Documente Academic

Documente Profesional

Documente Cultură

Paul Greene

Încărcat de

LiuJaluDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Paul Greene

Încărcat de

LiuJaluDrepturi de autor:

Formate disponibile

Anaerobic

Digestion & Biogas

© Copyright 2014 - Rev 4 - 07/01/2015

...A Better Way

Table of Contents

1. Introduction ............................................................................................................................. 3

2. Types of Digesters .................................................................................................................. 6

3. Settings for Digesters ............................................................................................................. 7

4. Digester Tank Design ............................................................................................................. 8

5. Digestate Management ...................................................................................................... 12

6. Gas Upgrading & Handling ................................................................................................. 14

7. Gas Use .................................................................................................................................... 17

8. Project Development and Finance ................................................................................... 19

9. Digester Construction Methodology ............................................................................... 19

11. US Project Examples .......................................................................................................... 22

12. Appendix............................................................................................................................... 26

About the Author ...................................................................................................................... 27

Acknowledgements: ................................................................................................................. 27

The latest update of this EBook is always available at www.digester.com. Tune to our podcast on digester.com and on ITunes for

interviews with leading edge facility operators.

Anaerobic Digestion & Biogas Page | 2

...A Better Way

1. INTRODUCTION

Biogas comes from the breakdown of organic matter in anaerobic

environments such as in landfills, in nature, in the human body, and in

engineered anaerobic digesters. Anaerobic Digestion (AD) is the breakdown

of organic matter in the absence of oxygen. AD units come in many different

styles, shapes and configurations with the commonalities being that they

operate in the absence of oxygen, in a sealed vessel and operate at elevated

temperatures. A common analogy is that food waste digesters operate quite

like the human body's or ruminant animal's digestive system. The gas

mixture that emanates from a digester is commonly referred to as biogas.

The remaining solids and nutrient rich liquid is referred to as digestate. This

document is focused on AD as an established means of converting organic

Food Waste to a Digester

matter to fertilizer and biogas.

Food waste is a common material used to feed digesters. A common pyramid for dealing with excess food is:

a. Feed People

b. Feed Animals

c. Generate Energy (send to a digester)

d. Produce Compost

AD is turning into an ever-popular recycling choice as an approach to get energy, compost and nutrient value out of discarded

organics and helps control methane emissions which are a highly potent greenhouse gas. Biogas can be used as a fuel in gas

pipelines, combusted to produce electricity or compressed into a vehicle fuel. The residual solids and liquid are good nutrient-rich

crop fertilizers.

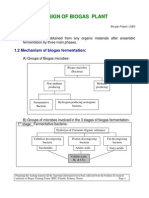

1.1 PROCESS CHEMISTRY

The pathway to making biogas from waste is multi-step. First, the

organic waste undergoes hydrolysis and acidification steps where large

molecules are broken apart and organic acids are formed. Material at

this phase would have a foul odor to it and be considered "rancid.”

From there, other steps including acetogeneis and methanization occur

where microbes called "acetogens" and "methanogens" generate

methane gas. The acetogenesis phase converts organic acids to

acetate. Methanogens are the key to making biogas but are slow

growing and can cause operational issues if not tended to properly.

Biogas is commonly a mix of both methane and carbon dioxide (CO2).

The compositions of biogas depend on the chemical pathway for

digestion but usually range from 50-70% for methane with the balance

being CO2, hydrogen sulfide and other trace gases. Steps in AD Process

1.2 GAS YIELD

Wastes make different amounts of gas in a digester. Gas yields are fairly analogous to calorie value of foods as both pertain to

energy values. In a digester, easy to digest carbohydrates such as pre consumer food waste from grocery stores can digest very

Anaerobic Digestion & Biogas Page | 3

...A Better Way

rapidly and convert to methane quickly much like our bodies metabolize sugars and starches quickly. Other materials like

proteins in waste meat or waste oils and fats can provide very significant energy potential but can take more time to degrade.

A common lab test to validate the potential gas yield of these various substrates is the Biomethane Potential Test, or BMP Test.

The BMP test simulates a digester on the laboratory scale as a batch test. A waste sample is put in a sealed beaker, diluted,

seeded with a bacteria inoculum, heated, and mixed for a number of weeks. Its resulting gas yield rate is traced over time.

Knowing the BMP profile of the waste with a particular process is critical to modeling system gas output. There is significant data

in industry literature on the gas yield of hundreds of different substrates.

To understand how gas comes from food waste one can come at it from a couple of perspectives. First one must appreciate that

food waste can contain 60-90% water. The remaining fraction is the material that provides the gas yield. A ton of food waste that

enters a digester will only yield gas from the Volatile Fraction, that being the carbonaceous fraction. Some will refer to the gas

yield of a wet ton of matter delivered to a facility while others will refer to gas yield that comes from volatile fraction not

including the water weight. The first would be considered the gas yield of "wet solids" the other would be considered the gas

yield of the "volatile solids.”

1.3 PROCESS MODELING

A number of digester computer-based performance models exist. Some are available for a fee and others are available for

download at no cost. A process model is a key step in the typical stage-gated project development process where local area

wastes are profiled and waste quantities are projected. By inputting projected tip fees, resulting energy and compost sales,

projected Return on Investment (ROI) can be calculated to determine if a project meets investor financial metrics.

Running a number of iterations of the process model to optimize the local circumstances and nuances of a particular project are

of paramount importance to optimizing digestion facility size. As all models can be subject to "Garbage In - Garbage Out"

scenarios it is important to feed the models with good, hard costing information of system construction cost, projected energy

sales and projected site tip fees to make educated decisions. Many of the free models work fine for project screening but once

projects get past the screening stage and into the project sizing stage, these models become too complex for the no-cost models.

1.4 DIGESTION PROCESS

"Volatile Solids" are the components of the wastes that are amenable to converting to gas. These are different from the non-

volatile fraction, also known as the ash fraction. Much as the volatile fraction of woody waste goes up in smoke in a fireplace, for

example, the ash is the fraction which is left behind and not able to be volatilized. Digester designers require data on organic

matter concentrations in feedstocks and project what fraction of the organics can convert to biogas. Roughly 40-60% of the

organic matter or "volatile fraction" of the feedstock will convert to gas in the digester, given proper residence time. The more

time the waste is allowed to digest in the system the more the conversion. Some molecules like cellulose and other fibrous

material will sometimes resist breakdown in a digester but given the right conditions can be digested.

There is a tradeoff and balance between the amount of digestion time, the amount of energy one is able to produce and system

costs.

1.4.1 LOADING RATES

A recent Cal Recycle study gives reference on loading rates used in anaerobic digesters. Loading rates they refer to include 0.02-

0.05 pounds of volatile solids per gallon of digester tank volume each day.

Example: Loading rate of food waste into a 1 Million gallon digester:

Anaerobic Digestion & Biogas Page | 4

...A Better Way

Assuming a food waste that was 70% water, 15% volatile solids and 15% nonvolatile (ash)

Assume a mid loading rate of 0.025 lb. of volatile solids per gallon of digester volume daily

As the food waste is 15% volatile one must first convert to total mass of food waste. That equates to 0.025/0.15 or 0.167

pounds of total food waste (or 2.6 ounces) per gallon of digester capacity each day.

So, for example, a typical 1 Million gallon digester tank might have about 167,000 wet pounds (1,000,000 gallons x 0.167

pounds per gallon per day loading rate) or 83 wet tons of food waste fed to it each day at these loading rates.

Common reactor retention times range from as little as a few days to as much as a month or two. The loading rate and retention

time varies with the type of waste and the type of digester being used.

1.4.2 GAS YIELD

A study from Sweden (Substrate Handbook 2009) quoted about shows that showed an average gas yield of 3.6 cubic of biogas

would come from the digestion of a pound of typical food waste:

Example: Gas Yield and Power Generation capacity for a large, 40,000 ton per year food waste digester:

40,000 ton / yr. x 2000 lb. /ton = 80,000,000 lb./yr. total food waste fed into digester

80,000,000 lb. of food waste x 3.6 cubic feet per pound = 288 million cubic feet per year of gas generated

288 Million cubic feet of biogas per year is 555 cubic feet per minute (SCFM)

Field data has shown a typical power gen system can produce 300 KW of power from 100 CFM of gas at typical efficiencies

(Bevington, 2013).

Electric Generation - Therefore a system that produces 555 CFM will produce (550/100 CFM or a 5.5 x factor) or 5.5 x

300KW or 1.65 Megawatts of electricity.

Vehicle Fuel - The same 555 SCFM of biogas = 800,000 cubic feet per day. Assuming 550 BTU in each cubic foot gives 440

Million BTU/day which also = 3140 GGE or gallon of gas equivalent (assuming 140,000 btu per gallon) of vehicle fuel.

In summary, one can get either 3140 gallons equivalent of vehicle fuel or 1.6 MW of electricity daily from 40,000 tons per

year of food waste in this case. The decision of which to produce would depend on local economics. If, for example, the

value of electricity was 8 cents per kilowatt-hour the value of this electricity would be $3168 per day. If in this case vehicle

fuel was valued at about $2 per gallon the value of this fuel would be about $6280 per day. It is also worth noting that the

vehicle fuel scenario incurs extra scrubbing costs, gas compression and extra digester heating costs compared to the

electricity scenario.

1.5 SUBSTRATES AND FEEDSTOCKS

Just as in the human body, anaerobic digesters are best fed a variety of substrates for a proper balanced "diet." This mix can

provide a balanced, buffered feed which makes a digester less prone to upset. Digesters function well with a baseload substrate

like municipal biosolids, animal manure or energy crops as they promote process stability. High energy feedstocks like fats and

oils are typically a minority of the feed load due to process stability and buffering concerns.

References:

CalRecylcle http://www.calrecycle.ca.gov/Publications/Documents/Organics%5C2008011.pdf page 52, Swedish Handbook

http://www.avfallsverige.se/fileadmin/uploads/Rapporter/Utveckling/U2009-14.pdf Page 31 translated from Swedish by Google Translate. Substrate Handbook for

Biogas Production, 2009, Gloversville Johnstown JWTP, 2013, Data from George Bevington, Operations Manager.

Anaerobic Digestion & Biogas Page | 5

...A Better Way

2. TYPES OF DIGESTERS

There are many configurations of anaerobic digesters and can run at different target temperatures the most common of which

are Mesophillic (95 F, 35 C) or Thermophilic (125 F, 50C). There are different populations of anaerobic microbes that thrive in

these temperature zones. Digesters can combine all the main process chemistry steps (hydrolysis, acidification, acetogenisis,

methanogenis) either in a single process reactor tank or in two separated reactor tanks. While separation of digestion phases

allows for some additional process control, it incurs additional capital costs for the additional tanks and monitoring.

2.1 WET DIGESTERS

The most common digester style is called a "Wet Digester.” They are known

as "wet" due to all the substrates being able to be moved around as liquid

slurries and mixed by pumps. The consistency of these digesters contents is

usually 3-15% total solids. Typical retention times range from 20-40 days.

Farm based digesters also come in lagoon or in-ground plug flow reactors. A

newer digester style is an Anaerobic Membrane Bioreactor (AnMBR) that

uses a membrane filter at the back end of the facility to separate reactor

slurry solids from the digestate liquids and hold solids in the system. Yet

another system is a multi-phased digester with hydrolysis step and a

Wet Style Digester

methanogenesis step, sometimes with interstage solids separation of inert

solids, which can allow for optimized residence time.

2.2 DRY DIGESTERS

Dry digesters keep the substrates in a stackable form and remain in a pile

during the digestion process. Food waste is mixed with green wastes such as

yard debris for structure and porosity and is put into a long, rectangular

vessel in a stack. The vessel is then sealed tight and warmed. Warm water, or

percolate, is sprayed over the waste stack, collected and recycled. The

percolate is biologically active which accelerates the digestion process.

Percolate is sent to a separate methanization digester tank where the biogas

is generated and the percolate recycled. There are also vertical down-flow

Dry Digester System

reactor configurations where waste is fed in the top and allowed to flow out

the bottom a number of days later while digesting along the way.

Front Door of Dry Digester Emptying Contents from Dry Digester Dry Digester Opened Doors

Anaerobic Digestion & Biogas Page | 6

...A Better Way

3. SETTINGS FOR DIGESTERS

3.1 MUNICIPAL WASTEWATER TREATMENT FACILITIES

Municipal treatment facilities commonly operate anaerobic digesters to convert the bulk of the volatile solids in their sludges to a

form that is more stable, has less volume, easier to dewater and reduced pathogens. Some municipalities have additional

available treatment volume and can take in outside substrates to gain tipping fees and increase energy production. Common

outside wastes taken by municipal treatment plants include food scraps, cheese and yogurt whey, beverage wastes, fats, oils &

grease (FOG) from sources like restaurant grease traps.

3.2 FARM BASED UNITS

Farmers have seen that anaerobic digestion can be an effective way to deal with dairy, swine and

poultry manures. The typical cow generates 20 gallons of manure each day. A large 2000 head

dairy farm, for example, can generate sizable quantities of manure. Digesters are able to reduce

manure odors, convert organic matter to energy, reduce pathogens, return solid bedding

materials to the barns and convert the nutrients from manure into more usable form. Farmers

are also realizing revenue opportunities in receiving outside feedstocks to feed into their digester

to increase gas yield. One thing for farms to be mindful of, however, are the additional nutrients

found in these outside substrates, as they will require proper management out the back end of

Centrifuge at Dairy Digest Happy

the digester. Farm Digester User

3.3 MERCHANT FACILITIES

A number of merchant digestion facilities have started up in recent years

that take in food scraps as their predominant feedstock. These are materials

that would usually otherwise have been landfilled or composted. Sending

this material first to AD gives it a chance to supply renewable energy, odor

reduction and waste stabilization on the way to further composting. Other

popular substrates to these merchant facilities include brown grease, food

industry processing residuals (i.e. dissolved air flotation float), and

wastewater treatment residuals. Large Urban Merchant Facility

3.4 INDUSTRIAL - HIGH STRENGTH WASTES

Many food and beverage industries commonly have an anaerobic treatment system in the back of their facility. For example,

most breweries have anaerobic digesters. Many big protein processors will incorporate large anaerobic lagoons into their

operations with long detention times to achieve breakdown of protein-laden wastes.

3.5 COMMERCIAL / INSTITUTIONAL

Large institutions such as universities, resorts and others can install their own anaerobic digestion systems. AD can help drive

these institutions to help meet their Climate Action plans and make them more carbon neutral and more sustainable. Often

several campus utility vehicles can be fueled by installing one's own digester and converting food scraps to vehicle fuel. These can

be great education opportunities for area students, are useful community showpieces and generate compost for local use. A

good sized institutional digester can routinely generate the equivalent of 100-200 gallons of liquid fuel equivalent to fuel on-site

vehicles.

Anaerobic Digestion & Biogas Page | 7

...A Better Way

4. DIGESTER TANK DESIGN

4.1 HEATING

Digesters need to be kept warm for proper bacteriological function. Heating

coils can be mounted inside the tank itself or placed within concrete tank

walls. External heat exchangers can also be used and can include a plate and

frame, spiral or shell-in-tube designs. Ideally excess heat is used from the

facilities' combined heat and power (CHP) unit to keep the tank warm, year

round. Direct steam injection is also done by injecting steam into a recycle

loop. For systems without CHP units or other sources of heat, a boiler system

may be required for ongoing heat. A heat source should be considered for

Heating Coils - Internal to Tank (w/mixer)

system startup.

4.2 MIXING

Good mixing is important for digesters to ensure proper stirring of the tank,

suspension of heavier solids and proper contact between the microbes and

the waste. Mixing time can vary from continuous to periodic to save on

power costs. Various configurations of mixers are widely adopted in digester

design and should be considered a major point of focus for the system's long

term reliability and mechanical integrity. Over-mixing can be an issue where

excess mixing intensity can de-stabilize the microbes and lead to process

upset. Some digester projects will incorporate a combination of the Top Mounted Roof Mixer

following mixing techniques in a given project.

4.2.1 MECHANICAL

Mechanical agitation can be done via a vertical shaft hanging from a fixed digester roof or by a side-mounted propeller style

mixers penetrating the tank wall. Submersible mechanical mixers can be mounted on rails connected to the interior tank wall

that allow for easy removal from the basin for maintenance. These mixers can be powered by a motor or by high pressure

hydraulics. Another style is a mechanical agitator mixer that is on a short shaft mounted inside the digester basin that spins

horizontally with paddles extended from the spinning shaft (as shown).

4.2.2 GAS MIXERS

Gas mixers compress digester biogas and reintroduce the gas back into the

tank bottom through long, gas lance pipes where large bubbles agitate tank

contents on their way back up to the tank surface.

4.2.3 JET MIXERS

Jet mixers operate by pulling sludge from tank contents and reintroducing

the sludge at a high speed back into the tank by use of a motive pump to

move the tank's contents, frequently spinning contents in a circular pattern

through several jets nozzles.

Horizontal Mixer

Anaerobic Digestion & Biogas Page | 8

...A Better Way

4.2.4 VERTICAL LINEAR MIXERS (VLM)

Vertical Linear Mixers operate by pushing and pulling reactor contents up

and down at a rapid frequency via a flat disk located deep inside the tank

held firm by a vertical shaft which is moved by a drive located at the top of

the tank. This offers the benefit of keeping all wear parts out of the digester

tank.

4.3 TANKS

Concrete is commonly used for digester tanks. Poured concrete can be

formed in a cylindrical tank shape or an egg tank shape using a network of

forms that shape the concrete and hold it in place for proper curing. Precast Precast Panels in Place to Form 26 ft. tall Digester Tank

concrete panels that are formed at an off-site factory can also be shipped by

truck to the project site where they are tipped up vertically and then tied together with a network of horizontal cable ties (see

picture). Concrete tanks will sometimes have a coating applied to the tank inner wall especially in the corrosive gas/water

interface zone to ensure long term durability.

Steel is also commonly used for digester tanks as well. Steel tanks can be erected either as bolted together panels or as welded

steel panels. Steel can either stainless steel or be coated with an epoxy paint system or with a glass-fused-to-steel coating.

Material selection is key so as to ensure long term durability and resistance to acid corrosion. Tanks are attached to the concrete

foundation by means of an embedded ring cast into the tank foundation. Access hatches are installed for access to the tank

interior.

Digester tanks are commonly insulated with either spray-on foam or rigid foam that is attached to the exterior tank surface.

Subsequent metal cladding, brick veneer, split block or other materials often attached to the foam's exterior for durability and

aesthetics.

4.4 CONVEYANCE (PUMPING)

Various types of pumps are successfully deployed at digester sites. Progressive cavity

pumps move very high solids streams using an internal impeller that looks like a

corkscrew and rotates in a way that pushes product along through process piping.

Piston style pumps move in a linear motion as an engine piston to convey very high

solids streams. Rotary lobe pumps utilize rubber or stainless steel lobes that spin in a

way that push against themselves and forces high solids material forward. Chopper

and grinder pumps are used in waste pits where significant trash and grit can

accumulate and can be tough to convey. Centrifugal pumps use a spinning impeller

to move material and are useful for liquid aqueous streams. Piping must be sized

large enough to prevent plugging.

Lobe Pump Used for Slurries

Anaerobic Digestion & Biogas Page | 9

...A Better Way

4.5 ROOFS & COVERS

4.5.1 FIXED & FLOATING

Many municipal digesters will commonly have a hard fastened roof on their

digesters with mixers hard mounted on the rooftop. Another common

digester roof, again found mostly in municipal settings is a metal roof

structure that floats on the digester contents and rides vertically on steel

guide members and roller mechanisms.

4.5.3 DUAL MEMBRANE

These covers have an outer membrane that spans the tank and is inflated by

a blower (see picture) and provides protection from severe weather and

odor containment. There is a separate, inner membrane that moves based Dual Membrane Cover at Merchant Site

on the quantity of biogas stored under the outer cover as shown in the

cutaway picture.

Cutaway Sketch of Complete Mix Digester showing layering of membrane covers

4.5.4 GAS BLADDER HOLDERS

A soft double membrane inflatable cover that is mounted at grade and holds

enough gas volume to buffer swings in demand (see picture). The outer

membrane is inflated by an air compressor while the inner layer holds the

biogas. Inner pressure settings can be adjusted to user’s gas pressure

Domed Gas Holder

requirements.

Anaerobic Digestion & Biogas Page | 10

...A Better Way

4.6 PROCESS CONTROL

A stable digester can bring years of steady performance. Unstable digesters, on the other hand, that have been overstressed can

lose their process biology and gas yield can suffer. Two common tests that an operator generally runs on the digester contents

are VFA (Volatile Fatty Acids) and Alkalinity. These tests are simple to run on the lab bench and the ratio of the two parameters to

each other show if the system is running in balance or is upset much like a person might experience as an upset stomach

reflecting too much digestive acids. Wastes that are deficient in alkalinity may require supplementation via the addition of lime

or caustic soda to buffer against the acids generated in the process.

4.7 PRETREATMENT

4.7.1 PASTEURIZATION

A mandatory feature for many digesters in Europe, pasteurization is only

now starting to take hold at some US facilities. Pasteurizers will commonly

heat batch volumes of feedstocks to roughly 70C for an hour to achieve virus

and pathogen kill. They commonly run as several parallel batch heating

tanks. In other places, pasteurization is accomplished at 50C for 24 hours.

Batch Pasteurizers in Parallel Operation

4.7.2 FOOD WASTE PROCESSING

Food waste commonly needs to be ground up into a liquid pulp before being fed to the digester to expedite the digestion

process. Grinding is commonly done in chopper pumps, macerators, hammermills, and hydropulpers. Each of these works like a

big blender. Grit can be controlled with hydrocyclones that spin grit out of suspension. Depackaging technology is used in settings

where damaged or expired packaged food is a feedstock and works by first slicing or breaking open the package, spinning out

product contents and rejecting the package material into a separate rejects bin. Post-consumer food waste (green bin) is

notorious for having contamination which often needs to be pulled out ahead of the digester

4.7.3 MUNICIPAL

Advanced pretreatment systems are gaining popularity that break open cells in waste sludges to assist in getting the AD process

started. Thermal hydrolysis and cell lysing systems that use microwaves, electrical currents, and mechanical shearing are

beginning to show value.

Anaerobic Digestion & Biogas Page | 11

...A Better Way

5. DIGESTATE MANAGEMENT

The resulting liquid from a digester contains dissolved organic matter,

fibrous material, and nutrients. Digester operations that have ample land

nearby that can apply this fertilizer seasonally to crop lands that are looking

for nutrients. Fertilizers derived from AD system can provide results that are

equal to or better than comparable synthetic fertilizers. The form of

nutrients in digestate is readily plant available. Nitrogen is present as mostly

dissolved ammonia, phosphorous as phosphate and potassium in the ionic

form. Furthermore, the fertilizers add hums and microbes to the soils

improving plant productivity. Screw Press at Dairy

Many farm based digesters have sizable storage volume to hold this nutrient

rich liquid until their crops call for fertilizer. Digestate can be further

processed as outlined below based on particular site needs.

5.1 DEWATERING

Liquid digestate commonly leaves a digester with roughly 2-10% Total Solids and thus

90-98%% water. Common devices used to squeeze the water out of these solids are

screw presses, belt presses and centrifuges. Screw presses press the solids laden feed

liquid against a firm plate which squeezes the liquid out from the digestate. Belt presses

utilize permeable belts that sandwich the solids between rollers that squeeze the water

from the solids. Centrifuges have a spinning bowl at the heart of the process which,

through centrifugal action builds a sludge cake on the inner surface of the bowl as

material flows through with relatively clean water emerging at the outlet. These

technologies generate a solid digestate material that is about 15-30% solids and 70%-

85% water. Fiber and cellulose in the incoming feed can help make for a better quality

solid digestate product out the back end. An operating cost to be mindful of is polymer

chemicals that are deployed as dewatering aids.

Centrifuge at Dairy Digest Happy Farm

An analysis from a Midwestern US food waste digester showed raw liquid digestate Digester User

constituents of 6.8% total solids, 7.1% Ammonia nitrogen, 0.8% total phosphorous, 0.8%

total potassium, as an example.

5.2 DRYING & PELLETIZING

For those applications, looking for a very dry solid product a thermal drying

step can be used. Systems like paddle dryers, direct fired dryers or infrared

dryers can generate a solid fertilizer of greater than 95% solid matter.

Pelletizers add an additional amount of solid particle recovery control

generating a hard, nutrient dense, dry fertilizer. Ideally, there would be

enough waste heat at the site to drive the dryers and avoid purchased gas

for drying purposes.

Solid Digestate

Anaerobic Digestion & Biogas Page | 12

...A Better Way

5.3 MANAGEMENT OF LIQUID FRACTION

The liquid fraction of dewatered digestate presents both opportunities and challenges. The ideal scenario is for liquid digestates

to be simply land applied. In those instances where logistics prevent direct land application, other options need to be evaluated

such as discharge to the local sewer (POTW) or to treat the water to stream discharge limits. Digestates can have nitrogen and

phosphorous levels that are considered elevated for discharge. Technologies for addressing elevated nutrients in liquid fraction

of digestates include:

5.3.1 ANAMMOX

A biological process that converts dissolved ammonia to nitrogen gas utilizing a specialized bacteria. Most applicable where

nitrogen levels are over 500 mg/l. Achieves about 85% efficiency.

5.3.2 MEMBRANE FILTRATION

Common membrane filters include ultrafiltration which removes suspended solids and longer molecules and reverse osmosis

which filters out virtually all molecules and ions from solution and allows only water to pass through. All membrane filters have a

reject stream that requires management, has significant electrical demand to drive the high pressure pumps and periodic

membrane cleaning and replacement. Membrane bioreactors (MBR) can be deployed to biologically treat the nutrients.

5.3.3 EVAPORATION

Using excess facility heat to drive an evaporator can be an effective way to reduce the volume of digestate and concentrate the

nutrients. Common evaporator types include scraped surface designs where a mechanical scraper is used to keep material from

caking onto the hot surfaces.

5.3.4 AIR STRIPPING

Ammonia can be stripped out of solution using stripping technology as it is often easily volatilized depending on its ionic state.

This is deployed usually in a tall, packed-tower design. Increasing pH of the digestate, warming the water and pulling a vacuum

on the water all enhance the system efficiency. Commonly stripped gasses will be scrubbed with a chemical such as sulfuric acid

so as to make a beneficial precipitate like ammonium sulfate fertilizer.

5.4.5 STRUVITE PRECIPITATION

Excess phosphorous in combination with magnesium and ammonium in the

digestate can precipitate with high efficiency. A molecular matrix molecule

known as struvite forms in the presence of a 1:1:1 ratio of magnesium,

nitrogen and phosphorous in the liquid. Struvite crystals can be stored,

bagged and shipped to users in need of the phosphorous. Struvite can pose

operational issues if allowed to build up in digester piping in an uncontrolled

fashion.

Struvite Fertilizer from Digestate

5.4 MANAGEMENT OF FINAL COMPOST

For some uses, solid digestate can be stable enough for immediate use. In other instances, the material is still biologically active

and can benefit from additional composting or curing. Solid digestate compost can have beneficial plant fertilizer properties as it

is loaded with organic matter and high quality nutrients.

Anaerobic Digestion & Biogas Page | 13

...A Better Way

6. GAS UPGRADING & HANDLING

6.1 HYDROGEN SULFIDE H2S

Hydrogen sulfide is found in all biogas streams to a varying degree based on the type of

feedstocks. Depending on the application, H2S levels can range from under 100 ppm to over

several thousand ppm. Due to its corrosive and odorous properties, removing the H2S is

generally a requirement. Additionally, chemicals based on iron salt chemistry, such as Ferric

(or ferrous) Chloride, ferric hydroxide or iron oxide can be added to digesters where the iron

will stabilize (oxidize) the sulfur in the sludge.

Alternatively, Iron Sponge filters use an iron based media, often iron impregnated wood

chips, that oxidizes the iron to a type of rust particle and requires periodic chemical

regeneration (see picture). Biological treatment scrubbers utilize a specialized aerobic

bacteria (Thiobacillus) that is applied in an upflow packed tower configuration (see picture).

The biology reacts with the sulfur in the biogas to form low pH sulfuric acid which can add

beneficial sulfur to final digestate upon blending. Biological H2S Scrubber

Water wash systems utilize a high pressure water scrubbing concept which

will dissolves the H2S into the liquid stream. There are also processes that

use proprietary iron oxide granular media or activated carbon media as an

adsorbent that are effective at removing H2S. An additional approach is to

manage the H2S inside the digester. As shown in the photograph below this

digester has wooden beams in the gas head space that exhibit properties

favorable to the growth of a bacteria that will oxidize the H2S right in the

reactor. Oxidized sulfur will periodically fall back down into the tank

contents. Other suppliers will furnish a fabric netting in the gas head space

that achieves a similar result. A small percentage of oxygen is sometimes

Iron Sponge Filters

injected in the digester head space to oxidize H2S but must be controlled to

<1% oxygen levels for safety purposes.

Concrete Digester tank showing Wood Planks for Desulfurization, Epoxy Paint for Corrosion Resistance, Center Pier Structure and Submersible Mixers

Anaerobic Digestion & Biogas Page | 14

...A Better Way

6.2 SILOXANES

Siloxanes are a class of compounds used in cosmetics and other personal

care products. They often find their way into digesters and biogas at

municipal WWTP and landfill settings. Proper removal by carbon filtration or

specialized adsorbents is critical to avoid formation of silica scale on hot

surfaces in downstream energy generation (see picture). Once formed, this

silica scale can be extremely difficult to remove. Fine silica can cause

premature wear and erosion of turbine or engine components leading to

failure.

6.3 HUMIDITY Siloxane Filters

Digester gas is saturated with water vapor. This can cause rusting and

corrosion in gas piping and create problems with downstream combustion equipment. As the gas cools, its vapor forms liquid

condensate which can pool in low spots and can plug improperly designed piping. Creating condensate either via refrigeration,

desiccant drying or through a series of knock-out pots can bring the dew point of the gas down to manageable levels. Condensate

management through properly designed piping and dehumidification will prevent a number of possible operational problems.

Furthermore, gas piping needs to accommodate and remove possible digester foam that can occur during process upsets. Simply

running biogas piping underground in northern climates can be very effective at knocking out moisture.

6.4 CO2

Biogas commonly has 30-50% CO2. Some downstream applications such as vehicle fuel or gas pipeline injection require reducing

that concentration to <2% CO2. There is a wide variety of commonly deployed approaches to this objective.

6.4.1 MEMBRANES

In a membrane filter system, pretreated gas is compressed and fed into a network of

fibers that are about the width of a human hair and packed into a vessel with many

thousands of such strands. Due to their ionic properties, methane molecules are rejected

by the membrane and the CO2 filters through the membrane. This allows for both a

purified CO2 and purified methane stream to be produced.

6.4.2 AMINES

These scrubbers incorporate a chemical reaction between the CO2 and a class of nitrogen

based compounds called amines to cleanse the gas. During the process, the amine

reaction first selectively scrubs out the CO2 and shortly thereafter the process is reversed

and the CO2 is vented and the liquid amine chemicals are reused.

Amine Scrubber

Anaerobic Digestion & Biogas Page | 15

...A Better Way

6.4.3 WATER WASH

Water Wash technology incorporates chemical concepts commonly found in making carbonated

soft drinks. CO2 does not dissolve well in water at ambient pressures but will dissolve in water at an

elevated pressure. Just as CO2 degasses out of a carbonated soft drink after the pressure is released

by opening the package the same happens in a water wash scrubber where biogas is scrubbed in a

pressurized water spray and later released from solution after subsequent depressurization.

6.4.4 PSA

Pressure Swing Adsorption technology extracts CO2

from biogas using a special adsorbent media and

allows methane to pass through. Much like a

charcoal filter, PSA systems operate several vessels

in parallel where at any given time one will be Water Wash System

filtering the gas and the others will be regeneration

done by backpulsing the beds with air to strip out the

adsorbed CO2. End purity of 98%+ methane is

700 CFM PSA Unit on Digester Gas

commonly achievable.

Anaerobic Digestion & Biogas Page | 16

...A Better Way

7. GAS USE

7.1 CHP

Combined heat and power (CHP) is the most prevalent means of utilizing

biogas. These units use engines similar to those used in cars and trucks

where pistons pressurize the gas, combust it and turn a shaft which, in turn,

spins a generator. A hard-shell jacket surrounds the exterior of the engine

that uses a heat transfer fluid like water or glycol to capture the heat that

comes from the combustion happening in the engine. Depending on the

quality of the gas, regular oil changes are a regular, significant, maintenance

expense. A rule of thumb is that about 100 cubic feet per minute of biogas

can drive a 300-Kilowatt engine which is enough power for about 300 homes

500 KW CHP Engine

(reference - Operating data from Gloversville Johnston, NY). Connecting the

electricity to the electrical grid can help local utilities meet their Renewable Portfolio Standards (RPS). The connection from

digester to power grid can sometimes be a complex process, as Utilities tend to closely scrutinize projects that provide power

onto their grid for ensuring grid integrity.

7.2 OTHER - MICROTURBINES & FUEL CELLS

These units require a higher feed pressure and higher feed gas quality than CHP engines but can provide decades of reliable

service and very high conversion efficiency.

7.3 VEHICLE FUEL

Once the gas has been upgraded and the CO2 removed, it is ready to be

compressed and used in vehicles. Compressed Natural Gas (CNG) is routinely

compressed to 2500 psi in high pressure cylinders to store the gas.

Compressing the gas reduces the volume by a factor of 200 vs atmospheric

gas. Upgraded biogas has about 950 Btu of energy in every cubic foot of gas.

Diesel fuel, on the other hand has about 140,000 Btu in a gallon. Gas units

are commonly referred to in units of GGE or Gallons of Gas Equivalent for

vehicle fuel projects. For example, the energy in 1000 cubic feet of upgraded

biogas equals about 7.2 Gallon of Gas Equivalent (GGE) as each of these

units has about 1 Million Btu's of energy. The illustration below compares High Pressure Bio CNG Trailer for Vehicle Fueling

how the equivalent amount of energy varies by volume in different gas

forms and pressures.

Anaerobic Digestion & Biogas Page | 17

...A Better Way

Biogas used in vehicle fuels can be considered an "Advanced Biofuel" as spelled out in the Renewable Fuel Standard (RFS2). This

is monetized by selling credits that are tracked by Renewable Identification Numbers (RIN). Biogas is considered the lowest

carbon intensity fuel and can qualify for California's Low Carbon Fuel Standard.

7.4 DIRECT CONNECTION TO GAS GRID

Upgraded biogas can also be injected into the natural gas utility grid as long

as local regulations allow and the grid is in close enough in geographical

proximity. Currently there are no national standards for upgraded

biomethane, so target gas quality and injection pressure is a locally driven

issue dependent on pipeline operator. Common specifications to connect

to the grid will be Methane, Oxygen, Nitrogen, CO2 levels and dew point.

An interconnect agreement has to be secured with the local pipeline in

order to connect to the grid. Once the facility is connected to the grid, the

gas can be sold to any user that uses natural gas from the grid.

7.5 GAS SAFETY

Gas safety equipment must allow a digester to vent gas should system

pressure elevate. Vented gas should be sent to a flare. Pressure relief valves

must be properly designed, insulated and heated to ensure proper year Gas Safety Device

round operation. Burst discs, foam traps and flame arrestors round out the

safety equipment needed.

Anaerobic Digestion & Biogas Page | 18

...A Better Way

8. PROJECT DEVELOPMENT AND FINANCE

Securing financing for a digester project can be challenging and takes significant time and effort. Each project progresses based

on its individual merits of owner's personal or corporate equity position, credit record, management resume and the projected

financial payback for investors. Often grants such as the USDA REAP grant, and other Federal and State grants are an integral part

of the financial backbone of a project. AD projects can also obtain a number of tax credits that can be of great value to businesses

that have tax burdens. AD projects can involve a complex web of securing the site, site permits, feedstock input agreements,

Power Purchase Agreements (PPA), off take agreements for fertilizer byproducts, equity financing, debt financing, construction

period financing, selection of the operations and maintenance crew and grant funding. The number of moving parts to a

successful AD project deal going forward can be daunting but generally makes for a great story when all the parts fall into place.

Public Private Partnerships (P3) are gaining in popularity whereby private companies can bring financing to project at municipal

settings in exchange for a long term partnership.

9. DIGESTER CONSTRUCTION METHODOLOGY

There are a wide number of ways to contract to build a digester project. Some projects will follow an EPC path

(Engineer/Procure/Construct). In the EPC case the owner deals with one single entity for all issues pertaining to system design,

process performance and construction. An EPC provider will often bring in a digester process provider onto their team for a

system performance guarantee. Early stage project geotechnical report and soil borings are required to understand site

constructability. Some urban sites require environmental site assessments in case of previous site contamination.

Some owners will chose to split projects into multiple contracts where they will contract separately for system design, permitting,

construction and the process and power generation equipment. This can put a heavier management responsibility on the owner

but can allow for some additional financial transparency, flexibility and hardware choices. This can provide additional

transparency and flexibility at the 30% design stage when system design and costing gets tightened up. A Basis of Design (BOD)

report is a common early stage deliverable that includes general arrangement drawings, process flow diagrams, equipment lists,

electrical one-line diagrams and process & instrumentation diagrams (P&IDs). At all times local building and construction codes

need to be understood and adhered to.

Each of these models provides their own level of flexibility and accountability for all participants involved. Some key points

involve payment considerations assumption of process performance risk, schedule risk, site condition risk, power output risk and

construction risks.

Anaerobic Digestion & Biogas Page | 19

...A Better Way

10. FACILITY INSTALLATIONS

Anaerobic Digestion & Biogas Page | 20

...A Better Way

Complete Mix Digester Tank Showing Freestanding Mixers, Wooden Desulfurizers and Center Pier Column

CSTR Complete Mix Digester, Inflatable Gas Storage and

Containerized CHP Units Submersible Mixers on a Freestanding Support Structure

Submersible Mixer on Support

Side Mounted Digester Mixer and Tank View Port Pole

Digester with Center Pole Cover Support Gas Storage Dome Showing Inflation Hose

Anaerobic Digestion & Biogas Page | 21

...A Better Way

11. US PROJECT EXAMPLES

Reduces byproduct management costs by over 60% through

cutting waste trucking and municipal surcharges. Reduces

odors; truck traffic; BOD and phosphorus loading to the

municipal treatment facility. Generates one-third of the

brewery’s electrical demand while nestled in a residential

neighborhood. Digests spent grains and wastewater.

Magic Hat Brewery in S. Burlington, VT

Fed by manure from 1500 cows. Community digester sends

heat and electricity to nearby prison and senior housing

development. 633KW electrical generation capacity. Hydraulic

Digester Technology. Biodesulfurization

$9.7 M total installed cost

Cayuga County, NY Soil and Water Conservation District

Co-Digests imported food waste and dairy cow manure from

1200 Head Dairy. Makes 1.4 MW of electricity. $7.7 M total

Capex. Includes Pasteurization

Synergy Digester -- Wyoming County, NY

Co-Digests imported food waste and dairy cow manure from

1500 milking cows. Generates 541 KW of electricity. $5M total

installed costs

Lawnhurst Dairy - Stanley, NY

Anaerobic Digestion & Biogas Page | 22

...A Better Way

Receives liquid industrial and municipal residual wastes from

local community and generates 1.6 MW power. $12M total

installed cost. Capacity – 60,000 – 75,000 wet tons per year of

wastewater treatment plant residuals (biosolids), Food

Processing Wastes, Urban GTW/FOG. Pasteurization for

achieving digestate/biosolids “unrestricted use” designation

under EPA 503 Class A biosolids. Start-up – Dec 2012

GenEarth – Berkeley County, SC (Charleston area)

Receives preconsumer food waste, grasses. 1.6 MW of

electricity. 30,000 tons per year. Entec Technology – Wet

Digester CSTR. Design, build, own, operate, and maintain. 100

tons per day or about 30,000 TPY of commercial organics (post

consumer food waste), fats/oils/greases, and some agriculture

residues (manure and straw).

JC Biomethane - Junction City OR

Cow manure from two large dairy farms conveyed by pipeline.

Community digester. $8M installed cost. Three large, complete

mix digester tanks.

Clear Horizons - Dane County, WI

Four fermentation vessels (70 ft. x 23 ft. x 17 ft. High), Runs as a

"dry" batch process that lasts one month for each cycle. Treats

8000 tons per year of food waste, yard wastes and crop wastes.

Biogas fires a 350 KW electrical generator

University of WI - Osh Kosh

Anaerobic Digestion & Biogas Page | 23

...A Better Way

Processes 40,000 tons per year of mixed food and yard waste from the

Metro Vancouver region (population 2.5 million). The batch two-stage high

solids anaerobic digester produces 2.2 MW combined heat-and-power and

15,000 metric tons of high quality compost hat is returned to local farms and

landscapes. Virtual tour at harvestpower.com/energygarden

Harvest Energy Garden - Richmond, BC

Co-digests 120,000 tons per year of commercial food waste and biosolids

from local theme parks and businesses. The facility produces 6 MW

combined heat and power -- enough to power 2,000 Floridian homes -- and

3,200 metric tons per year of granular fertilizer for application on local

agriculture.

Harvest Energy Garden - Orlando, FL

Uses low-solids anaerobic digestion to process 70,000 tons per year of

commercial food waste, producing 5.6 MW combined heat and power and

5,200 metric tons of granular fertilizer each year.

Harvest Energy Garden - London ON

PSA unit from Guild. 385 cubic feet per minute free rate. Generates pipeline

quality gas of 98% methane.

Biogas Upgrading System at GA Lagoon Based Digester

Anaerobic Digestion & Biogas Page | 24

...A Better Way

SAMPLE LIST OF SIGNIFICANT MERCHANT FOOD WASTE DIGESTERS IN THE US

Feed Power

Name / Developer Location

(wet tpy) (KW)/ GGE

Harvest Power Orlando, FL 120,000 3.2 MW

Novi Energy Freemont, MI 100,000 3 MW

FCPC Renewable Gen Milwaukee, WI 100,000 2 MW

Zero Waste

San Jose, CA 90,000 1.6 MW

(dry system)

GenEarth Sumter, SC 70,000 1.6 MW

quasar Columbus OH 43,000 1.3 MW

JC Biomethane Eugene, OR 30,000 1.6 MW

Clean World Partners/ U C

Sacramento, CA 20,000 450 GGE vehicle fuel

Davis

Anaerobic Digestion & Biogas Page | 25

...A Better Way

12. APPENDIX

TERMINOLOGY:

CSTR Completely Stirred Tank Reactor. Also known as a "wet" style digester

Feedstocks Any material including organics mixed wastes that are fed into a digester

Offtaker An entity that is buying fuels or fertilizer byproducts from a digestion facility.

Post-Consumer Waste Material collected from food plates from restaurants or cafeterias or home kitchen preparation

Preconsumer Waste Waste from food factories, grocery retailers

SSO Source Separated Organics - The system by which organic waste generators such as homes and

businesses segregate organic materials from other waste streams at the point of collection.

Substrates Term used interchangeably with "Feedstock"

Volatile Solids The fraction of the feed solids that is readily convertible to biogas. The opposite is the nonvolatile or

ash fraction.

FREE ANAEROBIC DIGESTION BIOGAS MODELS:

Anaerobic Digestion CREST Model

Biowatts

Energy 4 Farms

Additional Resources:

EPA Agstar

BioCycle Magazine

American Biogas Council

Digester.com - Industry blog & podcast

Anaerobic Digestion & Biogas Page | 26

...A Better Way

ABOUT THE AUTHOR

Paul Greene is a Vice President with Natural Systems Utilities a project development company dedicated to building anaerobic

digestion infrastructure and Founding member of the American Biogas Council (ABC). NSU features its Community CoDigestion

Service Offering that builds, owns operates and finances AD facilities in community settings. He is a former Chairman of the ABC.

He can be reached at 518-951-5766 and pgreene@naturalsystemsutilities.com.

ACKNOWLEDGEMENTS

Amber Blythe BioFerm Energy Systems

Blake Sturke Turning Earth, LLC

Derek Hundert, Vicki Elliott PlanET Biogas Solutions

Earl Brubacher Bio-En Systems

Eric Fitch Purpose Energy

George Bevington Gloversville Johnstown Joint Water Treatment Facility

Meredith Sorensen Harvest Power

Michael Mataritan Guild Associates, Inc.

Patrick Johnson Sattler

Sara Martin O'Brien & Gere

Sherry Heinly KSB Mixing

Surya Pidaparti Novus Energy

Tom Lawson Envitec Biogas

Any suggestions on contents can be forwarded to pgreene@naturalsystemsutilities.com.

Anaerobic Digestion & Biogas Page | 27

S-ar putea să vă placă și

- Lignocellulosic Biomass to Value-Added Products: Fundamental Strategies and Technological AdvancementsDe la EverandLignocellulosic Biomass to Value-Added Products: Fundamental Strategies and Technological AdvancementsÎncă nu există evaluări

- Conceptual Design Report DigesterDocument177 paginiConceptual Design Report DigesterRK Ramarack100% (1)

- Biomass Conversion Technology: Principles and PracticeDe la EverandBiomass Conversion Technology: Principles and PracticeÎncă nu există evaluări

- Biomass BoilerDocument4 paginiBiomass BoilerSuppachai DanpreechakulÎncă nu există evaluări

- Biogas Generation A Study: By: Madhav Mohan Bsc. Physics (Hons.) Ii Year Roll Number: 1815052Document17 paginiBiogas Generation A Study: By: Madhav Mohan Bsc. Physics (Hons.) Ii Year Roll Number: 1815052Madhav Mohan100% (1)

- Extraction of Methane From Biogas - FinalDocument23 paginiExtraction of Methane From Biogas - FinaldhanushÎncă nu există evaluări

- Biogas TecDocument131 paginiBiogas TecHabimana Fabien100% (1)

- Evaluation of Biochar Production Systems: ERG 211 - Renewable Energy and Green Technology Experiment Cycle IiDocument11 paginiEvaluation of Biochar Production Systems: ERG 211 - Renewable Energy and Green Technology Experiment Cycle IiDr. Kiruthika RajamanickamÎncă nu există evaluări

- A Review of Biogas Utilisation, Purification and Upgrading TechnologiesDocument17 paginiA Review of Biogas Utilisation, Purification and Upgrading TechnologiesXavier OrtizÎncă nu există evaluări

- Biogas Calculation Guide v3.0 - )Document98 paginiBiogas Calculation Guide v3.0 - )swordprakashÎncă nu există evaluări

- Publications - Design Biogas PlantDocument12 paginiPublications - Design Biogas Planttssa100% (15)

- Types of Biogas PlantDocument72 paginiTypes of Biogas PlantParth PatelÎncă nu există evaluări

- Biomass - Power PlantDocument16 paginiBiomass - Power PlantVinay MishraÎncă nu există evaluări

- Bio-Fuel: BY: K. Pramod E11-0031Document29 paginiBio-Fuel: BY: K. Pramod E11-0031Nurul HudaÎncă nu există evaluări

- Biogas PlantDocument8 paginiBiogas PlantAman BansalÎncă nu există evaluări

- Danish Centralised Biogas PlantsDocument28 paginiDanish Centralised Biogas PlantsXazolÎncă nu există evaluări

- HHV and LHVDocument2 paginiHHV and LHVYuji OhkusuÎncă nu există evaluări

- Optimization of Biogas Generation From Press Mud in Batch ReactorDocument6 paginiOptimization of Biogas Generation From Press Mud in Batch Reactorscm996Încă nu există evaluări

- The Status of Biomass Gasification in Thailand and CambodiaDocument103 paginiThe Status of Biomass Gasification in Thailand and CambodiacjoyeuxÎncă nu există evaluări

- Techno Commercial Aspects of bio-CNG From 100 TPD Press Mud PlantDocument12 paginiTechno Commercial Aspects of bio-CNG From 100 TPD Press Mud Plantpriyank sharmaÎncă nu există evaluări

- 4601423133391success Story of Biomethanation Projects-Dr - Bharat B NagarDocument16 pagini4601423133391success Story of Biomethanation Projects-Dr - Bharat B Nagarpuja MangalÎncă nu există evaluări

- Article From Coal To Biomass at MN PowerDocument3 paginiArticle From Coal To Biomass at MN PowerCory LukerÎncă nu există evaluări

- Pyrolysis 2014017017 ChelseaDocument24 paginiPyrolysis 2014017017 ChelseaerkiruthirajÎncă nu există evaluări

- Life Cycle Assessment of Biochar As A Partial Replacement To Portland CementDocument6 paginiLife Cycle Assessment of Biochar As A Partial Replacement To Portland CementStephen John ClementeÎncă nu există evaluări

- Biomass Torrefaction As A Preprocessing Step For Thermal Conversion - EvergreenDocument4 paginiBiomass Torrefaction As A Preprocessing Step For Thermal Conversion - EvergreenFernando TaleroÎncă nu există evaluări

- Sector Handbook BiogasDocument39 paginiSector Handbook BiogasMann HumanÎncă nu există evaluări

- Biomass For H&P - Lecture 2-2006Document51 paginiBiomass For H&P - Lecture 2-2006Leonardo Nanjar100% (1)

- Biogas Plant Sizes and DimensionsDocument7 paginiBiogas Plant Sizes and DimensionsSuhailShaikhÎncă nu există evaluări

- Biogas Calculator TemplateDocument27 paginiBiogas Calculator TemplateAlex Julian-CooperÎncă nu există evaluări

- Design, Construction and Maintenance of A Biogas GeneratorDocument23 paginiDesign, Construction and Maintenance of A Biogas GeneratorOxfamÎncă nu există evaluări

- Simultaneous Removal of CO2 and H2S From Biogas by Blending Amine AbsorbentsDocument9 paginiSimultaneous Removal of CO2 and H2S From Biogas by Blending Amine Absorbentshalla kerkacheÎncă nu există evaluări

- 1.0 Project Background: WWW - Gam-Rd - Co.inDocument17 pagini1.0 Project Background: WWW - Gam-Rd - Co.inljsflj alsfjoiÎncă nu există evaluări

- Biogas Upgrading AND Utilisation: IEA BioenergyDocument20 paginiBiogas Upgrading AND Utilisation: IEA BioenergyilariofabbianÎncă nu există evaluări

- Mass Balance For Biomass and Biogas Production From Organic WasteDocument14 paginiMass Balance For Biomass and Biogas Production From Organic WastedavidchemwenoÎncă nu există evaluări

- ICED OJK Overview of Biogas Power 160926 BK FinDocument57 paginiICED OJK Overview of Biogas Power 160926 BK FinDigdo Setyaji100% (1)

- Biogas Generator Design Construction and MaintenanceDocument23 paginiBiogas Generator Design Construction and MaintenanceCoevicÎncă nu există evaluări

- Biogas Yields TableDocument3 paginiBiogas Yields Tablesilenite13Încă nu există evaluări

- Bio Ethanol DBGDocument30 paginiBio Ethanol DBGGhulam RabbaniÎncă nu există evaluări

- Waste To EnergyDocument9 paginiWaste To Energyherb089Încă nu există evaluări

- Thesis Report FullDocument104 paginiThesis Report FullStory SungÎncă nu există evaluări

- Aerobic and Anaerobic Sludge DigestionDocument32 paginiAerobic and Anaerobic Sludge DigestionDiana Isis Velasco0% (1)

- Guide Lt2 UvguidanceDocument436 paginiGuide Lt2 Uvguidanceezygadlo6492Încă nu există evaluări

- Biomass Power Plants Final2Document34 paginiBiomass Power Plants Final2Abdulhadi EliasÎncă nu există evaluări

- Waste To EnergyDocument37 paginiWaste To EnergyCheng PasionÎncă nu există evaluări

- Wood Pyrolysis To Biochar: Submitted To: Engineering Physics Review Board Submitted By: Chris AlkireDocument20 paginiWood Pyrolysis To Biochar: Submitted To: Engineering Physics Review Board Submitted By: Chris AlkireMyriah WilsonÎncă nu există evaluări

- Biogas Consultants ContractorsDocument8 paginiBiogas Consultants ContractorsuemaaplÎncă nu există evaluări

- Biogas PurificationDocument5 paginiBiogas PurificationHarsh GutgutiaÎncă nu există evaluări

- Biogas Calculation From CodDocument41 paginiBiogas Calculation From CodReuben Malambugi100% (1)

- Anaerobic Digestion ModellingDocument73 paginiAnaerobic Digestion ModellingKentner Chavez CorreaÎncă nu există evaluări

- On Biogas Enrichment and Bottling Technology - IITD - IndiaDocument38 paginiOn Biogas Enrichment and Bottling Technology - IITD - Indiaअश्विनी सोनी100% (3)

- Gas Demand Forecasting Methodology 1Document55 paginiGas Demand Forecasting Methodology 1scribduserkrisÎncă nu există evaluări

- Solar Dryer Presentation For Franklin BOMADocument23 paginiSolar Dryer Presentation For Franklin BOMAUSA TODAY NetworkÎncă nu există evaluări

- Thermal Pyrolysis of Polypropylene Plastic Waste IDocument7 paginiThermal Pyrolysis of Polypropylene Plastic Waste IDiego CamachoÎncă nu există evaluări

- Charcoal PDFDocument294 paginiCharcoal PDFCapata OvidiuÎncă nu există evaluări

- Detailed Project Report For Biogas Power PlantDocument132 paginiDetailed Project Report For Biogas Power PlantShubham Jain100% (2)

- Small-Scale Biogas UpgradingDocument26 paginiSmall-Scale Biogas UpgradingDavid SaldarriagaÎncă nu există evaluări

- Biogas Processes For Sustainable DevelopmentDocument246 paginiBiogas Processes For Sustainable DevelopmentQuarterbore100% (4)

- Operation & Maintenance Guideline For Bio-Digesters: 6 Economics 11Document13 paginiOperation & Maintenance Guideline For Bio-Digesters: 6 Economics 11myco samÎncă nu există evaluări

- Bolt Action Italian Painting GuideDocument7 paginiBolt Action Italian Painting GuideTirmcdhol100% (2)

- Lecture5 PDE 2016Document22 paginiLecture5 PDE 2016isele1977Încă nu există evaluări

- Resumen C37 010 Aplicacion de Breaker Disenados IC Simetrica PDFDocument9 paginiResumen C37 010 Aplicacion de Breaker Disenados IC Simetrica PDFglendathais100% (1)

- Dell W2306C LCD Monitor Service ManualDocument104 paginiDell W2306C LCD Monitor Service ManualIsrael B ChavezÎncă nu există evaluări

- Banachek UnlimitedDocument34 paginiBanachek UnlimitedserenaÎncă nu există evaluări

- PEDocument12 paginiPEMae Ann Base RicafortÎncă nu există evaluări

- Uji Efektivitas Mikroba Rumpun BambuDocument7 paginiUji Efektivitas Mikroba Rumpun BambuUse Real ProjectÎncă nu există evaluări

- Properties of Matter ReviewDocument8 paginiProperties of Matter Reviewapi-290100812Încă nu există evaluări

- Pineapple in JohorDocument6 paginiPineapple in JohorHaiqal AzizÎncă nu există evaluări

- Electrical Design Project (Three Bedroom House)Document13 paginiElectrical Design Project (Three Bedroom House)Sufi Shah Hamid Jalali100% (2)

- Propert 447-445Document11 paginiPropert 447-445LUNA100% (1)

- Angewandte: ChemieDocument13 paginiAngewandte: ChemiemilicaÎncă nu există evaluări

- Dizziness - Vertigo and HomoeopathyDocument38 paginiDizziness - Vertigo and HomoeopathyDr. Rajneesh Kumar Sharma MD HomÎncă nu există evaluări

- Arts6,4, Week2, Module 2V4Document24 paginiArts6,4, Week2, Module 2V4Loreen Pearl MarlaÎncă nu există evaluări

- BS746 2014Document22 paginiBS746 2014marco SimonelliÎncă nu există evaluări

- Generalized Anxiety DisorderDocument24 paginiGeneralized Anxiety DisorderEula Angelica OcoÎncă nu există evaluări

- ODA X9 2SL DatasheetDocument8 paginiODA X9 2SL DatasheetYudy UtamaÎncă nu există evaluări

- Raspberry Pi 3 and BeagleBone Black For Engineers - UpSkill Learning 124Document124 paginiRaspberry Pi 3 and BeagleBone Black For Engineers - UpSkill Learning 124Dragan IvanovÎncă nu există evaluări

- Navy Supplement To The DOD Dictionary of Military and Associated Terms, 2011Document405 paginiNavy Supplement To The DOD Dictionary of Military and Associated Terms, 2011bateljupko100% (1)

- Relationships, 365 Day Devotional Mylesunroe 377pgDocument377 paginiRelationships, 365 Day Devotional Mylesunroe 377pgEla100% (7)

- Single Door Feeder Pillar 200A MCCBDocument1 paginăSingle Door Feeder Pillar 200A MCCBMiqdad AliÎncă nu există evaluări

- Vehicle Intercom Systems (VIS)Document4 paginiVehicle Intercom Systems (VIS)bbeisslerÎncă nu există evaluări

- RhythmDocument10 paginiRhythmSalcedo NoelÎncă nu există evaluări

- Furuno CA 400Document345 paginiFuruno CA 400Димон100% (3)

- Michelle LeBaron, Venashri - Pillay) Conflict AcrosDocument241 paginiMichelle LeBaron, Venashri - Pillay) Conflict AcrosBader100% (2)

- Cell Wall Synthesis InhibitorsDocument6 paginiCell Wall Synthesis InhibitorsRPh Krishna Chandra JagritÎncă nu există evaluări

- Electrical Power System Device Function NumberDocument2 paginiElectrical Power System Device Function Numberdan_teegardenÎncă nu există evaluări

- DCS YokogawaDocument17 paginiDCS Yokogawasswahyudi100% (1)

- Engineering Structures: C.X. Dong, A.K.H. Kwan, J.C.M. HoDocument14 paginiEngineering Structures: C.X. Dong, A.K.H. Kwan, J.C.M. HoElieser SinagaÎncă nu există evaluări

- Book BindingDocument14 paginiBook Bindingpesticu100% (2)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesDe la EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesEvaluare: 4.5 din 5 stele4.5/5 (21)

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsDe la EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsEvaluare: 4.5 din 5 stele4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressDe la EverandNuclear Energy in the 21st Century: World Nuclear University PressEvaluare: 4.5 din 5 stele4.5/5 (3)

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionEvaluare: 5 din 5 stele5/5 (1)

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceDe la EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceÎncă nu există evaluări

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe la EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterÎncă nu există evaluări

- Shorting the Grid: The Hidden Fragility of Our Electric GridDe la EverandShorting the Grid: The Hidden Fragility of Our Electric GridEvaluare: 4.5 din 5 stele4.5/5 (2)

- Renewable Energy: A Very Short IntroductionDe la EverandRenewable Energy: A Very Short IntroductionEvaluare: 4.5 din 5 stele4.5/5 (12)

- A Pathway to Decarbonise the Shipping Sector by 2050De la EverandA Pathway to Decarbonise the Shipping Sector by 2050Încă nu există evaluări

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDe la EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialÎncă nu există evaluări

- Heat Transfer Engineering: Fundamentals and TechniquesDe la EverandHeat Transfer Engineering: Fundamentals and TechniquesEvaluare: 4 din 5 stele4/5 (1)

- Handbook on Battery Energy Storage SystemDe la EverandHandbook on Battery Energy Storage SystemEvaluare: 4.5 din 5 stele4.5/5 (2)

- Photovoltaic Solar Energy: From Fundamentals to ApplicationsDe la EverandPhotovoltaic Solar Energy: From Fundamentals to ApplicationsÎncă nu există evaluări

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsDe la EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsÎncă nu există evaluări

- Power Electronics Diploma Interview Q&A: Career GuideDe la EverandPower Electronics Diploma Interview Q&A: Career GuideÎncă nu există evaluări

- Practical Reservoir Engineering and CharacterizationDe la EverandPractical Reservoir Engineering and CharacterizationEvaluare: 4.5 din 5 stele4.5/5 (3)

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerDe la EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerÎncă nu există evaluări

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsDe la EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsÎncă nu există evaluări

- Idaho Falls: The Untold Story of America's First Nuclear AccidentDe la EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentEvaluare: 4.5 din 5 stele4.5/5 (21)

- VSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsDe la EverandVSC-FACTS-HVDC: Analysis, Modelling and Simulation in Power GridsÎncă nu există evaluări

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977De la EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Încă nu există evaluări

- An Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksDe la EverandAn Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksÎncă nu există evaluări

- Introduction to Power System ProtectionDe la EverandIntroduction to Power System ProtectionÎncă nu există evaluări

- Formulas and Calculations for Drilling OperationsDe la EverandFormulas and Calculations for Drilling OperationsÎncă nu există evaluări

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!De la EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Încă nu există evaluări

- Global Landscape of Renewable Energy FinanceDe la EverandGlobal Landscape of Renewable Energy FinanceÎncă nu există evaluări

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetDe la EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetEvaluare: 2 din 5 stele2/5 (1)