Documente Academic

Documente Profesional

Documente Cultură

IX. Cost Considerations of The GTAW Process: Formulas To Figure Total Welding Cost

Încărcat de

vishnu300022Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

IX. Cost Considerations of The GTAW Process: Formulas To Figure Total Welding Cost

Încărcat de

vishnu300022Drepturi de autor:

Formate disponibile

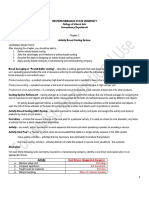

IX.

Cost Considerations of A cost evaluation of a welding process should include:

1. Labor and overhead cost per foot of weld.

the GTAW Process 2. Filler wire cost per foot of weld.

It is important to take into consideration all the facts that 3. Gas cost per foot of weld.

relate to a welding situation when attempting to attach a cost 4. Power cost per foot of weld.

to a foot of weld. Not only do direct costs such as filler wire, Computing these figures on a chart or proposal will show the

shielding gas, equipment, and labor have a bearing, but indirect economics of a particular process.

costs such as overhead and training of personnel have an

affect as well. Standard formulas for cost estimating as presented in this

book (Figure 9.1) are a reasonable measure for computing

Training should be considered in the cost since GTAW is data for cost comparison.

generally considered a more advanced process and will

require time by the welder to familiarize with the technical and The formulas as presented have no “plug-in” numerical values.

manipulative aspects of the process. The values will vary with each application and each company.

The cost of proper equipment to efficiently accomplish the

job at hand is of great importance. Manual GTAW equipment

in a production setup can run into thousands of dollars. If

there are many repetitive welds, automatic equipment should

be considered, and those costs can run into the tens of

thousands of dollars.

Formulas to Figure Total Welding Cost

Welder Rate in $ Per Hour

1. Labor = __________________________________________ = Cost per ft.

Weld Travel Speed (IPM) x Duty Cycle x 60 min./hr.

12"/ft.

Overhead Rate

2. Overhead = __________________________________________ = Cost per ft.

Weld Travel Speed (IPM) x Duty Cycle x 60 min./hr.

12"/ft.

3. Filler Metal Cost Weight of Deposit x Filler Metal Cost

Foot of Weld Deposition Efficiency

Cost of Gas/cu. ft. x Flow Rate (cfh) = Cost per ft.

4. Gas = ________________________________

Weld Travel Speed (IPM) x 60 min./hr.

12"/ft.

Volts x amps x power cost/kw. hr.

5. Power = ______________________________________________________ = Cost per ft.

Weld Travel Speed (IPM) x Machine Efficiency x 60 min./hr. x 1000

12"/ft.

6. Total = Total of Above Applying Formulas x Total Length of Weld = Total Cost

60 min./hr.

*The factor 5 will appear in some of the formula examples: This was derived from the ratio of:

12"/ft.

Figure 9.1 Formulas for cost considerations.

68

S-ar putea să vă placă și

- Estimation of Welding Cost: by K.R.Prasanna Venkatesan WE0663Document41 paginiEstimation of Welding Cost: by K.R.Prasanna Venkatesan WE0663Anonymous 7yN43wjl100% (1)

- Estimation of Welding CostDocument41 paginiEstimation of Welding CostAnkur2592% (13)

- Test Bank For Macroeconomics 8th Canadian Edition Andrew AbelDocument16 paginiTest Bank For Macroeconomics 8th Canadian Edition Andrew AbelstebinrothÎncă nu există evaluări

- Restoring PH Balance in The BodyDocument6 paginiRestoring PH Balance in The Bodycinefil70Încă nu există evaluări

- Field & Shop Inspection and Test Plan (Itp) With Prefabrication, Painting of Spools and Field Activities After InstallationDocument8 paginiField & Shop Inspection and Test Plan (Itp) With Prefabrication, Painting of Spools and Field Activities After Installationvishnu300022Încă nu există evaluări

- Determining The Cost of WeldingDocument7 paginiDetermining The Cost of WeldingSriram VjÎncă nu există evaluări

- Task / Description Structure Discipline Category Type Units Slow Ave Fast Units Slow Ave FastDocument31 paginiTask / Description Structure Discipline Category Type Units Slow Ave Fast Units Slow Ave FastMalik TanzilÎncă nu există evaluări

- GDB3023 Module2 PDFDocument30 paginiGDB3023 Module2 PDFAisar AmireeÎncă nu există evaluări

- Accounting For Manufacturing OverheadDocument9 paginiAccounting For Manufacturing OverheadKenzel lawasÎncă nu există evaluări

- Operating FactorDocument9 paginiOperating Factormekhman mekhtyÎncă nu există evaluări

- Rights of An Accused Under Custodial InvestigationDocument17 paginiRights of An Accused Under Custodial Investigationadrianfrancis9100% (1)

- Modern Cost Engineering PDFDocument38 paginiModern Cost Engineering PDFbertan dağıstanlı100% (1)

- Eco BreakevenDocument32 paginiEco Breakevenkhen026Încă nu există evaluări

- Determining The Cost of Welding Part 1 by Duane K. Miller 2004 7pDocument7 paginiDetermining The Cost of Welding Part 1 by Duane K. Miller 2004 7pjosea_pena100% (1)

- Equipment Cost Estimating - Otuonye - 2000Document42 paginiEquipment Cost Estimating - Otuonye - 2000Rotax_Kid0% (1)

- Cost Estimation: by P L MccarthyDocument5 paginiCost Estimation: by P L MccarthyCarlosSantelicesÎncă nu există evaluări

- Introduction To Cost Estimating Lec 2Document36 paginiIntroduction To Cost Estimating Lec 2Arwa HusseinÎncă nu există evaluări

- Drilling Economics PDFDocument47 paginiDrilling Economics PDF류태하100% (1)

- Chapter 2 - Cost ConceptDocument22 paginiChapter 2 - Cost ConceptNg Hon MengÎncă nu există evaluări

- Week 7-9Document28 paginiWeek 7-9Sohaib IrfanÎncă nu există evaluări

- ART-Journey Management PlanDocument1 paginăART-Journey Management Planvishnu300022100% (2)

- Rfi Request FormDocument1 paginăRfi Request Formvishnu300022Încă nu există evaluări

- Determination of A Mining Cutoff Grade Strategy Based On An Iterative Factor PDFDocument5 paginiDetermination of A Mining Cutoff Grade Strategy Based On An Iterative Factor PDFRenzo MurilloÎncă nu există evaluări

- Surface Preaparation and Painting SpecificiationDocument21 paginiSurface Preaparation and Painting Specificiationvishnu300022Încă nu există evaluări

- Cost Calculation Program For Productivity in WeldingDocument20 paginiCost Calculation Program For Productivity in WeldingiyigunÎncă nu există evaluări

- ECS 3390 - Business and Technical CommuncationsDocument293 paginiECS 3390 - Business and Technical CommuncationsEliseo Robles0% (3)

- E-F Hdpe InnogazDocument32 paginiE-F Hdpe Innogazvishnu300022Încă nu există evaluări

- Characteristics of Victorian BritainDocument3 paginiCharacteristics of Victorian BritainmwaqasenggÎncă nu există evaluări

- The Duty To Warn in Products Liability: Contours and CriticismDocument115 paginiThe Duty To Warn in Products Liability: Contours and CriticismArun HiroÎncă nu există evaluări

- Week 9-10Document26 paginiWeek 9-10Raja Umair RaufÎncă nu există evaluări

- Cost Estimation and EvaluationDocument4 paginiCost Estimation and EvaluationMuddassir DanishÎncă nu există evaluări

- The Economics of Hardfacing: Home PageDocument10 paginiThe Economics of Hardfacing: Home PageJR ZookÎncă nu există evaluări

- Ec Imp QuestionsDocument21 paginiEc Imp Questionswhitefang0606Încă nu există evaluări

- Machining EconomicsDocument21 paginiMachining Economicsswapnil nishaneÎncă nu există evaluări

- Systems Design: Job-Order Costing and Process Costing: MANAGEMENT ACCOUNTING - Solutions ManualDocument16 paginiSystems Design: Job-Order Costing and Process Costing: MANAGEMENT ACCOUNTING - Solutions ManualBianca LizardoÎncă nu există evaluări

- MALec Batch 2Document105 paginiMALec Batch 2duong duongÎncă nu există evaluări

- Chapter 2 Cost Concepts and Design Economics (Cont.)Document20 paginiChapter 2 Cost Concepts and Design Economics (Cont.)gar fieldÎncă nu există evaluări

- Unit 10 Machining Economics: StructureDocument22 paginiUnit 10 Machining Economics: StructureTapas BanerjeeÎncă nu există evaluări

- A Study of Automatic Determination of Cutting Conditions To Minimize Machining CostDocument5 paginiA Study of Automatic Determination of Cutting Conditions To Minimize Machining CostH 5895Încă nu există evaluări

- CBB 40104 Chapter 3 (02092020)Document29 paginiCBB 40104 Chapter 3 (02092020)Mira Lucis CaelumÎncă nu există evaluări

- ME6005/Process Planning & Cost Estimation Year/sem:IV/VIIDocument13 paginiME6005/Process Planning & Cost Estimation Year/sem:IV/VIIArshad RSÎncă nu există evaluări

- The Economics of HardfacingDocument6 paginiThe Economics of Hardfacingemad sabri100% (1)

- Parametric Cost Estimation of Design ActivitiesDocument6 paginiParametric Cost Estimation of Design ActivitiesincubusmanÎncă nu există evaluări

- PEB4102 Chapter 2Document41 paginiPEB4102 Chapter 2LimÎncă nu există evaluări

- Chapter 10 Answer PDFDocument13 paginiChapter 10 Answer PDFshaneÎncă nu există evaluări

- Unit Absorption of Overheads: 8 FactoryDocument17 paginiUnit Absorption of Overheads: 8 FactoryelmudaaÎncă nu există evaluări

- Exam 2009 10Document8 paginiExam 2009 10Yared MeseleÎncă nu există evaluări

- Chapter-8 Unit - Batch CostingDocument8 paginiChapter-8 Unit - Batch CostingAdi PrajapatiÎncă nu există evaluări

- L9. Economics of Metal Cutting1Document40 paginiL9. Economics of Metal Cutting1Fasil Getachew100% (1)

- 7B 2 AnderssonDocument13 pagini7B 2 Anderssonmwiweko2013Încă nu există evaluări

- TDC (Compatibility Mode)Document23 paginiTDC (Compatibility Mode)gianmarcoÎncă nu există evaluări

- Engineering CostDocument12 paginiEngineering CostH110Shreyan SarkarÎncă nu există evaluări

- PEB4102 Chapter 2Document32 paginiPEB4102 Chapter 2demure claw19Încă nu există evaluări

- Chap 03 Study GuideDocument10 paginiChap 03 Study Guidedimitra triantosÎncă nu există evaluări

- Lec - 4Document48 paginiLec - 4Tamene TayeÎncă nu există evaluări

- Chapter 3 Target Costing: 1. ObjectivesDocument9 paginiChapter 3 Target Costing: 1. ObjectivesMevika MerchantÎncă nu există evaluări

- Calamba: Department of Business EducationDocument3 paginiCalamba: Department of Business EducationMa Lhira MarcialÎncă nu există evaluări

- Ie463 Engineering Economics 59fcd9fe1723dde15af13c7aDocument24 paginiIe463 Engineering Economics 59fcd9fe1723dde15af13c7ahaseeb ahmedÎncă nu există evaluări

- Chapter 6 - Crashing Program-3Document34 paginiChapter 6 - Crashing Program-3Cowo Rasa AlpukatÎncă nu există evaluări

- Economic Studies For Investment and ReplacementDocument14 paginiEconomic Studies For Investment and ReplacementAkash Kumar RanaÎncă nu există evaluări

- CEV633 Engineering Economics & Project ManagementDocument59 paginiCEV633 Engineering Economics & Project ManagementgnaniÎncă nu există evaluări

- Activity Analysis, Cost BehaviorDocument63 paginiActivity Analysis, Cost BehaviorRaghavÎncă nu există evaluări

- Standard Cost Variance AnalysisDocument11 paginiStandard Cost Variance AnalysisJanarie Bosco OrofilÎncă nu există evaluări

- Analyzing The Cost of ReworkDocument11 paginiAnalyzing The Cost of ReworkGe EÎncă nu există evaluări

- Cost DynamicsDocument6 paginiCost DynamicskshamamehtaÎncă nu există evaluări

- Introduction To Cost Estimating Lec 1Document146 paginiIntroduction To Cost Estimating Lec 1Arwa HusseinÎncă nu există evaluări

- Chapter 2 - ABC System PDFDocument5 paginiChapter 2 - ABC System PDFchelsea kayle licomes fuentesÎncă nu există evaluări

- Principles and Techniques of Cost EstiatingDocument8 paginiPrinciples and Techniques of Cost EstiatingNick BelieberÎncă nu există evaluări

- Chap002 Basic Cost ManagementDocument36 paginiChap002 Basic Cost ManagementAneukphon Ryan Pramanda IsniÎncă nu există evaluări

- Production and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesDe la EverandProduction and Maintenance Optimization Problems: Logistic Constraints and Leasing Warranty ServicesÎncă nu există evaluări

- Numerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityDe la EverandNumerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityÎncă nu există evaluări

- Optimization and Business Improvement Studies in Upstream Oil and Gas IndustryDe la EverandOptimization and Business Improvement Studies in Upstream Oil and Gas IndustryÎncă nu există evaluări

- Check Valves: Without/with Lever and Counterweight, PN 10 - PN 16Document2 paginiCheck Valves: Without/with Lever and Counterweight, PN 10 - PN 16vishnu300022Încă nu există evaluări

- HaloSense PDFDocument2 paginiHaloSense PDFvishnu300022Încă nu există evaluări

- c4 1 Wasser Hawle en 2020Document2 paginic4 1 Wasser Hawle en 2020vishnu300022Încă nu există evaluări

- Rfi JN12 SR1 M08 01Document1 paginăRfi JN12 SR1 M08 01vishnu300022Încă nu există evaluări

- Cla ValDocument3 paginiCla Valvishnu300022Încă nu există evaluări

- 1060A Bronze Swing Type Check ValveDocument8 pagini1060A Bronze Swing Type Check Valvevishnu300022Încă nu există evaluări

- Product BrochureDocument16 paginiProduct Brochurevishnu300022Încă nu există evaluări

- Rothenberger Roweld P355B User ManualDocument16 paginiRothenberger Roweld P355B User Manualvishnu300022Încă nu există evaluări

- Hepwo PlastiDrain ML PDFDocument8 paginiHepwo PlastiDrain ML PDFvishnu300022Încă nu există evaluări

- Algorithm Design TechniquesDocument24 paginiAlgorithm Design TechniquespermasaÎncă nu există evaluări

- Symbolic Interaction Theory: Nilgun Aksan, Buket Kısac, Mufit Aydın, Sumeyra DemirbukenDocument3 paginiSymbolic Interaction Theory: Nilgun Aksan, Buket Kısac, Mufit Aydın, Sumeyra DemirbukenIgor Dutra BaptistaÎncă nu există evaluări

- Resume Pet A Sol LanderDocument3 paginiResume Pet A Sol LanderdreyesfinuliarÎncă nu există evaluări

- Final Report of BBSMDocument37 paginiFinal Report of BBSMraazoo1967% (9)

- GEODynamics CONNEX Brochure 2008.10 - Rev2 Final PDFDocument12 paginiGEODynamics CONNEX Brochure 2008.10 - Rev2 Final PDFSusin LimÎncă nu există evaluări

- Diploma Thesis-P AdamecDocument82 paginiDiploma Thesis-P AdamecKristine Guia CastilloÎncă nu există evaluări

- Omran WalidDocument196 paginiOmran WalidDébora AmougouÎncă nu există evaluări

- Applications Description: General Purpose NPN Transistor ArrayDocument5 paginiApplications Description: General Purpose NPN Transistor ArraynudufoqiÎncă nu există evaluări

- Transfer CaseDocument46 paginiTransfer Casebantuan.dtÎncă nu există evaluări

- A. Erfurth, P. Hoff. Mad Scenes in Early 19th-Century Opera PDFDocument4 paginiA. Erfurth, P. Hoff. Mad Scenes in Early 19th-Century Opera PDFbiarrodÎncă nu există evaluări

- Study of Noise Mapping at Moolchand Road Phargang New DelhiDocument10 paginiStudy of Noise Mapping at Moolchand Road Phargang New DelhiEditor IJTSRDÎncă nu există evaluări

- ENG11H Realism 6-Outcasts of Poker FlatDocument3 paginiENG11H Realism 6-Outcasts of Poker FlatJosh Cauhorn100% (1)

- Power Systems (K-Wiki - CH 4 - Stability)Document32 paginiPower Systems (K-Wiki - CH 4 - Stability)Priyanshu GuptaÎncă nu există evaluări

- Networking With OrganizationsDocument23 paginiNetworking With OrganizationsClaudette Lui Cabanos- Mercado-ReyesÎncă nu există evaluări

- Tia Portal V16 OrderlistDocument7 paginiTia Portal V16 OrderlistJahidul IslamÎncă nu există evaluări

- Amlodipine Besylate Drug StudyDocument2 paginiAmlodipine Besylate Drug StudyJonieP84Încă nu există evaluări

- FS1 Worksheet Topic 6Document2 paginiFS1 Worksheet Topic 6ALMALYN ANDIHÎncă nu există evaluări

- Week 5 Teradata Practice ExerciseDocument14 paginiWeek 5 Teradata Practice ExerciseWooyeon ChoÎncă nu există evaluări

- Chapter - 01 Geography The Earth in The Solar SystemDocument10 paginiChapter - 01 Geography The Earth in The Solar SystemKarsin ManochaÎncă nu există evaluări

- Prince Ryan B. Camarino Introduction To Philosophy of The Human PersonDocument2 paginiPrince Ryan B. Camarino Introduction To Philosophy of The Human PersonKyle Aureo Andagan RamisoÎncă nu există evaluări

- Difference Between Dada and SurrealismDocument5 paginiDifference Between Dada and SurrealismPro FukaiÎncă nu există evaluări

- Syllabus (2020) : NTA UGC-NET Computer Science and ApplicationsDocument24 paginiSyllabus (2020) : NTA UGC-NET Computer Science and ApplicationsDiksha NagpalÎncă nu există evaluări

- RegistryDocument4 paginiRegistryRajan KhandelwalÎncă nu există evaluări

- Calgary Project Consultants, DubaiDocument18 paginiCalgary Project Consultants, DubaiManish GuptaÎncă nu există evaluări