Documente Academic

Documente Profesional

Documente Cultură

Geo-Technical Characterization of Pond Ash As A Highway Fill Material

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Geo-Technical Characterization of Pond Ash As A Highway Fill Material

Drepturi de autor:

Formate disponibile

Volume 3, Issue 10, October – 2018 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Geo-Technical Characterization of Pond Ash as a

Highway Fill Material

Subhadip Chakraborty

M . Tech in Transportation Engineering, Department of Civil Engineering

Manav Rachna International Institute of Research & Studies

Faridabad, India

Abstract- The evolution of mankind has caused overall I. INTRODUCTION

development of a nation with which there has been an

increase in demand of daily utilities. One such increasing Coal usage for power generation results in generation

demand is of electric power. Though many resources are of approximately 100 million tonnes of coal ash every year.

used for its production, one of the major raw materials is In India, 65% are thermal power stations, utilizing domestic

‘coal’ used for the generation of electricity and outcomes coal in 75% of them, with nearly generation of 20 million

the generation of waste in the form of coal ash is a pre- tonnes fly ash every year according to Bharathi Ganesh

requisite to it. With more than 65 % of India’s electricity et.al[1]. Coal ash viz. fly ash, bottom ash and Pond ash are

capacity generated by thermal power plants, 85% of the by-products of thermal power plants and considered as

them use coal as their burning fuel and thus produces a waste materials whose dumping has been a major problem

huge quantity of coal ash and its disposal has always from an environmental point of view and a lot of land needs

been a serious issue of concern for the safety of to be allocated to act as a disposable site. According to the

environment. The coal ash generated is dumped as Pond Ministry of Environment and Forest, Government of India

ash in major portions to disposal site also known as ash MOEF 1999 on September 14, 1999[2], the present thermal

pond, located near the plant. Due to use of different type power plants were proposed to acquire 20% utilization of fly

of coal, the properties of Pond ash vary within two ash by 3 years and 100% utilization by 15 years. But till date

thermal power plants and also near the disposal point only about 60% of thermal waste has been successfully used

(inflow) and outflow point within the same ash pond. To as useful resource. According to Shenbaga et.al [3], countries

assess the feasibility of pond ash as a fill material, pond like India, China, Poland and the US, alone are responsible

ash sample was collected from the ash pond situated for production of more than 270 million tons of fly ash

near the National Thermal power plant in Badarpur, every year. Yet less than half of it remains un-utilized. The

New Delhi. This paper presents a detailed study on the utilization of fly ash has increased from 3% in 1994, 13% in

characterization of the Index, geotechnical and chemical 2002, 56% in 2011 and nearly 62% by end of 2017[4]. The

properties of pond ash sample. Results reveal that pond overall land required for disposal of ash would be about

ash has Coefficient of uniformity. 5.0 and coefficient of 82,200 ha by the end of 2020 at an estimated rate of 0.6 ha

curvature, 1.65. Pond ash shows low specific gravity 2.30 per MW.

g/cm3 as compared to soil (2.6–2.7 g/cm³), i.e.natural fill

material, low amount of unburned carbon content 2.84 In fact there are three types of ash produced thermally,

% and the maximum dry density is 1.19 g/cm3 and 1.23 viz. (1) fly ash, (2) bottom ash, and (3) pond ash. Huge

g/cm3 whereas optimum moisture content is 28 % and quantity of fly and bottom ash are generated by thermally in

24.53 % for light and heavy compaction respectively. power plants (TPPs) as a by-product. Usually 80 % of the

CBR value for un-soaked sample at light compaction is coal ash is of the fly ash type and rest being bottom ash [5,6].

9.02% and at heavy compaction is 19.10 % at 2.5 mm Fly ash is collected with the help of Electrostatic

penetration. Soaked sample showed a value of 1.34 %. Precipitators (ESP) from the flue gases of power plant;

EDXRF test indicates the combined concentration of whereas, bottom ash gets accumulated at the bottom of the

SiO₂, Al₂O₃ and Fe₂O₃ was 91.85 % and CaO was boilers. When these two types of ashes are blended together,

0.95%, which verifies it as a Class F category fly ash. transported in slurry form and stored in the lagoons, the

The results of chemical analysis indicates that deposit material is termed as pond ash. This way of disposal

concentration of Arsenic(As), Lead(Pb), Barium(Ba)and is known as wet disposal system. This system causes

Chromium (Cr)are relatively higher than the standard segregation of coal ash and two distinctly significant types

land disposal limit, specified by United States of materials are obtained at inflow and outflow points for

Environment Protect agency (USEPA) TCLP limits for the same ash pond, which have significant chemical

hazardous wastes. So it can be used adequately as properties than both fly ash and bottom ash. The inflow

embankment and subgrade construction fill material for point contains the coarser and heavier particles of ash. Finer

low-lying areas. Caution must be adopted to prevent and lighter particles are transported away and settle in the

vicinity of outflow point[7-9].

contamination of ground water due to the high

concentration of some hazardous heavy metals. The specific coal bed composition determines the

Keywords:- Pond ash; Fill material; Embankment; minor constituents of fly ash but may include one or more of

Characterization; LOI; ED-XRF. the following elements or compounds in trace

concentrations (up to hundreds ppm): arsenic, barium,

beryllium, boron, cadmium, chromium, cobalt, copper, lead,

IJISRT18OC372 www.ijisrt.com 594

Volume 3, Issue 10, October – 2018 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

manganese, mercury, nickel, selenium, silver, sulphur, of sizes 4.75, 2.36, 0.600, 0.300,0.150, 0.090 and 0.075 mm.

thallium, vanadium, along with dioxins and PAH This test was carried out 3 times to obtain average value of

compounds in very small concentrations[10,11]. It also has all the results obtained. Also hydrometer test was carried out

percentage of un-burnt carbon[12]. Pond ash being 80 % fly on fine grained ash fraction, passing 0.075 mm sieve already

ash and 20 % can be categorized in two classes defined collected in a pan. The specific gravity (G) of ash sample

by ASTM C618: Class F fly ash and Class C fly ash. These was determined by Pycnometer bottle as per IS 2720 (Part

classes are differentiated based on the combined amount of 3) 1980 sect/2[17]. Standard Proctor and Modified Proctor

silica, alumina, iron and the presence of free lime. Adding to tests were conducted to determine Maximum dry

this the type of coal burned (i.e., anthracite, bituminous, density(MDD) and Optimum moisture content(OMC).

and lignite) also have large influence on the chemical Standard Proctor apparatus mould have 100 mm diameter

properties of the pond ash. [13] and 127.3 mm height (capacity of 1000 ml) as per IS: 2720-

Part 7[18] . Modified Proctor was conducted with the help of

Fly ash itself has some amount of cementitious nature mould of 150 mm diameter and 127.3 mm height(capacity

but with the presence of moisture it reacts chemically to of 2250 ml) as per IS:2720-Part 8[19]. CBR was performed at

form cementitious compounds and attributes to the strength OMC for both soaked and un-soaked sample with reference

improvement and compressibility characteristics of soils and to IS: 2720(Part 16)-1973- Methods of test for soil-

acts an economic replacement for finely grained stones or Laboratory determination of CBR [20]. A sample was kept in

soil which have been practiced for a long time till now. the mould for soaking for a period of 96 hours or more.

Under this condition the sample in the mould attains

Various efforts have been made by researchers to optimum saturation. CBR test is then performed on the

utilize this waste to resource as useful material such as fill sample so as to determine the strength, if pond ash is to be

material in roads and embankments, cement production, used as fill material or subgrade which has to undergo

brick manufacture and construction of road embankments, adverse climatic situation such as heavy rainfall exceeding

Stabilization of soil, for backfilling retaining walls & 500 mm.

embankments by Behera, B. et al. (2011), Bhattacharjee U.

et al, (2000), Kolay, P.K., et al. (2011), Heidrich C.(2003) [14- Unconfined Compression (UCS) test was performed

15]

. on a sample of 3.8 mm diameter and 7.6 mm height under

standard loading conditions with a rate of strain of 1.2

The primary objective of this research was to gauge mm/min as per IS:2720-Part 10-1991[21] . Loss on Ignition

the geotechnical properties like specific gravity, bulk (LOI) test was performed to determine the amount of un-

density, moisture content, dry density, strength and chemical burnt carbon in Pond ash sample so as to facilitate the test

composition of pond ash. The present study deals with the for determining the chemical composition of the same.

characterization done by physical and chemical analysis and Energy dispersive X-ray fluorescence (ED-XRF) test was

its suitability is measured to be used as a replacement of soil conducted in order to find out the chemical composition and

in highway and embankments. presence of heavy metals the pond ash comprises. Huang

II. MATERIALS AND METHODS (1990) experimented on the Indiana bottom ash and boiler

slag to study the shear strength compacted to varying mass

Materials to volume ratio using direct shear testing. The results of

In order to understand the properties of pond ash, friction angles shows a variation from 35 to 55°, depending

sample was collected from the ash pond where disposal is on the density of the sample [22].

done by wet disposal method in NTPC Badarpur, Haryana,

India. For proper identification of physical and chemical Manju Suthar et.al [23] determined that samples at the

properties, the ash samples collected were dried under inflow have the major component of fine sand size i.e.

sunlight to remove partial moisture and oven dried (0.425–0.075 mm) and outflow samples from Khedar and

whenever necessary. A test for calculating the percentage of Yamunanagar, had the major component of silt size (0.075–

un-burnt carbon, Loss on Ignition (LOI) test was conducted. 0.002 mm). Specific gravity of coal ash was 1.66-2.86

whereas 2.21–2.27 and 2.03–2.06 for inflow and outflow

Characterization Methods pond ash respectively. Bulk density point ranged between

The characterization was carried out by performing 1.114–1.275 g/cc. MDD of inflow was 1.212–1.322 g/cc and

test for physical and chemical properties of Pond ash sample 1.093–1.312 g/cc for the outflow samples.; OMC ranges

in laboratory. Important physical properties of any material from 18.01–28.3 to 18.6–32.2 %, respectively. Pandian et.al

[24]

to be used as a fill material were determined. Parameters researched on the outcome of two types of fly ashes

like Grain size; specific gravity(G); bulk density; maximum namely Fly ash-Raichur (Class F) and Fly ash-Neyveli

dry density(MDD); optimum moisture content(OMC); (Class C). The CBR characteristics of the black cotton (BC)

California Bearing Ratio(CBR) test for soaked(at least 96 soil was determined. The fly ash content had an increase

hours0 and un-soaked sample were conducted. Unconfined from 0 to 100%. Generally the cohesion and friction

compression strength of pond ash was also conducted to contributed to the CBR strength. The addition of fly ash to

determine strength of sample. Black Cotton soil increased the CBR up to the first optimum

level due to the frictional resistance and cohesion from fly

Grain size test was performed as per IS:2720 (Part ash and BC soil, respectively. A decrease up to 60% when

4)[16] and sample was sieved through Indian standard sieves fly was added beyond optimum level and then there was an

increase up to the second optimum level. Thus the relative

IJISRT18OC372 www.ijisrt.com 595

Volume 3, Issue 10, October – 2018 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

contribution of cohesion and friction from fly ash or BC soil content and specific density. Linear empirical models were

attributes to the variation of CBR of fly ash-BC soil mixes. developed to estimate MDD and OMC in the field at any

compaction energy. Practicing engineers might use these

P. V. V. Satyanarayana [25] investigated on a models to control compaction while in the field and for

combination of recycled concrete aggregate and pond ash. preliminary estimate MDD and OMC of pond ash.

Both were mixed at different proportions to determine

geotechnical characteristics such as graduation, compaction Efforts are continuously given by making strict

and strength characteristics. The pond ash was used as a regulations by the Government to fully utilize the fly ash.

replacement below the size of 4.75mm. At 30% pond ash India currently produces about 130 million tonnes of fly ash

replacement CBR was 55% which was maximum. A 30-40 by FLY ASH RESOURCE CENTRE (FARC), STATE

% of pond ash mixed with recycled aggregate generates POLLUTION CONTROL BOARD, ODISHA [29] which

CBR values greater than 60 % and 30 % which can be used calls for an increase in the utilization percentage. The

as base and sub-base course materials respectively as a dumping of fly ash would require 1000 km² which in turn

substitute to natural aggregate and sand in the design and shall make require new areas of disposal, involving

construction of pavement. displacement and hence rehabilitation problems. Pond ash

chemically is amorphous ferro-alumina silicate, Fe-Al₂SiO₅

The chemical composition of pond ash was pozzolonic with major elements like Si, Al, Fe along with significant

as it contains SiO₂ (61.77 to 65.95 %); Al₂O₃ (20.56 to amounts of major / secondary nutrients (Ca, P, K, Mg, S)

21.64 %); Fe₂O₃ (8.70 to 11.48 %) and CaO (0.76 to 1.12 and micro nutrients (Cu, Fe, Mn, Mo, Zn)

%) at the inflow and SiO₂ (62.45 to 63.85 %); Al₂O₃ (25.03

to 27.77 %); Fe₂O₃ (4.35 to 5.95 %) and CaO (0.66 to 0.90 As compared to other materials, fly ash being very

%) at outflow by Manju Suthar. According to Sushovan finer and more reactive is consequently suitable as

Dutta et.al [26] fly ash consisted 63.52% SiO₂; 26.89% embankment and road construction material. Fly ash alone /

Al₂O₃; 5% Fe₂O₃; and 1.23% CaO. Un-burnt carbon was soil stabilized fly ash / fly ash mixed with admixtures and

1.49%. ASTM C618 categorize this fly ash as Class F. heir potential application for road construction has been

Specific gravity was 2.15. It consisted 78% of silt sized, reported by a number of researchers. Arumugam K

15% sand sized and 7% clay sized particles. The trace et.al(2011) [30] experimented to investigate the possibility of

elements such as Zn, Cd, Pb, Mo, Ni, As, Se and B imposed using pond ash in varying percentage as substitute of fine

a concern for land disposal regarding safety of environment. aggregate in cement concrete with the workability and

According to N.S. Pandian [27] the silica content was 37 to compressive strength of concrete and was compared with

75% alumina content ranges between 11 and 53% for pond standard concrete. With addition of pond ash a reduction in

ashes. The free lime lies in the range of 0.2 to 0.6% for pond unit weight and slump value was observed for fresh concrete

ashes. It was derived that Indian coal ashes satisfy the as specific gravity is less than soil. The strength of concrete

chemical requirements to be used as a pozzolona. Neyveli also improved with age of concrete up to the addition of

fly ash was classified as Class C and other coal ashes were 20% fine aggregate replacement with pond ash. Further

found to be Class F as per ASTM Classification. addition reduces the strength.

Sushovan Dutta researched on the Use of Waste III. RESULTS & DISCUSSIONS

Plastic Bottles and Fly Ash in Civil Engineering

Applications. They performed Compression test on plastic Grain size distribution

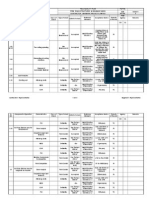

water bottles with fly ash and stone aggregates as in-fill The results of Grain size distribution (GSD) of pond

materials. He studied the workability of reusing plastic ash sample after sieve analysis are outlined in Fig 1.

water bottles as ideal compression member in Geotechnical Uniformity coefficient, (Cu) and Coefficient of curvature,

applications. Compression tests at a constant displacement (Cc) are calculated and is presented in graph.

of 1.2mm/min were performed on the composite cells.

Results of tests showed plastic bottles not only sustain 30% D60

Cu =

to 40% axial strain before failure but also fails at a high D10

compressive pressure of 4000 kPa to 5000 kPa. Study

suggested that these materials (pond ash) could be used for (D30 )2

Cc = × D10

supporting higher loads and if required could permit higher D60

settlements.

D10, D30 and D60 are particle sizes in a way that 10, 30

Bera et al. (2007) [28] studied on compaction and 60% of the ash are finer than these size, respectively.

characteristics of three different types of pond ash. Herein, The results of GSD are shown in Figure 1. The results show

the effects of compaction energy, moisture content, layer that the pond ash sample was uniformly graded and non-

thickness, mould area, tank size, and specific gravity on dry plastic in nature. The major component of the pond ash

density of pond ash were highlighted. The MDD and OMC sample was of fine sand size i.e. (0.425-0.075 mm). Check

vary within 8.40–12.25 KN/m³ and 29–46% respectively. In values of Cu and Cc from the graph. The value of

that investigation, the degree of saturation at OMC of pond coefficient of uniformity was within permissible range

ash varied from 63–89%. An empirical model was according to IRC:SP:58-2001[27].

developed to estimate dry density of pond ash, using

multiple regression analyses, in terms of compaction, water

IJISRT18OC372 www.ijisrt.com 596

Volume 3, Issue 10, October – 2018 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

100

90

1.25

80

1.20

70

Dry density (g/cm³)

PERCENT FINER BY WEIGHT

60

1.15

50

40

1.10

30

20

1.05

10

0

0.001 0.01 0.1 1

1.00

PA R T IC L E SI ZE , m m

0.00 10.00 20.00 30.00 40.00 50.00

Water content (%)

Fig 1:- Grain Size Distribution curve

Specific Gravity and Bulk Density Fig 3:- Comparison of MDD and OMC for light and heavy

The results of specific gravity (G) and bulk density (ρ) compaction

are presented in table. The specific gravity of coal ash

The results of heavy compaction are shown in Figure

generally lies between 1.90-2.55 g/cc as per IRC:SP:58-

3. It can be observed from the results that in case of heavy

2001. The average Specific gravity (for 3 samples) obtained

compaction OMC had a decrease by 3.32 % and MDD

after Pycnometer test of the oven dried pond ash sample was

showed higher value by 2.52 %. It can be concluded that

2.30 g/cm³. The low specific gravity could be due to the

with an increase in MDD of the sample the OMC decreases

presence of a large number of hollow cenospheres from

proving to be inversely proportional to each other.

which entrapped air cannot be removed. However the

specific gravity value of pond ash sample lies significantly California Bearing Ratio

below the specific gravity of soil i.e. natural fill material. In order to determine the strength of Pond ash,

The higher value of specific gravity of the ash sample is California bearing ratio test was performed at OMC for both

may be due to presence of high amount of Fe₂O₃ obtained Standard and Modified Proctor test. CBR value was

from chemical analysis. Bulk Density (ρ) of ash sample was determined for un-soaked samples of pond ash. Test for

found out to be in between 1.117-1.517 g/cm³. Soaked sample was also conducted to understand the

strength characteristics of subgrade under adverse situations

Compaction Characteristics

such as heavy rainfall exceeding 500 mm. For the un-soaked

The compaction test results were determined using

sample at Standard Proctor OMC the CBR was found to be

standard procedure and presented in the following figures.

9.02 % and 15.18 % for 2.5 mm and 5.0 mm penetration

The results for light compaction are shown in Figure 2. In

respectively. The soaked sample showed relatively lower

case of light compaction(Standard Proctor method), test

value of 1.64 % and 1.87 % for 2.5 mm and 5.00 mm

results it was observed that the Maximum Dry

penetration of the plunger, respectively. The results of load

Density(MDD) of the ash sample range was 1.19 g/cc while

against penetration are shown in the Figure 4 and 5.

ranging from 1.04–1.19 g/cc; Optimum Moisture

Content(OMC) was 28% and ranges from 12.41–45.89 %.

55 blows

Whereas in case of heavy compaction i.e. Modified Proctor 30.00

tests, MDD was found out to be 1.23 g/cm³ and OMC was

27.03%. MDD and OMC results for the Pond ash sample are 25.00

found to be within specified limits (MDD- 0.9–1.6 g/cm³

and OMC- 18.0–38 %) as per IRC:SP:58-2001 acceptable 20.00

for highway embankment construction.

Load (kg/cm²)

15.00

1.22

1.20

10.00

1.18

Maximum Dry density, g/cm³

1.16

1.14 5.00

1.12

1.10

0.00

1.08

- 2 4 6 8 10 12 14 16 18 20

1.06

1.04

Penetration (mm)

1.02

0.00 10.00 20.00 30.00 40.00 50.00 Fig 4:- Load-Penetration relation for Un-soaked Pond ash

Water content(%) sample at 28 % OMC

Fig 2:- Water content-dry density relation for Standard

Proctor Compaction

IJISRT18OC372 www.ijisrt.com 597

Volume 3, Issue 10, October – 2018 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

55 blows 250

5.00

200

4.50

Compressive stress, Kpa

4.00 150

3.50

100

Load (kg/cm²)

3.00

2.50 50

2.00

0

1.50 0 1 2 3 4 5

Strain %

1.00

Fig 7:- Relation between Stress and Strain under axial load

0.50

0.00 Loss on Ignition

- 2 4 6 8 10 12 14 16 18 20 The coal ash obtained from thermal power plants has

Penetration (mm) some amount of un-burnt carbon in it which may affect the

composition of oxides and heavy metals in Coal ash. So in

Fig 5:- Load-Penetration relation for Soaked Pond ash order to determine the amount of un-burnt carbon in Pond

sample at 28% OMC ash, a test on loss on ignition was carried out at a

temperature of 450˚C in a blast furnace for 5 hours. The

In case of CBR performed at OMC obtained by heavy weight of the sample before and after the Ignition was

compaction, for 2.5 mm and 5.00 mm penetration the measured and the loss of weight due to removal of moisture

sample showed a value of 19.10 % and 28.15 % respectively was calculated with the help of the equation as given below.

for the un-soaked sample. The results are analysed

W2−W3

graphically and shown in Figure 6. LOI = W2−W1 × 100

Where, W1= Weight of empty crucible

55 blows W2= Weight of crucible + Sample

70.00 W3= Weight of dried sample + crucible

The loss on Ignition was found out to be 2.84%.

60.00

Chemical Properties

50.00 The chemical composition was determined using ED-

Load (kg/cm²)

XRF Epsilon testing machine on the Pond ash sample. The

40.00

Epsilon 5 is a fully integrated X-ray analysis system. It

combines of a unique energy-dispersive X-ray fluorescence

30.00

spectrometer, with instrument control and analysis software

20.00 to derive the composition of major and minor elements up to

PPM. The results of chemical analysis of Pond ash sample

10.00 are presented in Table 1. From the results, it was observed

that Pond ash sample are primarily rich in Silica (SiO₂),

0.00 Alumina (Al₂O₃) and Iron oxide (Fe₂O₃). It also contains

- 2 4 6 8 10 12 14 16 18 20 CaO, P₂O₅, K₂O, MgO, MnO, TiO₂ and ZnO in small

Penetration (mm) amounts. Heavy metals like arsenic, barium, lead and

chromium were found in trace amounts but they are high

Fig 6:- Load-Penetration relation for Un-soaked Pond ash than the permissible limits as given by the USEPA TCLP

sample at MPCT limits for hazardous heavy metals in waste[28]. Table 2

shows the amount of heavy metals in comparison with

Unconfined Compression test TCLP limits for hazardous wastes. Mishra and Das reported

Unconfined Compression test was done to determine the presence of SiO₂ (≥60 % of the total composition) in

the behaviour of Pond ash under axial load so as to find out higher amount may help in increasing the strength as a fill

the compressive strength and shear strength. The test was material and offer better bearing capacity. The presence of

carried out on a cylindrical sample having diameter of 3.6 small amount of free lime(CaO) (0.95%), which being less

cm and height 7.6 cm under a rate of strain of 1.2 mm/min at than 1% causes very negligible pozzolonic or cementing

standard loading conditions. The compressive strength was properties[29].

found to 2.037 kg/cm² and shear strength was 1.019 kg/cm²

at an elapsed time of 2.5 min. Results from Figure 7 shows According to ASTM C 618-08a, the sample of Pond

the ultimate compressive stress is observed at a strain of ash falls in the category of Class- F ash; this is because the

3.68 %. combined amount of oxides of silica, alumina and iron is

91.85 % and the percentage of CaO is very less than 0.95 %.

IJISRT18OC372 www.ijisrt.com 598

Volume 3, Issue 10, October – 2018 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

Results of the chemical characterization are found to be in value of specific gravity can be due to the presence of

justified with the study conducted by Jakka et al. high amount of Fe₂O₃ as found in the chemical analysis.

The low specific gravity of pond ash as compared to

It is clear from Table that the LOI value (i.e. un-burnt natural soil is advantageous to use as fill materials in

carbon) of the sample is very low which is less than 5.0 %. embankment and backfill for retaining walls because it

i.e. maximum limit specified as per ASTM C618-08a. Due shall exert lesser earth pressure.

to low LOI value, the risk of self heating is eliminated or Compaction characteristics show that, ash sample have

spontaneous heating if pond ash can be utilized as a fill higher MDD but a decrease in OMC in case of heavy

material for highways and embankments studied by Manju compaction than in light compaction method. Results of

Suthar et.al. the MDD and OMC for pond ash sample are within the

permissible limits as specified by IRC:SP:58-2001 for

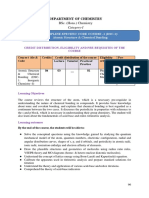

MAJOR ELEMENTS POND ASH % suitability of ash in embankment construction.

SiO₂ 59.20 From the results of Unconfined Compression tests, it is

observed that the maximum compressive stress occurs at

Al₂O₃ 27.24 a strain of 3.684 % with an elapsed time of 2.5 minutes.

The LOI value being < 5% indicates low amount of un-

Fe₂O₃ 5.41

burnt carbon. Hence there is no risk of spontaneous

SiO₂+Al₂O₃+Fe₂O₃ 91.85 heating if pond ash sample is used as fill material.

Chemical analysis result, specifies that the combined

CaO 0.95 amount oxides of silica, alumina and iron is more than

TiO₂ 1.83 70 % and CaO percentage is less than 1% in the ash

sample. As per ASTM C618-08a, the pond ash sample

P₂O₅ 0.42 collected is classified as Class F.

K₂O 1.89 The presence of hazardous heavy metals like barium,

chromium and lead in the ash sample higher than that

MgO 0.48 specified by USEPA TCLP limits for hazardous wastes

LOI 2.84 can have adverse impacts including contamination of

surface and subsurface water, loss of soil fertility around

Table 1:- Chemical composition of Pond ash sample the plant sites, etc. Hence this requires a detailed study of

their chemical composition, morphological studies, pH

HEAVY TCLP LIMITS POND ASH and total soluble solids.

METALS (mg/L) (mg/L) The presence of heavy metals like Br, Cr and Pb in

Arsenic 5 0.268 Badarpur Pond ash sample in mg/l was found higher than

the specified limits. Hence there is a need for

Barium 100 743.82 stabilization of pond ash with economical and

environment friendly admixtures such as lime, marble

Cadmium 1 0 dust, granite powder, etc. A mechanical stabilization is

preferred over chemical stabilization in this case so as to

Chromium 5 783.35 avoid use of chemicals which can have adverse effects

on the underlying soil in future.

Lead 5 54.43

REFERENCES

Mercury 0.2 0

[1]. Bharathi Ganesh et. al (2005) “Effective utilization of

Silver 1 0

pond ash for sustainable construction – need of the

Selenium 5 1.88 hour”, International Journal of Earth Sciences and

Engineering ISSN 0974-5904, Volume 04, No 06 SPL,

Table 2:- Composition of Heavy metals in Pond ash sample

October 2011, pp 151-154.

IV. CONCLUSIONS [2]. Ministry of Environment and Forest, Government of

India MOEF 1999 on September 14, 1999.

The following conclusions can be drawn based on the above [3]. Shenbaga et.al (2004) “Permeability and Consolidation

results and discussions:

Characteristics of Compacted Fly Ash”, Journal of

Grain size distribution (GSD) shows most of the particles

of ash sample are of fine sand size and fine silt size. The Energy Engineering, Vol. 130, No. 1, April 1, 2004.

ash sample shall be better fill material being well graded [4]. Dr. S.K. Handoo Fly Ash Utilization 2018 Conference

in nature. – Expo – Awards March 15-16, 2018.

Pond ash sample shows low specific gravity value of [5]. Sarkar A et.al (2005) “Particle size distribution profile

2.30 due to the presence of hollow cenospheres. The of some Indian fly ash-a comparative study to assess

specific gravity value lies within permissible range their possible uses”, Fuel Process Technol

(1.90-2.55) as specified by IS:SP:58-2001. The higher

86(11):1221–1238.

IJISRT18OC372 www.ijisrt.com 599

Volume 3, Issue 10, October – 2018 International Journal of Innovative Science and Research Technology

ISSN No:-2456-2165

[6]. Bumjoo kim et.al(2015) “The Geotechnical Properties [21]. Wei-Hsing Huang “The use of bottom ash in highway

of Fly and Bottom Ash Mixtures for Use in Highway embankments, subgrades, and subbases”, Joint

Embankments”, Journal of geotechnical and geo- highway research project- Indiana department of

environmental engineering ASCE/ July 2005, pp-914- highways.

924. [22]. Manju Suthar et.al (2016) “Environmental Impact and

[7]. Bross B (1981) “Pollution from ash lagoons and use of Physico-chemical Assessment of Pond Ash for its

ash for embankments”, Proceedings of the 10th Potential Application as a Fill Material”, Int. J. of

international conference on soil mechanics and Geosynthethic. and Ground Eng. (2016).

foundation engineering, Stockholm, pp 309–312. [23]. Pandian, N. et.al(2001) "California Bearing Ratio

[8]. Datta M et.al (1996) “Spatial variation of ash Behavior of Soil/Fly Ash Mixtures", Journal of

characteristics in an ash pond”, Raju V.S et al. “Ash Testing and Evaluation, Vol. 29, No. 2, 2001, pp. 220-

pond and ash disposal systems”, pp 111–119. 226.

[9]. Sridharan A et.al (1996) “Geotechnical [24]. P. V. V. Satyanarayana et.al(2013) “A study on

characterization of pond ash”, Raju VS et al (eds) Ash utilization of recycled aggregate and pond ash in road

pond and ash disposal systems, Narosa Publishers, construction”, International Journal of Civil,

Delhi, pp 97–110. Structural, Environmental and Infrastructure

[10]. “Managing Coal Combustion Residues in Mines”, Engineering Research and Development

Committee on Mine Placement of Coal Combustion (IJCSEIERD)ISSN(P):2249-6866; ISSN(E): 2249-

Wastes, National Research Council of the National 7978 Vol. 3, Issue 5, Dec 2013, 109-116.

Academies, 2006. [25]. Sushovan Datta et.al(2015) “An Overview on the Use

[11]. Human and Ecological Risk Assessment of Coal of Waste-‘Plastic Bottles and Fly Ash’ in Civil

Combustion Wastes, RTI, Research Triangle Park, Engineering Applications”, International Conference

August 6, 2007, prepared for the United States on Solid Waste Management, 2015.

Environmental Protection Agency. [26]. S.Pandian (2004) Fly ash characterization with

[12]. Sonia Helle et.al. “Coal blend combustion: link reference to geotechnical applications in J. Indian

between unburnt carbon in fly ashes and maceral Institute of Science, Nov–Dec. 2004, 84, 189–216.

composition” ASTM C618 “Standard Specification for [27]. Bera A.K, Ghosh, A(2007). “Compaction

Coal Fly Ash and Raw or Calcined Natural Pozzolan characteristics of pond ash”. Journal of Materials in

for Use in Concrete". ASTM International Revision Civil Engineering ASCE, 19 (4): 349-357

17A, December 15, 2017. [28]. Fly ash resource centre (FARC),State Pollution

[13]. Kolay P.K et.al(2011) “Tropical Peat Soil Stabilization Control Board, Odisha, August 2015.

using Class F Pond Ash from Coal Fired Power Plant- [29]. Arumugam K et.al(2011), “Study on characterization

World Academy of Science”, Engineering and and use of Pond Ash as fine aggregate in Concrete”,

Technology International Journal of Civil, International Journal of Civil and Structural

Environmental, Structural, Construction and Engineering Volume 2, no 2, 2011.

Architectural Engineering Vol:5, No:2, 2011.

[14]. Ujwal Bhattacharjee et.al(2002) “Potential of fly ash

utilization in India”, Centre for Energy Studies, Indian

Institute of Technology Delhi, Hauz Khas, New Delhi

110 016, India.

[15]. IS:2720 (Part.4) 1985 “Grain size analysis”.

[16]. IS 2720 (Part 3) 1980 sect/2 “Standard test for Specific

Gravity of Soil Solids by Water Pycnometer”.

[17]. IS: 2720 (Part. VII) 1980 “Determination of water

content-dry density relation using light compaction”.

[18]. IS:2720 (Part VIII) 1983 “Determination of water

content-dry density relation using heavy compaction”.

[19]. IS: 2720(Part 16)-1973 “Methods of test for soil-

Laboratory determination of CBR”.

[20]. IS:2720 (Part 10)-1991 “Determination f Unconfined

compressive strength”.

IJISRT18OC372 www.ijisrt.com 600

S-ar putea să vă placă și

- GEOGREEN BlanketsDocument13 paginiGEOGREEN Blanketsshravan38100% (2)

- 22m High Wall at Durga Temple With PECDocument5 pagini22m High Wall at Durga Temple With PECGerald TanÎncă nu există evaluări

- Indian Standard (First Revision) : Method of Chemical Analysis of Hydraulic CementDocument44 paginiIndian Standard (First Revision) : Method of Chemical Analysis of Hydraulic CementArijit dasguptaÎncă nu există evaluări

- Is 4082Document14 paginiIs 4082Priyanka MishraÎncă nu există evaluări

- Sec PrsDocument32 paginiSec PrsMathew SebastianÎncă nu există evaluări

- 90th Percentile CBR 4.5 Borrow Area CBR 14.2Document4 pagini90th Percentile CBR 4.5 Borrow Area CBR 14.2Akshay Aithal KandoorÎncă nu există evaluări

- Layer No. Layer Top Width (M) Length (M) Width (M) Depth (M) Quantit y (M )Document6 paginiLayer No. Layer Top Width (M) Length (M) Width (M) Depth (M) Quantit y (M )RayÎncă nu există evaluări

- Procedure For The Petrographic Analysis of Coarse AggregateDocument18 paginiProcedure For The Petrographic Analysis of Coarse AggregatePushpendra ChouhanÎncă nu există evaluări

- Detailed Project Report For Vertical Gardening Under Flyover From Dogra Chowk To KC ChowkDocument26 paginiDetailed Project Report For Vertical Gardening Under Flyover From Dogra Chowk To KC ChowkRani Arun ShakarÎncă nu există evaluări

- Economic and Financial Analysis For Polymer Modified BitumenDocument11 paginiEconomic and Financial Analysis For Polymer Modified Bitumennicholas100% (1)

- Irc-Sp-100-2014 Use of Cold Mix Technology in Consturction & Maintainance of Roads Using Bitumen EmulsionDocument94 paginiIrc-Sp-100-2014 Use of Cold Mix Technology in Consturction & Maintainance of Roads Using Bitumen EmulsionAkash Yadav100% (2)

- Soil Stabilization by Using Lime and Fly AshDocument5 paginiSoil Stabilization by Using Lime and Fly AshEditor IJTSRDÎncă nu există evaluări

- Stabilization of Expansive SoilDocument4 paginiStabilization of Expansive SoilSamara LujanÎncă nu există evaluări

- Sasan Power LimitedDocument24 paginiSasan Power LimitedgoutamÎncă nu există evaluări

- 1 RMR PDFDocument14 pagini1 RMR PDFchakrapanithotaÎncă nu există evaluări

- An Experimental Study On Stabilization Modification of Locally Available Expansive Soil Using Industrial WastesDocument40 paginiAn Experimental Study On Stabilization Modification of Locally Available Expansive Soil Using Industrial WastesEditor IJTSRDÎncă nu există evaluări

- Showimg 2 PDFDocument60 paginiShowimg 2 PDFTanuj1122Încă nu există evaluări

- September 14Document89 paginiSeptember 14abhilashÎncă nu există evaluări

- Iaetsd-Jaras-Effect of Soil Stabilization by Consolid System OnDocument5 paginiIaetsd-Jaras-Effect of Soil Stabilization by Consolid System OniaetsdiaetsdÎncă nu există evaluări

- Material Design: Construction PracticesDocument19 paginiMaterial Design: Construction PracticesP Guru RajuÎncă nu există evaluări

- Guidelines FOR USE OF Geosynthetics in Road Pavements and Associated WorksDocument108 paginiGuidelines FOR USE OF Geosynthetics in Road Pavements and Associated WorksPhuc Nguyen QuangÎncă nu există evaluări

- The MTHL BridgeDocument5 paginiThe MTHL BridgeShanu AthiparambathÎncă nu există evaluări

- Not For Sale: Amendment No. 2 March 2010 TO Is 4032: 1985 Method of Chemical Analysis of Hydraulic CementDocument5 paginiNot For Sale: Amendment No. 2 March 2010 TO Is 4032: 1985 Method of Chemical Analysis of Hydraulic CementRaghu NagarÎncă nu există evaluări

- Marble Waste Bonafide - HariDocument6 paginiMarble Waste Bonafide - HariHarihara PriyadharshanÎncă nu există evaluări

- Coal Bottom Ash As Sand Replacement in ConcreteDocument9 paginiCoal Bottom Ash As Sand Replacement in ConcretexxqÎncă nu există evaluări

- Astm-C1660 (MPD) (2009)Document3 paginiAstm-C1660 (MPD) (2009)anglejalgoÎncă nu există evaluări

- Lec VFVFVFDocument72 paginiLec VFVFVFSaeed AyeenÎncă nu există evaluări

- Prosopis Juliflora in ConcreteDocument7 paginiProsopis Juliflora in ConcreteCampus ConnectÎncă nu există evaluări

- Partial Replacement of Cement With GGBS in ConcreteDocument10 paginiPartial Replacement of Cement With GGBS in ConcreteE Hammam El MissiryÎncă nu există evaluări

- Is 383 Specification For Coarse and Fine Aggregates From Nat.180180049Document21 paginiIs 383 Specification For Coarse and Fine Aggregates From Nat.180180049love9Încă nu există evaluări

- Indian Standard: Specification FOR Concrete Masonry UnitsDocument18 paginiIndian Standard: Specification FOR Concrete Masonry UnitsDevendrasinh PadhiyarÎncă nu există evaluări

- Geotextile Tube Designs PDFDocument155 paginiGeotextile Tube Designs PDFNILRATAN SARKARÎncă nu există evaluări

- Ritika Report For ProjfbddectDocument37 paginiRitika Report For Projfbddectadidas100% (1)

- Reference Books For IES Civil Engineering PDFDocument1 paginăReference Books For IES Civil Engineering PDFDanish Ahmad100% (1)

- Transport For NSW (TFNSW) Qa Specification R57 Design of Reinforced Soil WallsDocument69 paginiTransport For NSW (TFNSW) Qa Specification R57 Design of Reinforced Soil WallsGhassan Abood HabeebÎncă nu există evaluări

- Fyp Reinforced Soil by CH JunaidDocument26 paginiFyp Reinforced Soil by CH JunaidChaudary Junaid MughalÎncă nu există evaluări

- A Comparative Study On The Mechanical Properties of Concrete Using M-Sand and Ground Nut Shell Ash As A Partial Replacement of River SandDocument17 paginiA Comparative Study On The Mechanical Properties of Concrete Using M-Sand and Ground Nut Shell Ash As A Partial Replacement of River SandIJRASETPublicationsÎncă nu există evaluări

- Drip Irrigation SystemDocument1 paginăDrip Irrigation SystemFahad NaveedÎncă nu există evaluări

- Tunneling in Himalaya'sDocument9 paginiTunneling in Himalaya'sAjay SinghÎncă nu există evaluări

- 35th Monitroing ReportDocument81 pagini35th Monitroing ReportamitÎncă nu există evaluări

- Rajarajeswari College of EngineeringDocument23 paginiRajarajeswari College of Engineeringchetan maitriÎncă nu există evaluări

- Backfilling Practices With Fly Ash in Underground Coal MinesDocument19 paginiBackfilling Practices With Fly Ash in Underground Coal MinesmanikantaÎncă nu există evaluări

- Study of Strength Properties of Polyester Fibre Reinforced ConcreteDocument5 paginiStudy of Strength Properties of Polyester Fibre Reinforced ConcreteJournal 4 ResearchÎncă nu există evaluări

- Standard DeviationDocument8 paginiStandard DeviationArunKumar ChandrasekarÎncă nu există evaluări

- Strength of Concrete Structure Partial Replacement of Sand by Copper SlagDocument6 paginiStrength of Concrete Structure Partial Replacement of Sand by Copper SlagEditor IJTSRDÎncă nu există evaluări

- Strength Aspects of Concrete by Partially Replacing Cement by GGBS and Coarse Aggregate by Waste Ceramic Tiles PDFDocument5 paginiStrength Aspects of Concrete by Partially Replacing Cement by GGBS and Coarse Aggregate by Waste Ceramic Tiles PDFInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Geotechnical Reuse of Waste MaterialnewDocument42 paginiGeotechnical Reuse of Waste MaterialnewPrak BaÎncă nu există evaluări

- Experimental Investigation On Partial Replacement of Cement With Dolomite Powder PDFDocument9 paginiExperimental Investigation On Partial Replacement of Cement With Dolomite Powder PDFSalman AghariyaÎncă nu există evaluări

- Construction and Demolition Waste Management With Reference To Case Study of PuneDocument19 paginiConstruction and Demolition Waste Management With Reference To Case Study of Punekapil rajÎncă nu există evaluări

- Analysis of Durability and Strength of Cement Treated Soils For Sub-Base and Base Layers of PavementDocument16 paginiAnalysis of Durability and Strength of Cement Treated Soils For Sub-Base and Base Layers of PavementIJRASETPublicationsÎncă nu există evaluări

- International Journal of Mining Science and TechnologyDocument9 paginiInternational Journal of Mining Science and Technologyhasja palutaÎncă nu există evaluări

- Characterization and Utilization of Rice Husk Ash (RHA) in Fly Ash - BlastDocument6 paginiCharacterization and Utilization of Rice Husk Ash (RHA) in Fly Ash - BlastLuis Fernando Tonholo Domingos100% (1)

- Study of Fly Ash Cement Concrete Pavement: Anjali Yadav 1, Nikhil Kumar YadavDocument6 paginiStudy of Fly Ash Cement Concrete Pavement: Anjali Yadav 1, Nikhil Kumar YadavKANDIKONDA RAVINDERÎncă nu există evaluări

- International Journal of Mining Science and TechnologyDocument9 paginiInternational Journal of Mining Science and TechnologySushanta Kumar BeheraÎncă nu există evaluări

- Bottomash 1990Document15 paginiBottomash 1990sajanmalviya30Încă nu există evaluări

- Mallick-Mishra2017 Article EvaluationOfClinkerStabilizedFDocument16 paginiMallick-Mishra2017 Article EvaluationOfClinkerStabilizedFCHRISTIAN ARIZA GOMEZÎncă nu există evaluări

- Evaluation of Clinker Stabilized Fly AshDocument18 paginiEvaluation of Clinker Stabilized Fly AshManoj Kumar MishraÎncă nu există evaluări

- Microstructure and Leaching Characteristics of Fly Ash-Mine Overburden-Lime MixturesDocument5 paginiMicrostructure and Leaching Characteristics of Fly Ash-Mine Overburden-Lime MixturesTusharGuptaÎncă nu există evaluări

- Sustainable Energy Consumption Analysis through Data Driven InsightsDocument16 paginiSustainable Energy Consumption Analysis through Data Driven InsightsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Utilization of Waste Heat Emitted by the KilnDocument2 paginiUtilization of Waste Heat Emitted by the KilnInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Influence of Principals’ Promotion of Professional Development of Teachers on Learners’ Academic Performance in Kenya Certificate of Secondary Education in Kisii County, KenyaDocument13 paginiInfluence of Principals’ Promotion of Professional Development of Teachers on Learners’ Academic Performance in Kenya Certificate of Secondary Education in Kisii County, KenyaInternational Journal of Innovative Science and Research Technology100% (1)

- Entrepreneurial Creative Thinking and Venture Performance: Reviewing the Influence of Psychomotor Education on the Profitability of Small and Medium Scale Firms in Port Harcourt MetropolisDocument10 paginiEntrepreneurial Creative Thinking and Venture Performance: Reviewing the Influence of Psychomotor Education on the Profitability of Small and Medium Scale Firms in Port Harcourt MetropolisInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Osho Dynamic Meditation; Improved Stress Reduction in Farmer Determine by using Serum Cortisol and EEG (A Qualitative Study Review)Document8 paginiOsho Dynamic Meditation; Improved Stress Reduction in Farmer Determine by using Serum Cortisol and EEG (A Qualitative Study Review)International Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Designing Cost-Effective SMS based Irrigation System using GSM ModuleDocument8 paginiDesigning Cost-Effective SMS based Irrigation System using GSM ModuleInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- An Overview of Lung CancerDocument6 paginiAn Overview of Lung CancerInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Detection and Counting of Fake Currency & Genuine Currency Using Image ProcessingDocument6 paginiDetection and Counting of Fake Currency & Genuine Currency Using Image ProcessingInternational Journal of Innovative Science and Research Technology100% (9)

- Impact of Stress and Emotional Reactions due to the Covid-19 Pandemic in IndiaDocument6 paginiImpact of Stress and Emotional Reactions due to the Covid-19 Pandemic in IndiaInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- An Efficient Cloud-Powered Bidding MarketplaceDocument5 paginiAn Efficient Cloud-Powered Bidding MarketplaceInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Cyber Security Awareness and Educational Outcomes of Grade 4 LearnersDocument33 paginiCyber Security Awareness and Educational Outcomes of Grade 4 LearnersInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Computer Vision Gestures Recognition System Using Centralized Cloud ServerDocument9 paginiComputer Vision Gestures Recognition System Using Centralized Cloud ServerInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Digital Finance-Fintech and it’s Impact on Financial Inclusion in IndiaDocument10 paginiDigital Finance-Fintech and it’s Impact on Financial Inclusion in IndiaInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Ambulance Booking SystemDocument7 paginiAmbulance Booking SystemInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Comparative Evaluation of Action of RISA and Sodium Hypochlorite on the Surface Roughness of Heat Treated Single Files, Hyflex EDM and One Curve- An Atomic Force Microscopic StudyDocument5 paginiComparative Evaluation of Action of RISA and Sodium Hypochlorite on the Surface Roughness of Heat Treated Single Files, Hyflex EDM and One Curve- An Atomic Force Microscopic StudyInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Predictive Analytics for Motorcycle Theft Detection and RecoveryDocument5 paginiPredictive Analytics for Motorcycle Theft Detection and RecoveryInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Effect of Solid Waste Management on Socio-Economic Development of Urban Area: A Case of Kicukiro DistrictDocument13 paginiEffect of Solid Waste Management on Socio-Economic Development of Urban Area: A Case of Kicukiro DistrictInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Auto Tix: Automated Bus Ticket SolutionDocument5 paginiAuto Tix: Automated Bus Ticket SolutionInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- An Industry That Capitalizes Off of Women's Insecurities?Document8 paginiAn Industry That Capitalizes Off of Women's Insecurities?International Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Study Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoDocument6 paginiStudy Assessing Viability of Installing 20kw Solar Power For The Electrical & Electronic Engineering Department Rufus Giwa Polytechnic OwoInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Forensic Advantages and Disadvantages of Raman Spectroscopy Methods in Various Banknotes Analysis and The Observed Discordant ResultsDocument12 paginiForensic Advantages and Disadvantages of Raman Spectroscopy Methods in Various Banknotes Analysis and The Observed Discordant ResultsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Unmasking Phishing Threats Through Cutting-Edge Machine LearningDocument8 paginiUnmasking Phishing Threats Through Cutting-Edge Machine LearningInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Visual Water: An Integration of App and Web To Understand Chemical ElementsDocument5 paginiVisual Water: An Integration of App and Web To Understand Chemical ElementsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Blockchain Based Decentralized ApplicationDocument7 paginiBlockchain Based Decentralized ApplicationInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Parastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueDocument2 paginiParastomal Hernia: A Case Report, Repaired by Modified Laparascopic Sugarbaker TechniqueInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Smart Health Care SystemDocument8 paginiSmart Health Care SystemInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Compact and Wearable Ventilator System For Enhanced Patient CareDocument4 paginiCompact and Wearable Ventilator System For Enhanced Patient CareInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Factors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaDocument6 paginiFactors Influencing The Use of Improved Maize Seed and Participation in The Seed Demonstration Program by Smallholder Farmers in Kwali Area Council Abuja, NigeriaInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Impact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldDocument6 paginiImpact of Silver Nanoparticles Infused in Blood in A Stenosed Artery Under The Effect of Magnetic Field Imp. of Silver Nano. Inf. in Blood in A Sten. Art. Under The Eff. of Mag. FieldInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Smart Cities: Boosting Economic Growth Through Innovation and EfficiencyDocument19 paginiSmart Cities: Boosting Economic Growth Through Innovation and EfficiencyInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Is.3987.2006 SorbitolDocument14 paginiIs.3987.2006 SorbitolHafizur RahmanÎncă nu există evaluări

- Anti Crack Fiber GlassDocument6 paginiAnti Crack Fiber GlassDinesh KabraÎncă nu există evaluări

- E1-Material Log 6Document5 paginiE1-Material Log 6stefenjohnÎncă nu există evaluări

- International Conference On Chemical Sciences (ICCS-2007) International Conference On Chemical Sciences (ICCS-2007)Document7 paginiInternational Conference On Chemical Sciences (ICCS-2007) International Conference On Chemical Sciences (ICCS-2007)syaripatul haniÎncă nu există evaluări

- Elastic Dental Prostheses - Alternative Solutions For Patients Using Acrylic Prostheses: Literature ReviewDocument5 paginiElastic Dental Prostheses - Alternative Solutions For Patients Using Acrylic Prostheses: Literature Reviewannacm97Încă nu există evaluări

- Metal Air Battery - An Overview - ScienceDirect TopicsDocument10 paginiMetal Air Battery - An Overview - ScienceDirect TopicsSenen100% (1)

- 70-0716-7207-8 Coveralls Brochure InteractiveDocument12 pagini70-0716-7207-8 Coveralls Brochure InteractiveOpteron K.Încă nu există evaluări

- Industria Home Care ProductsDocument14 paginiIndustria Home Care ProductsAndré MeloÎncă nu există evaluări

- Or Use Calcium Carbonate Caco3 + 2Hcl Cacl2 + H2O+ Co2: Sodium Bicarbonate Nahco3Document1 paginăOr Use Calcium Carbonate Caco3 + 2Hcl Cacl2 + H2O+ Co2: Sodium Bicarbonate Nahco3AV kayanÎncă nu există evaluări

- Setari CuraDocument24 paginiSetari CurastefysimonÎncă nu există evaluări

- Astm C881Document13 paginiAstm C881Jan LhesterÎncă nu există evaluări

- Syllabus of Chemistry H NEP 96 105 1Document10 paginiSyllabus of Chemistry H NEP 96 105 1Vijay Kumar VishvakarmaÎncă nu există evaluări

- Objective of DelimingDocument5 paginiObjective of DelimingjewelhuqÎncă nu există evaluări

- Adhimix Trial Mix DocumentationDocument92 paginiAdhimix Trial Mix Documentationyudha satriaÎncă nu există evaluări

- A380 Astm Pickling & PassivationDocument94 paginiA380 Astm Pickling & Passivationpurav_patel200792320% (1)

- P104 Extrusion Final 11Document16 paginiP104 Extrusion Final 11Yanpiero BalladoresÎncă nu există evaluări

- Ash and Minerals AnalysisDocument36 paginiAsh and Minerals AnalysisNicholas BoampongÎncă nu există evaluări

- Catalogue Bernecker - Pipe ClampsDocument15 paginiCatalogue Bernecker - Pipe ClampsJunior CorrêaÎncă nu există evaluări

- 典型加速腐蝕實驗方法Document4 pagini典型加速腐蝕實驗方法Nelly TsaiÎncă nu există evaluări

- Turbine Oil Condition Monitoring Training GuideDocument8 paginiTurbine Oil Condition Monitoring Training Guidemauriciojj100% (1)

- Call 08823937292: Kamal HardwareDocument5 paginiCall 08823937292: Kamal HardwareARIHANT ASSOCIATESÎncă nu există evaluări

- Test Bank - Ch.19-New PDFDocument2 paginiTest Bank - Ch.19-New PDFBinit KoiralaÎncă nu există evaluări

- Faculty of Engineering and Science MAEN 1000: Engineering Materials Lab Report Cover SheetDocument18 paginiFaculty of Engineering and Science MAEN 1000: Engineering Materials Lab Report Cover SheetPanadol PanadolÎncă nu există evaluări

- Inspección de Esfera de GLP - Mexico PDFDocument10 paginiInspección de Esfera de GLP - Mexico PDFJorge Rogger Yopla BasaldúaÎncă nu există evaluări

- Financial Comparative Study Between Post-Tensioned and Reinforced Concrete Flat SlabDocument6 paginiFinancial Comparative Study Between Post-Tensioned and Reinforced Concrete Flat SlabtienaicvnÎncă nu există evaluări

- Reactions of Metals and Acids Activity No. 4: Distance Education Course Guide Using Obtl Design V1Document3 paginiReactions of Metals and Acids Activity No. 4: Distance Education Course Guide Using Obtl Design V1John Mark LabtoÎncă nu există evaluări

- ENGIN - Heat Treatment For Stronger Aerospace GearsDocument15 paginiENGIN - Heat Treatment For Stronger Aerospace GearsGG_04100% (1)

- CH 21Document51 paginiCH 21Mostafa AhmedÎncă nu există evaluări

- Chapter 10: The S-Block ElementsDocument13 paginiChapter 10: The S-Block Elementsgyogi1989Încă nu există evaluări

- Katalog Produk General ARITADocument72 paginiKatalog Produk General ARITAanon_969520527Încă nu există evaluări