Documente Academic

Documente Profesional

Documente Cultură

Form2!01!01Process FMEA Worksheet (RCL SMALL)

Încărcat de

Muhammad Reza GadranDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Form2!01!01Process FMEA Worksheet (RCL SMALL)

Încărcat de

Muhammad Reza GadranDrepturi de autor:

Formate disponibile

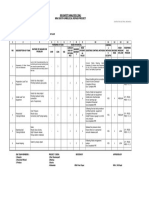

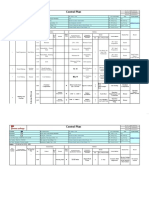

Process FMEA Worksheet 1704 Form 2-01-01

Supplier code PY26 Document No.

Model TD Part Name LAMP ASSY, DRL COMBI,LH/RH

Approved Checked Prepared

□ Safety part Supplier name BS INDONESIA

Part

Part No. ML250077/78

General part including safety

Divisio □ quality characteristics

n New edition 07. 03, 17 1st Edition Leader

Process Name L/A DRL COMBI LH/RH Operator

□ General part Revision sign month/day/year Reason of revision Approval Member

Influence of failure Result after countermeasures

Degree importance

Frequency of

Percentage

occurrence

Characteristics

Inspection/confirmatio

Degree of

influence

detected

R Person in

No. Process name Process functions Failure mode Causes of failure n P Countermeasures Schedule Measures R

charge Degree of Frequency of Percentage

Part Completed vehicle method N execution P

influence occurrence detected

situation N

Reflektor Assy (Insert Cannot insert reflektor to

1 Insert Pivot Clip Forget to insert pivot clip 4 Operator Negligence 2 Visual check 100 % 1 8 0

Pivot Clip) housing

Knob assy not function if

Reflektor Assy (Insert Aiming retainer doesn't

2 Insert Aiming Retainer aiming retainer not 4 Operator Negligence 2 Visual check 100 % 1 8 0

Aiming Retainer) inserted properly

inserted properly

Torque Screw driver is to

Reflektor Assy Demage on reflektor &

large & Forget to Visual Check & Tester for

3 ( Installation Bulb Installation Bulb Fixing Bulb fixing doesn't 5 Operator Negligence 3 2 30 0

tightening bulb fixing with Screw Driver

Fixing) installed properly

Screw M4x8

Reflektor to be dirty Shid doesn’t installed

Operator not use hand Visual check 100 % &

Reflektor Assy during installation Forget properly & Demage on

4 Installation Shid 5 gloove and forget to 3 Operator Shall use hand 2 30 0

(Installation Shid) to tightening shid with reflektor

tightening the screw gloove during production

screw M4x8

Reflekor Assy ( Insert Bulb can't installed

5 Insert Bulb H3 12V 55 Watt Wrong pairs/upside down 3 Operator Negligence 3 Visual Check 100 % 1 9 0

Bulb H3 12V 55 Watt) properly

Housing Assy (Insert

Insert Knob Assy+Push Forget install Oring to Leakage on part may Operator forget to install Visual Check 100% &

6 Knob Assy +Push 7 2 2 28 0

Nut+Oring knob occur Oring. Leak Test

nut+ Oring)

Housing Assy (Insert Demage on harness Appereance is not good,

Insert Harness Assy + Bulb Visual Check 100% &

7 Harness Assy + Bulb assy and forget to and lamp not function 4 Operator Negligence 2 2 16 0

12 V 21 W Lighting Test

12 V 21 W) installation bulb may occur.

Reflektor to be dirty & Demage on reflektor &

Housing Assy (Insert Wrong prameter & Tester for first production

8 Insert Reflektor to Housing demage during reflektor doesn’t installed 7 2 2 28 0

Reflektor to Housing) operator negligence run & Visual Check

installation may occur properly

Wrong pairs during

Housing Assy Operator wong pairs the Lighting test & Visual

9 Connecting Wire connecting wire to Lamp cannot turn on 7 2 1 14 0

(Connecting Wire) wire during installation Check

terminal

Housing Assy (Install Dust cover becomes Visual Check 100% &

Install Dust Cover + Oring Forget to install oring

10 dust cover + oring loose and leak of the 6 Operator Negligence 2 Minimum Sample & Leak 1 12 0

Gasket gasket to dust cover

gasket) part may occur Test

Leak of the part may Visual Check, Make

Hot Melt ( To attach the Wrong Parameter

11 Hot Melt Hot Melt Uneven occur and hot melt can 6 3 Sample Tester & Leak 1 18 0

housing and the lens) Machine

be spill over Test

Appereance of lens is Torque Setting of the

tester for screw driver &

12 Lens Installation Installation Lens to Housing Crack at housing not good & Effect on light 5 screw driver is to large & 2 2 20 0

visual check 100%

produced by lens Operator negligence

Wrong parameter setting

To Know There is a Leak on Wrong detection of the Leaked parts can be Make master sampel NG

13 Leak Test 7 & Machine is not good 2 1 14 0

The part or not machine missed & Good condition

condition

Wrong parameter setting

To know part have been Wrong detection of the Make master sampel NG

14 Lighting Test NG Part can be missed 7 & machine is not good 2 1 14 0

function or not machine & Good condition

condition

There is no production Operator negligence,

Production Code + Difficult to traceability,

code, wrong production wrong setting date, &

15 Installation Dust Production code difficult to identification 7 1 Visual check 100% 2 14 0

code, production code is Production code stamp

Cover product

not clear have been demage

0 0

0 0

Mitsubishi Fuso Truck & Bus Co., Ltd.

S-ar putea să vă placă și

- 4M Change Management FormatDocument1 pagină4M Change Management FormatSUBODHH100% (2)

- Itp-Inspection & Test Plan: Containment InstallationDocument1 paginăItp-Inspection & Test Plan: Containment InstallationwagwahkiabatheÎncă nu există evaluări

- JSA Tubing Leak TestDocument1 paginăJSA Tubing Leak TestMuhammad Reza Gadran67% (3)

- GED 7 Life and Works of Jose RizalDocument104 paginiGED 7 Life and Works of Jose RizalRheamie Fuyonan100% (1)

- Form2-01-01Process FMEA WorksheetDocument1 paginăForm2-01-01Process FMEA WorksheetMuhammad Reza GadranÎncă nu există evaluări

- 7.7 F-04 Intermediate FormatDocument1 pagină7.7 F-04 Intermediate FormatAshish DubeyÎncă nu există evaluări

- Plating Process Control Plan Template (2738)Document10 paginiPlating Process Control Plan Template (2738)George Hardy100% (1)

- Control Plan: FG 260 As Per IS 210: 2009Document24 paginiControl Plan: FG 260 As Per IS 210: 2009Suraj RawatÎncă nu există evaluări

- Use This As Reference For Painting Process It May Be Similar To YoursDocument7 paginiUse This As Reference For Painting Process It May Be Similar To Yoursabdelnasser hasanÎncă nu există evaluări

- Aspect Impact RegisterDocument17 paginiAspect Impact RegisterVi KraÎncă nu există evaluări

- Casting CPDocument2 paginiCasting CPSuraj RawatÎncă nu există evaluări

- Appendix 1 - Inspection & Test PlanDocument4 paginiAppendix 1 - Inspection & Test PlanwagwahkiabatheÎncă nu există evaluări

- Meenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09Document4 paginiMeenakshi Molding Private Limited Process FMEA: Form No - FM/7.1/01/09ilaya rajaÎncă nu există evaluări

- D10414410A CP Rev 00Document21 paginiD10414410A CP Rev 00Suraj RawatÎncă nu există evaluări

- New IPCR FormDocument4 paginiNew IPCR FormAlas Tres0% (1)

- 04 - Internal Audit Report and Check ListDocument4 pagini04 - Internal Audit Report and Check ListSriramhospital HopeÎncă nu există evaluări

- Potential Failure Mode and Effects Analysis (Design)Document12 paginiPotential Failure Mode and Effects Analysis (Design)PiyushÎncă nu există evaluări

- GM Casting CPDocument3 paginiGM Casting CPSuraj RawatÎncă nu există evaluări

- BLDG - Revised Inspection and Test PlanDocument23 paginiBLDG - Revised Inspection and Test Plan124th EAGLECOM KimJaveroÎncă nu există evaluări

- ISO 16232 Contamination Analysis: VHX Series Digital MicroscopeDocument2 paginiISO 16232 Contamination Analysis: VHX Series Digital Microscopelil10zinÎncă nu există evaluări

- Defect History: Sr. No Typeof Defect Action StatusDocument22 paginiDefect History: Sr. No Typeof Defect Action StatusSameer SaxenaÎncă nu există evaluări

- Inspection and Test Plan - Cavite - Laguna Expressway ProjectDocument17 paginiInspection and Test Plan - Cavite - Laguna Expressway ProjectRennee Son BancudÎncă nu există evaluări

- OMV Operations PUNCH LIST: Nawara and South Tunisia Development Central Process Facilities (CPF) Flowlines and WellpadsDocument1 paginăOMV Operations PUNCH LIST: Nawara and South Tunisia Development Central Process Facilities (CPF) Flowlines and WellpadsAbderrazak ChaabiniÎncă nu există evaluări

- AS-NZS 1554.1-2014 Procedure Qualification Record (PQR)Document1 paginăAS-NZS 1554.1-2014 Procedure Qualification Record (PQR)Bobby CurrieÎncă nu există evaluări

- Fmea Sfe47.005 WeldingDocument8 paginiFmea Sfe47.005 Weldingkumaraswamy.kÎncă nu există evaluări

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument3 paginiInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiÎncă nu există evaluări

- Anpqp - Design Potential FmeaDocument2 paginiAnpqp - Design Potential FmeaJoaquinÎncă nu există evaluări

- PFMEA Format v01 AdaDocument1 paginăPFMEA Format v01 AdaBalakumaran MurugesanÎncă nu există evaluări

- Ehs - Hazard Identification and Risk Assessment (Hira) : SL.N oDocument5 paginiEhs - Hazard Identification and Risk Assessment (Hira) : SL.N oNarayanasami KannanÎncă nu există evaluări

- Ceklis Alat Berat - ResultDocument2 paginiCeklis Alat Berat - Resultary fauzi rahmanÎncă nu există evaluări

- Potential Failure Mode and Effects Analysis (Process FEMA)Document1 paginăPotential Failure Mode and Effects Analysis (Process FEMA)Asif Iqbal100% (2)

- DPH 2011 3rd Q IM-1 PDFDocument15 paginiDPH 2011 3rd Q IM-1 PDFamirÎncă nu există evaluări

- 237 Preventive Check Sheet of Lps Mechanical Press ReDocument5 pagini237 Preventive Check Sheet of Lps Mechanical Press ReAjayÎncă nu există evaluări

- Calibration Log Form: 10330 - New Pta Complex ProjectDocument1 paginăCalibration Log Form: 10330 - New Pta Complex Projectum erÎncă nu există evaluări

- Control Plan: Process / Operation DescriptionDocument3 paginiControl Plan: Process / Operation DescriptionsharanÎncă nu există evaluări

- Supplier Change Request Form 8 DB 34 B 1 BaDocument2 paginiSupplier Change Request Form 8 DB 34 B 1 BaHussein100% (1)

- 03 (SQ) - Process Product Audit ReportDocument2 pagini03 (SQ) - Process Product Audit ReportDEVENDERÎncă nu există evaluări

- Inspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportDocument5 paginiInspection Standard: Daily Inprocess Inspection/Prod./Rejection ReportPrakash kumarTripathiÎncă nu există evaluări

- Details of Purchase Orders Placed Against Open Tenders During The Month of MARCH, 2020 From Materials Dept. DuliajanDocument4 paginiDetails of Purchase Orders Placed Against Open Tenders During The Month of MARCH, 2020 From Materials Dept. DuliajanAliakbar BharmalÎncă nu există evaluări

- Machining Control PlannDocument18 paginiMachining Control PlannSuraj RawatÎncă nu există evaluări

- Emmforce Inc.: Failure Mode and Effects Analysis (Process Fmea)Document1 paginăEmmforce Inc.: Failure Mode and Effects Analysis (Process Fmea)Satya PalÎncă nu există evaluări

- Tempering Process Monitoring Report (CMBF) : Product Details HT. Process ControlDocument1 paginăTempering Process Monitoring Report (CMBF) : Product Details HT. Process ControlShoaib AkhtarÎncă nu există evaluări

- Working at Height Risk AssessmentsDocument1 paginăWorking at Height Risk AssessmentsRajan GuptaÎncă nu există evaluări

- Inspection and Test PlanDocument1 paginăInspection and Test PlanMohsin MohdÎncă nu există evaluări

- ServiceSchedule MD22Document3 paginiServiceSchedule MD22theo_swaranÎncă nu există evaluări

- Isir - (00003)Document1 paginăIsir - (00003)ducthangspktÎncă nu există evaluări

- AMEF Evidencia 3Document15 paginiAMEF Evidencia 3Brandon VidalÎncă nu există evaluări

- Actividad 11 Plan de FalllasDocument15 paginiActividad 11 Plan de FalllasBrandon VidalÎncă nu există evaluări

- Actividad 4 - AMEFDocument15 paginiActividad 4 - AMEFBrandon VidalÎncă nu există evaluări

- AMEF Evidencia 1Document15 paginiAMEF Evidencia 1Brandon VidalÎncă nu există evaluări

- Potential Failure Mode and Effective Analysis (Process FMEA)Document1 paginăPotential Failure Mode and Effective Analysis (Process FMEA)nainarmuthuramalingamÎncă nu există evaluări

- CD6 Prototype Control PlanDocument3 paginiCD6 Prototype Control Planmpedraza-1Încă nu există evaluări

- Document No.: 374679 Fitting Mudguards On CA4x2Document5 paginiDocument No.: 374679 Fitting Mudguards On CA4x2Rodolfo Alberto Muñoz CarcamoÎncă nu există evaluări

- 2023-02-08 MAR-080 IMC Pipes and Fittings (Smartube) - ANAKO Philippines Corporation RRAADocument1 pagină2023-02-08 MAR-080 IMC Pipes and Fittings (Smartube) - ANAKO Philippines Corporation RRAAjaymarÎncă nu există evaluări

- 06) - Fmea For 11190722 - DDocument192 pagini06) - Fmea For 11190722 - DMONISHRAJÎncă nu există evaluări

- Efwe 2 e 4 GF 1 W 3Document1 paginăEfwe 2 e 4 GF 1 W 3BALACHANDAR SÎncă nu există evaluări

- Process Failure Mode and Effects Analysis: SEV OCC DETDocument15 paginiProcess Failure Mode and Effects Analysis: SEV OCC DETMomoZhÎncă nu există evaluări

- CP20200804-A Model Control Plan - FoundationsDocument6 paginiCP20200804-A Model Control Plan - Foundationsmanno200Încă nu există evaluări

- Method Statements of Surface Treatment and Painting For Valves Nh3 ProjectDocument5 paginiMethod Statements of Surface Treatment and Painting For Valves Nh3 ProjectDuongthithuydung0% (1)

- Lampiran - IKA CM Rotating EquipmentDocument1 paginăLampiran - IKA CM Rotating Equipmentahmadalfan662Încă nu există evaluări

- Work Report Callout Ilovepdf CompressedDocument10 paginiWork Report Callout Ilovepdf CompressedMuhammad Reza GadranÎncă nu există evaluări

- SPPB AssemblingDocument83 paginiSPPB AssemblingMuhammad Reza GadranÎncă nu există evaluări

- Company Profile TPIDocument9 paginiCompany Profile TPIMuhammad Reza GadranÎncă nu există evaluări

- List Aplicator Crimping Proses Wiring Harness: NO Part No Part Name Proses Model Tahun M/C Metode Crimping KeteranganDocument1 paginăList Aplicator Crimping Proses Wiring Harness: NO Part No Part Name Proses Model Tahun M/C Metode Crimping KeteranganMuhammad Reza GadranÎncă nu există evaluări

- BOM - Altronic 1 For Arrow C-96Document3 paginiBOM - Altronic 1 For Arrow C-96Muhammad Reza GadranÎncă nu există evaluări

- C&e PetrochinaDocument66 paginiC&e PetrochinaMuhammad Reza GadranÎncă nu există evaluări

- Work Schedule Upgrading Panel GC 'CP-5000Document6 paginiWork Schedule Upgrading Panel GC 'CP-5000Muhammad Reza GadranÎncă nu există evaluări

- Sahala Pressure GaugeDocument2 paginiSahala Pressure GaugeMuhammad Reza GadranÎncă nu există evaluări

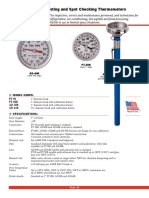

- Bimetal Thermometers: Tel-Tru Manufacturing CompanyDocument8 paginiBimetal Thermometers: Tel-Tru Manufacturing CompanyMuhammad Reza GadranÎncă nu există evaluări

- Contoh Membuat Daftar Komponen Quotation Temperature GaugeDocument3 paginiContoh Membuat Daftar Komponen Quotation Temperature GaugeMuhammad Reza Gadran100% (1)

- Risk Assessment TSDocument5 paginiRisk Assessment TSMuhammad Reza GadranÎncă nu există evaluări

- Non-Contact Infrared Thermometers: Tel-Tru Manufacturing CompanyDocument2 paginiNon-Contact Infrared Thermometers: Tel-Tru Manufacturing CompanyMuhammad Reza GadranÎncă nu există evaluări

- Catalog For Pahala BahariDocument4 paginiCatalog For Pahala BahariMuhammad Reza GadranÎncă nu există evaluări

- Teltru Bimetal Thermometers DatasheetDocument28 paginiTeltru Bimetal Thermometers DatasheetMuhammad Reza GadranÎncă nu există evaluări

- Back Connected Testing and Spot Checking ThermometersDocument2 paginiBack Connected Testing and Spot Checking ThermometersMuhammad Reza GadranÎncă nu există evaluări

- AA575RDocument16 paginiAA575RMuhammad Reza GadranÎncă nu există evaluări

- Cause Amp Effects Rating MatrixDocument5 paginiCause Amp Effects Rating MatrixMuhammad Reza GadranÎncă nu există evaluări

- Raw Meal Grinding Aids: Improving BurnabilityDocument3 paginiRaw Meal Grinding Aids: Improving BurnabilityfaheemqcÎncă nu există evaluări

- AHRICertificateDocument1 paginăAHRICertificaterenatosustentechÎncă nu există evaluări

- 10D Unit-Coral Reefs PDFDocument14 pagini10D Unit-Coral Reefs PDFIWAN KUNCOROÎncă nu există evaluări

- Slide Topic 2 - PR TheoriesDocument26 paginiSlide Topic 2 - PR TheoriesJeneesh RajendranÎncă nu există evaluări

- How To "Revert-Back" To "Previous-Version"???: Build 1 Testing DeploymentDocument19 paginiHow To "Revert-Back" To "Previous-Version"???: Build 1 Testing DeploymentClaudiu Stefan HaiduÎncă nu există evaluări

- Dist Census Book Latur PDFDocument770 paginiDist Census Book Latur PDFMP100% (1)

- LAtihan Ujian Inggris MinatDocument13 paginiLAtihan Ujian Inggris MinatDfzh HhÎncă nu există evaluări

- Find The Belt Length at A 72 in Distance Connected in Open Belt. The Pulley Diameters Are 6 and 12 inDocument4 paginiFind The Belt Length at A 72 in Distance Connected in Open Belt. The Pulley Diameters Are 6 and 12 inGeoffrey GolbequeÎncă nu există evaluări

- BAEnglish Language Linguistics PDFDocument93 paginiBAEnglish Language Linguistics PDFAnonymous p5BEJzvqrkÎncă nu există evaluări

- CV - Pinki Arindra P&GDocument6 paginiCV - Pinki Arindra P&GPinqi Arindra PutraÎncă nu există evaluări

- LTE OFDMA SimulationDocument9 paginiLTE OFDMA Simulationrajendra4343Încă nu există evaluări

- HPC Module 1Document48 paginiHPC Module 1firebazzÎncă nu există evaluări

- GX30G Non EU (150113) - ??Document2 paginiGX30G Non EU (150113) - ??ggpetÎncă nu există evaluări

- Allen: Pre Nurture & Career Foundation DivisionDocument7 paginiAllen: Pre Nurture & Career Foundation DivisionSiddharth Singh100% (1)

- Dynamic Modelling of Gas TurbinesDocument8 paginiDynamic Modelling of Gas TurbinesdannyÎncă nu există evaluări

- Psychology Concepts and Applications 4Th Edition Nevid Solutions Manual Full Chapter PDFDocument49 paginiPsychology Concepts and Applications 4Th Edition Nevid Solutions Manual Full Chapter PDFfidelmanhangmhr100% (9)

- Sternberg TheoryDocument20 paginiSternberg TheoryKhadijah ElamoreÎncă nu există evaluări

- Karma: "Dove La Legge Della Grazia È Attiva, Finisce La Legge Del Karma"Document37 paginiKarma: "Dove La Legge Della Grazia È Attiva, Finisce La Legge Del Karma"Lars JensenÎncă nu există evaluări

- SPPU Report FormatDocument50 paginiSPPU Report FormatAmit Devidas AherÎncă nu există evaluări

- Eng8Quarter1Week1 2Document6 paginiEng8Quarter1Week1 2Duero-Hadjilatip KayeÎncă nu există evaluări

- Image Processing (Rry025)Document22 paginiImage Processing (Rry025)Babasrinivas GuduruÎncă nu există evaluări

- Modul Customer ServiceDocument5 paginiModul Customer ServiceFandy Bestario HarlanÎncă nu există evaluări

- Toyota Toyota+sienna+2013+manualDocument1 paginăToyota Toyota+sienna+2013+manualNur Cholik Widyan Sa0% (1)

- Black Mirror Analysis: 15 Million Merits (Due 27/04/16)Document11 paginiBlack Mirror Analysis: 15 Million Merits (Due 27/04/16)Will MunnyÎncă nu există evaluări

- DS-KH6320-TE1 Video Intercom Network Indoor Station: Key FeatureDocument3 paginiDS-KH6320-TE1 Video Intercom Network Indoor Station: Key FeatureDaniellMargaritÎncă nu există evaluări

- Real Time Manufacturing' Using Oracle Cloud 13: A Manufacturing Execution System by WiproDocument18 paginiReal Time Manufacturing' Using Oracle Cloud 13: A Manufacturing Execution System by WiproSatya NekkantiÎncă nu există evaluări

- Lecture On Dictionaries - Jupyter NotebookDocument13 paginiLecture On Dictionaries - Jupyter NotebookruchikaÎncă nu există evaluări

- E-Rpms Portfolio (Design 3) - Depedclick-1Document42 paginiE-Rpms Portfolio (Design 3) - Depedclick-1angeliÎncă nu există evaluări

- In Search of The Indo Europeans J P Mallory TextDocument289 paginiIn Search of The Indo Europeans J P Mallory TextHISTORY OF MUSICÎncă nu există evaluări