Documente Academic

Documente Profesional

Documente Cultură

02 Quite Success PDF

Încărcat de

Rizki Fajar NovantoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

02 Quite Success PDF

Încărcat de

Rizki Fajar NovantoDrepturi de autor:

Formate disponibile

Rail

Just one press of a button by the train driver is all that is required to switch over to

electric traction mode.

Fuel consumption up to 25 percent lower hybrid traction system with a diesel engine and

and almost silent operation even on routes electric motor,” Lehmann explains. As part of a

without overhead power lines. Both are joint pilot project with Deutsche Bahn subsidiary

made possible by the new MTU Hybrid Po- DB RegioNetz Verkehr GmbH Westfrankenbahn,

werpack. It is currently undergoing testing in MTU converted a Class 642 railcar with diesel-

a railcar in Germany and is expected to be mechanical traction to hybrid power. Since May

approved for use on local services by the end 2012 it has been in action at shows and in prac-

of the year. tical trials. Approval for operation on passen-

ger services is scheduled for the end of the year.

All of a sudden silence descends. Not even the The project has been subsidized by the German

distinct hum of the MTU diesel engines is to be Federal Ministry for Transport, Construction and

Quiet

heard. They have gone quiet too. Almost noise- Urban Development as part of the Electric Trans-

lessly, the red Siemens Desiro VT 642 railcar port Model Regions program which is coordinated

glides past the green forests and white houses by NOW GmbH, Germany’s national organization

of the hilly Bavarian landscape. Just before for hydrogen and fuel cell technology.

everything fell silent, there was a soft click – just

the press of a button by the train driver was all Fuel consumption up to 25 percent lower

that was required to switch the diesel engine of The Hybrid Powerpack has been developed from

Since May 2012 the hybrid railcar has been in action

success

at shows and in practical trials.

the new MTU Hybrid Powerpack off and the elec- the proven MTU underfloor traction modules. Up

tric motor on. A smile spreads over the face of to now they have contained only a single power

MTU project manager Ingo Lehmann. He and his unit, a diesel engine. The Hybrid Powerpack has

team have been working on this special hybrid not only a 315-kilowatt Type 6H 1800 R75 die-

powerpack for years. It has long since demons- sel unit but also a up to 400-kilowatt electric

trated its capabilities on the test bench. Now it is motor. And MTU has also incorporated an SCR

being tested out on the German railway. exhaust aftertreatment system with an urea tank

in the hybrid power module to comply with EU

Approval for passenger service by end IIIB emission standard which came into force as

of the year of 2012. In this configuration, the Hybrid Power-

“The VT 642 is something new in Continental pack is also suitable for ecologically repowering

Europe. It is the first railcar to be powered by a existing diesel railcars. As a parallel hybrid unit,

«The VT 642 is the first railcar in Continental Europe to be

the underfloor traction module can be operated

in diesel-only or electric-only mode or in diesel-

electric mode. And that pays dividends. Both fuel

powered by a hybrid traction system with a diesel engine and consumption and carbon dioxide emissions can

»

be reduced by as much as 25 percent.

electric motor. Ingo Lehmann, MTU Friedrichshafen

18 I MTU Report 02/12 MTU Report 02/12 I 19

Rail

ME MO

Brake & Save

When a train brakes, it releases large amounts of energy in the form

of heat. Normally, that energy simply dissipates and is not used.

However, it can be used to drive the train and MTU’s Hybrid Power-

pack makes use of the principle involved: A specially developed

crankshaft starter-generator (CSG) absorbs the kinetic energy, con-

verts it to electrical energy and stores it in a lithium-ion battery.

When the train moves off, the current flows from the battery to the

CSG which re-converts the electrical energy to kinetic energy, dri-

ving the crankshaft. Depending on demand, a frequency converter

With the MTU Hybrid Powerpack railcars can reduce both fuel consumption and carbon dioxide emissions by as much as 25 percent. Conventional Powerpacks form the basis for the MTU hybrid system.

controls the flow of energy from the battery to the drive unit and

However, they have been modified to create enough space for the

back.

hybrid technology. That means that they can be fitted in trains as

«This project is a significant milestone along the way to

part of routine repowering operations.

Energy from braking

The new traction system enables recovery of

the kinetic energy from braking by converting it universal use of low-emission and environmentally friendly

into electrical energy using an alternator. Ingo

Lehmann, the man in charge of the rail hybrid

project at MTU, explains the principle: “Every

trains on non-electrified lines.

»

Claus Werner, DB RegioNetz Verkehrs GmbH

time the train brakes, the energy is stored in a

lithium-ion battery. And whenever it is required to

power the electric motor, the battery gives that air conditioning by ten percent. The system will adapted to different topographical conditions. It

energy back – when passing through a tunnel, also be powered by energy from the lithium-ion will thus be fundamentally transferrable to diffe-

arriving at a station or traveling through a densely batteries. rent classes and usable across Deutsche Bahn or

populated area.” The recovered braking energy is by other public transport companies. “This pro-

also used to supply auxiliary electrical equipment “Significant milestone” ject is therefore a significant milestone along the

such as air conditioning compressors. It is a tech- Following passenger-service approval, the hybrid way to universal use of low-emission and environ-

nology that is particularly effective on local ser- prototype will go into service with Deutsche Bahn mentally friendly trains on non-electrified lines,”

vice routes involving stop-and-go operation with subsidiary Westfrankenbahn on the route bet- states Clause Werner, who is in charge of testing

frequent braking and acceleration phases. ween Aschaffenburg and Miltenberg in the Lower and approval of the hybrid railcar at DB Region-

Main region of Bavaria. With its 14 stops in the Netz Verkehrs GmbH.

The division of tasks between MTU and Deut- space of 37 kilometers, this route provides the

sche Bahn was clear – MTU developed the Hybrid ideal situation for testing out the hybrid trac- Text: Lucie Dammann

Powerpack and bench-tested it. Deutsche Bahn, tion unit in stop-and-go conditions. The insights Pictures: Robert Hack

for their part, integrated the components and gained from passenger service operation there Graphics: Roland Witsch

systems in the existing railcar and will have the will inform related follow-on projects. The aim is

vehicle approved for local passenger service. to convert more locomotives in the coming years

As another part of the project, the manufac- and to develop the hybrid technology to the point To find out more, contact:

turer Konvekta Schwalmstadt also developed and where it is ready for series production as a trac- Ingo Lehmann

tested out an eco-friendly CO2 air conditioning tion unit for local transport railcars. The techno- ingo.lehmann@mtu-online.com

system which will reduce the energy demand for logy will be a modular concept so that it can be Tel. +49 7541 90-3467 9

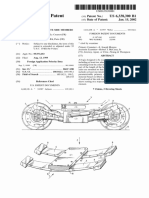

1 Diesel engine

2 Crankshaft Starter-Generator

The lithium-ion batteries for traction and onboard (CSG)

power supply on the railcar are mounted on the roof 3 Gearbox

of the vehicle together with the DC/DC transformer 4 Exhaust aftertreatment system

for onboard power supply, the central control cabinet, 5 AdBlue® tank

the air conditioner for the lithium-ion batteries, the 3 5 2 1 8 4 7 6 6 Lithium-ion battery

new-design air conditioning system for the passenger 7 Traction power converter

compartment and the auxiliary equipment power 8 System controller

converter it requires. 9 Onboard power supply

MTU Report 02/12 I 21

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- 50c PDFDocument43 pagini50c PDFRizki Fajar NovantoÎncă nu există evaluări

- Caf EnglishDocument4 paginiCaf EnglishRizki Fajar NovantoÎncă nu există evaluări

- New Master Plan of Jabodetabek Railway: A-Nehashi@jarts - Or.jpDocument16 paginiNew Master Plan of Jabodetabek Railway: A-Nehashi@jarts - Or.jpRizki Fajar NovantoÎncă nu există evaluări

- 6364605Document15 pagini6364605Rizki Fajar NovantoÎncă nu există evaluări

- Interoperability In: Progress With Railway The European UnionDocument50 paginiInteroperability In: Progress With Railway The European UnionRizki Fajar NovantoÎncă nu există evaluări

- DYF WEB X UNI 001 01 - Presentation - PTFE - PDFDocument22 paginiDYF WEB X UNI 001 01 - Presentation - PTFE - PDFRizki Fajar NovantoÎncă nu există evaluări

- Alstom Health Hub PDFDocument2 paginiAlstom Health Hub PDFRizki Fajar NovantoÎncă nu există evaluări

- A Totally Different View On Signals: The Colour Light Signals of Vialis Railway SystemsDocument2 paginiA Totally Different View On Signals: The Colour Light Signals of Vialis Railway SystemsRizki Fajar NovantoÎncă nu există evaluări

- Quality Infrastructure Preparation and TransactionDocument6 paginiQuality Infrastructure Preparation and TransactionRizki Fajar NovantoÎncă nu există evaluări

- Trainguard PTC Safe and Efficient Train Operation - Siemens PDFDocument4 paginiTrainguard PTC Safe and Efficient Train Operation - Siemens PDFRizki Fajar NovantoÎncă nu există evaluări

- Trainguard Basic Indusi en PDFDocument4 paginiTrainguard Basic Indusi en PDFRizki Fajar NovantoÎncă nu există evaluări

- A Look at Technological Challenges Facing Africa: Thi-Mai TRAN Managing Director MoroccoDocument21 paginiA Look at Technological Challenges Facing Africa: Thi-Mai TRAN Managing Director MoroccoRizki Fajar NovantoÎncă nu există evaluări

- BRI Briefing Paper English PDFDocument26 paginiBRI Briefing Paper English PDFRizki Fajar Novanto100% (1)

- The Impact of Indusi Technology On Disruption of Interoperability in European Rail TrafficDocument10 paginiThe Impact of Indusi Technology On Disruption of Interoperability in European Rail TrafficRizki Fajar NovantoÎncă nu există evaluări

- Paper Paper Paper Paper Paper: Guide Pin Locking Block Outer Sleeve Outer Rotor of MotorDocument4 paginiPaper Paper Paper Paper Paper: Guide Pin Locking Block Outer Sleeve Outer Rotor of MotorRizki Fajar NovantoÎncă nu există evaluări

- WRSL Encompass A Highly Experienced Multi-Skilled Team Spe-Cialising in The Comprehensive Design and Professional Delivery of Level Crossing ServicesDocument2 paginiWRSL Encompass A Highly Experienced Multi-Skilled Team Spe-Cialising in The Comprehensive Design and Professional Delivery of Level Crossing ServicesRizki Fajar NovantoÎncă nu există evaluări

- Surelock: Points Drive System Points Drive SystemDocument2 paginiSurelock: Points Drive System Points Drive SystemRizki Fajar NovantoÎncă nu există evaluări

- OS&D Claim Form: Customer InformationDocument1 paginăOS&D Claim Form: Customer InformationRizki Fajar NovantoÎncă nu există evaluări

- DC Locomotive System PDFDocument2 paginiDC Locomotive System PDFRizki Fajar NovantoÎncă nu există evaluări

- United States Patent: Landrot (10) Patent N0.: (45) Date of PatentDocument7 paginiUnited States Patent: Landrot (10) Patent N0.: (45) Date of PatentRizki Fajar NovantoÎncă nu există evaluări

- EM2000 Control System Retrofit Improves Performance and Reliability of Older LocomotivesDocument2 paginiEM2000 Control System Retrofit Improves Performance and Reliability of Older LocomotivesRizki Fajar NovantoÎncă nu există evaluări

- Us4173933 PDFDocument10 paginiUs4173933 PDFRizki Fajar NovantoÎncă nu există evaluări

- Colmar T10000FS HS PDFDocument2 paginiColmar T10000FS HS PDFRizki Fajar NovantoÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Mitsubishi ASXDocument15 paginiMitsubishi ASXreadalotbutnowisdomyetÎncă nu există evaluări

- An EV - Simulator For Electric Vehicle EducationDocument7 paginiAn EV - Simulator For Electric Vehicle EducationNarendra YadavÎncă nu există evaluări

- L494 Range Rover SPORT Catálogo Brochure 2017Document90 paginiL494 Range Rover SPORT Catálogo Brochure 2017RedacTHORÎncă nu există evaluări

- Webinar - Fire Safety For EV Parking Garage PresentationDocument16 paginiWebinar - Fire Safety For EV Parking Garage PresentationDarkoÎncă nu există evaluări

- EE469 Electric and Hybrid VehiclesDocument2 paginiEE469 Electric and Hybrid VehiclesTanaji Shinde0% (1)

- Ford PresentationDocument47 paginiFord PresentationDIEGOÎncă nu există evaluări

- Wheel Loaders BrochureDocument7 paginiWheel Loaders BrochureManuel Montenegro PérezÎncă nu există evaluări

- Marine Propulsion Systems 2021 en WebDocument32 paginiMarine Propulsion Systems 2021 en Webhumayun121Încă nu există evaluări

- Ford PresentationDocument37 paginiFord PresentationRasik Sawant100% (4)

- Kinetic Energy Recovery System (Kers)Document15 paginiKinetic Energy Recovery System (Kers)Rohan SahniÎncă nu există evaluări

- A Technology Review Paper For Drives Used in Electrical Vehicle (EV) & Hybrid Electrical Vehicles (HEV)Document5 paginiA Technology Review Paper For Drives Used in Electrical Vehicle (EV) & Hybrid Electrical Vehicles (HEV)Satyam GuptaÎncă nu există evaluări

- British Icon 50 Years of The Range Rover - Issue 1 2020.Document100 paginiBritish Icon 50 Years of The Range Rover - Issue 1 2020.Digital EdukaÎncă nu există evaluări

- Ultimate Diesel Builders Guide - September 2015 USADocument132 paginiUltimate Diesel Builders Guide - September 2015 USAdapsiduÎncă nu există evaluări

- Panthera Brochure6Document12 paginiPanthera Brochure6sovsepÎncă nu există evaluări

- Car Components CircuitsDocument40 paginiCar Components Circuitssudhakar417Încă nu există evaluări

- Haeusler Evo Brochure Web UsDocument9 paginiHaeusler Evo Brochure Web UsVetriselvan ArumugamÎncă nu există evaluări

- CleanCool2010 MeetTheUKCleantechCompanies FinalFeb23Document211 paginiCleanCool2010 MeetTheUKCleantechCompanies FinalFeb23tonychaoÎncă nu există evaluări

- The Federal Reserve SystemDocument38 paginiThe Federal Reserve SystemHuế ThùyÎncă nu există evaluări

- 4 5942822423568057313 PDFDocument10 pagini4 5942822423568057313 PDFRasoolKhadibiÎncă nu există evaluări

- The Evolution of CarsDocument1 paginăThe Evolution of CarsmikkelÎncă nu există evaluări

- Kinetic Energy Recovery SystemDocument25 paginiKinetic Energy Recovery SystemAmeen MÎncă nu există evaluări

- Mercedes-Benz M254 Engine - Press ReleaseDocument4 paginiMercedes-Benz M254 Engine - Press Releasefransiscus_282501842Încă nu există evaluări

- Bosch Training Brochure 2017Document4 paginiBosch Training Brochure 2017Janne PuhakkaÎncă nu există evaluări

- ST1927 SP41 High-Voltage BatteryDocument33 paginiST1927 SP41 High-Voltage BatteryKhachik900% (1)

- CFD Analysis For Drag Force Reduction in Inter-City BusesDocument6 paginiCFD Analysis For Drag Force Reduction in Inter-City BusesAnonymous kw8Yrp0R5rÎncă nu există evaluări

- Project ChandruDocument33 paginiProject ChandruBhavaniÎncă nu există evaluări

- Mechanical Project TilesDocument33 paginiMechanical Project TilesElakkiya Karthic0% (1)

- The Volkswagen Emissions Scandal-DesbloqueadoDocument17 paginiThe Volkswagen Emissions Scandal-DesbloqueadoQUEVEDO HEREDIA ALISON LOURDESÎncă nu există evaluări

- F6000 English ManualDocument12 paginiF6000 English ManualJuan Alberto Saldaña Quiroz100% (1)

- WWW 11 023884zfge 8HP Produkt enDocument5 paginiWWW 11 023884zfge 8HP Produkt enValdir GomieroÎncă nu există evaluări