Documente Academic

Documente Profesional

Documente Cultură

Sikadur 42 ZA PDF

Încărcat de

nap_carinoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sikadur 42 ZA PDF

Încărcat de

nap_carinoDrepturi de autor:

Formate disponibile

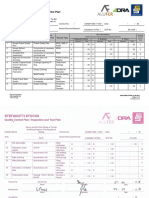

Product Data Sheet

Edition 09/05/2016

Identification no:

010202010010000001

Sikadur® -42 ZA

Sikadur® -42 ZA

High strength fluid epoxy resin grout

Product ®

Description Sikadur -42 ZA is a solvent-free, three component grout, based on a combination

Construction

of epoxy resins and special fillers. The product has a fluid consistency and is self

levelling.

®

Uses Sikadur -42 ZA can be used for:

Grouting under crane rails

Grouting under bridge bearing plates and machine bases

Grouting of steel reinforcement, holding down bolts, etc. into existing concrete

or masonry

Filling of voids and cavities in concrete

®

Characteristics / Sikadur -42 ZA has the following advantages:

Advantages Easy to mix and apply

Suitable for dry and damp concrete surfaces

Very good adhesion to most construction materials

High early strength

Solvent free

Hardens without shrinkage

No primer needed

High initial and ultimate mechanical strength

Good abrasion resistance

Good chemical resistance

Good flow characteristics

Tests

Approval / Standards

1 Sikadur® -42 ZA 1/4

Product Data

Form Liquid

Appearance /Colours Part A: Opaque

Part B: Amber

Part C: Sand

Parts A+B+C mixed: Grey

Packaging 8.7 litre (3.0 Litre component (A + B) and 15.0kg component C) kit.

Storage

Storage Conditions/ 12 months from date of production if stored properly in original unopened,

Shelf-Life sealed and undamaged packaging, in dry conditions at temperatures between

+5°C and +25°C. Protect from direct sunshine.

Technical Data

Chemical Base Epoxy resin.

Density 2.06 kg/l (Part A+B+C mixed) (at +23°C)

Layer Thickness Minimum 3 mm and a maximum of 40 mm.

When using multiple units, one after the other. Do not mix the following unit until

the previous one has been used in order to avoid a reduction in handling time.

Change of Volume Shrinkage:

Hardens without shrinkage.

Mechanical / Physical

Properties

Compressive Strength

Curing time 8 hrs 24 hrs 7 days 14 days

Compressive

Strength at 10.0 N/mm2 50.0 N/mm2 65.0 N/mm2 70.0 N/mm2

25°C

Flexural Strength

Flexural Strength

7 days 28.0 N/mm2

at 25°C

Tensile Strength

Tensile Strength at

7 days 17.0 N/mm2

25°C

Bond Strength Sandblasted steel – 20Mpa approx.

Sandblasted concrete – 3.5Mpa approx. (concrete failure)

Strength Development Confirm the strength development by producing cubes on site and testing them

for compressive and flexural strength.

2 Sikadur® -42 ZA 2/4

System Information

Application Details

® 2

Consumption / Dosage The consumption of Sikadur -42 ZA is ~ 1 litre/m per mm of thickness.

Substrate Quality Mortar and concrete must be older than 28 days (depends on minimal

requirement of strengths).

Verify the substrate strength (concrete, masonry, natural stone).

The substrate surface (all types) must be clean, dry and free from contaminants

such as dirt, oil, grease, existing surface treatments and coatings etc.

Steel substrates must be de-rusted similar to Sa 2.5

The substrate must be sound and all loose particles must be removed.

Substrate Preparation Concrete, mortar, stone, bricks:

Substrates must be sound, dry, clean and free from laitance, ice, standing water,

grease, oils, old surface treatments or coatings and all loose or friable particles

must be removed to achieve a laitance and contaminant free, open textured

surface.

Steel:

Must be cleaned and prepared thoroughly to an acceptable quality i.e. by blast

cleaning and vacuum. Avoid dew point conditions.

Application Conditions/

Limitations

Substrate Temperature +10°C min. / +30°C max.

Ambient Temperature +10°C min. / +30°C max.

®

Material Temperature Sikadur -42 ZA must be applied at a temperatures between +10°C and +30°C.

Substrate Humidity When applied to mat moisture concrete, brush the adhesive well into substrate.

Dew Point Beware of condensation!

Ambient temperature during application must be at least 3°C above dew point.

Application Instructions

Mixing

Mixing Time Pre-batched units:

Mix parts A+B together for at least 3 minutes with a mixing

spindle attached to a slow speed electric drill

(max. 600 rpm) until the material becomes a smooth

consistency and uniform in colour. Add part C and continue

until mixture is homogeneous. Avoid aeration while mixing.

Pour the whole mix into a clean container and stir again for

approx. 1 minute at low speed to keep air entrapment at a

minimum. Mix only that quantity which can be used within its

potlife.

3 Sikadur® -42 ZA 3/4

Application Method / Tools Underplate grouting

When grouting under bearing pads, rails or bases, ensure that there is sufficient

pressure to maintain movement of the grout. Make allowance for the air to

escape.

For large volumes, apply in more than one layer and ensure that previous layers

have hardened and cooled.

Anchor bolt grouting

®

The correct quantity of Sikadur -42ZA required to completely fill the annular gap

between the bolt and the sides of the hole should be determined before

installation is attempted.

®

Place the pre-determined quantity of Sikadur -42ZA directly into the bolt hole.

Push the anchor bolt into the hole and press it gently to the bottom, displacing the

®

Sikadur -42 ZA and filling the annulus around the bolt. A slight agitation of the

®

bolt will assist the Sikadur -42 ZA to fill the annulus evenly. Centre or locate the

bolt in the desired position, using shims if necessary, and then leave undisturbed

®

until the Sikadur -42 ZA has set.

Construction

®

If the Sikadur -42 ZA does not fill the annular gap evenly during bolt insertion,

®

withdraw the bolt and insert additional Sikadur -42 ZA and re-insert the bolt. Do

®

not attempt to add additional Sikadur -42 ZA with the bolt in place.

®

Cleaning of Tools Clean all tools and application equipment with Sika Colma Cleaner immediately

after use. Hardened / cured material can only be mechanically removed.

Potlife Potlife (3.0 litre) is approximately 30 minutes.

The potlife begins when the resin and hardener are mixed. It is shorter at high

temperatures and longer at low temperatures. The greater the quantity mixed, the

shorter the potlife. To obtain longer workability at high temperatures, the mixed

grout may be divided into portions. Another method is to chill parts A+B and C

before mixing them (not below +5°C).

All technical data stated in this Product Data Sheet are based on laboratory tests.

Value Base Actual measured data may vary due to circumstances beyond our control.

Please note that as a result of specific local regulations the performance of this

Local Restrictions product may vary from country to country. Please consult the local Product Data

Sheet for the exact description of the application fields.

Health and Safety

Information

The information, and, in particular, the recommendations relating to the

Legal Notes application and end-use of Sika products, are given in good faith based on Sika's

current knowledge and experience of the products when properly stored, handled

and applied under normal conditions in accordance with Sika’s recommendations.

In practice, the differences in materials, substrates and actual site conditions are

such that no warranty in respect of merchantability or of fitness for a particular

purpose, nor any liability arising out of any legal relationship whatsoever, can be

inferred either from this information, or from any written recommendations, or

from any other advice offered. The user of the product must test the product’s

suitability for the intended application and purpose. Sika reserves the right to

change the properties of its products. The proprietary rights of third parties must

be observed. All orders are accepted subject to our current terms of sale and

delivery. Users must always refer to the most recent issue of the local Product

Data Sheet for the product concerned, copies of which will be supplied on

request.

Sika South Africa (Pty) Ltd E-mail: headoffice@za.sika.com

9 Hocking Place, Phone +27 31 792 6500

Westmead, 3608 Telefax +27 31 700 1760

South Africa www.sika.co.za

4 Sikadur® -42 ZA 4/4

S-ar putea să vă placă și

- Safety Officer Interview Questions and AnswersDocument48 paginiSafety Officer Interview Questions and AnswersRaza Muhammad Soomro60% (5)

- Architectural SpecificationsDocument55 paginiArchitectural SpecificationsGiovani Carl Dauz Pascua100% (5)

- Aisc Design Examples v15.0 PDFDocument1.609 paginiAisc Design Examples v15.0 PDFenrique colli100% (1)

- Painting ProcedureDocument8 paginiPainting ProcedureSunday Paul50% (2)

- Blasting and Painting ProcedureDocument9 paginiBlasting and Painting Procedureisukuru67% (12)

- Sikadur - 53 (UF) : Moisture Insensitive Injection ResinDocument4 paginiSikadur - 53 (UF) : Moisture Insensitive Injection ResinBijaya RaulaÎncă nu există evaluări

- Sikadur - 53 (UF) : Moisture Insensitive Injection ResinDocument4 paginiSikadur - 53 (UF) : Moisture Insensitive Injection ResinEr. Subhasish PanjaÎncă nu există evaluări

- Sikadur®-42 IN: Product Data SheetDocument4 paginiSikadur®-42 IN: Product Data SheetJackson OmindiÎncă nu există evaluări

- Sikadur® PF: Product Data SheetDocument3 paginiSikadur® PF: Product Data SheetSHAIK ASIMUDDINÎncă nu există evaluări

- Sikadur®-42 (Au) : Product Data SheetDocument3 paginiSikadur®-42 (Au) : Product Data SheetPramuditha SuraweeraÎncă nu există evaluări

- Sikadur - 52: Low Viscosity Injection ResinDocument3 paginiSikadur - 52: Low Viscosity Injection ResinSunny RohillaÎncă nu există evaluări

- Sikadur - 52: Low Viscosity Injection ResinDocument3 paginiSikadur - 52: Low Viscosity Injection ResinJoeÎncă nu există evaluări

- Sikadur®-42 LP: Product Data SheetDocument4 paginiSikadur®-42 LP: Product Data SheetMuhammad ShahidÎncă nu există evaluări

- Sikadur 42 T PDFDocument4 paginiSikadur 42 T PDFFederico.IoriÎncă nu există evaluări

- Sikadur 731Document2 paginiSikadur 731widayat81100% (1)

- Sikadur - 43 TaDocument3 paginiSikadur - 43 TaSylvester WafulaÎncă nu există evaluări

- sikadur_-53_uf_groutDocument4 paginisikadur_-53_uf_groutDebiprasad PradhanÎncă nu există evaluări

- Sika Chapdur TDSDocument4 paginiSika Chapdur TDSDavid TumboimbelaÎncă nu există evaluări

- Sikadur 42 - PDSDocument2 paginiSikadur 42 - PDSUa AnyanhunÎncă nu există evaluări

- Sikadur - 53 Uf GroutDocument3 paginiSikadur - 53 Uf GroutJU SHUANGÎncă nu există evaluări

- Sikadur - 33: High Modulus, High-Strength, Structural, Rapid Curing Epoxy, Smooth-Paste AdhesiveDocument4 paginiSikadur - 33: High Modulus, High-Strength, Structural, Rapid Curing Epoxy, Smooth-Paste AdhesivefachirrisÎncă nu există evaluări

- Shrinkage Compensated Cementitious GroutDocument3 paginiShrinkage Compensated Cementitious GroutPramod SinghÎncă nu există evaluări

- Sikadur® 731Document2 paginiSikadur® 731Nguyễn Hoang AnhÎncă nu există evaluări

- Sikadur - 52 LP (IN) : Low Viscosity Injection ResinDocument3 paginiSikadur - 52 LP (IN) : Low Viscosity Injection ResinSunny RohillaÎncă nu există evaluări

- Sikadur®-53: Product Data SheetDocument3 paginiSikadur®-53: Product Data Sheetjet toledoÎncă nu există evaluări

- Sikalastic 632 R PDFDocument4 paginiSikalastic 632 R PDFDan BermasÎncă nu există evaluări

- Sikadur - 31: Thixotropic Epoxy Resin Adhesive MortarDocument4 paginiSikadur - 31: Thixotropic Epoxy Resin Adhesive MortarAnonymous jbvNLNANLIÎncă nu există evaluări

- Sikadur - 32: Epoxy Resin Bonding AgentDocument3 paginiSikadur - 32: Epoxy Resin Bonding AgentMuhammad SafdarÎncă nu există evaluări

- Sikadur®-53 UF (Mortar) : Product Data SheetDocument3 paginiSikadur®-53 UF (Mortar) : Product Data Sheetharish GiriÎncă nu există evaluări

- Sika Chapdur CorondumDocument4 paginiSika Chapdur CorondumTolga YazanÎncă nu există evaluări

- Consol 71 FC: 2-Part Thixotropic Multipurpose Epoxy AdhesiveDocument2 paginiConsol 71 FC: 2-Part Thixotropic Multipurpose Epoxy AdhesiveMuhammad FirdausÎncă nu există evaluări

- SikaGrout® - 114 - PDS PDFDocument4 paginiSikaGrout® - 114 - PDS PDFSheraz BashirÎncă nu există evaluări

- TDS Consol Grout 600 MFDocument2 paginiTDS Consol Grout 600 MFPEP GUDANGÎncă nu există evaluări

- Top 122 Hs 091228Document3 paginiTop 122 Hs 091228Basava NÎncă nu există evaluări

- Sikadur-42 HS 2012-07 - 1Document4 paginiSikadur-42 HS 2012-07 - 1Chee Soon LeeÎncă nu există evaluări

- Sikadur-42 HS 2012-07 - 1 PDFDocument4 paginiSikadur-42 HS 2012-07 - 1 PDFincineratoriumÎncă nu există evaluări

- Sikadur 752Document2 paginiSikadur 752Dify Rizky KÎncă nu există evaluări

- Sikadur®-42 PC: Product Data SheetDocument4 paginiSikadur®-42 PC: Product Data SheetMohammed AwfÎncă nu există evaluări

- Technical Data Sheet for CONSOL GROUT 600 MF Cementitious GroutDocument2 paginiTechnical Data Sheet for CONSOL GROUT 600 MF Cementitious GroutKhaerul SidikÎncă nu există evaluări

- Sikadur-42 HF PDS PDFDocument4 paginiSikadur-42 HF PDS PDFMiljan MilanovicÎncă nu există evaluări

- Sikatop - 122Document3 paginiSikatop - 122YOSAFAT YUDHA GUNTOROÎncă nu există evaluări

- Sikagrout - 215 NewDocument3 paginiSikagrout - 215 NewAlex Tri WijayantoÎncă nu există evaluări

- Sikagrout - 215 NewDocument3 paginiSikagrout - 215 NewPeralatan Divisi3Încă nu există evaluări

- Sikagrout - 215 NewDocument3 paginiSikagrout - 215 Newmanuel rgÎncă nu există evaluări

- Sikagrout®-215 (New) : Product Data SheetDocument3 paginiSikagrout®-215 (New) : Product Data SheetWahyu MahaendraÎncă nu există evaluări

- SikaTop Seal-107 Standard PB ENGDocument4 paginiSikaTop Seal-107 Standard PB ENGJoshua WijayaÎncă nu există evaluări

- Sikagard - 694 F (I) : Moisture Insensitive Epoxy PuttyDocument3 paginiSikagard - 694 F (I) : Moisture Insensitive Epoxy Puttykartick adhikaryÎncă nu există evaluări

- Sikadur - 52 inDocument3 paginiSikadur - 52 inRavi Kumar KadivetiÎncă nu există evaluări

- Sikadur®-32 IN: Product Data SheetDocument3 paginiSikadur®-32 IN: Product Data SheetDeep GandhiÎncă nu există evaluări

- Sikagrout 215 New - Pds en PDFDocument3 paginiSikagrout 215 New - Pds en PDFDeny Anarista SitorusÎncă nu există evaluări

- Sika Top® - 111 - 1 - 3Document2 paginiSika Top® - 111 - 1 - 3muhammednaar32Încă nu există evaluări

- PDS Sikacrete 145IN en IN 11 2022 3 1Document4 paginiPDS Sikacrete 145IN en IN 11 2022 3 1Hiren ShahÎncă nu există evaluări

- Sikadur®-41 IN: Product Data SheetDocument3 paginiSikadur®-41 IN: Product Data Sheetcrs reportÎncă nu există evaluări

- Sikadur - 42 ZaDocument4 paginiSikadur - 42 ZaPatrickKisulaÎncă nu există evaluări

- Sika Nigeria - Sika Grout 212 - V2Document3 paginiSika Nigeria - Sika Grout 212 - V2willy iremÎncă nu există evaluări

- Consol 71 Ep RevDocument3 paginiConsol 71 Ep RevMaximillian DewantoroÎncă nu există evaluări

- Sikagrout®-214 Ae: Product Data SheetDocument3 paginiSikagrout®-214 Ae: Product Data Sheetmohammed rinshinÎncă nu există evaluări

- Sikafloor-ColourSeal W 0307Document4 paginiSikafloor-ColourSeal W 0307Chris AdaminovicÎncă nu există evaluări

- Sikagrout® 215 (New) : Product Data SheetDocument3 paginiSikagrout® 215 (New) : Product Data SheetWan Fikri DarmawanÎncă nu există evaluări

- Sikarep Microcrete-4Document4 paginiSikarep Microcrete-4indrajeet4911Încă nu există evaluări

- Sikagard 63n Pds enDocument3 paginiSikagard 63n Pds enariorasalahÎncă nu există evaluări

- Pds Sikascreed 45terrazzobinderDocument4 paginiPds Sikascreed 45terrazzobinderRade SimeunovicÎncă nu există evaluări

- The Fabrication of Materials: Materials TechnologyDe la EverandThe Fabrication of Materials: Materials TechnologyEvaluare: 5 din 5 stele5/5 (1)

- 2014 05 16 Project Manual IncompleteDocument376 pagini2014 05 16 Project Manual Incompletenap_carinoÎncă nu există evaluări

- One-Way Solid RC Slab Design To Bs 81101997 CW AnalysisDocument18 paginiOne-Way Solid RC Slab Design To Bs 81101997 CW AnalysisANGEL .Încă nu există evaluări

- RCC21 Subframe AnalysisDocument9 paginiRCC21 Subframe AnalysisZayyan RomjonÎncă nu există evaluări

- LATICRETEDocument164 paginiLATICRETEnap_carino100% (1)

- SIMPLIFIED RC DESIGN FORMULA FOR BEAMS AND SLABSDocument3 paginiSIMPLIFIED RC DESIGN FORMULA FOR BEAMS AND SLABSnap_carinoÎncă nu există evaluări

- Luxury Living Icon Phoenix Resort La CalaDocument31 paginiLuxury Living Icon Phoenix Resort La Calanap_carinoÎncă nu există evaluări

- 2014 05 16 Project Manual IncompleteDocument376 pagini2014 05 16 Project Manual Incompletenap_carinoÎncă nu există evaluări

- OasisDocument14 paginiOasisnap_carinoÎncă nu există evaluări

- Luxury Living Icon Phoenix Resort La CalaDocument31 paginiLuxury Living Icon Phoenix Resort La Calanap_carinoÎncă nu există evaluări

- Design of 6 Storey Building in EtabsDocument51 paginiDesign of 6 Storey Building in EtabsMisqal A Iqbal100% (2)

- S8 - Pile Driving Analyzer (PDA) and CAPWAP Proven Pile Testing Technology Principles and Recent Advances - LTC2013Document46 paginiS8 - Pile Driving Analyzer (PDA) and CAPWAP Proven Pile Testing Technology Principles and Recent Advances - LTC2013walaywan100% (3)

- IEI Rules of Thumb Line Card 03012016Document2 paginiIEI Rules of Thumb Line Card 03012016Anonymous 4ItkiwIÎncă nu există evaluări

- Office Building Structural Load Design CriteriaDocument4 paginiOffice Building Structural Load Design Criterianap_carinoÎncă nu există evaluări

- Concrete Mix Design GuideDocument5 paginiConcrete Mix Design Guideluke_0126Încă nu există evaluări

- M035 - QMS - ITP044 - Rev00 - Piling ITP PDFDocument3 paginiM035 - QMS - ITP044 - Rev00 - Piling ITP PDFnap_carinoÎncă nu există evaluări

- Falsework A HANDBOOK OF DESIGN & PRACTICE PDFDocument186 paginiFalsework A HANDBOOK OF DESIGN & PRACTICE PDFnap_carino100% (1)

- Design of Box Culvert BridgeDocument25 paginiDesign of Box Culvert BridgeVal Beltran100% (1)

- Contract Construction ManagementDocument63 paginiContract Construction ManagementprodandanliviuÎncă nu există evaluări

- V1 0 PDFDocument8 paginiV1 0 PDFnap_carino100% (1)

- CSengineermag 0418 PDFDocument68 paginiCSengineermag 0418 PDFnap_carinoÎncă nu există evaluări

- Design and Analysis of Two-Way Reinforced Concrete SlabsDocument16 paginiDesign and Analysis of Two-Way Reinforced Concrete Slabsgullipalli75% (4)

- Imi Rycroft Expansion VesselsDocument6 paginiImi Rycroft Expansion Vesselsnap_carinoÎncă nu există evaluări

- 121 (Pianc) Work - Group - ROM 3.1 PDFDocument15 pagini121 (Pianc) Work - Group - ROM 3.1 PDFnap_carino100% (2)

- Accessibility Code 2007, SingaporeDocument204 paginiAccessibility Code 2007, SingaporeChin HoeÎncă nu există evaluări

- Post - Tension Tendon Installation and Grouting Manual 2013Document184 paginiPost - Tension Tendon Installation and Grouting Manual 2013bala-kris100% (4)

- PCI - Precast Prestressed Concrete Parking StructuresDocument40 paginiPCI - Precast Prestressed Concrete Parking Structuresnap_carinoÎncă nu există evaluări

- MIL-DTL-53072D With Amendment 1Document38 paginiMIL-DTL-53072D With Amendment 1pmicjenÎncă nu există evaluări

- Repairing Fractured Metal-Ceramic Restorations Using Sandblasting and ResinDocument1 paginăRepairing Fractured Metal-Ceramic Restorations Using Sandblasting and Resinzahra serajÎncă nu există evaluări

- STP ShaliFloor-SL-TC-4EDocument3 paginiSTP ShaliFloor-SL-TC-4ERana MahatoÎncă nu există evaluări

- Pds Hempadur 15570 En-GbDocument3 paginiPds Hempadur 15570 En-GbdcsamaraweeraÎncă nu există evaluări

- Endo Angl v2011Document58 paginiEndo Angl v2011Yousab CreatorÎncă nu există evaluări

- Bristle Blaster BrochureDocument12 paginiBristle Blaster BrochureAZLAN ABDULLAIÎncă nu există evaluări

- Euroblast Scope of SupplyDocument5 paginiEuroblast Scope of SupplyUmair AwanÎncă nu există evaluări

- Warpaint Iss 39 Final UDocument74 paginiWarpaint Iss 39 Final Udemitsif100% (1)

- Surface Preparation - Monday: ATC88-40915 Revision Questions 23-2Document2 paginiSurface Preparation - Monday: ATC88-40915 Revision Questions 23-2Omar DhiebÎncă nu există evaluări

- Shot Blasting MachineDocument1 paginăShot Blasting MachineKarthi KeyanÎncă nu există evaluări

- Dycote 02Document30 paginiDycote 02nfcastings100% (1)

- Nose Wheel - Assembly and Disassembly ModificadoDocument17 paginiNose Wheel - Assembly and Disassembly ModificadoDanilo Diaz MontañezÎncă nu există evaluări

- British Standard: A Single Copy of This British Standard Is Licensed ToDocument13 paginiBritish Standard: A Single Copy of This British Standard Is Licensed ToHaiÎncă nu există evaluări

- Metal CastingDocument46 paginiMetal CastingAtul JainÎncă nu există evaluări

- Hygroscopic (Osmotic) Blisters Tiny, Pin Head Size, Water Filled Blisters. Caused by Hygroscopic Salts (Iron Sulphates and Iron Chlorides)Document25 paginiHygroscopic (Osmotic) Blisters Tiny, Pin Head Size, Water Filled Blisters. Caused by Hygroscopic Salts (Iron Sulphates and Iron Chlorides)Usab GamalÎncă nu există evaluări

- Catalog Portable Abrasive Blasting en v9 0 0 WebDocument72 paginiCatalog Portable Abrasive Blasting en v9 0 0 WebRiyaz BasheerÎncă nu există evaluări

- At 222 - Aps FenolanDocument14 paginiAt 222 - Aps FenolanApril FenolanÎncă nu există evaluări

- Ch3 Crack SealingDocument26 paginiCh3 Crack SealingWinengkuÎncă nu există evaluări

- 2011-02-01-Kiosk Tenants Design Criteria ManualDocument9 pagini2011-02-01-Kiosk Tenants Design Criteria ManualMihai MarcoviciÎncă nu există evaluări

- Painting Technical RequirementsDocument28 paginiPainting Technical RequirementshazopmanÎncă nu există evaluări

- CDI0 Part ListDocument61 paginiCDI0 Part ListcuongÎncă nu există evaluări

- Masterseal TC 244 - TdsDocument2 paginiMasterseal TC 244 - TdsAlbert NajjarÎncă nu există evaluări

- Devran 224HS PdsDocument2 paginiDevran 224HS Pdsjopedro96Încă nu există evaluări

- TDS Nitoflor SL3000 UT IndiaDocument4 paginiTDS Nitoflor SL3000 UT IndiaqmsudhirÎncă nu există evaluări

- Application Instructions: HempelDocument4 paginiApplication Instructions: HempelSharath ReddyÎncă nu există evaluări

- PDS en-GB 16490Document2 paginiPDS en-GB 16490Anuar SalehÎncă nu există evaluări