Documente Academic

Documente Profesional

Documente Cultură

Institut Kemahiran Tinggi Belia Negara: Kementerian Belia Dan Sukan

Încărcat de

Aswaja313Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Institut Kemahiran Tinggi Belia Negara: Kementerian Belia Dan Sukan

Încărcat de

Aswaja313Drepturi de autor:

Formate disponibile

Kod Kertas TP-300-4/M3/02 Muka Surat: 1 drpd 8

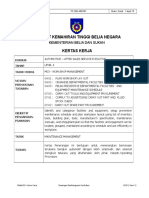

INSTITUT KEMAHIRAN TINGGI BELIA NEGARA

KEMENTERIAN BELIA DAN SUKAN

KERTAS KERJA

KURSUS AUTOMOTIVE – AFTER SALES SERVICE EXECUTIVE

TAHAP LEVEL 4

TAJUK MODUL M03 - WORKSHOP MANAGEMENT

04.01 : PLAN WORKSHOP LAY OUT

NO DAN 04.02 : ORGANISE DEPARTMENTAL FACILITIES AND EQUIPMENT

PERNYATAAN 04.03 : PELAN PREVENTIVE DEPARTMENTAL FACILITIES AND

TUGASAN EQUIPMENT MAINTENANCE SCHEDULE

07.03 : CARRY OUT TOOLS AND EQUIPMENT PROCUREMENT

07.01 : COMPLY TO ADVERTISING CARRY OUT PART AND FLUID

STOCK CHECK

07.02 : CARRY OUT SPARE PART PROCUREMENT

Identify and categorize facilities and equipment, setup preventive

OBJEKTIF maintenance schedule and plan workplace layout using list of inventory

PENCAPAIAN book, building plan, tools, manufacturer’s specification, maintenance

PIAWAIAN manuals, workshop/plant plan so that the facilities and equipment can be

located, grouped, maintained according to schedule and use efficiently in

workplace.

TAJUK MAINTENANCE MANAGEMENT

Kertas Penerangan ini bertujuan untuk menerangkan berkenaan

TUJUAN terutama bengkel automotif dengan lebih sistematik dan selamat

mengikut tatacara yang dikehendaki oleh pihak industri.Operating

Procedure.

Modul 03- Kertas Kerja Cawangan Pembangunan Kurikulum 2015 ( Versi 1)

Kod Kertas TP-300-4/M3/02 Muka Surat: 2 drpd 8

PENGENALAN :

Peralatan, mesin dan bangunan dalam sesebuah industri itu lama-kelamaan akan menjadi

buruk dan rosak. Bila ini berlaku maka terpaksalah pihak industri tersebut membeli peralatan, mesin

atau membina bangunan baru. Ini memerlukan belanja yang besar. Tempoh masa sebelum

sesebuah mesin, peralatan, atau bangunan itu rosak, bergantung kepada sejauh mana ia dijaga.

Penjagaan inilah yang dipanggil senggaraan.

Senggaraan yang baik lagi berkesan amatlah diperlukan untuk memastikan setiap peralatan,

mesin dan bangunan itu boleh digunakan dalam satu jangka masa yang dianggap mengutungkan.

Peralatan, mesin dan bangunan yang tidak di senggarakan dengan baik dan betul akan cepat rosak

dan merugikan dari segi pelaburan modal membeli. Untuk itu perlulah sesebuah industri merancang

dan mengamalkan satu sistem senggaraan yang berkesan sekiranya ingin menjadi sebuah industri

yang menguntungkan.

DRAWING / DATA / TABLE:

Not Available

TOOLS / EQUIPMENTS / MATERIAL:

1. Organization chart

2. Flammable items (thinner, petrol treatment, etc.)

3. Toxic materials (brake fluid, battery acid, etc.)

4. Source stock inventory record

5. Company’s Standard Operating Procedure

6. Parts catalogue (parts list, price list, parts drawing, etc.)

7. Spare parts inventory records

8. Product range (model, variant, year of make, etc.)

9. Organisation Chart 6) Company’s

10. Categories of tools and equipment

11. Company inventory system record

12. List of supplier of tools and equipment

13. Manufacture specification (brand name, warranty period, etc).

Modul 03- Kertas Kerja Cawangan Pembangunan Kurikulum 2015 ( Versi 1)

Kod Kertas TP-300-4/M3/02 Muka Surat: 3 drpd 8

14. Tools and equipment capital asset order form

15. Standard Operating Procedure (SOP)

Modul 03- Kertas Kerja Cawangan Pembangunan Kurikulum 2015 ( Versi 1)

Kod Kertas TP-300-4/M3/02 Muka Surat: 4 drpd 8

DETAIL

WORK STEPS

1. Identify type of 1.1 Determine categories of spare parts

parts and fluid

1.2 Determine location of spare parts

1.3 Determine safekeeping of flammable parts

1.4 Determine safekeeping of toxic materials

1.5 Read precaution symbol (flame, skull, etc.)

2. Obtain parts and fluid 2.1 Determine Inventory control system

stock inventory record

2.2 Utilise Workshop Management System

2.3 Sourcing stock inventory record (IT system, bin card, etc.)

2.4 Extracting parts and fluid stock inventory records

2.5 Comply to company SOP for obtaining inventory data

3. Prepare parts and fluid 3.1 Prepare parts and fluid stock check activities

stock check

3.2 Determine responsible personnel/parties involved.

arrangement

3.3 Scheduling manpower for stock check (timetabling, etc.)

3.4 Comply to company`s SOP to conduct stock check

4. Check spare parts and 4.1 Determine parts and fluid stock check activities

fluid stock

4.2 Follow stock check procedure.

4.3 Schedule stock check (timetabling, etc.)

4.4 Comply to company SOP to conduct stock check

Modul 03- Kertas Kerja Cawangan Pembangunan Kurikulum 2015 ( Versi 1)

Kod Kertas TP-300-4/M3/02 Muka Surat: 5 drpd 8

5. Record parts and fluid 5.1 Utilise record format

stock check

5.2 Utilise inventory control system (record, etc)

5.3 Utilise Workshop Management system

5.4 Comply company`s standard Operating Procedure (SOP)

Attitude/Safety

- Meticulous to identify business capacity and manpower

Requirements

- Diligent in Identifying type of parts and fluid

- Resourceful in Obtaining parts and fluid stock inventory record

6. Identify type of spare 6.1 Determine categories of spare parts

parts required

6.2 Access company inventory system

6.3 Determine parts number

6.4 Determine urgency to order

6.5 Determine vehicle model variation

6.6 Determine monthly average demand

7. Obtain spare part 7.1 Interpret parts catalogue (parts list, price list, parts drawing, etc.)

specification

7.2 Determine list of available supplier of spare parts

7.3 Determine spare parts suitable for product range (model, variant,

year of make, etc.)

Modul 03- Kertas Kerja Cawangan Pembangunan Kurikulum 2015 ( Versi 1)

Kod Kertas TP-300-4/M3/02 Muka Surat: 6 drpd 8

8. Prepare spare parts 8.1 Interpret spare parts inventory records

procurement

documentation 8.2 Determine price of spare parts

8.3 Determine quantity of spare parts required

8.4 Determine delivery schedule of spare parts (i.e. daily, weekly,

monthly, etc)

8.5 Determine mode of delivery

8.6 Employ method of preparing procurement documentation

8.7 Follow procedure of preparing procurement documentation

8.8 Utilise Management Information System (MIS)

8.9 Determine responsible personnel / party involved

8.10 Comply to company’s Standard Operating Procedure (SOP)

9. Submit spare parts 9.1 Determine categories of forms to be submitted for approval

order form for approval

9.2 Follow Parts Order Form approval process

9.3 Utilise Management Information System (MIS)

9.4 Determine responsible personnel / parties involved

9.5 Comply to company’s Standard Operating Procedure (SOP)

Attitude/Safety:

- Meticulous to identify spare parts required

- Diligent in identifying spare parts specification

- Resourceful in preparing procurement documentation

- Accountable in submitting documentation for approval

Modul 03- Kertas Kerja Cawangan Pembangunan Kurikulum 2015 ( Versi 1)

Kod Kertas TP-300-4/M3/02 Muka Surat: 7 drpd 8

10. Identify type of tools 10.1 Source of allocation approval budget

and equipment

10.2 Determine categories of tools and equipment

required

10.3 Determine manufacture specification (brand name, warranty

period, etc.)

10.4 Determine company inventory system(quantity level, etc)

10.5 Interpret catalytic of tool and equipment

11. Obtain tools and 11.1 Determine specification of equipment

equipment

11.2 Determine list of available supplier of tools and equipment

specification

12. Prepare tools and 12.1 Interpret tools and equipment inventory records

equipment

12.2 Determine price of tools and equipment

procurement

documentation 12.3 Determine quantity of tools and equipment required

12.4 Determine delivery schedule of tools and equipment

12.5 Determine mode of transportation of tools and equipment

12.6 Follow procurement process for tools and equipment

12.7 Follow procedure of preparing procurement documentation

12.8 Follow method of preparing procurement documentation

12.9 Determine responsible personnel / party involved

12.10 Comply to Company`s Standard Operating Procedure (SOP)

13. Submit tools and 13.1 Determine categories of forms to be submitted for approval

equipment order form

13.2 Follow Tools Capital Asset Order Form approval process

for approval

13.3 Determine responsible personnel / party involved

13.4 Comply to company`s Standard Operating Procedure (SOP)

Modul 03- Kertas Kerja Cawangan Pembangunan Kurikulum 2015 ( Versi 1)

Kod Kertas TP-300-4/M3/02 Muka Surat: 8 drpd 8

CHECK LIST

No Competency Level Accepted Not Note

Accepted

A. WORK OUTPUT

1 Survey had been done.

B. WORK PROCESS

1 Determine competitive information

2 Checklist

3 Analyse data

C. TIME

1 Within given time

D. ATTITUDE

1 Discipline

2 Commitment

3 Responsibility

E. SAFETY

1 Personal

2 Tools

3 Environment

(Trainee’s name & signature) (PP’s name & signature)

Date Date

Modul 03- Kertas Kerja Cawangan Pembangunan Kurikulum 2015 ( Versi 1)

S-ar putea să vă placă și

- Institut Kemahiran Tinggi Belia Negara: Kementerian Belia Dan SukanDocument10 paginiInstitut Kemahiran Tinggi Belia Negara: Kementerian Belia Dan SukanAswaja313Încă nu există evaluări

- Institut Kemahiran Tinggi Belia Negara Kertas Kerja: Kementerian Belia Dan Sukan MalaysiaDocument4 paginiInstitut Kemahiran Tinggi Belia Negara Kertas Kerja: Kementerian Belia Dan Sukan MalaysiaAswaja313Încă nu există evaluări

- BJ2 S4hana2022 BPD en deDocument76 paginiBJ2 S4hana2022 BPD en deBessemÎncă nu există evaluări

- Sap PM Course ContentDocument4 paginiSap PM Course ContentNaveen KumarÎncă nu există evaluări

- Standard Operating ProcedureDocument5 paginiStandard Operating ProceduredugdugdugdugiÎncă nu există evaluări

- Department: CNC SHOP Auditee: AuditorDocument33 paginiDepartment: CNC SHOP Auditee: AuditormuthuselvanÎncă nu există evaluări

- Documents Specified by ISO - TS 29001 But Not by ISO 9001Document1 paginăDocuments Specified by ISO - TS 29001 But Not by ISO 9001Natgas Farmer0% (1)

- 4.3 - Maintenance Processing V2.0Document14 pagini4.3 - Maintenance Processing V2.0ఈశ్వర్ భరణి100% (1)

- Perbandingan Kursus MPI8033Document3 paginiPerbandingan Kursus MPI8033farizanÎncă nu există evaluări

- Material Handling Technical-SpecificationDocument60 paginiMaterial Handling Technical-Specificationbk kumarÎncă nu există evaluări

- Session 02 - Maintenance Document (I)Document29 paginiSession 02 - Maintenance Document (I)PartheepanPartheeÎncă nu există evaluări

- A9R1wavcwr 1oltzi5 7h0.tmp PDFDocument1 paginăA9R1wavcwr 1oltzi5 7h0.tmp PDFSuresh KumarÎncă nu există evaluări

- Standard Operating Procedure: Title: Materials Control - Work in Process (WIP) ApprovalsDocument2 paginiStandard Operating Procedure: Title: Materials Control - Work in Process (WIP) ApprovalsRAHUL YADAV100% (1)

- 2 - Example System Retirement Plan TemplateDocument5 pagini2 - Example System Retirement Plan TemplateAriane Café da cunhaÎncă nu există evaluări

- AV ME SOP 01 Plant Equipment MaintenanceDocument5 paginiAV ME SOP 01 Plant Equipment MaintenancejfejfeÎncă nu există evaluări

- PIP-Guidelines For Spare Parts ManagementDocument16 paginiPIP-Guidelines For Spare Parts ManagementrizaÎncă nu există evaluări

- SOP 0102 Standard Operating Procedures 1Document6 paginiSOP 0102 Standard Operating Procedures 12211091007Încă nu există evaluări

- SOP 0102 Standard Operating Procedures 1Document6 paginiSOP 0102 Standard Operating Procedures 1Agil MahendraÎncă nu există evaluări

- Stages Steps in Production Planning and ControlDocument5 paginiStages Steps in Production Planning and ControlJonathan SanchezÎncă nu există evaluări

- List of Business Processes To Be Implemented: 1.1 Master DataDocument41 paginiList of Business Processes To Be Implemented: 1.1 Master DataSowjanya KÎncă nu există evaluări

- 8509-Production & Operations ManagementDocument6 pagini8509-Production & Operations ManagementHassan Malik100% (1)

- Operation Scheduling, Control, PlanningDocument3 paginiOperation Scheduling, Control, PlanningAnkit BhadesiaÎncă nu există evaluări

- K5-Nota Kuliah OSHADocument9 paginiK5-Nota Kuliah OSHAMuhamad Ismail Mohd JamilÎncă nu există evaluări

- Using Aspect-Oriented Programming for Trustworthy Software DevelopmentDe la EverandUsing Aspect-Oriented Programming for Trustworthy Software DevelopmentEvaluare: 3 din 5 stele3/5 (1)

- Operations Management 2Document18 paginiOperations Management 2aniloveish0901Încă nu există evaluări

- MECE5109 Maintenance Management Lectures - PlanningDocument6 paginiMECE5109 Maintenance Management Lectures - PlanningCedricÎncă nu există evaluări

- JJ616 Maintenance Management Survey FormDocument5 paginiJJ616 Maintenance Management Survey FormAkiff JayariÎncă nu există evaluări

- FS - MM-RP-077 - Physical Verification Report - V0.2Document8 paginiFS - MM-RP-077 - Physical Verification Report - V0.2SUBHOJIT BANERJEEÎncă nu există evaluări

- CANTIER MES, FPS & QMS DetailsDocument8 paginiCANTIER MES, FPS & QMS DetailsMariver LlorenteÎncă nu există evaluări

- First Steps in Routing MaintenanceDocument14 paginiFirst Steps in Routing MaintenanceBirukÎncă nu există evaluări

- Real-Time Systems: Scheduling, Analysis, and VerificationDe la EverandReal-Time Systems: Scheduling, Analysis, and VerificationÎncă nu există evaluări

- 0705 Die ApprovelDocument4 pagini0705 Die ApprovelSundara Rajan RamakrishnanÎncă nu există evaluări

- Ie8693 - Part B Important-1Document2 paginiIe8693 - Part B Important-1Laden SurfarazÎncă nu există evaluări

- 8509Document7 pagini8509Danyal ChaudharyÎncă nu există evaluări

- P05 - ProductionDocument14 paginiP05 - ProductionEDWARD ACHEAMPONGÎncă nu există evaluări

- MRP Bus 822Document6 paginiMRP Bus 822glonyxÎncă nu există evaluări

- Syllabus Special Topics in INFORMATION SYSTEMDocument5 paginiSyllabus Special Topics in INFORMATION SYSTEMGALANAGA Desiree M.Încă nu există evaluări

- Stocking Strategy For Service Parts A Case StudyDocument19 paginiStocking Strategy For Service Parts A Case StudyFernando GómezÎncă nu există evaluări

- DTC 03 of 2022 TPMDocument12 paginiDTC 03 of 2022 TPMANURAG GUDHENIAÎncă nu există evaluări

- Bio Analytical SopDocument17 paginiBio Analytical SopalexpharmÎncă nu există evaluări

- Spare Parts ManagementDocument20 paginiSpare Parts ManagementNUWAHEREZA GODWINÎncă nu există evaluări

- MPS AND MRP FinalDocument25 paginiMPS AND MRP FinalMahakÎncă nu există evaluări

- Performance Metrics for Mobile Mining Equipment Version 1.1.PDFDocument64 paginiPerformance Metrics for Mobile Mining Equipment Version 1.1.PDF1181003Încă nu există evaluări

- 6 VOL+II+ +5.5.1 EquipLogWI v1.3 UpdatedDocument6 pagini6 VOL+II+ +5.5.1 EquipLogWI v1.3 UpdatedPowellAbogadoÎncă nu există evaluări

- FS - MM-RP-095 - Returnable Packaging Stock With Aging Report (Cylinders) - v0.1Document7 paginiFS - MM-RP-095 - Returnable Packaging Stock With Aging Report (Cylinders) - v0.1SUBHOJIT BANERJEEÎncă nu există evaluări

- Appendix 25 VDA 6 3 Process AuditDocument14 paginiAppendix 25 VDA 6 3 Process AuditRahul BenkeÎncă nu există evaluări

- SAEP-31 Corporate Equipment DataDocument5 paginiSAEP-31 Corporate Equipment DataHabib ShinwariÎncă nu există evaluări

- Vendor Survey Questionnaire (Self-Assessment)Document6 paginiVendor Survey Questionnaire (Self-Assessment)John MascarenhasÎncă nu există evaluări

- SAP Implementation: Need The Following BenefitsDocument3 paginiSAP Implementation: Need The Following BenefitsNaveen Reddy KasarlaÎncă nu există evaluări

- Assessment Mapping MatrixDocument3 paginiAssessment Mapping MatrixAnuu BhattiÎncă nu există evaluări

- Traceability Audit ChecklistDocument12 paginiTraceability Audit ChecklistFirmino Simplicio0% (1)

- Production Engineering BFF3503: Assembly Line SetupDocument10 paginiProduction Engineering BFF3503: Assembly Line SetupMuhd ZackuanÎncă nu există evaluări

- Appendix 25 VDA 6 3 Process AuditDocument12 paginiAppendix 25 VDA 6 3 Process AuditSeda De Drasnia100% (1)

- MEICM-TTLM MaintenanceDocument43 paginiMEICM-TTLM MaintenanceAnonymous 0IToZUwXÎncă nu există evaluări

- Tooling Management SummaryDocument10 paginiTooling Management SummaryabraÎncă nu există evaluări

- 21 CFR 820 Audit ChecklistDocument7 pagini21 CFR 820 Audit ChecklistFrankMartinez100% (1)

- RCM RCM-CL Classic SyllabusDocument4 paginiRCM RCM-CL Classic SyllabusRCM2 rizkyÎncă nu există evaluări

- Materials ManagementDocument35 paginiMaterials ManagementarÎncă nu există evaluări

- FMS Assignment 1Document4 paginiFMS Assignment 1tutorfelix777Încă nu există evaluări

- Productivity and Reliability-Based Maintenance Management, Second EditionDe la EverandProductivity and Reliability-Based Maintenance Management, Second EditionÎncă nu există evaluări

- Chapter 7 PDFDocument28 paginiChapter 7 PDFAswaja313Încă nu există evaluări

- Chapter 6 - 1Document14 paginiChapter 6 - 1Aswaja313Încă nu există evaluări

- Chapter 6 - 2 PDFDocument12 paginiChapter 6 - 2 PDFAswaja313Încă nu există evaluări

- Root Cause Analysis? StepsDocument8 paginiRoot Cause Analysis? StepsAswaja313Încă nu există evaluări

- Chapter 3 PDFDocument30 paginiChapter 3 PDFAswaja313Încă nu există evaluări

- Chapter 4 - 1 PDFDocument29 paginiChapter 4 - 1 PDFAswaja313Încă nu există evaluări

- Chap 1 Tech MathDocument17 paginiChap 1 Tech MathNoorfadzlina HassanÎncă nu există evaluări

- Chapter 2 - 3 PDFDocument27 paginiChapter 2 - 3 PDFAswaja313Încă nu există evaluări

- Chapter 2 - 1 PDFDocument24 paginiChapter 2 - 1 PDFNoorfadzlina HassanÎncă nu există evaluări

- Chapter 5 - 2Document35 paginiChapter 5 - 2Aswaja313Încă nu există evaluări

- Chapter 4 - 2 PDFDocument18 paginiChapter 4 - 2 PDFAswaja313Încă nu există evaluări

- Chapter 5 - 1 PDFDocument19 paginiChapter 5 - 1 PDFAswaja313Încă nu există evaluări

- UMP Faculty of Engineering Quality Control FundamentalsDocument58 paginiUMP Faculty of Engineering Quality Control FundamentalsAswaja313Încă nu există evaluări

- Stress and Strain LoadingDocument46 paginiStress and Strain LoadingAswaja313Încă nu există evaluări

- Calculator Visual BasicDocument86 paginiCalculator Visual BasicAswaja313Încă nu există evaluări

- Summary 1.0Document3 paginiSummary 1.0Aswaja313Încă nu există evaluări

- BTM2133-Chapter 5 Application of Gauge BlockDocument26 paginiBTM2133-Chapter 5 Application of Gauge BlockAswaja313Încă nu există evaluări

- 1.0 - Basic of Stress Analysis PDFDocument21 pagini1.0 - Basic of Stress Analysis PDFAswaja313Încă nu există evaluări

- Btv2213 Thermodynamics s1 0218Document9 paginiBtv2213 Thermodynamics s1 0218Aswaja313Încă nu există evaluări

- SummaryDocument7 paginiSummaryAswaja313Încă nu există evaluări

- BTM2133-Chapter 4 Measuring InstrumentsDocument61 paginiBTM2133-Chapter 4 Measuring InstrumentsAswaja3130% (1)

- BTM2133-Chapter 6 Reference PlaneDocument9 paginiBTM2133-Chapter 6 Reference PlaneAswaja313Încă nu există evaluări

- CH7 Depreciation and Income TaxesDocument57 paginiCH7 Depreciation and Income TaxesAswaja313Încă nu există evaluări

- Chapter 1 Metrology Basics: Understand Basics of Metrology, Standards and Calculate Least Count of Measuring InstrumentsDocument34 paginiChapter 1 Metrology Basics: Understand Basics of Metrology, Standards and Calculate Least Count of Measuring InstrumentsAswaja313Încă nu există evaluări

- Lecture-3 Tolerances and SurfacesDocument56 paginiLecture-3 Tolerances and SurfacesAswaja313Încă nu există evaluări

- BTM2133-Chapter 8 Surface MeasurementDocument46 paginiBTM2133-Chapter 8 Surface MeasurementAswaja313Încă nu există evaluări

- CMM Chapter 9: Measuring Parts with Coordinate Measuring MachinesDocument35 paginiCMM Chapter 9: Measuring Parts with Coordinate Measuring MachinesAswaja313Încă nu există evaluări

- Unit 3 MetrologyDocument38 paginiUnit 3 MetrologyMuthuvel M92% (36)

- Wood GroupDocument22 paginiWood GroupMuhammad Haris BaigÎncă nu există evaluări

- Norsok O-CR-001r1 Life Cycle Cost For Systems & EquipmentDocument38 paginiNorsok O-CR-001r1 Life Cycle Cost For Systems & EquipmentspottedkelpieÎncă nu există evaluări

- Bretec M7 Parts Manual 5B15DDocument16 paginiBretec M7 Parts Manual 5B15DBenoitÎncă nu există evaluări

- CBH PräsentationDocument15 paginiCBH PräsentationDirector GeneraciónÎncă nu există evaluări

- Photometer 5010 V5+ Service ManualDocument133 paginiPhotometer 5010 V5+ Service ManualБогдан Ступка100% (1)

- Spare Parts ProvisioningDocument47 paginiSpare Parts Provisioningapi-3732848100% (3)

- Aircraft Spare PartsDocument24 paginiAircraft Spare PartsLocatoryÎncă nu există evaluări

- Intermediate Accounting - Property Plant and EquipmentDocument55 paginiIntermediate Accounting - Property Plant and Equipment박은하Încă nu există evaluări

- AMR Research REPORT 20939-Service Parts Planning and OptimizationDocument28 paginiAMR Research REPORT 20939-Service Parts Planning and OptimizationSameer MohanÎncă nu există evaluări

- Usm 464Document32 paginiUsm 464schaefer1015719Încă nu există evaluări

- Lincoln Centralized Lubrication SystemDocument66 paginiLincoln Centralized Lubrication SystemMiguel Angel Santos PintadoÎncă nu există evaluări

- Recommendations For The Inspection of Steam TurbinesDocument20 paginiRecommendations For The Inspection of Steam Turbinesjmsponte100% (2)

- Fiat Hitachi Fb90 2 Fb100 2 Fb110 2 Fb200 2 Service ManualDocument1.057 paginiFiat Hitachi Fb90 2 Fb100 2 Fb110 2 Fb200 2 Service Manualnicolae788716988% (68)

- Denaneso GemechuDocument86 paginiDenaneso GemechumedrekÎncă nu există evaluări

- Maintenance SimulationDocument43 paginiMaintenance SimulationSundaramali Govindaswamy GÎncă nu există evaluări

- Supply of GoodsDocument44 paginiSupply of GoodskhalisahsmslÎncă nu există evaluări

- Volvo CE Special Tool Catalog 02092023Document647 paginiVolvo CE Special Tool Catalog 02092023Bradley D Kinser0% (1)

- Maintenance Manual DIWA.6: Voith TurboDocument24 paginiMaintenance Manual DIWA.6: Voith TurboYaşar BaşerÎncă nu există evaluări

- Why EagleBurgmann 29.03.2011Document15 paginiWhy EagleBurgmann 29.03.2011ybozbasÎncă nu există evaluări

- MM 1Document72 paginiMM 1Amit KumarÎncă nu există evaluări

- VBR Strategic Spare Parts Planning-2Document18 paginiVBR Strategic Spare Parts Planning-2jampukÎncă nu există evaluări

- TM MasterDocument39 paginiTM MasterKomang DeliÎncă nu există evaluări

- Rammer 1655 Parts Manual 2015Document36 paginiRammer 1655 Parts Manual 2015SerkanAl100% (3)

- Government Accounting: Accounting For Non-Profit OrganizationsDocument42 paginiGovernment Accounting: Accounting For Non-Profit OrganizationsYuvia KeithleyreÎncă nu există evaluări

- Maintenance Engineering As A Basic Tool For Maximum ProductionDocument6 paginiMaintenance Engineering As A Basic Tool For Maximum ProductionEnrique Sáenz VeràsteguiÎncă nu există evaluări

- Your Life Cycle Partner: in Air CompressorsDocument19 paginiYour Life Cycle Partner: in Air CompressorsИван ПарлапановÎncă nu există evaluări

- Equipment Task List in SAP PMDocument14 paginiEquipment Task List in SAP PMkumar100% (1)

- Improve Your Business - Buying and Stock Control PDFDocument114 paginiImprove Your Business - Buying and Stock Control PDFRc M. Santiago IIÎncă nu există evaluări

- Effective Spare Part ManagementDocument23 paginiEffective Spare Part ManagementMuhd TasyrifÎncă nu există evaluări

- EcopipeDocument25 paginiEcopipeHailu MiÎncă nu există evaluări