Documente Academic

Documente Profesional

Documente Cultură

18F102

Încărcat de

israelita77671Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

18F102

Încărcat de

israelita77671Drepturi de autor:

Formate disponibile

Certification

14A Redi-Bath

Date: 06/29/2018

Purchase Order:

Batch #: 18F102

It is hereby certified that the above listed magnetic particle inspection material and batch number

meets the require-ments of the following specifications:

• ASME Boiler and Pressure Vessel Code, Section V, 2004, 2007, 2010, 2013, 2015 and 2017 Edition,

Nondestructive Examination, including 2005, 2006, 2008, 2009b and 2011a Addenda,

Paragraph T-731(B) and Article 25 as applicable.

• ASME Boiler and Pressure Vessel Code, Section V 1995, 1998 and 2001 Edition, Nondestructive

Examination, including 1995 Winder Addenda, 1999, 2000, 2002 and 2003 Addenda, Paragraphs

T-752, T-731(B) and Article 25 as applicable.

• ASTM E-709-15, Paragraphs 8.1.2, 8.2, 8.3, 8.5 and 8.5.3.

• NAVSEA 250-1500-1, (Rev. 10 - June 1979, Rev. 11 - May 1983, Rev. 12 - December 1987, including

ACN 2 - November 15, 1990, Rev. 13 - October 1993, including ACN 4 June 30, 1995, Rev. 16

May 9, 2003, including ACN 5, Rev. 17 September 2007 including ACN 6, and Rev. 18 August 2013)

Paragraph 12.4.1.6.

• ASTM E-1444/E1444M-16 and ASTM E-3024/E3024M-16, Paragraphs 5.5.2 and 5.5.4.

• MIL-STD-271(SH) June 27, 1986, Paragraphs 4.2.7, 4.3.2.1 and 4.3.2.3, including Notice 1, June

21, 1993.

• NAVSEA T9074-AS-GIB-010/271( April 30, 1997 including Notice 1, September 11, 2014 Rev. 1)

Paragraphs 4.3.2.1 and 4.3.2.6.1.

• MIL-STD-2132D, February 11, 2003, Paragraphs 6.1.3, 6.2.3, 6.2.4, 6.2.5, 6.2.6 and 6.2.7.

It is further certified that this material does not contain mercury as a basic element and that no

mercury bearing equipment has been used in its manufacture.

Batch Numbers appear on labels of bulk containers and on bottoms of aerosol cans.

Mathew Plamoottil Laurie Marx

Quality Assurance Manager Quality Control Manager

155 Harlem Ave.

Glenview, IL 60025

P: 1-847-657-5300

FORM NO F-1565B R- 11/17 magnaflux.com

Certification

14A Redi-Bath

Date: 06/29/2018

Purchase Order:

Batch #: 18F102

It is hereby certified that the above listed fluorescent magnetic particle inspection material and batch

number manufactured inJune of 2018

________________________________________ and provided under

the identified purchase order meets the requirements of Aerospace Material Specification AMS-

3044F, Magnetic Particles, Fluorescent, Wet Method, Dry Powder:

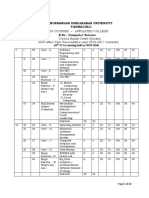

TEST PARAGRAPH LIMIT RESULT

Contamination 3.2.1 No foreign material, Conforms

agglomeration, scum

Color 3.2.2 Fluorescence: Yellow Green Conforms

Particle Size 3.2.3 Pass #325 sieve: 98% minimum Conforms

Sensitivity 3.2.5 7 hole indications shown Conforms

Durability 3.2.4 Retain initial sensitivity (show 7 hole Conforms

indications), color and brightness

Batch Numbers appear on labels of bulk containers and on bottoms of aerosol cans.

Mathew Plamoottil Laurie Marx

Quality Assurance Manager Quality Control Manager

155 Harlem Ave.

Glenview, IL 60025

P: 1-847-657-5300

FORM NO F-1570 R-2/16 magnaflux.com

S-ar putea să vă placă și

- Water Suspendible ZP-5B: CertificationDocument2 paginiWater Suspendible ZP-5B: Certificationisraelita77671Încă nu există evaluări

- MSDS Ir192Document2 paginiMSDS Ir192israelita77671Încă nu există evaluări

- 08E17KDocument2 pagini08E17KRonny AndalasÎncă nu există evaluări

- Date: Purchase Order No: Subject: Type: Batch No. SKD - S2 Spotcheck Developer 08D17KDocument2 paginiDate: Purchase Order No: Subject: Type: Batch No. SKD - S2 Spotcheck Developer 08D17Kisraelita77671Încă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Understanding ASCP Dataflow PDFDocument18 paginiUnderstanding ASCP Dataflow PDFPrahant Kumar0% (1)

- Practice Class2Document1 paginăPractice Class2Mutahher MuzzammilÎncă nu există evaluări

- Characteristics of EntrepreneurDocument16 paginiCharacteristics of EntrepreneurJaideHizoleSapulÎncă nu există evaluări

- Date Los No App No Contact NoDocument8 paginiDate Los No App No Contact Nodfged54Încă nu există evaluări

- Audit Quality in AustraliaDocument71 paginiAudit Quality in AustraliaShuyan LiÎncă nu există evaluări

- Aging Accounts Receivable and Calculating Doubtful Accounts ExpenseDocument7 paginiAging Accounts Receivable and Calculating Doubtful Accounts Expenselala gasÎncă nu există evaluări

- Panasonic Fiscal Year 2022 Q1 ResultsDocument26 paginiPanasonic Fiscal Year 2022 Q1 ResultsMaria MeranoÎncă nu există evaluări

- IBM SWOT Analysis MatrixDocument4 paginiIBM SWOT Analysis MatrixKeizer DelacruzÎncă nu există evaluări

- Kumagawa - 2BR (44.1sqm)Document1 paginăKumagawa - 2BR (44.1sqm)qwincomputationÎncă nu există evaluări

- ECON7Document2 paginiECON7DayLe Ferrer AbapoÎncă nu există evaluări

- Importer of Bangladeshi furniture targeting designers and retailersDocument57 paginiImporter of Bangladeshi furniture targeting designers and retailersBhavesh MishraÎncă nu există evaluări

- Financial Accounting Canadian 6th Edition Harrison Test BankDocument43 paginiFinancial Accounting Canadian 6th Edition Harrison Test Bankvioletviolet969y5k100% (26)

- Manonmani am Sundaranar University B.Sc. Computer Science Course DetailsDocument23 paginiManonmani am Sundaranar University B.Sc. Computer Science Course DetailslousieÎncă nu există evaluări

- Unit 4 Chapter 15 Exercise ProformaDocument11 paginiUnit 4 Chapter 15 Exercise ProformaValeria MaiÎncă nu există evaluări

- Command Economy DefinitionDocument9 paginiCommand Economy Definitionselozok1Încă nu există evaluări

- SECTION II Management Control Alternatives and Their EffectsDocument20 paginiSECTION II Management Control Alternatives and Their EffectsErna PurwatiningsihÎncă nu există evaluări

- Microeconomics Canada in The Global Environment Canadian 8th Edition Parkin Test BankDocument35 paginiMicroeconomics Canada in The Global Environment Canadian 8th Edition Parkin Test Bankserenadinhmzi100% (29)

- Wilkerson ABC Costing Case StudyDocument8 paginiWilkerson ABC Costing Case StudyParamjit Singh100% (4)

- LettersDocument4 paginiLetterssrinivas197Încă nu există evaluări

- Poi & PoaDocument14 paginiPoi & PoaKoundinyasa NishanthÎncă nu există evaluări

- Addressing The Employability Crisis: Reconnecting Education, Skills and JobsDocument24 paginiAddressing The Employability Crisis: Reconnecting Education, Skills and JobslizanÎncă nu există evaluări

- A Critical Assessment of Credit Policies and Facilities by Bank of BarodaDocument78 paginiA Critical Assessment of Credit Policies and Facilities by Bank of BarodaMayank100% (1)

- Service Textile Industry Internship ReportDocument54 paginiService Textile Industry Internship Reportbbaahmad89100% (1)

- Productivitybenchmarkingdgl2016 160810162308 PDFDocument60 paginiProductivitybenchmarkingdgl2016 160810162308 PDFJigneshSaradavaÎncă nu există evaluări

- Obiee Dashboard & Report Design Challenges & Tips: by Kevin Mcginley, AccentureDocument6 paginiObiee Dashboard & Report Design Challenges & Tips: by Kevin Mcginley, AccentureJaghannathan KsÎncă nu există evaluări

- Share Certificate FormatDocument8 paginiShare Certificate FormatRanen SinhaÎncă nu există evaluări

- Fundsa Flow Hero MotocorpDocument73 paginiFundsa Flow Hero MotocorpANOOPALINOORJAHANÎncă nu există evaluări

- Himalayan Package Drinking WaterDocument34 paginiHimalayan Package Drinking WaterSheikh Zain UddinÎncă nu există evaluări

- Terrance Arbitration DemandDocument9 paginiTerrance Arbitration DemandTechCrunch100% (1)

- Airtel Org SstructureDocument5 paginiAirtel Org SstructureAntuvane AntuÎncă nu există evaluări