.6 - BoedekerMas ZuhadÎncă nu există evaluări

- Castrol Tribol GR 4020 220-460 PD Tds-EnDocument3 paginiCastrol Tribol GR 4020 220-460 PD Tds-EnIulian BarbuÎncă nu există evaluări

- Páginas desdeC-CS-50-005 HDPE - REV0 PDFDocument1 paginăPáginas desdeC-CS-50-005 HDPE - REV0 PDFBenjamin Enmanuel Mango DÎncă nu există evaluări

- Iron-Iron Carbide Phase Diagram ExampleDocument3 paginiIron-Iron Carbide Phase Diagram ExampleBenjamin Enmanuel Mango DÎncă nu există evaluări

- MSS-SP-006 Standard Finishes For Contact Faces of Pipe Flanges 1996Document6 paginiMSS-SP-006 Standard Finishes For Contact Faces of Pipe Flanges 1996quack1111Încă nu există evaluări

- Bsi 5352-1981Document32 paginiBsi 5352-1981Benjamin Enmanuel Mango DÎncă nu există evaluări

- QC Matrix - EstructurasDocument8 paginiQC Matrix - EstructurasBenjamin Enmanuel Mango DÎncă nu există evaluări

- Bsi 1868-1975Document25 paginiBsi 1868-1975Benjamin Enmanuel Mango DÎncă nu există evaluări

- H 99 Sec 8 D 1 App 1Document9 paginiH 99 Sec 8 D 1 App 1Benjamin Enmanuel Mango DÎncă nu există evaluări

- T60n02rg PDFDocument8 paginiT60n02rg PDFsandor9116100% (2)

- Pigging Training Course Mod 7 Rev 1Document26 paginiPigging Training Course Mod 7 Rev 1Suparerk Sirivedin100% (1)

- 2020 Landfill Capacity Calculation Work SheetDocument4 pagini2020 Landfill Capacity Calculation Work SheetLYÎncă nu există evaluări

- ECE 374 - Part - 1c - S2017Document37 paginiECE 374 - Part - 1c - S2017Zakaria ElwalilyÎncă nu există evaluări

- Ligamentele LargiDocument2 paginiLigamentele LargiIoana IonicaÎncă nu există evaluări

- Ground PlaneDocument1 paginăGround Planeaeronautical rajasÎncă nu există evaluări

- A General Strategy For The Synthesis of Reduced Graphene Oxide-Based CompositesDocument8 paginiA General Strategy For The Synthesis of Reduced Graphene Oxide-Based CompositesCristian Gonzáles OlórteguiÎncă nu există evaluări

- 2014 Catbalogan Landslide: September, 17, 2014Document6 pagini2014 Catbalogan Landslide: September, 17, 2014Jennifer Gapuz GalletaÎncă nu există evaluări

- Dynamic-Light-Scattering - MDLDocument5 paginiDynamic-Light-Scattering - MDLJose Daniel Izquierdo MorenoÎncă nu există evaluări

- Sunfix Blue SPRDocument7 paginiSunfix Blue SPRDyeing 2 Wintex100% (2)

- Block-1 BLIS-03 Unit-2 PDFDocument15 paginiBlock-1 BLIS-03 Unit-2 PDFravinderreddynÎncă nu există evaluări

- Parts PrecedentDocument252 paginiParts PrecedentOscar PinzonÎncă nu există evaluări

- CA InsideDocument1 paginăCA InsideariasnomercyÎncă nu există evaluări

- DST Tmpm370fydfg-Tde en 21751Document498 paginiDST Tmpm370fydfg-Tde en 21751trân văn tuấnÎncă nu există evaluări

- Advanced Logic Synthesis: Multiple Choice QuestionsDocument16 paginiAdvanced Logic Synthesis: Multiple Choice QuestionsmanojkumarÎncă nu există evaluări

- Consent For Diagnostic And/or Therapeutic ParacentesisDocument2 paginiConsent For Diagnostic And/or Therapeutic ParacentesisnaveenÎncă nu există evaluări

- PPP-B-676 e PDFDocument34 paginiPPP-B-676 e PDFffincher4203Încă nu există evaluări

- Pump Shotgun: Instruction ManualDocument5 paginiPump Shotgun: Instruction ManualJustinÎncă nu există evaluări

- API 571 Quick ReviewDocument32 paginiAPI 571 Quick ReviewMahmoud Hagag100% (1)

- WorldShop CatalougeDocument200 paginiWorldShop Catalougee2ashÎncă nu există evaluări

- Aircraft Structures - Ii (AER18R372)Document15 paginiAircraft Structures - Ii (AER18R372)sarathkumar sebastinÎncă nu există evaluări

- Infineon IRFZ44N DataSheet v01 - 01 ENDocument9 paginiInfineon IRFZ44N DataSheet v01 - 01 ENIkram RidhoÎncă nu există evaluări

- History of Costa RicaDocument2 paginiHistory of Costa Ricakrishnan MishraÎncă nu există evaluări

- Red Oaks Drive, Frankton, Queenstown-Lakes, Otago PDFDocument1 paginăRed Oaks Drive, Frankton, Queenstown-Lakes, Otago PDFCintiah KenedyÎncă nu există evaluări

- E Installation of BatteryDocument16 paginiE Installation of BatteryPrashant KadamÎncă nu există evaluări

- The Use of Proton Pump Inhibitors in Treating and Preventing NSAID-induced Mucosal DamageDocument6 paginiThe Use of Proton Pump Inhibitors in Treating and Preventing NSAID-induced Mucosal DamageFriska Rachmanita PrayogoÎncă nu există evaluări

- Reservoir Rock PropertiesDocument148 paginiReservoir Rock Propertiesiscribdusername100% (7)

- Food ProductionDocument106 paginiFood ProductionAna Marie100% (1)

- Mensuration Practice SheetDocument1 paginăMensuration Practice SheetSonia SabuÎncă nu există evaluări

- 16950Document16 pagini16950uddinnadeemÎncă nu există evaluări