Documente Academic

Documente Profesional

Documente Cultură

A Study On Stripping of Coarse Aggregates of Andhra Pradesh: Md. Ismail Baig, P. Gopi, M. Balraj Naik

Încărcat de

Anupam SinghTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A Study On Stripping of Coarse Aggregates of Andhra Pradesh: Md. Ismail Baig, P. Gopi, M. Balraj Naik

Încărcat de

Anupam SinghDrepturi de autor:

Formate disponibile

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2015): 6.391

A Study on Stripping of Coarse Aggregates of

Andhra Pradesh

Md. Ismail Baig1, P. Gopi2, M. Balraj Naik3

1, 2, 3

MVR College of Engineering and Technology, Paritala, Andhra Pradesh, India

Abstract: Stripping of the aggregates from bituminous roads is a very common problem in our country. Stripping is generally defined

as the breaking of the adhesive bond between the aggregate surface and the bitumen. Stripping is a complex problem comprise of many

variables, including the type and use of mix, aggregate and bitumen characteristics, construction practice and use of anti-stripping

additives. External factors which mainly affect stripping are traffic and environmental conditions. To evaluate the stripping of

aggregates, Indian Standard has prescribed the stripping test for which aggregates coated with bitumen are kept immersed in water for

24 hours at 400C. However, when the same aggregates are used on the road they do undergo stripping underwater. This happens

probably due to the fact that lab and field conditions are different in respect of contact period of water with bitumen, prevailing field

temperature and environmental conditions and various other factors. This study brings forth and discusses the results of a lab study

conducted on coarse aggregates of Andhra Pradesh to evaluate their stripping value under prevailing field conditions.

Keywords: stripping, coarse aggregates, additives on aggregate stripping, stone quarry, alkaline and acidic condition

1. Introduction damage to the road. Bad condition of the road due to

stripping creates various transportation problems like

Proper adhesion between aggregate and bitumen is one of the congestion, delay, maneuvering difficulties, increment in

principal fundamental properties for good performance of travel time and travel cost, socio-economic losses. Loss of

bituminous pavement. This adhesion can be reduced by lives in case of fatal accidents due to bad road condition must

presence of water which may cause de-bonding of bitumen be taken into account because approximately 1.5% of road

from aggregate. The phenomenon is known as „stripping‟. accidents occur due to poor condition of the road. The

Contact of water with bituminous pavement is one of the present study investigates the problem of stripping including

main factors for stripping. The moisture affects physical various factors which show their existence in the field and

properties and mechanical behavior of bitumen paving may help in mitigating its ill-effects.

mixtures as aggregates that have a dry surface adhere better

to bitumen and have a higher stripping resistance than wet 1.2 Objectives of the Study

aggregates. The physical and chemical characteristics of

aggregates have a significant effect on the bonding between The study under consideration aims to identify the factors

aggregate and bitumen. In addition, aggregate surface causing stripping of coarse aggregate. It investigates the

texture, aggregate porosity and pore structure are also known factors causing stripping of coarse aggregate including traffic

to affect stripping. A deficiency in properties of aggregate and other environmental factors such as temperature,

reduces the strength of the bond and leads bitumen-aggregate alternate wetting and drying and pH value of the water.

mixture towards stripping. Stripping may further cause The main objectives of the study are:

rutting, raveling, bleeding, cracking and formation of 1) To evaluate the stripping of coarse aggregate obtained

potholes and culminate with complete failure of the from different sources of West Godavari, Krishna and

pavement. Hence, to prevent pavement from these failures, Guntur under standard test conditions.

we need to thoroughly investigate various factors which 2) To vary the standard test conditions of temperature,

affect the stripping of aggregate. immersion time and load to simulate the field conditions

and to evaluate the stripping under these varying

1.1 Research Topic and Its Importance conditions.

3) To evaluate the stripping by subjecting the coated

The topic entitled “A Study on Stripping of Coarse aggregate to a specified cycle of alternate wetting and

Aggregates of West Godavari, Krishna and Guntur” aims at drying.

determining and analyzing various factors influencing 4) To study the effect of additives on stripping.

stripping of coarse aggregates. The problem of stripping is 5) To discuss the factors affecting stripping.

very common in India and road network in West Godavari,

Krishna and Guntur also faces this problem. Many a times it 1.3 Scope of Research

is experienced that the stripping of aggregate takes place on

the road, even when laboratory tests indicate no stripping. In this study, experiments for evaluating the stripping value

This mainly happens because laboratory testing conditions of road aggregate selected from different sources of West

are different from the field conditions. It is very important to Godavari, Krishna and Guntur have been conducted under

control the problem of stripping as it is initiated with de- varying conditions. The aggregates have been selected from

bonding and gradually leads to complete collapse of Donabanda, Koduru, Gouripatnam, Perecharla, Maaturu,

pavement. Such an acute problem may cause innumerous Chimakurthi and I.pangidi quarries. Stripping test is

Volume 5 Issue 10, October 2016

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20162146 967

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2015): 6.391

performed on selected aggregate samples keeping into friction has been simulated by applying light pressure with

consideration various affecting factors like traffic load, finger nails of the observer.

temperature variation, wetting-drying cycles and extended

immersion time in the water. These tests as well distinguish the result of type of bitumen

grade i.e. viscosity grade 10 and 30, type of aggregates i.e.

2. Methodology of the Study simple, dust coated and round aggregates and the presence of

additives on the value of stripping of bitumen from the

The research approach used to achieve the study objectives is aggregate surface.

detailed in Figure 2.1.

3. Experimental Investigation

This chapter describes the materials used, the preparation of

the test samples and the test procedure. In order to achieve

the stated objective, the study was carried out in stages. At

the initial stage, all the materials and equipment needed were

procured. Bitumen and aggregates were used in preparing

samples in predefined proportions. Prepared samples were

tested under standard and varying conditions. Finally, the

results obtained were analyzed to draw out conclusions.

3.1 Materials Used

Materials used with their types are given in Table 3.1.

Table 3.1: Materials used in Tests

Material Type

Crushed Aggregates Type 1, Source: Donabanda Quarry,

Colour: Bluish-white.

Type 2, Source: Koduru Quarry,

Colour: Light bluish-white

Type 3, Source: Gouripatnam Quarry,

Colour: Reddish white.

Dust Coated Crushed Type 1

Aggregates Type 2

Type 3

Gravels (Rounded Type 1

aggregates) Type 2

Bitumen VG-10 grade, Source: I.pangidi

Refinery, 5% of mass of aggregate.

VG-30 grade, Source: I.pangidi

Figure 2.1: Flow Chart Illustrating the Research Steps Refinery, 5% of mass of aggregate.

Additive Quick lime

2.1 Tests to Determine Stripping Portland cement

Water Potable water

2.1.1 Test as per Indian Standard

„Method of Test for Determination of Stripping Value of

3.2 Experiment results

Road Aggregates (IS: 6241-1971)‟ is the standard describing

the stripping test for the coarse aggregate.

Stripping test is carried out under standard conditions and

varying conditions to determine the change in the value of

2.2 Tests under Varying Conditions

stripping on different aggregates. To observe the effect of

grade of bitumen on the value of stripping, the tests have

In this study, testing is performed on the aggregate-bitumen

been conducted with two types of bitumen of VG-10 grade

sample by undertaking various field conditions into

and VG-30 grade respectively.

consideration. Most of the times it is envisioned that the

laboratory test conditions and field conditions vary a large

3.3 Stripping tests on crushed aggregates general

extent leads to stripping of aggregates on the road even when

laboratory tests indicate nil stripping value.

Three types of aggregates from different sources are taken

for evaluating the value of stripping under various testing

To determine the effect of these variables on stripping,

conditions. These three types of aggregates from Donabanda,

experiments have been carried out in the highway

Koduru, Gouripatnam quarries are shown in figure 3.1.

engineering lab of M.V.R College of engineering and

technology, Paritala. The effect of traffic load and tyre

Volume 5 Issue 10, October 2016

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20162146 968

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2015): 6.391

3.4 Stripping value using bitumen of viscosity grade 3

(VG-30):

3.4.1Stripping of Aggregates at Different Temperatures

A sample of Type 2 aggregates (Koduru Quarry) are tested at

200C, 400C and 600C respectively and increase in water

Figure 3.1: Type 1 Aggregate from Quarries immersion time from 1 day to 7 days in order to determine

the effect of temperature and extended contact time of water

All the tests were performed on the aggregates which are on the value of striping. The effect of traffic load and tyre

menstioned at different sections explained above. From the friction has been simulated by applying light pressure with

test results the discussion and analysis is carried out. finger nail. The results obtained are mentioned in Table 3.2

and graphically presented in Fig. 3.3.

Figure 4.2: Stripping of aggregates in alkaline and acidic

condition

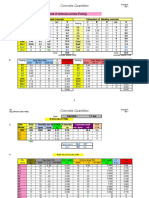

Table 3.2: Stripping at Different Temperatures (Type-2 Aggregates)

Contact time of Stripping value in % at Temperature

S Bituminous mix 200C 400C 600C

No with water Without With finger Without With finger Without With finger

(Days) pressure pressure pressure pressure pressure Pressure

1 1 Nil Nil Nil Nil Nil Nil

2 2 Nil Nil Nil 0-0.5 0-0.3 0-0.5

3 3 Nil 0.2-0.3 0-0.5 0.5-1 0.5 0.5-1

4 4 0-0.3 0.3-0.5 <1 <2 0.5-1 1-2

5 5 0.3-0.5 0.5-1.0 1.5 2 <2 <3

6 6 0.5-0.8 1.0-1.5 1.5-2 2-2.5 2-2.5 3-4

7 7 0.8-1.0 1.5-2.0 2.5 3 3-3.5 >4

4. Analysis and Discussion of Results

To find out stripping of coarse aggregate obtained from

different sources of Krishna, stripping tests are conducted

under standard and varying conditions. Several trials have

been performed in accordance with the methods identified in

chapter-3. The test results are discussed here in this chapter.

The discussion is divided into seven sections according to the

objectives stated in the earlier part of the thesis. The seven

sections mentioned are:

1. Effect of temperature and immersion time on stripping.

2. Effect of bitumen grade on stripping.

3. Effect of wet-dry cycles and altered temperature on

stripping.

4. Effect of surface moisture on stripping.

Figure 3.3: Stripping at Different Temperatures 5. Effect of type of aggregates on stripping.

6. Effect of alkaline and acidic water on stripping.

It is observed from Fig. 3.3 that the stripping of coarse 7. Effect of additives on stripping.

aggregate increases with increase in temperature of water,

number of days the water remains in contact with coated 3.1 Effect of temperature and immersion time on

aggregates and the applied pressure on the coated aggregates. stripping

Likewise all the tests were performed and recorded.

It is experienced that the friction between aggregates is

retained at high temperature but bitumen-fines viscosity and

stability reduces at high temperature thus resulting in strength

Volume 5 Issue 10, October 2016

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20162146 969

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2015): 6.391

loss, which eventually increases the value of stripping reported that bitumen with high viscosity resists displacement

(International Symposium, 1985). by moisture better than those that have low viscosity.

Bitumen with high viscosity usually carry high concentrations

Various lab experiments show that with the increase in of polar functionalities that provide more resistance to

temperature the stripping value increases as viscosity of stripping and provide a better coating (Bahia, H. U., et al

bitumen decreases which reduces the bonding of bitumen 2007). It has likewise been reported that the bond strength is

with aggregate. immediately associated to film thickness. Samples with

thicker bitumen film tend to have cohesive failure after

Stripping test conducted on bitumen coated aggregates at moisture conditioning. On the other hand, specimens with

200C, 400C and 600C and it is observed from the Fig. 4.1and thinner asphalt film have an adhesive failure. A thin asphalt

4.2 that stripping value increases with increase in contact film makes the mix more susceptible to stress and weathering

time, test temperature and applied pressure on the aggregates. (Kanitpong, K. and Bahia, H. U. 2003).

The stripping value increases from zero to about 5% with

increase in temp from 20 to 400C, contact time from one to Various tests are conducted taking bitumen of viscosity grade

seven days and pressure condition from „No pressure‟ to 10 and 30 to determine their effect on the value of stripping.

slight pressure of finger nails. It is observed from the Fig. 4.3 that the bitumen of grade 10

(VG-10) shows higher value of stripping as compared to

bitumen of grade 30 (VG-30).

Figure 4.3: Stripping Value due to the Different Bitumen

Figure 4.1: Striping Value at Different Temperature and Grade (under Applied Pressure)

Days (without Pressure)

3.3 Effect of wet-dry cycle and altered temperature on

stripping

Variations in temperature, freeze–thaw cycles, and wetting–

drying cycles increase the stripping potential of bituminous

pavements (Roberts F.L. el at 1991).

To simulate field conditions of temperature variation during

the day and night (in summer season) and water contact

during rainy season, tests are conducted on an aggregate-

bitumen, mixture under the condition of wetting-drying

cycles and altered temperature. The effects reported in

previous chapter shows that the value of stripping increases

Figure 4.2: Striping Value at Different Temperature and radically as these variations affect stability of the mixture.

Days (under Applied Pressure)

The value of stripping increased to about 5% when

3.2 Effect of bitumen grade on stripping aggregate-bitumen sample is tested under wetting-drying

cycles as compared to its values under standard conditions

Bitumen must adhere to the aggregate for providing proper with applied finger pressure.

adhesive binding between bitumen and aggregate. Bitumen-

aggregate interaction is important to resist stripping and The value of stripping increased to about 10% when

maintain stability in mix against various other factors. The aggregate-bitumen sample is tested under altered temperature

properties of the bitumen that influence the bitumen- condition as compared to its values under standard conditions

aggregate bond are viscosity, film thickness and surface with applied finger pressure.

energy.

Comparison of the stripping values under different test

The viscosity of the bitumen does play a role in the conditions is presented graphically in Figure 5.4.

propensity of the bitumen mixture to strip. It has been

Volume 5 Issue 10, October 2016

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20162146 970

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2015): 6.391

Figure 4.4: Stripping Value under Varying Conditions

(under Applied Pressure) Figure 4.5: Stripping Value under Moist Condition (under

Applied Pressure)

4.4 Effect of surface moisture on stripping

3.4 Effect of type of aggregates on stripping

Moisture damage can be defined as the loss of strength and

durability in bitumen mixtures caused by the presence of Aggregate type and their physical properties have

water. The level and the extent of moisture damage, also confounding effect on the value of stripping. Bitumen-

called moisture susceptibility, depend on environmental, aggregate interactions are strongly influenced by the

construction, and pavement design factors. composition and surface chemistry of the aggregate. Some

literature considers that aggregate property is much more

Moisture damage is induced by the loss of bond between the influential in determining adsorption and stripping behavior

bitumen or the mastic (bitumen, the mineral filler and small than are bitumen properties. The nature of aggregate surface

aggregates) and the fine and coarse aggregate. Moisture to which bitumen is to adhere is the first item to be

damage accelerates as moisture permeates and weakens the considered in determining the formation and permanence of a

mastic, making it more susceptible to moisture during cyclic bitumen-aggregate bond (Thelen,E., 1958).

loading and ultimately leads towards stripping.

Lab tests indicate that rounded aggregates are more prone

There are various factors which affect the process of towards stripping as a bituminous mixture derives its strength

stripping, but contact of water with bituminous pavement is from the cohesion resistance of the binder and grain interlock

one of the main factors for stripping. Presence of moisture on and frictional resistance of the aggregate and the rounded

the surface of aggregate reduces the potency of bond with aggregates have a smooth surface with the negligible

bitumen, such mixture under cyclic load and high tyre frictional value.

pressure shows stripping. Aggregates that have a dry surface

adhere better to bitumen and have higher stripping resistance If good bond exists, failure of the mixture occurs within the

than do damp or wet aggregates (Majidzadra, K. and binder. If the bond is poor, the failure may occur at the

Brovold, F.N., 1968). binder-aggregate interface and may result in premature

failure of the mix (Majidzadra, K. and Brovold, F.N., 1968).

When bituminous mixtures are exposed to water, bitumen Lab tests specifythat susceptibility of dust coated aggregates

can be displaced from the aggregate because water breaks towards stripping is lower than rounded aggregates, but

interfacial adhesive bonds between the two materials. When higher as compared to crushed aggregates. Dust on aggregate

water enters the interface, it tends to wet aggregate surfaces surfaces have a tendency to trap air when the road oils or

and removes bitumen from it. Although, the process of cutbacks are applied.

bitumen removal is dependent characteristics of both the

bitumen and aggregate. This weakens the bitumen/aggregate bonding, or joint, by

preventing intimate contact between the aggregate and the

The effect of the presence of moisture on stripping value is bitumen. It also promotes stripping by creating channels at

evaluated by conducting a stripping test on moist aggregates the interface, through which water can penetrate.

with an increasing immersion time of sample of water from

one day to seven days. It is observed from the Fig. 4.5 that It is observed from the Fig. 4.6 that the value of stripping is

the value of stripping is continuously increasing and raised highest for gravel (round aggregate) and least for crushed

up to 15% under this condition with application of finger aggregates. Dust coated aggregates show slightly higher

pressure as compared to standard test condition. value of stripping as compare to crushed aggregates.

Comparison of stripping value of different aggregates is

presented graphically in Figure 4.6.

Volume 5 Issue 10, October 2016

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20162146 971

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2015): 6.391

ASA for reducing the moisture susceptibility of bitumen mix.

Some other solid ASAs used are Portland cement, fly-ash,

flue dust, etc. The liquid ASAs used include liquid amines

and di-amines, liquid polymers, etc.

The mechanism by which liquid anti-stripping agents work is

by reducing the surface tension between bitumen binder and

aggregate surface, thus improving the aggregate coating and

reducing the moisture damage of bituminous pavements

(Dybalski, 1982). The addition of lime is the most accepted

way to reduce the moisture susceptibility. The general

practice is to add 1 to 1.5 percent of lime by the dry weight

Figure 4.6: Stripping Value of Different Aggregates (under of the aggregate to the mix. If the aggregate contains more

Applied Pressure) fines, more lime may be required to be added to the mix due

to the increased surface area of the aggregate. Generally,

3.5 Effect of alkaline and acidic condition on stripping three forms of lime are used in HMA: Hydrated Lime

(Ca(OH) ), Quick Lime (CaO), and Dolomitic Lime.

PH value of water is a dominating factor which involve in the 2

process of stripping as instability in pH value cause stripping It is assumed that the mechanism by which hydrated lime

of bitumen mix. Change in pH of water, which is in contact improves the moisture susceptibility of the HMA involves a

with bituminous pavement influences the adhesion property chemical interaction between the calcium in the lime with the

of aggregate-bitumen bond. It is seen that the water silicates in the aggregate (Selim, 1997). Hydrated lime has

susceptibility of the hydrogen bonds and salt links at the proven to work effectively in a wide variety of aggregate

interface would increase with pH of the water at the sources.

aggregate surface.

The chemical and electro-chemical properties between water

and aggregate surface play a greater role in striping than the

physical characteristics of aggregates.

The zeta potential of aggregate surface in water and/or the

pH value of water imparted by aggregate could be used to

measure stripping potential. In general, higher zeta potential

and/or the pH value, higher the probability of stripping

(Russell G. Hicks, 1991).

The nature of the water to which the mix is exposed (salt

content, pH) affects stripping. The pH causes a shift in angle

of contact and significantly affects the wetting properties of Figure 4.7: Stripping Value at varying pH Values (under

bitumen. The higher the pH value of water higher will be the Applied Pressure)

chances of stripping.

Hydrated lime and Portland cement are used as anti-stripping

Experiments conducted at lab under acidic and alkaline agents in lab experimentation to determine their effect on the

conditions show that the value of stripping is very high under value of stripping on various aggregates. It is observed from

alkaline condition as compared to acidic conditions. the Fig. 4.8 that in case of crushed aggregates value of

Stripping value of aggregates increase up to 15 percent under stripping reduced to an average of 10 % and resides to about

applied pressure in alkaline condition as compared to the 2%. Fig. 4.9 and 4.10 shows that the value of stripping

normal condition. On the other hand, there was not much reduced to an average of 12% and 30% in case of dust coated

difference in the value of stripping under acidic condition as and rounded aggregates and resides to about 2.5% and 4%

compare to the normal value of stripping. respectively.

Comparison of the stripping values is presented graphically Fig. 4.8, 4.9 and 4.10 present stripping value of different

in Figure 4.7. aggregates with use of additive (hydrated lime) under applied

finger

3.6 Effect of additives on stripping

Additives are used to reduce moisture susceptibility of

bitumen mix. Reduction in inclination of bitumen mix

towards moisture decreases the chances of stripping of the

mix. Anti-stripping agents are used as additives as these are

chemically designed to improve the adhesion between the

binder and the aggregate. Hydrated lime is widely used as

Volume 5 Issue 10, October 2016

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20162146 972

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2015): 6.391

pressure. not properly simulate the field conditions. The difference

in test and field conditions leads to stripping in the field

many a times whereas lab test results indicate no

stripping.

2. The lab test results indicate that stripping increases with

increase in contact time, test temperature and applied

pressure on the aggregates at the time of stripping.

3. Higher viscosity grade bitumen shows higher resistance to

stripping than low viscosity bitumen.

4. Altered temperature cycles and wetting-drying cycles

increase the stripping of aggregates.

5. Rounded aggregates have the highest value of stripping

because of their smooth surface which does not offer any

frictional resistance and grain interlock.

6. Dust coated aggregates have higher stripping value than

Figure 4.8: Stripping of Crushed Aggregate Type 3 (under

simple aggregates as presence of dust on aggregate

Applied Pressure)

surface reduces aggregate-bitumen bond potency.

7. pH value of water also affects the stripping. It is seen that

the mix exposed to water with a high pH value

undergoes more stripping.

8. Use of additives reduces the value of stripping and limit it

to approximately 2%, which is acceptable as per IS

6241:1971.

9. Lab test conditions need to be modified to take into

consideration the field conditions that affect the

stripping.

Figure 4.9: Stripping of Dust Coated Crushed Aggregate

Type 3 (under Applied Pressure)

References

[1] A.R. Tarrer and VinayWagh, (1991), “The effect of the

physical and chemical characteristics of theaggregate

on bonding”,SHRP-A/UIR-91-507, pp. 1- 19.

[2] Bahia, H. U., Hanz, A., Kanitpong, K., and Wen, H.

(2007), “Testing Methods to Determine

Aggregate/Asphalt Adhesion Properties and Potential

Moisture Damage”. WHRP 07-02, Wisconsin Highway

Research Program, Madison.

[3] Bradley J. Putman, Serji N. Amirkhanian (2006),

“Laboratory Evaluation of Anti-Strip Additives in Hot

Figure 4.10: Stripping of (Gravel) Rounded Aggregate Type Mix Asphalt”, Department of Civil Engineering,

2 (under Applied Pressure) Clemson University, pp. 10.

[4] Covington, A. K., Ferra, M. I. A., Robinson, R. A., J.

5. Conclusions (1977), “Ionic Product and Enthalpyof Ionization of

Water From,m Electromotive Force Measurements”,

The present study on the topic “A Study on Stripping of Chem. Soc. Faraday Trans.I, No. 73, pp. 1721.

Coarse Aggregates of West Godavari, Krishna and Guntur” [5] Curtis, C. W., Lytton, R. L., Brannan, C. J. (1992),

has been carried out with a perspective to determining and “Influence of Aggregate Chemistry on the Adsorption

analyzing various factors influencing stripping of coarse and Desorption of Asphalt”, TRR 1362, NRC,

aggregates. Tests are conducted to investigate the effect of Washington, D. C.

traffic load, tyre friction and other field conditions on the [6] Dukatz, E. L. (1989), “Aggregate Properties Related to

value of stripping. Effect of type of bitumen and various Pavement Performance”, AAPT, vol. 58, pp. 492-502.

types of aggregates on the value of stripping is also taken into [7] Dybalski, J.N. (1982) "Cationic Surfactants in Asphalt

consideration. This study also involves the variation in the Adhesion", Symposium on Anti-stripping Additives in

standard laboratory testing procedure recommended for Paving Mixtures, Proceedings, AAPT.

determining the value of stripping for aggregates. [8] Elizabeth Rae Hunter and Khaled Ksaibati, (2002),

The main conclusions drawn from the study are: “Evaluating Moisture Susceptibility of Asphalt

Mixes”,Department Civil and Architectural Engineering

1. Stripping of aggregates is caused on the roads when they University of Wyoming, pp. 3-7.

are subjected to inundated conditions due to poor [9] Ensley, E. K., Petersen, J. C., Robertson, R.

drainage and improper construction of the roads. The E.(1984),“Asphalt-Aggregate Bonding Energy

test conditions to determine stripping value in the lab do Measurement by Micro calorimetric Methods”,

Volume 5 Issue 10, October 2016

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20162146 973

International Journal of Science and Research (IJSR)

ISSN (Online): 2319-7064

Index Copernicus Value (2013): 6.14 | Impact Factor (2015): 6.391

Thermochimica Acta, 77, Elsevier Science,Amsterdam,

pp. 95-107.

[10] HodaSeddik and John Emery (1997), “Moisture damage

of asphalt pavements”, Paper presented at IRF World

Meeting Toronto, Ontario, Canada. pp. 1- 7.

[11] Roberts F.L., Kandhal PS, Brown ER, Lee Dah-Yinn,

Kenedy TW (1991),“Hot Mix Asphalt Materials,

Mixture Design, and Construction”. MD: NAPA

Education Foundation; pp. 490.

[12] Saad Abo-Qudais, Haider Al-Shweily (2005), “Effect of

aggregate properties on asphalt mixtures stripping and

creep behavior”, Civil Engineering Department, Jordan

University of Science and Technology, Jordan, pp. 1-2.

[13] Hunter, E.R., and Ksaibati, K. (2002), “Evaluating

Moisture Susceptibility of Asphalt Mixes,” Department

of Civil and Architectural Engineering, University of

Wyoming.

[14] Jeon, Y.W., Curtis, C.W.(1990), “A Literature Review

of Adsorption of Asphalt Functionalities on Aggregate

Surface” SHRP Report A-003B report, 1990.

[15] Kandhal, P. S. (1992), “Moisture Susceptibility of HMA

Mixes: Identification of Problem and Recommended

Solutions”, NCAT Report 92-1.

[16] Kandhal,P.S.,Parkerjr, F. (1998), “Aggregate Tests

Related to Asphalt Concrete Performance in Pavement”,

NCHRP Report 405, TRB, NRC, Washington, D.C.

[17] (Kanitpong, K. and Bahia, H. U. (2003) “Role of

Adhesion and Thin Film Tackiness of Asphalt Binders in

Moisture Damage of HMA”.In Asphalt Paving

Technology, Vol. 72, pp. 502-528.

[18] Kennedy, T., R. McGennis, and F. Roberts (1983),

“Investigation of Moisture Damage to Asphalt Concrete

and the Effect of Field Performance-A Case Study”,

Transportation Research Record 911. Washington D.C.

[19] Kiggundu, B. M. Humphrey, B. J., Newman, J. K.

(1986), “Determine Parameter Causing Water Damage

to Asphalt Concrete”, Report to New Mexico

Engineering Research Institute (NMERI), University of

New Mexico, Albuquerque.

[20] Majidzadra, K. and Brovold, F.N., (1968),“State of the

Art: Effect of Water on Bitumen Aggregate Mixtures”,

HRB, Special Rept. 98.

[21] Roberts, F., P. Kandhal, E. Brown, D. Lee, and T.

Kennedy (1996), “Hot Mix Asphalt Materials, Mixture

Design, and Construction.” 2nd edition. Lanham,

Maryland: NAPA Education Foundation.

[22] Russell G. Hicks, (1991), “Moisture Damage in Asphalt

Concrete”, Transportation Research Boardpp no. 4-5.

[23] Selim, A.A. (1997), “Cost Effective/User Friendly Anti-

Stripping Additives in HMA,” Quartzite Quotes,

Quartzite Rock Association, March 1997.

[24] Stuart, K. D.(1990),“Moisture Damage of Asphalt

Mixture- State of the Art”, Report No. FHWARD-90-

019, FHWA, 6300, VA 22101-2296.

[25] Thelen, E. (1958),“Surface Energyand Adhesion

Properties in Asphalt-Aggregate Systems”,HRB, Bull.

192, pp. 63-74).

Volume 5 Issue 10, October 2016

www.ijsr.net

Licensed Under Creative Commons Attribution CC BY

Paper ID: ART20162146 974

S-ar putea să vă placă și

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsDe la EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsÎncă nu există evaluări

- Chapter-1: 1.1.GENERALDocument37 paginiChapter-1: 1.1.GENERALعقيل باسم عبد فرحانÎncă nu există evaluări

- Materials Today: Proceedings: Amit Kumar Rai, Gaurav Singh, Atul Kumar TiwariDocument6 paginiMaterials Today: Proceedings: Amit Kumar Rai, Gaurav Singh, Atul Kumar Tiwaripradeep kattaÎncă nu există evaluări

- Geotechnical Report of Annapurna HotelDocument31 paginiGeotechnical Report of Annapurna HotelshaimenneÎncă nu există evaluări

- Minerals 11 01429Document23 paginiMinerals 11 01429AndreasÎncă nu există evaluări

- A Study of Black Cotton Soil Stabilization With Lime and Waste Plastic Bottle StirrupDocument8 paginiA Study of Black Cotton Soil Stabilization With Lime and Waste Plastic Bottle StirrupIJRASETPublicationsÎncă nu există evaluări

- NSPDF PDFDocument13 paginiNSPDF PDFmrcopy xeroxÎncă nu există evaluări

- International Society For Soil Mechanics and Geotechnical EngineeringDocument5 paginiInternational Society For Soil Mechanics and Geotechnical EngineeringRonald ArbeÎncă nu există evaluări

- Estabilización Del Suelo Limoso Con Polvo de Mármol y Cenizas de Bagazo de Caña de AzúcarDocument8 paginiEstabilización Del Suelo Limoso Con Polvo de Mármol y Cenizas de Bagazo de Caña de Azúcarnilron savedraÎncă nu există evaluări

- Determination of Index PropertiesDocument85 paginiDetermination of Index Propertiesjsyadav.nithÎncă nu există evaluări

- Agrieletric RHADocument9 paginiAgrieletric RHAAINA SAMÎncă nu există evaluări

- Project On Preparation of Plastic Road Using Single Used Waste PlasticDocument10 paginiProject On Preparation of Plastic Road Using Single Used Waste PlasticIJRASETPublicationsÎncă nu există evaluări

- Materials Today: Proceedings: Amit Kumar Rai, Gaurav Singh, Atul Kumar TiwariDocument6 paginiMaterials Today: Proceedings: Amit Kumar Rai, Gaurav Singh, Atul Kumar TiwariKlisman A. Flores DurandÎncă nu există evaluări

- IEBPaperwith ZakariaDocument8 paginiIEBPaperwith ZakariaAs ReÎncă nu există evaluări

- 17ICESMESM Civil6Document11 pagini17ICESMESM Civil6Sherry SherÎncă nu există evaluări

- Report PDFDocument32 paginiReport PDFkrupaÎncă nu există evaluări

- Hydraulic Conductivity and Compressive Strength of Cemented SoilsDocument9 paginiHydraulic Conductivity and Compressive Strength of Cemented SoilsFaklish LoufiÎncă nu există evaluări

- Project Outline - 2203902Document6 paginiProject Outline - 2203902Mohammed ElaidyÎncă nu există evaluări

- Jurnal 1 GeotekDocument7 paginiJurnal 1 Geotekputrielsari26Încă nu există evaluări

- StabiStabilization of Weak Soils Using Locust Beanlization of Weak Soils Using Locust BeanDocument6 paginiStabiStabilization of Weak Soils Using Locust Beanlization of Weak Soils Using Locust BeanSamaila SalehÎncă nu există evaluări

- Soil Satbilization Using Plastic WasteDocument5 paginiSoil Satbilization Using Plastic WasteSabbir NadimÎncă nu există evaluări

- Jurnal Durabilitas 2Document8 paginiJurnal Durabilitas 2Eva IndrianiÎncă nu există evaluări

- IJSDR2005013Document11 paginiIJSDR2005013D. AnweshÎncă nu există evaluări

- Geotechnical Investigation of Black Cotton Soils: June 2015Document9 paginiGeotechnical Investigation of Black Cotton Soils: June 2015Youness CharihÎncă nu există evaluări

- Permeability Analysis of Dredged Material and Its Stabilization Using Surkhi Brick DustDocument8 paginiPermeability Analysis of Dredged Material and Its Stabilization Using Surkhi Brick DustIJRASETPublicationsÎncă nu există evaluări

- Gunadi Khola CH47+578Document36 paginiGunadi Khola CH47+578Anjan LuitelÎncă nu există evaluări

- 2 11 1619677415 2 11 1618558824 Ijcseierdjun20214Document6 pagini2 11 1619677415 2 11 1618558824 Ijcseierdjun20214TJPRC PublicationsÎncă nu există evaluări

- Ravikumar 13102023 IJECC106896Document13 paginiRavikumar 13102023 IJECC106896obotsam1Încă nu există evaluări

- Standard Test Method For Water Absorption of Plastics 1: March 2019Document5 paginiStandard Test Method For Water Absorption of Plastics 1: March 2019swapon kumar shillÎncă nu există evaluări

- Soil Stabilization Using Waste Fiber MaterialsDocument4 paginiSoil Stabilization Using Waste Fiber MaterialsAlipaspas, Jill AnneÎncă nu există evaluări

- Dishafifthpaperfromher PH DthesisDocument15 paginiDishafifthpaperfromher PH DthesiskatherineÎncă nu există evaluări

- Study of Black Cotton Soil Characteristics With Ce PDFDocument10 paginiStudy of Black Cotton Soil Characteristics With Ce PDFPatel SachinÎncă nu există evaluări

- IRD Building Dharan SunsariDocument34 paginiIRD Building Dharan SunsariMilan KarkiÎncă nu există evaluări

- Pre PrintDocument21 paginiPre PrintDany Josua KmÎncă nu există evaluări

- An Experimental Study On Effect of Polystyrene On The Marshall Properties of Bituminous Concrete MixDocument6 paginiAn Experimental Study On Effect of Polystyrene On The Marshall Properties of Bituminous Concrete MixCivil StructureÎncă nu există evaluări

- Atterberg Limit Test DetailsDocument10 paginiAtterberg Limit Test Detailsmaroof nahinÎncă nu există evaluări

- 2020serie de Conferencias IOP Ciencia e Ingeniera de MaterialesDocument7 pagini2020serie de Conferencias IOP Ciencia e Ingeniera de MaterialesSebastian CorzoÎncă nu există evaluări

- Improvement of Soil Properties by Using Jute Fibre As Soil StabilizerDocument7 paginiImprovement of Soil Properties by Using Jute Fibre As Soil StabilizerJanai MarngarÎncă nu există evaluări

- Water Absorption Capacity of Low Calcium Fly Ash and Slag Based Geopolymer ConcreteDocument4 paginiWater Absorption Capacity of Low Calcium Fly Ash and Slag Based Geopolymer Concretealok chaudharyÎncă nu există evaluări

- JETIRC006007Document5 paginiJETIRC006007vyshnavkumarÎncă nu există evaluări

- Swelling Behavior of Expansive SoilsDocument13 paginiSwelling Behavior of Expansive SoilsGorakMethreÎncă nu există evaluări

- Deformation Characteristics of Basalt Reinforced Concrete With SuperplasticizerDocument7 paginiDeformation Characteristics of Basalt Reinforced Concrete With SuperplasticizerBanÎncă nu există evaluări

- Soil Stabilisation Using Flyash: Civil EngineeringDocument28 paginiSoil Stabilisation Using Flyash: Civil EngineeringNeeraj GuptaÎncă nu există evaluări

- The Effects of Different Compaction Energy On Geotechnical Properties of Kaolin and LateriteDocument8 paginiThe Effects of Different Compaction Energy On Geotechnical Properties of Kaolin and LateriteTita Kartika DewiÎncă nu există evaluări

- Effect of Different CuringDocument7 paginiEffect of Different Curingpronab kumarÎncă nu există evaluări

- Review - Utilization of Inferior Quality Aggregates in Asphalt MixesDocument16 paginiReview - Utilization of Inferior Quality Aggregates in Asphalt Mixesfukuzawa.office.toolÎncă nu există evaluări

- CBR JCDVDocument9 paginiCBR JCDVErnest Omorose OsemwegieÎncă nu există evaluări

- Morang Building - 2Document38 paginiMorang Building - 2Samsul HaqueÎncă nu există evaluări

- Using Waste and Polymer For Soil StabilizationDocument3 paginiUsing Waste and Polymer For Soil StabilizationInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Soil Stabilization Using Plastic BottlesDocument3 paginiSoil Stabilization Using Plastic Bottlessuresh choudhary50% (2)

- Simple Method For Measuring Soil Sand Content by Nylon Mesh SievingDocument6 paginiSimple Method For Measuring Soil Sand Content by Nylon Mesh Sievingsriramgopal.anne8356Încă nu există evaluări

- Jurnal TS B - ANNISA MIFTAHUL ARZADocument12 paginiJurnal TS B - ANNISA MIFTAHUL ARZATS BAnnisa Miftahul ArzaÎncă nu există evaluări

- An Experimental Study On Plastic Blended Bituminous Concrete Mix RoadsDocument6 paginiAn Experimental Study On Plastic Blended Bituminous Concrete Mix RoadsCivil StructureÎncă nu există evaluări

- Application of in Situ Tests in Unsaturated Soils To Analysis of Spread FootingsDocument13 paginiApplication of in Situ Tests in Unsaturated Soils To Analysis of Spread FootingsascguilhermeÎncă nu există evaluări

- An Experimental Study On Waste Plastic Aggregate Based Concrete - An Initiative Towards Cleaner EnvironmentDocument5 paginiAn Experimental Study On Waste Plastic Aggregate Based Concrete - An Initiative Towards Cleaner Environmentshalom napoleonÎncă nu există evaluări

- Reserch Report PlastDocument11 paginiReserch Report PlastHafiz YousafÎncă nu există evaluări

- Experimental Investigation On 7 Day Ordinary Concrete 1Document6 paginiExperimental Investigation On 7 Day Ordinary Concrete 1Lizzette Danna DecenaÎncă nu există evaluări

- Stress-Strain Behaviour of Fine Grained Soils With Varying Sand ContentDocument9 paginiStress-Strain Behaviour of Fine Grained Soils With Varying Sand ContentAbdelmoez ElgarfÎncă nu există evaluări

- HASSAN - Strength Improvement of Clayey Soil With Waste Plastic Strips and Cement Kiln DustDocument5 paginiHASSAN - Strength Improvement of Clayey Soil With Waste Plastic Strips and Cement Kiln DustVitória MoraisÎncă nu există evaluări

- Astm D570Document3 paginiAstm D570MEMTINE NDONG AUGUSTINÎncă nu există evaluări

- Design of StaircaseDocument3 paginiDesign of StaircasecabechesterÎncă nu există evaluări

- Cementation Calculations SpreadsheetDocument8 paginiCementation Calculations SpreadsheetAnupam SinghÎncă nu există evaluări

- Calculation of Brick Masonry Estimating Quantity Excel SheetDocument2 paginiCalculation of Brick Masonry Estimating Quantity Excel SheetEr Bharat Prajapati0% (1)

- Retaining Wall DesignDocument180 paginiRetaining Wall DesignsnirosÎncă nu există evaluări

- Dog Legged Stair CaseDocument10 paginiDog Legged Stair CaseĐÀO NGỌC TÙNGÎncă nu există evaluări

- Calculation of Cement and Sand For Plastering Excel SheetDocument2 paginiCalculation of Cement and Sand For Plastering Excel SheetAnupam SinghÎncă nu există evaluări

- EARTHWORK Calculation Sheet-STANDARD v5.0Document3 paginiEARTHWORK Calculation Sheet-STANDARD v5.0SureshKumar78% (9)

- RCC21 Subframe AnalysisDocument9 paginiRCC21 Subframe AnalysisZayyan RomjonÎncă nu există evaluări

- CONCRETE QuantitiesDocument9 paginiCONCRETE QuantitiesdoxoÎncă nu există evaluări

- DPRDocument2 paginiDPRSyed Adnan AqibÎncă nu există evaluări

- Road Sector - Skills Development StrategyDocument14 paginiRoad Sector - Skills Development StrategyAkhilesh DwivediÎncă nu există evaluări

- Whitetopping - A Cost-Effective Rehabilitation PDFDocument18 paginiWhitetopping - A Cost-Effective Rehabilitation PDFAnupam SinghÎncă nu există evaluări

- RCC Box Culvert - Methodology and Designs Including Computer MethodDocument31 paginiRCC Box Culvert - Methodology and Designs Including Computer Methodmohan1441Încă nu există evaluări

- Rutting in Flexible Pavements - A Case StudyDocument15 paginiRutting in Flexible Pavements - A Case StudyAla ThajilÎncă nu există evaluări

- Use of Seismic Reaction Block As A HorizontalDocument21 paginiUse of Seismic Reaction Block As A HorizontalAndrea DeleonÎncă nu există evaluări

- CONCRETE QuantitiesDocument9 paginiCONCRETE QuantitiesdoxoÎncă nu există evaluări

- Road Sector - Skills Development StrategyDocument14 paginiRoad Sector - Skills Development StrategyAkhilesh DwivediÎncă nu există evaluări

- Whitetopping - A Cost-Effective RehabilitationDocument10 paginiWhitetopping - A Cost-Effective RehabilitationAnupam SinghÎncă nu există evaluări

- Well FoundationDocument9 paginiWell FoundationManmeet SinghÎncă nu există evaluări

- Irc 58 2015 Excel Sheet PDFDocument3 paginiIrc 58 2015 Excel Sheet PDFtally3tallyÎncă nu există evaluări

- Comparative Study On Analysis and Design of Flexible and Rigid PavementsDocument6 paginiComparative Study On Analysis and Design of Flexible and Rigid PavementsAnupam SinghÎncă nu există evaluări

- 2alotus Jinvani Sangrah Pooja Vidhi PrarambhDocument4 pagini2alotus Jinvani Sangrah Pooja Vidhi PrarambhAnupam SinghÎncă nu există evaluări

- Shri Sookt PDFDocument4 paginiShri Sookt PDFAnupam SinghÎncă nu există evaluări

- Design of Geocell Reinforced Flexible PavementDocument4 paginiDesign of Geocell Reinforced Flexible Pavementsundra0Încă nu există evaluări

- Flexible Pavement Design in IndiaDocument20 paginiFlexible Pavement Design in Indiaairpavset100% (1)

- Highway Design Data Hand Book PDFDocument38 paginiHighway Design Data Hand Book PDFConnect Civil EnggÎncă nu există evaluări

- Irc Ammendments 2018Document3 paginiIrc Ammendments 2018Anupam SinghÎncă nu există evaluări

- Road Accident Analysis and Identify The Black Spot Location On State Highway-5 (Halol-Godhra Section)Document7 paginiRoad Accident Analysis and Identify The Black Spot Location On State Highway-5 (Halol-Godhra Section)Anupam SinghÎncă nu există evaluări

- Roman Number RulesDocument4 paginiRoman Number RulesAnupam SinghÎncă nu există evaluări

- The Development of A Machine Vision Assisted, Teleoperated Pavement Crack SealerDocument10 paginiThe Development of A Machine Vision Assisted, Teleoperated Pavement Crack SealerByronÎncă nu există evaluări

- Asphalt Part 1Document23 paginiAsphalt Part 1Louise LuyÎncă nu există evaluări

- Local Shelter Plan 2018-2026: Santa Rita PampangaDocument38 paginiLocal Shelter Plan 2018-2026: Santa Rita PampangaELIAS BUENAVENTEÎncă nu există evaluări

- Guidelines For Construction and Maintenance of City RoadsDocument144 paginiGuidelines For Construction and Maintenance of City RoadsCitizen Matters100% (2)

- MOS - Flexible Pavement RehabilitationDocument6 paginiMOS - Flexible Pavement RehabilitationcdipcinÎncă nu există evaluări

- Roads: Master Specification RD-PV-D1 Pavement Design (Austroads Supplement)Document52 paginiRoads: Master Specification RD-PV-D1 Pavement Design (Austroads Supplement)La FoliakÎncă nu există evaluări

- Company Profile - Mitsubishi Metal - 2014 - en PDFDocument16 paginiCompany Profile - Mitsubishi Metal - 2014 - en PDFAnton AviyantoÎncă nu există evaluări

- Report On Bituminous MixDocument75 paginiReport On Bituminous MixBibhuti B. BhardwajÎncă nu există evaluări

- Measurement of Texture Depth of Pavement Using Potable Laser ProfilerDocument14 paginiMeasurement of Texture Depth of Pavement Using Potable Laser Profilerสํานักวิเคราะห์และตรวจสอบ ส่วนสํารวจและประเมินสภาพทางÎncă nu există evaluări

- Micro Surfacing Process Design Overview - 0Document3 paginiMicro Surfacing Process Design Overview - 0RenugopalÎncă nu există evaluări

- Pavement MaterialsDocument126 paginiPavement MaterialsSaleemAhmadMalikÎncă nu există evaluări

- Traffic Loads NotesDocument6 paginiTraffic Loads Noteschurchill ochiengÎncă nu există evaluări

- Floor Type Characterization Temperature and Humidity Tolerance For Tunga Penetrans Infestation in Igbokoda Ondo State NigeriaDocument7 paginiFloor Type Characterization Temperature and Humidity Tolerance For Tunga Penetrans Infestation in Igbokoda Ondo State NigeriaIJARP PublicationsÎncă nu există evaluări

- MoRTH Specifications Pocket Book 09.04.2019 FinalDocument92 paginiMoRTH Specifications Pocket Book 09.04.2019 FinalsombansÎncă nu există evaluări

- Aggregate Impact Value TestDocument5 paginiAggregate Impact Value TestKimi RusdiÎncă nu există evaluări

- Pavement Design Excel SheetDocument23 paginiPavement Design Excel Sheetharishreddy198571% (17)

- What Is White Cement wc001Document4 paginiWhat Is White Cement wc001sr srÎncă nu există evaluări

- 8 - Design of Rigid PavementsDocument32 pagini8 - Design of Rigid PavementsBAMS100% (1)

- Vibratory Roller Handbook: With Standardized Terms and DefinitionsDocument16 paginiVibratory Roller Handbook: With Standardized Terms and Definitionsfrankjer4Încă nu există evaluări

- Pump Station Design ManualDocument66 paginiPump Station Design ManualPablo Angel Olguin VivarÎncă nu există evaluări

- Department of Civil and Environmental Engineering, School of Engineering Cedat, Makerere UniversityDocument60 paginiDepartment of Civil and Environmental Engineering, School of Engineering Cedat, Makerere UniversityBAMSÎncă nu există evaluări

- Glass Fiber SpecsDocument4 paginiGlass Fiber SpecsJanus AntonioÎncă nu există evaluări

- Excel For Civil Engineers-1Document36 paginiExcel For Civil Engineers-1mp SinghÎncă nu există evaluări

- Detail Methodology of Premix Carpet Road in NepalDocument2 paginiDetail Methodology of Premix Carpet Road in NepalSudip Shrestha50% (2)

- Intenship ReportDocument17 paginiIntenship ReportYdv DeepÎncă nu există evaluări

- Factors Affecting Transportation - Tom v. Mathew, Tom v. 2009Document12 paginiFactors Affecting Transportation - Tom v. Mathew, Tom v. 2009Michaella GalasÎncă nu există evaluări

- Aashto CatalogDocument32 paginiAashto Catalogkbuchan1Încă nu există evaluări

- List of Accrediated 149 New MaterialsDocument9 paginiList of Accrediated 149 New MaterialsjoyÎncă nu există evaluări

- Highway Geometric Design Guide AUGUST 1999: Alberta InfrastructureDocument64 paginiHighway Geometric Design Guide AUGUST 1999: Alberta InfrastructureM iqbalÎncă nu există evaluări

- Repair Solutions: Repair, Rebuild, and Coating ProductsDocument9 paginiRepair Solutions: Repair, Rebuild, and Coating ProductsProveedora de servicios y suministros PSSÎncă nu există evaluări

- The Future of Geography: How the Competition in Space Will Change Our WorldDe la EverandThe Future of Geography: How the Competition in Space Will Change Our WorldEvaluare: 4 din 5 stele4/5 (6)

- The Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaDe la EverandThe Beekeeper's Lament: How One Man and Half a Billion Honey Bees Help Feed AmericaÎncă nu există evaluări

- Hero Found: The Greatest POW Escape of the Vietnam WarDe la EverandHero Found: The Greatest POW Escape of the Vietnam WarEvaluare: 4 din 5 stele4/5 (19)

- Sully: The Untold Story Behind the Miracle on the HudsonDe la EverandSully: The Untold Story Behind the Miracle on the HudsonEvaluare: 4 din 5 stele4/5 (103)

- The Fabric of Civilization: How Textiles Made the WorldDe la EverandThe Fabric of Civilization: How Textiles Made the WorldEvaluare: 4.5 din 5 stele4.5/5 (58)

- The End of Craving: Recovering the Lost Wisdom of Eating WellDe la EverandThe End of Craving: Recovering the Lost Wisdom of Eating WellEvaluare: 4.5 din 5 stele4.5/5 (82)

- Pale Blue Dot: A Vision of the Human Future in SpaceDe la EverandPale Blue Dot: A Vision of the Human Future in SpaceEvaluare: 4.5 din 5 stele4.5/5 (588)

- Highest Duty: My Search for What Really MattersDe la EverandHighest Duty: My Search for What Really MattersÎncă nu există evaluări

- Transformed: Moving to the Product Operating ModelDe la EverandTransformed: Moving to the Product Operating ModelEvaluare: 4 din 5 stele4/5 (1)

- Dirt to Soil: One Family’s Journey into Regenerative AgricultureDe la EverandDirt to Soil: One Family’s Journey into Regenerative AgricultureEvaluare: 5 din 5 stele5/5 (125)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindDe la EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindÎncă nu există evaluări

- Reality+: Virtual Worlds and the Problems of PhilosophyDe la EverandReality+: Virtual Worlds and the Problems of PhilosophyEvaluare: 4 din 5 stele4/5 (24)

- The Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyDe la EverandThe Intel Trinity: How Robert Noyce, Gordon Moore, and Andy Grove Built the World's Most Important CompanyÎncă nu există evaluări

- System Error: Where Big Tech Went Wrong and How We Can RebootDe la EverandSystem Error: Where Big Tech Went Wrong and How We Can RebootÎncă nu există evaluări

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDe la EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestEvaluare: 4 din 5 stele4/5 (28)

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterDe la EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterÎncă nu există evaluări

- The Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeDe la EverandThe Manager's Path: A Guide for Tech Leaders Navigating Growth and ChangeEvaluare: 4.5 din 5 stele4.5/5 (99)

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreDe la EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcreEvaluare: 4.5 din 5 stele4.5/5 (33)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDe la EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerEvaluare: 4.5 din 5 stele4.5/5 (54)

- Packing for Mars: The Curious Science of Life in the VoidDe la EverandPacking for Mars: The Curious Science of Life in the VoidEvaluare: 4 din 5 stele4/5 (1396)

- Broken Money: Why Our Financial System is Failing Us and How We Can Make it BetterDe la EverandBroken Money: Why Our Financial System is Failing Us and How We Can Make it BetterEvaluare: 5 din 5 stele5/5 (3)

- Four Battlegrounds: Power in the Age of Artificial IntelligenceDe la EverandFour Battlegrounds: Power in the Age of Artificial IntelligenceEvaluare: 5 din 5 stele5/5 (5)

- A Place of My Own: The Architecture of DaydreamsDe la EverandA Place of My Own: The Architecture of DaydreamsEvaluare: 4 din 5 stele4/5 (242)

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDe la EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerEvaluare: 4.5 din 5 stele4.5/5 (122)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansDe la EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansÎncă nu există evaluări