Documente Academic

Documente Profesional

Documente Cultură

Toolbox LOTO General

Încărcat de

KlinsmannJanujajJurgen0 evaluări0% au considerat acest document util (0 voturi)

160 vizualizări2 paginiloo

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentloo

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

160 vizualizări2 paginiToolbox LOTO General

Încărcat de

KlinsmannJanujajJurgenloo

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

Lockout/Tagout/Try out

What is Lockout/Tagout/Tryout? Lockout/Tagout/Tryout

Lockout/Tagout/Tryout (LOTO) protects a worker by Identify the equipment/ machinery that needs to

preventing others from turning on equipment or from be shut down and ALL its energy sources.

a release of energy while working on or servicing • Electrical, mechanical, gravitational, thermal,

equipment & machinery, working inside a grain bin, hydraulic, pneumatic, and chemical.

and working around conveyors and augers. LOTO Determine if there are any stored energy sources:

controls hazardous energy. • Capacitors, springs; elevated components;

rotating flywheels; hydraulic systems; air, gas,

How does it work? steam, water pressure; piles that can shift; etc.

All power sources are disconnected and locked in

Properly shut down equipment and machines:

the off position . Each person involved locks out

• Notify affected workers about the shutdown –

the pow er w ith their ow n personal lock and

those who work on the machines or equipment

key so they have control of the energy source .

or work in area where LOTO will be done.

They place a tag on the lock to warn others and to

• Shut off the power sources.

identify who is responsible. Before beginning work,

• Apply locks & tags to the power sources so the

each person tries the energy source to ensure it is

machine/equipment cannot be started.

locked out. No one else can remove another’s lock.

TRY OUT - Test to see if the equipment is

Therefore, no one can accidently turn on the

properly locked out by trying to start it.

equipment. In some facilities, only designated people

can lockout power sources and/or an alternative • After the work is completed, remove all tools.

group lockout process is used. • Notify all employees the locks will be removed

and the equipment will be restarted.

INJURY EXAMPLE:

When do we need to LOTO?

#1 Sam was investigating a clogged pipe. He

Before any repairs, maintenance or service on

decided to take the cover off a conveyor. He reached

equipment.

into the screw conveyor and his hand was crushed.

Before any entry into a grain bin.

Sam had seen a disconnect nearby and saw it was

Before any work that requires a person to place

off. Sam did not realize that disconnect was for

any part of their body in or near the point of

another piece of equipment.

operation.

1. How could have this injury been avoided? Additional Resources

2. What should be done when you see a OSHA regulation 1910.147

disconnect is off? GHSC video – LOTO Each Time, Every Time

about Our Worksite

1. What are Lockout/Tagout procedures at this worksite? Who is responsible?

2. What are some of the common mistakes we make with LOTO?

3. How can we get better? What can we do at this workplace to ensure proper

lockout/tagout is used?

4. What can we do today to demonstrate proper lock out/tag out/try out techniques ?

Lock out all energy sources.

Put on a tag to warn others &

identify responsible person.

Test to make sure the

equipment is locked out.

ONLY the person w ho

put on the lock and tag

rem oves it.

Grain Handling Safety Coalition 2015. This material was produced under grant number SH-26294-SH4 from the Occupational

Safety and Health Administration, U. S. Department of Labor. It does not necessarily reflect the views or policies of the U. S. Department

of Labor, nor does mention of trade names, commercial products, or organizations imply endorsement by the U. S. Government..

S-ar putea să vă placă și

- 1.0 Driver Induction, Agreements & ChecklistDocument10 pagini1.0 Driver Induction, Agreements & Checklistdave.muir.25Încă nu există evaluări

- 0545SP LUISRODRIGUEZ SELF-PACED U7 RN2 PruebaDocument84 pagini0545SP LUISRODRIGUEZ SELF-PACED U7 RN2 PruebafilipfilipondioÎncă nu există evaluări

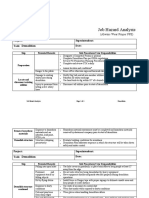

- Job Hazard Analysis Form Stripping Forms: ReferenceDocument2 paginiJob Hazard Analysis Form Stripping Forms: ReferenceReden Mejico PedernalÎncă nu există evaluări

- Fork Lift Truck-Risk Assessment - Date: R A - S A /SDocument2 paginiFork Lift Truck-Risk Assessment - Date: R A - S A /SJalagandeeswaran KalimuthuÎncă nu există evaluări

- General Lifting JHA SummaryDocument1 paginăGeneral Lifting JHA Summarysujith s pÎncă nu există evaluări

- Woodsmith 239 PDFDocument68 paginiWoodsmith 239 PDFdomingo figueroa100% (2)

- Lesson Learned RegisterDocument2 paginiLesson Learned Registernasir habibÎncă nu există evaluări

- Toolbox Talk 5 Eye ProtectionDocument2 paginiToolbox Talk 5 Eye ProtectionSajid HussainÎncă nu există evaluări

- General Risk Assessment FormDocument6 paginiGeneral Risk Assessment Formeagledev100% (1)

- Rescue Plan To Prevent Suspension Trauma: Ahmed AgbomireDocument8 paginiRescue Plan To Prevent Suspension Trauma: Ahmed AgbomireOsama ShaalanÎncă nu există evaluări

- JSP 42 Use of Power ToolsDocument6 paginiJSP 42 Use of Power ToolsMuhammad AtifÎncă nu există evaluări

- Fire Safety Requirements Part 3 - Trasport Storage Handeling and Installations of Liquified Petroleum GasDocument47 paginiFire Safety Requirements Part 3 - Trasport Storage Handeling and Installations of Liquified Petroleum Gasadnan amal yusfarÎncă nu există evaluări

- Risk Assessment - 1106Document2 paginiRisk Assessment - 1106Francis Enriquez TanÎncă nu există evaluări

- Ev02 - Brief Program For New Work at Height CampaignDocument2 paginiEv02 - Brief Program For New Work at Height CampaignFrancis Enriquez TanÎncă nu există evaluări

- Transformation Manager Job DescriptionDocument3 paginiTransformation Manager Job DescriptionworldfedksimcÎncă nu există evaluări

- Method Statement For Light Beacons and Buoys C04Document93 paginiMethod Statement For Light Beacons and Buoys C04Olugbemiga James OlalekanÎncă nu există evaluări

- HSE ViolationDocument1 paginăHSE ViolationBrian GiduduÎncă nu există evaluări

- Tiling Lesson 1.5.17Document7 paginiTiling Lesson 1.5.17Daryl MurrayÎncă nu există evaluări

- 2020 06 17 JSA For AC Servicing-Server RoomDocument12 pagini2020 06 17 JSA For AC Servicing-Server RoomDarren OscarÎncă nu există evaluări

- Toolboxtalk2 Housekeeping PDFDocument2 paginiToolboxtalk2 Housekeeping PDFSajid HussainÎncă nu există evaluări

- Risk Assessment Related To Confind SpaceDocument2 paginiRisk Assessment Related To Confind SpaceIhtisham UlhaqÎncă nu există evaluări

- First Aid Risk AssessmentDocument4 paginiFirst Aid Risk AssessmentJohn GeddesÎncă nu există evaluări

- Risk Assessment For Anti Termite TreatmentDocument4 paginiRisk Assessment For Anti Termite TreatmentBulent AkÎncă nu există evaluări

- Safety Flash - FlagmanDocument1 paginăSafety Flash - FlagmanarslanahmedkhawajaÎncă nu există evaluări

- Ibrahim Saad C.V Storekeeper, "Manufacture - Supply Chain"Document5 paginiIbrahim Saad C.V Storekeeper, "Manufacture - Supply Chain"Ibrahim Mohamed Saad Ibrahim67% (3)

- 37 HSE Lesson Learnt 29 - Eye InjuryDocument1 pagină37 HSE Lesson Learnt 29 - Eye InjuryKyaw MinÎncă nu există evaluări

- Intel Construction EHS: Processes and Procedures ManualDocument127 paginiIntel Construction EHS: Processes and Procedures ManualRanjan BhaumikÎncă nu există evaluări

- Cable Pulling Lubricant - Data Sheet (En Ingles)Document2 paginiCable Pulling Lubricant - Data Sheet (En Ingles)angel de mi guardaÎncă nu există evaluări

- Confined Space ES&H PowerPointDocument42 paginiConfined Space ES&H PowerPointChungNguyenÎncă nu există evaluări

- General Consideration For Stacking and StorageDocument4 paginiGeneral Consideration For Stacking and StorageSiddhantShrivastavÎncă nu există evaluări

- Al Majal QMS - 2018Document19 paginiAl Majal QMS - 2018Adam DeviatteyÎncă nu există evaluări

- Ocp BatchingDocument1 paginăOcp BatchingAarya Mishra TiwariÎncă nu există evaluări

- Water Safety For Construction Over or Near WaterDocument17 paginiWater Safety For Construction Over or Near WaterSawyu NandarÎncă nu există evaluări

- Manual Kestrel 5400Document24 paginiManual Kestrel 5400Larissa JaramilloÎncă nu există evaluări

- Toolbox Talk 9: Critical Risks - ExcavationsDocument2 paginiToolbox Talk 9: Critical Risks - ExcavationsPravin GowardunÎncă nu există evaluări

- Safety Harness Monthly Checklist-Register JAN23Document1 paginăSafety Harness Monthly Checklist-Register JAN23Iqbal HossainÎncă nu există evaluări

- TBT Manual HandlingDocument1 paginăTBT Manual HandlingNishadh NishÎncă nu există evaluări

- Job Hazard Analysis ProcessDocument25 paginiJob Hazard Analysis ProcessPavithraÎncă nu există evaluări

- 2 Consequence Management ProcedureDocument10 pagini2 Consequence Management ProcedureriyazaliÎncă nu există evaluări

- EHS-2035.Safety Management Procedure - 582020Document11 paginiEHS-2035.Safety Management Procedure - 582020hoangmtbÎncă nu există evaluări

- Health and Safety - ManualDocument156 paginiHealth and Safety - ManualedloradoÎncă nu există evaluări

- Contractor's Work Permit Latest 2020Document2 paginiContractor's Work Permit Latest 2020Zoey ChongÎncă nu există evaluări

- Machinery Equipment Repair and MaintenanceDocument18 paginiMachinery Equipment Repair and Maintenancepradeepgamage4513Încă nu există evaluări

- Job Safety Analysis (JSA) : Diesel Transfer From Truck To Rig Receive Tank Diesel TanksDocument1 paginăJob Safety Analysis (JSA) : Diesel Transfer From Truck To Rig Receive Tank Diesel TanksAdel AlKhedawyÎncă nu există evaluări

- FORM 3 For Maintaining Records of Hazardous Waste at FacilityDocument1 paginăFORM 3 For Maintaining Records of Hazardous Waste at Facilitysandeep MÎncă nu există evaluări

- Incident / Injury Occurrence Report Part BDocument2 paginiIncident / Injury Occurrence Report Part BHamzaNoumanÎncă nu există evaluări

- 3.management Review Meeting ProcedureDocument2 pagini3.management Review Meeting ProcedurekitekÎncă nu există evaluări

- SG-13 Safety Guideline For Material Handling (Manual and Mechanized) & StorageDocument41 paginiSG-13 Safety Guideline For Material Handling (Manual and Mechanized) & StorageJames HoltÎncă nu există evaluări

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 paginiAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferÎncă nu există evaluări

- Job Hazard Analysis DemolishDocument4 paginiJob Hazard Analysis Demolishyajid bustomiÎncă nu există evaluări

- Task Risk AssesmentDocument3 paginiTask Risk Assesmentafsalkareem100% (1)

- Thinner B MSDS PDFDocument4 paginiThinner B MSDS PDFEKO PURWANTOÎncă nu există evaluări

- Risk Assessment - House and Office CleaningDocument6 paginiRisk Assessment - House and Office CleaningVimal Thomas100% (1)

- HIRAC B224 Najarul On ConcreteDocument9 paginiHIRAC B224 Najarul On ConcreteSurendra JangidÎncă nu există evaluări

- 1.11 - UA-UC Report & Accident Investigation TemplateDocument2 pagini1.11 - UA-UC Report & Accident Investigation TemplateUnachukwu Sopulu SopsyÎncă nu există evaluări

- Hse Plan 3Document14 paginiHse Plan 3YcRij SeYerÎncă nu există evaluări

- NC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Document1 paginăNC-FRM-DRA 6-1 Rev.0 Lorry Mounted Cranes (HIAB)Patrick Bibila NdansiÎncă nu există evaluări

- Mod10 Work at Height QuizDocument11 paginiMod10 Work at Height QuizMhanna AYÎncă nu există evaluări

- LOTO Toolbox 1 General 4.2016 PDFDocument2 paginiLOTO Toolbox 1 General 4.2016 PDFf4user97Încă nu există evaluări

- Health and Safety On Construction Sites: Lockout - TagoutDocument8 paginiHealth and Safety On Construction Sites: Lockout - Tagoutmichael.cotugnoÎncă nu există evaluări

- Fuel Storage Tanks: Group V Anokye Eric Gyimah Ofoe Banjamin Sabih Frank Gyimah Nignamon Samuel Agyei KlinsmannDocument6 paginiFuel Storage Tanks: Group V Anokye Eric Gyimah Ofoe Banjamin Sabih Frank Gyimah Nignamon Samuel Agyei KlinsmannKlinsmannJanujajJurgenÎncă nu există evaluări

- Industrial AttachmentDocument28 paginiIndustrial AttachmentKlinsmannJanujajJurgen100% (1)

- Table Cam MotionsDocument1 paginăTable Cam MotionsKlinsmannJanujajJurgenÎncă nu există evaluări

- Ai MLDocument10 paginiAi MLKlinsmannJanujajJurgenÎncă nu există evaluări

- Automatic Control Part IDocument22 paginiAutomatic Control Part IDennis ArhinÎncă nu există evaluări

- Internship Report KlinsDocument1 paginăInternship Report KlinsKlinsmannJanujajJurgenÎncă nu există evaluări

- Gearless TransmissionDocument51 paginiGearless TransmissionSid Max83% (6)

- Lab Report EnochDocument73 paginiLab Report EnochKlinsmannJanujajJurgenÎncă nu există evaluări

- How Solar Energy Is Used To Produce Energy.Document10 paginiHow Solar Energy Is Used To Produce Energy.KlinsmannJanujajJurgenÎncă nu există evaluări

- Maxwell NeedleDocument10 paginiMaxwell NeedleKlinsmannJanujajJurgenÎncă nu există evaluări

- ANSYS TutorialDocument44 paginiANSYS Tutorialsauravc88Încă nu există evaluări

- Introduction To SensorsDocument17 paginiIntroduction To SensorskedirabduriÎncă nu există evaluări

- Gearless TransmissionDocument51 paginiGearless TransmissionSid Max83% (6)

- Francis TurbineDocument9 paginiFrancis TurbineKlinsmannJanujajJurgenÎncă nu există evaluări

- Creating Powerpoint Presentations: For Presentations Submitted To Professor BlankDocument17 paginiCreating Powerpoint Presentations: For Presentations Submitted To Professor BlankKlinsmannJanujajJurgenÎncă nu există evaluări

- Heat ExchangerDocument14 paginiHeat ExchangerKlinsmannJanujajJurgenÎncă nu există evaluări

- ME 374 Equations and TablesfinalDocument29 paginiME 374 Equations and TablesfinalKlinsmannJanujajJurgenÎncă nu există evaluări

- Chapter 1 Answer KeyDocument18 paginiChapter 1 Answer KeyZohaib SiddiqueÎncă nu există evaluări

- E Ommerce Notes PDFDocument35 paginiE Ommerce Notes PDFRoop Ch Jha75% (4)

- John T. Grenie Charged With Indirect Criminal ContemptDocument317 paginiJohn T. Grenie Charged With Indirect Criminal ContemptChristopher Stoller EDÎncă nu există evaluări

- Chapter 17Document7 paginiChapter 17Le QuangÎncă nu există evaluări

- Individual Assignment 26june 2017Document6 paginiIndividual Assignment 26june 2017Eileen OngÎncă nu există evaluări

- Global Halal Market OpportunityDocument18 paginiGlobal Halal Market OpportunityDiana BlueseaÎncă nu există evaluări

- Core Banking SolutionDocument12 paginiCore Banking SolutionMamta Grover100% (1)

- PDF September Ict Notespdf - CompressDocument14 paginiPDF September Ict Notespdf - CompressSagar BhandariÎncă nu există evaluări

- Risk Assesment FormatDocument2 paginiRisk Assesment FormatThumbanÎncă nu există evaluări

- Fabio Penuela ResumeDocument5 paginiFabio Penuela Resumedayro herreraÎncă nu există evaluări

- Swot Analysis R&D: NPD Stages and ExplanationDocument3 paginiSwot Analysis R&D: NPD Stages and ExplanationHarshdeep BhatiaÎncă nu există evaluări

- Industrial Development in Nepal (Final)Document4 paginiIndustrial Development in Nepal (Final)susmritiÎncă nu există evaluări

- Mep Consultant Services RFP FinalDocument17 paginiMep Consultant Services RFP FinalAbhik BhattacharjeeÎncă nu există evaluări

- D. Abstract & Executive Summary - Docx FormattedDocument12 paginiD. Abstract & Executive Summary - Docx FormattedJeston TamayoÎncă nu există evaluări

- Heidi RoizenDocument2 paginiHeidi RoizenAthena ChowdhuryÎncă nu există evaluări

- CVE156 SampleDocument14 paginiCVE156 SampleLightning SparkÎncă nu există evaluări

- InspectionDocument32 paginiInspectionmaruf19900100% (1)

- Presented By: Namrata Singh Samiksha Sahej Grover Sonal MidhaDocument35 paginiPresented By: Namrata Singh Samiksha Sahej Grover Sonal MidhaYatin ChopraÎncă nu există evaluări

- Book TocDocument7 paginiBook TocAli FarooqÎncă nu există evaluări

- Nike From Concept To CustomerDocument9 paginiNike From Concept To CustomerJigyasa GautamÎncă nu există evaluări

- 1preface For EDDocument15 pagini1preface For EDrajendrakumarÎncă nu există evaluări

- Airports Authority of India: Aai Office ComplexDocument52 paginiAirports Authority of India: Aai Office ComplexanupamkhannaÎncă nu există evaluări

- Terms and Conditions: Pre-Employment RequirementsDocument5 paginiTerms and Conditions: Pre-Employment RequirementsKarl D AntonioÎncă nu există evaluări

- Desmopan 192 ISODocument2 paginiDesmopan 192 ISOaakashlakhanpal9830Încă nu există evaluări

- Finance SyllabusDocument11 paginiFinance SyllabusEarl Russell S PaulicanÎncă nu există evaluări

- About Tata AigDocument3 paginiAbout Tata Aigsatishyadav1234Încă nu există evaluări

- Resume of JohnquerqueDocument2 paginiResume of Johnquerqueapi-28247722Încă nu există evaluări

- Nationwide IULDocument20 paginiNationwide IULdjdazedÎncă nu există evaluări