Documente Academic

Documente Profesional

Documente Cultură

Grout Checking List

Încărcat de

Jennifer DamascoDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Grout Checking List

Încărcat de

Jennifer DamascoDrepturi de autor:

Formate disponibile

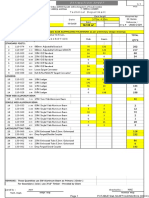

Check List for Grouting Work

8.2014

When to

NO. Item Testing /Inspection Method Criteria Trouble Shooting

inspect

Check the Lot Number printed on the bag

to confirm the bag life, which should be Make sure that SS Mortar does not expire the Discard the expired material and use only the

1 SS Mortar inspection Before grouting

within one year from the date bag life of one year material within one year bag life

manufactured

Make sure that there is no damage on the

2 SS Mortar inspection Visual inspection on SS Mortar Before grouting Discard the damaged material

bag

Measure the temperature with a Apply proper curing if it goes below or above

3 Ambient temperature Before grouting Between 35 ~140℉ (2~60℃)

thermometer the appropriate temperature

Location & number of sleeves Check the location, number, & types of Note location and quantity of sleeves to be

4 Before grouting Report to the supervisor for instruction

to be grouted sleeves to be grouted grouted and get materials ready at site

Check by blowing out with air (using air

compressor or by mouth and flexible Make sure that there is a clear passage from

5 Sleeve passage Inspection Before grouting Report to the supervisor for instruction

tube) or flush out sleeves with high- the inlet to outlet ports

pressure water from top port.

To avoid the blockage of grout, pump slowly

Use water to saturate grout pump and Fill the hopper with water before mixing grout

Saturating grout pump and until the grout comes out from the tip of the

6 hose for smooth flow (If a long hose is Before grouting and flush out through the hose right before

hose hose. If tip becomes blocked insert stiff wire to

being used, apply mortar slurry instead) pouring mixed grout into the hopper.

clear blockage

At the time of 1 gallon per 55 lbs. bag (Min. 0.98 ~Max. Measure the water within the specified

7 Mixing water Confirm with User's Manual

each grouting 1.03 gallon/55 lbs. bag) amount as described in the User's Manual

Discard the mixing mortar that is not within the

At the time of Measure the temperature of mixed grout that

8 Mixing temperature Confirm with User's Manual range and make the necessary adjustment

each grouting should be within 50~95℉ (10~35℃)

(such as using cold or hot water)

Minimum 2.5 minutes at 500-1300 rpm with 7

At the time of

9 Mixing time Confirm with User's Manual amp or larger electric mixer with proper Check with flow test

each grouting

paddle

During the Discard the mixed mortar 40 minutes after

10 Grout working time (Pot Life) Confirm with User's Manual Within 40 minutes

grouting mixing. Do NOT add water to increase time

Follow the instruction on the "SS Mortar Grout

Immediately

Confirm with User's Manual (Use Flow The consistency measurement should fall in Consistency/Flow Test Chart." Discard the

11 Consistency test (Flow test) after mixing the

Table with cylinder) the range of 6" to 9-1/4". mixed mortar that was beyond 9-1/4" in

first batch

diameter

Immediately Assemble test specimens for compressive

Confirm with User's Manual (Use 2" x 2"

12 Compressive strength test after mixing the strength of grout to determine performance of Report to the supervisor for instruction

steel or brass cube mold)

first batch NMB Splice-Sleeve.

Make sure that all sleeves were totally

Determine the cause of trouble and make the

At the time of grouted inside and keep pumping until the

13 Full grouting Confirm with User's Manual necessary correction before re-grouting. Re-

each grouting grout is observed coming from the outlet hole

grout within the grout working time

in a solid flow.

Reconfirm that all sleeves and joint areas are

Before-during- Grout all sleeves that are scheduled for

14 Record keeping Confirm with User's Manual completely grouted by using grouting report

after grouting grouting on that day

as a checklist

S-ar putea să vă placă și

- JSA For Crawler Crane Installation FormDocument3 paginiJSA For Crawler Crane Installation FormDaniel Prakoso0% (1)

- Indra: Method Statement For Load Test of Trolley Beams, A-Frame and Jib Crane (Davit Type) (JGC Direct Work)Document57 paginiIndra: Method Statement For Load Test of Trolley Beams, A-Frame and Jib Crane (Davit Type) (JGC Direct Work)med chabaneÎncă nu există evaluări

- Compactor Daily Inspection ChecklistDocument1 paginăCompactor Daily Inspection ChecklistThandabantu Magengelele33% (3)

- Crane Monthly Inspection Check ListDocument1 paginăCrane Monthly Inspection Check ListJoy BDÎncă nu există evaluări

- Repair Grouting ChecklistDocument1 paginăRepair Grouting ChecklistSushil GuptaÎncă nu există evaluări

- Hydraulic Jack Inspection ChecklistDocument1 paginăHydraulic Jack Inspection ChecklistHario Pramudito100% (1)

- DSM-xxx-0xxx-xx, Checklist For HDPE Piping InstallationDocument1 paginăDSM-xxx-0xxx-xx, Checklist For HDPE Piping Installationkadir tanzania100% (4)

- Checklist For Equipment Inspection Winch Machine .Docx - Documentos de GoogleDocument1 paginăChecklist For Equipment Inspection Winch Machine .Docx - Documentos de GoogleMarisabel Maidana100% (2)

- Method Statement For Assembly of 200 Ton Crawler CraneDocument7 paginiMethod Statement For Assembly of 200 Ton Crawler CraneAnjo MolinaÎncă nu există evaluări

- Grating Handrails Ladders Stairways Quality Control and Inspection Report FormDocument1 paginăGrating Handrails Ladders Stairways Quality Control and Inspection Report Formhasan_676489616Încă nu există evaluări

- Check List For Connection BoltsDocument1 paginăCheck List For Connection BoltstreyÎncă nu există evaluări

- FC 4.1.5 - Flexible Steel Wire Rope Sling (FSWR) Inspection Checklist FormDocument2 paginiFC 4.1.5 - Flexible Steel Wire Rope Sling (FSWR) Inspection Checklist FormJosef Demner Tiu Paspe100% (1)

- Horizontal Life Line Inspection FormDocument1 paginăHorizontal Life Line Inspection FormSelva GanapathiÎncă nu există evaluări

- CraneDocument2 paginiCraneIfkar Apriadi100% (2)

- Tower Light Inspection ChecklistDocument19 paginiTower Light Inspection ChecklistMOHAMMED RIYAN TÎncă nu există evaluări

- 123Document7 pagini123Jennifer Damasco100% (2)

- Arthur Eddington's Two Tables ParadoxDocument2 paginiArthur Eddington's Two Tables ParadoxTimothy ChambersÎncă nu există evaluări

- Schwarzer Schmarsow - The Emergence of Architectural Space August Schmarsows Theory of RaumgestaltungDocument15 paginiSchwarzer Schmarsow - The Emergence of Architectural Space August Schmarsows Theory of RaumgestaltungDimitra BilliaÎncă nu există evaluări

- Steel Wire Rope Sling Safety ChecklistDocument1 paginăSteel Wire Rope Sling Safety ChecklistImad ChaudharyÎncă nu există evaluări

- Checklist For Equipment Inspection BOOM PLACERDocument2 paginiChecklist For Equipment Inspection BOOM PLACERIdada Ezekiel100% (1)

- GD380A-L ListDocument6 paginiGD380A-L ListNam Won HongÎncă nu există evaluări

- Wire Rope Checklist FormDocument1 paginăWire Rope Checklist FormРашад ИбрагимовÎncă nu există evaluări

- Crawler Crane Checklist Rev 0Document2 paginiCrawler Crane Checklist Rev 0Maizatul Akmar Manshor100% (2)

- 006 Mobile Crane Pre-Use Checklist - NO NEED FOR UPDATEDocument1 pagină006 Mobile Crane Pre-Use Checklist - NO NEED FOR UPDATELijo JohnÎncă nu există evaluări

- Check List (Pre Entry) For Cutting Machine: Tpipl/Fabs/Pem/Hse-001Document1 paginăCheck List (Pre Entry) For Cutting Machine: Tpipl/Fabs/Pem/Hse-001Mithlesh Singh100% (2)

- Telehandler Forklift Pre-Use Inspection ChecklistDocument1 paginăTelehandler Forklift Pre-Use Inspection ChecklistMalika Baboo100% (1)

- Vibro Hammer ChecklistDocument2 paginiVibro Hammer ChecklistAbdus Samad100% (1)

- Petroleum Development Oman: Lift Plan For Lifting OperationDocument7 paginiPetroleum Development Oman: Lift Plan For Lifting OperationVuthpalachaitanya KrishnaÎncă nu există evaluări

- 4 Plant & Equipment Checklist - Docx-1Document2 pagini4 Plant & Equipment Checklist - Docx-1REHAN IQBALÎncă nu există evaluări

- 06 Portable Grinding MachineDocument1 pagină06 Portable Grinding MachineGyanendra Narayan NayakÎncă nu există evaluări

- TBT FormatDocument1 paginăTBT FormatSurya Narayan Mahapatra100% (1)

- Wire Rope Sling - Rejection CriteriaDocument1 paginăWire Rope Sling - Rejection CriteriaKhairulz Anuar100% (1)

- Loading-Unloading-Low-Loader Risk AssmntDocument10 paginiLoading-Unloading-Low-Loader Risk AssmntStansilous Tatenda NyagomoÎncă nu există evaluări

- Transit Mixer Safety Inspection Checklist: SR. No Item OK Not OK NA RemarksDocument1 paginăTransit Mixer Safety Inspection Checklist: SR. No Item OK Not OK NA RemarksRísês ÃfrözÎncă nu există evaluări

- Risk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelDocument3 paginiRisk Assessment Maintenance: L - Likelihood S - Severity RL - Risk LevelMohamed ElnagdyÎncă nu există evaluări

- 10 Risk Assessment - Pot BearingDocument1 pagină10 Risk Assessment - Pot BearingEticala RohithÎncă nu există evaluări

- Jha Batching Plant PlatformDocument5 paginiJha Batching Plant PlatformsoubhagyaÎncă nu există evaluări

- Inspection Checklist of Drill Machine: Project Name: Date: Time: Checked byDocument1 paginăInspection Checklist of Drill Machine: Project Name: Date: Time: Checked byRaza Muhammad Soomro0% (1)

- Crane InspectionDocument2 paginiCrane InspectionAdhy DarmawanÎncă nu există evaluări

- Tower Crane Inspection ChecklistDocument4 paginiTower Crane Inspection Checklistmailme_viju100% (1)

- HIRA For Steam Drum ErectionDocument18 paginiHIRA For Steam Drum ErectionNagendra Kumar SinghÎncă nu există evaluări

- Handrail ChecklistDocument2 paginiHandrail ChecklistKharisma JayatraÎncă nu există evaluări

- Boom Placer Safety Inspection ChecklistDocument1 paginăBoom Placer Safety Inspection ChecklistMyo LwinÎncă nu există evaluări

- Crane Carry - in InspectionDocument3 paginiCrane Carry - in InspectionAdhy Darmawan100% (1)

- Mobile Crane Monthly ChecklistDocument3 paginiMobile Crane Monthly ChecklistDAOUMY YOUNESSÎncă nu există evaluări

- Checklist For Equipment Inspection CONCRETE PUMPDocument1 paginăChecklist For Equipment Inspection CONCRETE PUMPbagas prakosoÎncă nu există evaluări

- Mobile CranesDocument5 paginiMobile CranesSAYED100% (1)

- Unlocked - F031 - Tower Crane Inspection Report - Rev 0Document2 paginiUnlocked - F031 - Tower Crane Inspection Report - Rev 0Minami ChiengÎncă nu există evaluări

- Concrete Pump TPIDocument1 paginăConcrete Pump TPIWakil AhmadÎncă nu există evaluări

- Check List (Pre Entry) For Portable Grinding Machine: Doc No:Tippl/Mitl/Hse/13Document1 paginăCheck List (Pre Entry) For Portable Grinding Machine: Doc No:Tippl/Mitl/Hse/13MuhRachmat100% (1)

- POTABLE Slab SCAFFOLDING BOQ (CRCC)Document1 paginăPOTABLE Slab SCAFFOLDING BOQ (CRCC)Mohamed AdelÎncă nu există evaluări

- RMC Plant Check ListDocument8 paginiRMC Plant Check ListAbhaÎncă nu există evaluări

- 10 - Cherry Picker Inspection ChecklistDocument1 pagină10 - Cherry Picker Inspection Checklistsanjeev kumarÎncă nu există evaluări

- Check ListDocument88 paginiCheck ListRaafat SaadÎncă nu există evaluări

- Crane Inspection Checklist: General InformationDocument7 paginiCrane Inspection Checklist: General InformationArunachu ArunachuÎncă nu există evaluări

- Dewatering Pump Checklist: Description Status RemarksDocument1 paginăDewatering Pump Checklist: Description Status RemarksMansoor BabarÎncă nu există evaluări

- Crane ChecklistDocument3 paginiCrane ChecklistAbdul Rehman SheikhÎncă nu există evaluări

- 03 - Hydra Crane ChecklistDocument1 pagină03 - Hydra Crane ChecklistAfzal Akhtar100% (5)

- 27g Night Work PermitDocument1 pagină27g Night Work PermitMohammed Minhaj100% (1)

- DCP002F01 - Blower Daily Check SheetDocument2 paginiDCP002F01 - Blower Daily Check SheetSTEVEN DELAHUNTY0% (1)

- AATCC 42 2000 (2007) Water Resistance Impact Penetration TestDocument2 paginiAATCC 42 2000 (2007) Water Resistance Impact Penetration TestHà Trần MạnhÎncă nu există evaluări

- WT 16 WSBDocument55 paginiWT 16 WSBJuan ChávezÎncă nu există evaluări

- Tex-437-A, Test For Flow of Grout Mixtures (Flow Cone Method)Document8 paginiTex-437-A, Test For Flow of Grout Mixtures (Flow Cone Method)Abdi Septia PutraÎncă nu există evaluări

- PDF 20220215 144454 0000Document7 paginiPDF 20220215 144454 0000Jennifer DamascoÎncă nu există evaluări

- Growth Status Leaders Name of Vips Submitted Not Yet Submitted WorshipDocument4 paginiGrowth Status Leaders Name of Vips Submitted Not Yet Submitted WorshipJennifer DamascoÎncă nu există evaluări

- Faith Over Fear - MANUSCRIPTDocument3 paginiFaith Over Fear - MANUSCRIPTJennifer DamascoÎncă nu există evaluări

- Greater-Things UpdatedDocument8 paginiGreater-Things UpdatedJennifer DamascoÎncă nu există evaluări

- Cpe For Technical Result Central Office August 2022Document6 paginiCpe For Technical Result Central Office August 2022Jennifer DamascoÎncă nu există evaluări

- New Year New BeginningDocument10 paginiNew Year New BeginningJennifer DamascoÎncă nu există evaluări

- Foundation: "The Strength of The Building Is Highly Depends On The Strength of Its Foundation"Document9 paginiFoundation: "The Strength of The Building Is Highly Depends On The Strength of Its Foundation"Jennifer DamascoÎncă nu există evaluări

- CacaDocument1 paginăCacaAgu ArataÎncă nu există evaluări

- Ultracolor PlusDocument6 paginiUltracolor PluskikoÎncă nu există evaluări

- The Blessings of God's WordDocument7 paginiThe Blessings of God's WordJennifer DamascoÎncă nu există evaluări

- Philippine Embassy Launches PH Food Festival in QatarDocument2 paginiPhilippine Embassy Launches PH Food Festival in QatarJennifer DamascoÎncă nu există evaluări

- BDG StudyguideDocument90 paginiBDG Studyguidejulia_myneedsÎncă nu există evaluări

- Being HappyDocument6 paginiBeing HappyAnone Soree50% (2)

- Instructions For Installation and Use: Warning! Cib 644 C E Cib 64 C. S CIB644.1 CE Cib 644 B EDocument12 paginiInstructions For Installation and Use: Warning! Cib 644 C E Cib 64 C. S CIB644.1 CE Cib 644 B EJennifer DamascoÎncă nu există evaluări

- The Problem of Pain: Reading and Discussion Guide ForDocument5 paginiThe Problem of Pain: Reading and Discussion Guide ForJennifer DamascoÎncă nu există evaluări

- MoF Qatar - Excise Tax Awareness Workshop v0Document18 paginiMoF Qatar - Excise Tax Awareness Workshop v0Jennifer DamascoÎncă nu există evaluări

- 2014 Catalog Lighting Control PanelsDocument27 pagini2014 Catalog Lighting Control PanelsJennifer DamascoÎncă nu există evaluări

- The Problem of Pain: Reading and Discussion Guide ForDocument5 paginiThe Problem of Pain: Reading and Discussion Guide ForJennifer DamascoÎncă nu există evaluări

- The Problem of Pain: Reading and Discussion Guide ForDocument5 paginiThe Problem of Pain: Reading and Discussion Guide ForJennifer DamascoÎncă nu există evaluări

- LDR - Being Happy PDFDocument22 paginiLDR - Being Happy PDFmuraliÎncă nu există evaluări

- Vodafone Qatar - Vodafone Online Bill Payment - Process - Vodafone - Qa PDFDocument1 paginăVodafone Qatar - Vodafone Online Bill Payment - Process - Vodafone - Qa PDFJennifer DamascoÎncă nu există evaluări

- The Problem of Pain: Reading and Discussion Guide ForDocument5 paginiThe Problem of Pain: Reading and Discussion Guide ForJennifer DamascoÎncă nu există evaluări

- Panoderamufine Rebecca ST James Wait For Me ZanoposufDocument4 paginiPanoderamufine Rebecca ST James Wait For Me ZanoposufJennifer DamascoÎncă nu există evaluări

- Force Majeure Claims in FIDIC PDFDocument16 paginiForce Majeure Claims in FIDIC PDFkevin jordanÎncă nu există evaluări

- The FIDIC Suite of ContractsDocument9 paginiThe FIDIC Suite of ContractsRaluca CazanescuÎncă nu există evaluări

- DC Exam 1aDocument7 paginiDC Exam 1aJennifer DamascoÎncă nu există evaluări

- DC Exam 1aDocument7 paginiDC Exam 1aJennifer DamascoÎncă nu există evaluări

- DC Exam 1aDocument7 paginiDC Exam 1aJennifer DamascoÎncă nu există evaluări

- Sample Reviewer GEODocument10 paginiSample Reviewer GEOlance adrian del rosarioÎncă nu există evaluări

- CHAPTER 31 Faraday S LawDocument27 paginiCHAPTER 31 Faraday S LawSattishZeeÎncă nu există evaluări

- Catalog Produk Arduino Rajacell Ver10.4 - End - UserDocument192 paginiCatalog Produk Arduino Rajacell Ver10.4 - End - UserSanto SetiawanÎncă nu există evaluări

- O Level Physics 2023-2025 ATP TipsDocument7 paginiO Level Physics 2023-2025 ATP TipsAmy WolmesÎncă nu există evaluări

- Is.11921.1993 Fuel Efficiency StandardDocument12 paginiIs.11921.1993 Fuel Efficiency StandardParminder SinghÎncă nu există evaluări

- EE223 - Signals & Systems Assignment #3 (CLO#3)Document3 paginiEE223 - Signals & Systems Assignment #3 (CLO#3)haider aliÎncă nu există evaluări

- Unit - I Dynamics of Electric Drives: Electrical Power Transmission SystemsDocument4 paginiUnit - I Dynamics of Electric Drives: Electrical Power Transmission Systemsyemane gebremichalÎncă nu există evaluări

- MATLAB AssignmentsDocument12 paginiMATLAB AssignmentsnilimaÎncă nu există evaluări

- Programa A4Q Selenium Tester FoundationDocument3 paginiPrograma A4Q Selenium Tester FoundationAdrian MazgaÎncă nu există evaluări

- ECE7360 Project3Document58 paginiECE7360 Project3Icaro.RedwarriorÎncă nu există evaluări

- Design of Machine Elements - IDocument69 paginiDesign of Machine Elements - IAnonymous utfuIcnÎncă nu există evaluări

- Exam I: Turabo University School of Engineering Department of Mechanical Engineering MEEN 621 Boundary LayersDocument2 paginiExam I: Turabo University School of Engineering Department of Mechanical Engineering MEEN 621 Boundary LayersJoseph O. Camacho IrizarryÎncă nu există evaluări

- Oxyacids of SulphurDocument29 paginiOxyacids of SulphurSumaira Yasmeen100% (1)

- STHAMB or Pillars of The Hindu TemplesDocument31 paginiSTHAMB or Pillars of The Hindu TemplesudayÎncă nu există evaluări

- Product and Service DesignDocument17 paginiProduct and Service DesignRahul KhannaÎncă nu există evaluări

- RFID Adoption by Supply Chain Organizations in MalaysiaDocument5 paginiRFID Adoption by Supply Chain Organizations in MalaysiaWalid GradaÎncă nu există evaluări

- Kathrein 80010430 PDFDocument1 paginăKathrein 80010430 PDFRaúl Fernández SánchezÎncă nu există evaluări

- Ecs448 Chapter 5a ArchDocument28 paginiEcs448 Chapter 5a Archdixn__Încă nu există evaluări

- Elysium TranslatorDocument24 paginiElysium Translatorfilip_bonacic3908Încă nu există evaluări

- Users Manual ACS 501 PDFDocument94 paginiUsers Manual ACS 501 PDFmodelador3dÎncă nu există evaluări

- Lab 1Document4 paginiLab 1zakariaÎncă nu există evaluări

- LG Rp29fa40Document15 paginiLG Rp29fa40palomoqro100% (1)

- Polynomials Class 9THDocument4 paginiPolynomials Class 9THAbinash KatochÎncă nu există evaluări

- Mathematical Model of Transportation ProblemDocument14 paginiMathematical Model of Transportation ProblemwasimghghÎncă nu există evaluări

- On The Molecular Theories of Liquid Crystals by C. ZannoniDocument221 paginiOn The Molecular Theories of Liquid Crystals by C. ZannoniclaudiozannoniÎncă nu există evaluări

- On The Way To Zero Defect of Plastic-Encapsulated Electronic Power DevicesPart III Chip Coating Passivation and DesignDocument8 paginiOn The Way To Zero Defect of Plastic-Encapsulated Electronic Power DevicesPart III Chip Coating Passivation and DesignJiyang WangÎncă nu există evaluări

- Partially Miscible LiquidsDocument4 paginiPartially Miscible LiquidsCatriona BlackÎncă nu există evaluări

- Engineering MeasurementsDocument77 paginiEngineering MeasurementsFemi Prince0% (1)

- Conte R Fort WallDocument30 paginiConte R Fort Wallmirko huaranccaÎncă nu există evaluări