Documente Academic

Documente Profesional

Documente Cultură

Page02 Ultimate Killsheet

Încărcat de

George IkpeDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Page02 Ultimate Killsheet

Încărcat de

George IkpeDrepturi de autor:

Formate disponibile

ELECTRONIC KILLSHEETS

Imperial U.S. • SI/Metric • Mixed Units (Imperial and Metric)

Killsheet Capabilities The “Well Control Calculation” page provides calculations for volumes,

strokes, and circulating times for each section of the well along with kill

• Job site use with real time data mud, circulating pressures and differences in Maximum Allowable Surface

• Volumetric – calculates psi/bbl and determines bleed cycles Pressure.

• L & B – establishes injection fluid volumes vs pressure bleed down

• Safety and working margins established for volumetric and L & B The “Well Control Checklist” page is a collection point for the results of all

• Produces support charts and graphs to assist with well operations calculations required for the well kill operation, plus a chart for circulating

• Bullhead – assists in killing wells in workover operations pressures.

Imperial US – SI Metric – Mixed Units (Imperial and Metric) Killsheets. Support Calculations 1: Ever wonder if you have enough weight up material,

WWCI has developed killsheets to meet worldwide demands. While how much the pits may gain, or the max surface pressure? This page provides

Imperial and Metric killsheets already exist, operators expressed a need for answers. The pressure vs strokes schedule has the flexibility to graph and

a killsheet that combines the best of both worlds. These killsheets were compare the difference between a “straight” and deviated/ horizontal well.

designed with the flexibility to allow operations to pick required units

specific to that country and/or job site. These killsheets are provided for Support Calculations 2: Provides a look at how circulating pressures (ECDs) may

students in all WWCI classes. affect the well control operation throughout the various sections of the well.

Surface Killsheet: This program was developed to handle complex wells Bullhead – Producing well must be killed? The industry standard is using

with up to 4 casing/liner strings and 9 different drill string components the Bullhead Method. This sheet calculates the volumes that must be used

while calculating up to fourteen geometric sections! If a well kick occurs, and pressure limits while pumping to minimize or eliminate downhole and

as soon as pressures are known, the program provides the necessary well equipment damages! Also assists in calculating kill fluids.

control calculations.

Lubricate & Bleed – Wherever a gas cap exists at surface and must be

Subsea Killsheet: Does everything the surface killsheet does, plus provides replaced with fluid, the L&B worksheet is required. After injecting fluid into

the additional calculations for choke and kill lines, riser, CLFP and a modified the well, this sheet assists operations in calculating the pressure to volume

pump start up schedule. The well schematic also takes water depth and relationship, and provides real time data for the well site supervisor. Both a

choke/kill lines into its dynamic drawing! chart and graph provide written and visual information for planning further

injection cycles.

Volumetric Method: Gas is Migrating Up the Wellbore

Killsheet Capabilities

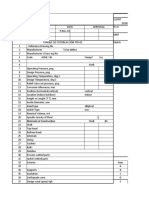

Shut in Well Well #: Completed By: Page 1

Information

Initial Time

Well Shut In (Hrs:Min)

Initial Shut In 0

Annulus Pressure (psi)

Initial Kick 0.0

Size (bbls)

Well Depth 0

• Handles simple and complex wells

TVD (ft)

2202 Oil Center Court

Calculate psi/bbl for Bleed Houston, Texas USA 77073

Cycle Phone: 281.784.4700

Annular 0.0000 E-mail: wildwell@wildwell.com

©Wild Well Control, Inc. V20.20

• Easy to use in both field and office environments

Capacity (bbls/ft)

Mud Weight 0.0

In Well (ppg)

Mud 0.0

Gradient (psi/ft) Gas will migrate up the well. As it does

• Designed with minimal user inputs

Gas 0.0 pressure will increase due to the

Gradient (psi/ft) difference between the pressure within

Mud's 0.0 the gas and the hydrostatic pressure

Pressure/Barrel

Determining Safety and

(psi/bbls)

psi Click here to above the gas. You should hold

pressure fairly constant (or within a

• Numbers and displays well string components

recalculate a New range) according to the calculations

Working Margin

Cycle 1 Total Pit Volume Cycle and for next provided to allow gas expansion (that

Working 0.0

Margin (bbls)

bbls "Hold" Pressure

reduces its pressure) and minimize

well pressures.

Working 0 Bleed Cycle

Margin's Hydrostatic (psi)

bbls

• Real time results

Safety 0

Margin (psi)

Beginning Pit Volume

Cycle Start And Hold Small Easily Total Pit Volume

Beginning 0 This Pressure Until Measured Tank

Pit Volume (bbls)

Starting Gas Bubble Selecting Working

Pressure, psi Margin in Barrels

Formation 0 Volumes vs Pressure Relationship

Pressure (if known) (psi)

1.00 bbls = 0 psi Print All

Well illustration dynamically numbers and draws the well string components

This assists in plotting gas

bubble pressure during Volumetric Control Log Volumetric

bleed cycles For Controlling Gas Expansion Before Reaching BOP Stack

Procedures: Cycle Cycle Allow Cycle Total Total Pit Total Start Time for Stop Time for Total Time For Estimated Gas Estimated Estimated

Number Start Pressure Volume Volume Volume Hydrostic Volumetric Volumetric Cycle Migration Rate Time to Time of Day WasCalledb6 Safety Margin Zone Gas Bubble Pressure

Safety Margins are typically

assisting operations with well kill. This visual aid also provides operations

Pressure (psi) Increase Bled Bled (bbls) (bbls) Pressure Cycle Cycle (hh:mm) (ft/min) Surface Expected

200 psi or less. In addition, a (psi) and hold until (bbls) Released (hh:mm)

Working Margin is also used. next cycle From Well

The Working Margin is based Pressure Held vs Mud Bled

on an easy to measure 1700

with a quick reference and positioning of all tubulars within the well.

1

increment of volume or an

On cycle #1 a safety margin is added in. This is the ONLY time it is added. Additional changes are from the Working Margin's psi only!

easy to see increment of

pressure on a gauge. 2 1600

Repeat allowing pressure to increase to calculated value and hold until next barrel bled cycle, allow pressure to increase, repeat, etc.

The principle concept of this 3

method is to swap out the 4

5 1500

mud's hydrostatic pressure

(allowed out of well) for 6

7

additional pressure held at the

8

Pressure psi

choke. This allows the 1400

9

pressure within the gas to 10

decrease and pressure in the 11

wellbore to stay within a 12 1300

constant range. 13

14

Continue cycles until gas 15

16 1200

reaches surface. Once gas

reaches surface use another 17

method (e.g., Lubricate & 18

19

Bleed Method) to remove gas 1100

20

correctly.

21

The chart and graph give a 22

visual overview of what is 1000

happening in the wellbore. 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

Restart Total Volume Bled bbls

Volumetric – is a MUST for every rig. Once a kick is taken and circulation

is not possible, this tool becomes invaluable for all operations when gas

migration and increasing well pressures must be dealt with. This sheet assists

in calculating psi/bbl, establishes safety and working margins, projects bleed

cycles, maximum surface pressures, and anticipated volumes gained.

Note: Procedures and Instructional tabs are provided to assist users when

filling in the different killsheets.

www.WildWell.com 2202 Oil Center Court | Houston, TX 77073 | Tel: +1.281.784.4700 | training@wildwell.com

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Assistant Driller HandoverDocument1 paginăAssistant Driller HandoverGeorge IkpeÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Broiler ManualsDocument27 paginiBroiler ManualsGeorge IkpeÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- CAT10310405PDFDocument64 paginiCAT10310405PDFGeorge IkpeÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Pineapple Booklet PDFDocument17 paginiPineapple Booklet PDFGeorge IkpeÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Growing Watermelon Commercially in Nigeria Training ManualDocument14 paginiGrowing Watermelon Commercially in Nigeria Training ManualGeorge IkpeÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Unit Conversion TableDocument43 paginiUnit Conversion TableGeorge IkpeÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Metric Nut Size Chart PDFDocument1 paginăMetric Nut Size Chart PDFGeorge IkpeÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Nokia 9500 Communicator User Guide: 9230564 Issue 4Document108 paginiNokia 9500 Communicator User Guide: 9230564 Issue 4Gupta ManishÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Driller ResponsibilityDocument3 paginiDriller ResponsibilityGeorge IkpeÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- GrantPrideco Drill Pipe Data TablesDocument24 paginiGrantPrideco Drill Pipe Data TablesMaximo Biarrieta RodriguezÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Ashrae Ic 90.1-2016-1Document2 paginiAshrae Ic 90.1-2016-1widiantoekoÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Alaa-Pipeline Mechanical DesignDocument106 paginiAlaa-Pipeline Mechanical DesignDavid Muñoz Castro100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- CH E 441 Ex1 Spring 05Document6 paginiCH E 441 Ex1 Spring 05Jhon Barzola PalominoÎncă nu există evaluări

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Jet - Technical Sheet - EngDocument11 paginiJet - Technical Sheet - EngJairo CarvajalÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- Procedure For Column Line Stress AnalysisDocument6 paginiProcedure For Column Line Stress AnalysisNilesh GohelÎncă nu există evaluări

- SP-P-004 - Rev 1 - Specification For Steam TracingDocument51 paginiSP-P-004 - Rev 1 - Specification For Steam Tracingvishal bhamreÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Air Cycle Refrigeration:-Bell - Coleman CycleDocument21 paginiAir Cycle Refrigeration:-Bell - Coleman CycleSuraj Kumar100% (1)

- Abu Zaid1996Document12 paginiAbu Zaid1996Prantik DasÎncă nu există evaluări

- Spe 120449 PaDocument8 paginiSpe 120449 PaTECH JSC FHDÎncă nu există evaluări

- 30XA0252-1502 30XQ0330-1500: Aquaforce Liquid ChillerDocument32 pagini30XA0252-1502 30XQ0330-1500: Aquaforce Liquid Chillermithilesh5103Încă nu există evaluări

- Pipe Stress Analysis Case Study - Pump Discharge - Piping Technology & Products, IncDocument10 paginiPipe Stress Analysis Case Study - Pump Discharge - Piping Technology & Products, Inckaliya12100% (1)

- Hemical Ngineering Inetics: Based On CHEM - ENG 408 at Northwestern UniversityDocument49 paginiHemical Ngineering Inetics: Based On CHEM - ENG 408 at Northwestern UniversityzamijakaÎncă nu există evaluări

- Hard Chrome Plated Plungers: Custom Hoists IncDocument3 paginiHard Chrome Plated Plungers: Custom Hoists IncPalyyÎncă nu există evaluări

- Flowserve CV PDFDocument36 paginiFlowserve CV PDFAlvin SmithÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- SBRDocument8 paginiSBRThông NguyễnÎncă nu există evaluări

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument38 paginiAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZÎncă nu există evaluări

- R19 - Mech - VI - HVACR - Sample Question BankDocument6 paginiR19 - Mech - VI - HVACR - Sample Question BankSailee AcharekarÎncă nu există evaluări

- Hoja de Datos Tanque de AlmacenamientoDocument8 paginiHoja de Datos Tanque de AlmacenamientoRodrigo Gracia100% (1)

- Valvulas CartridgeDocument332 paginiValvulas Cartridgecaprit_her_771605Încă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Lab ReportDocument2 paginiLab Reportbrianna torralbaÎncă nu există evaluări

- Quiz HMT Question PaperDocument2 paginiQuiz HMT Question Papersutha_me20098282Încă nu există evaluări

- 7.1 Brief Introduction To Valves: 5Xeehu6Hdohg Dwh9DoyhDocument7 pagini7.1 Brief Introduction To Valves: 5Xeehu6Hdohg Dwh9Doyhttplan800Încă nu există evaluări

- Moving Bed ProcessorsDocument11 paginiMoving Bed ProcessorsWaqar AhmedÎncă nu există evaluări

- Chapter 8 - Mechanisms of Heat TransferDocument10 paginiChapter 8 - Mechanisms of Heat TransferBảo Tín TrầnÎncă nu există evaluări

- Piping StopplerDocument3 paginiPiping Stoppleranusaan2007Încă nu există evaluări

- L16 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiDocument25 paginiL16 CRE II Heterogeneous Catalysis: Prof. K.K.Pant Department of Chemical Engineering IIT DelhiMehul VarshneyÎncă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Cooling Towers: Cold Water BasinDocument13 paginiCooling Towers: Cold Water BasinmichsantosÎncă nu există evaluări

- UASB Upflow Anaerobic Sludg..Document2 paginiUASB Upflow Anaerobic Sludg..Devendra BansalÎncă nu există evaluări

- Convertidos de PDFDocument136 paginiConvertidos de PDFJohn Nilton Ccama LipaÎncă nu există evaluări

- Marathon-Fluid Mechanics by Sandeep Jyani Sir WIFISTUDY PDF Version 2Document443 paginiMarathon-Fluid Mechanics by Sandeep Jyani Sir WIFISTUDY PDF Version 2Nandkishore MeenaÎncă nu există evaluări