Documente Academic

Documente Profesional

Documente Cultură

PEE Issue 8 2007 Curent Sensing-Selecting The Most Effective Current Sensing Technology

Încărcat de

Tu BeeDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

PEE Issue 8 2007 Curent Sensing-Selecting The Most Effective Current Sensing Technology

Încărcat de

Tu BeeDrepturi de autor:

Formate disponibile

www.raztec.co.

nz CURRENT SENSING 27

Selecting the Most Effective

Current Sensing Technology

When faced with selecting the most suitable method of accurate current measurement, a design

engineer is faced with a number of possible alternative technologies. The selection of the most

appropriate technology can often appear a little daunting. This article will assist the designer to the best

choice for their specific application. Warren Pettigrew, CTO Raztec Sensors, Christchurch, New

Zealand

Firstly, what are the necessary qualities

that need to be considered? Of course

product cost and the desired performance.

The latter covers accuracy over current

range (linearity, calibration, hysteresis);

desired current range; acceptable output

signal level; stability of offset over

temperature range; stability of gain over

temperature range; required frequency and

transient response; satisfactory steady state

signal to noise ratio and noise rejection

from the primary circuit; stability over time;

and satisfactory physical size. Other factors

include compliance with appropriate

standards; rated for application temperature

range; acceptable level of heat generation,

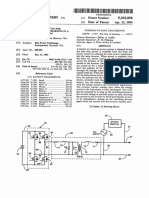

voltage and insulation rating and creepage Figure 1: Basic shunt interface circuit

distance of desired galvanic isolation,

quiescent current, supply voltage, influence would be far too unwieldy. It is also need for heat dissipation), using a 4

on the measuring circuit (impedance), and complicated by the fact that appropriate terminal configuration, using a low

acceptable output resistance. technology changes with the level of inductance winding if high (100KHz)

When considering the extensive current to be measured. Instead, the merits frequencies are to be measured, or

(although, not exhaustive) list of qualities of each available technology, in turn, will be interfacing with an op-amp which has low

necessary, it becomes obvious that the examined. and stable offset voltage and high

design of current sensing is non-trivial and frequency response and high common

is often underestimated. This is further Shunts mode rejection. If galvanic isolation is

confounded by the number of available If no galvanic isolation is needed, shunts needed, opto-isolation can be incorporated,

sensor options. are often the technology of choice for but this would then probably push costs

measuring ground referenced currents higher than that of Hall sensors for all

The most popular of the available below approximately 20A. Performance can current ratings.

technologies be improved by increasing the voltage If the shunt is not ground referenced

There are numerous technologies across them (which, in turn, increases the and is switched between ground and the

available such as shunts, PCB track

resistance, FET on-resistance, current

transformer, Rogowski coil, open/closed-

loop Hall effect sensors, or closed loop flux-

gate. The task boils down to matching a

technology to the need.

Something a designer really cannot

afford to ignore is the time taken to design

a product. If production volumes are small,

normally a short design time is important

so the selection of a simple, sure to work

solution would be useful. To assist with the

selection of appropriate technology, it

should be possible to draw up a matrix

matching qualities against the different

technologies. However, such a matrix Figure 2: Various current sensing positions

Power Electronics Europe Issue 8 2007

28 CURRENT SENSING www.raztec.co.nz

to interface to. They have good immunity

to short-term overload, give negligible

loading to the primary circuit and are self-

powered. So what are their weak points?

They don’t like a DC component within

the AC current that they are measuring.

This causes saturation. However, there are

special DC immune transformers, but this

then often makes them more susceptible

to stray magnetic fields. They can display

non-linear phase shifts. Again, if special

core material is chosen this effect can be

reduced, but this then results in increased

cost. Larger current devices are bulky, much

Figure 3: Simplistic DCCT more bulky than certain Hall effect based

devices. There could be cost advantages in

supply voltage, it is a distinct challenge for application for lower frequency these sizes as well. Unless electrostatic

any operational amplifier to reliably see measurements. shielding is fitted, primary voltage noise will

millivolts across the shunt with a relatively inevitably appear on the output. Output

high common mode voltage - especially if FET on-resistance voltage overshoot protection may be

the common mode voltage has PWM If your application allows you to get away needed to protect the monitoring circuit.

superimposed on it. One would be much with it, the cheapest current sensor is FET

better off choosing a galvanically isolated on-resistance. A FET is a resistor when Rogowski coil

current sensor technology (see Figure 1). turned on. However, there is a daunting A Rogowski coil is an air-cored current

For example, using the classical array of variables such as gate-source transformer. Its output is proportional to

differential amplifier circuit, the shunt voltage; junction temperature which is di/dt, so for it to generate a useful output

voltage can swing high R1>>R6 and dependant on time, junction to heat-sink an integrator is required to recover the

R3>>R5 so that the op-amp is kept within thermal resistance (device mounting current. By definition, they can’t measure

its specified input voltage. However, if pressure), ambient temperature, current DC current, but are immune to DC current

R1>>R6 and R3>>R5, the gain of the (non-linear), or device characteristics. in the primary circuit. The coils themselves

circuit is <<1 for a signal which is already Despite all these issues, this technique is are cheap. They are often flexible, so they

small, it can be a challenge to re-amplify. useful for detecting overload or can be wrapped around a conductor. They

Very stable, low noise amplifiers and desaturation of the FET. are excellent for measuring high AC

resistors are needed. The amplification and currents or high frequency currents.

noise suppression circuitry is likely to harm Current transformers So what are the downsides of using

the frequency response and introduce These devices can only measure AC Rogowski coils? When required to measure

significant phase shifts which, in turn can currents, but can do so very precisely over low mains frequency currents, their outputs

create instability. A Hall effect sensor is a wide dynamic range and up to high are minute. This results in the need for

much easier to implement and is very likely frequencies (>100KHz). Small units are expensive amplifiers and an integrator to

to be cheaper than the combined cheap, offer galvanic isolation and are easy recover a useful signal. Dedicated interface

shunt/amplifier configuration.

As the current gets higher, dissipation Figure 4: Hall sensing

increases with an increase of footprint and without magnetic

cost. circuit

For example, if we need to measure

100A and the minimum practical voltage

that can be sensed is 0.2mV (noise

limited) and we choose a 1mΩ shunt; its

dissipation is 10W @ 100A and the

minimum sensed current is 0.2A. An

open-loop Hall effect current sensor would

out-perform the shunt for size and cost,

especially if the cost of the shunt’s interface

circuit is included. For any shunts, it is

essential that thermocouple induced

voltages are taken into effect – these WILL

substantially limit dynamic range. Figure 2

shows various current sensing positions.

For non-critical applications and lower

current applications, a piece of PCB trace

can be used as a shunt. Its actual

resistance would have to be calibrated, as

there will be substantial batch to batch

variation. Temperature compensation

would probably also be necessary. The

trace will be inductive, thus reducing its

Issue 8 2007 Power Electronics Europe

www.raztec.co.nz CURRENT SENSING 29

Figure 5: Hall sensing measure the flux surrounding a current

with magnetic circuit carrying conductor (Figure 4).

This is very simple and generally low cost

technology and is appropriate for some

applications. Strong points are i.e. simplicity

and low cost, providing galvanic isolation

for measuring AC and DC currents;

compact design especially when high

(~150A) currents are to be measured;

reasonable frequency response up to

50kHz; and good signal to noise ratio for

high current sensing.

Weak points i.e. are very sensitive to

stray magnetic fields. Even the earth’s

magnetic field gives a 0.5A error. Stray

fields could arise from nearby conductors

or contactor coils. Needs to be located

very close to the current carrying

conductor, this can then lead to insulation

and electrostatic screening issues.

Controlling the drift of offset voltage with

temperature can be quite a challenge.

Gain changes with temperature can be an

issue.

The gain calibration of the devices will be

very loose, as their output is very

circuits are available which claim operation components, exhibit admirable dependant on conductor position. This

over a wide dynamic range of current. performance. There are two distinct means that in-process calibration probably

Since signals are small, careful electrostatic families:- units with a magnetic circuit and will be required.

screening will often be needed. units without. The latter technology simply This technology may be worth a look if it

uses a magnetic field strength sensor to is necessary to measure reasonably high

Direct current current-transformer

These sensors work on the principle that

when a magnetic core saturates, it loses is

inductance. A typical DCCT has an

excitation winding wound onto a torroidal

core which has enough excitation to just

drive it into saturation. A primary conductor

is passed through the core. The conductors

current will modulate the core saturation

which, in turn, will modulate the second

harmonic of the excitation current. This is

then the monitored output. For mains

frequency applications, they can be excited

using a sinusoidal mains frequency voltage.

Figure 3 shows the DCCT principle.

As the name suggests, DCCTs can

measure DC and AC currents with galvanic

isolation. The strengths of these devices are

simplicity and ruggedness against overload;

if an appropriate core material is selected,

they are sensitive to low (<20mA) currents;

their offset is stable over a wide temperature

range; and they offer good immunity to stray

magnetic fields. But they don’t have very

good linearity; their frequency response is

low (~500Hz) for a basic unit; they have

limited dynamic range of current; and the

output may carry excitation noise.

A single core design injects noise into

the primary circuit.

Open-loop hall effect current

transducers

These fundamentally simple devices

can, with the selection of appropriate Figure 6: Effect of conductor passes through core

Power Electronics Europe Issue 8 2007

30 CURRENT SENSING www.raztec.co.nz

Raztec and the Solar Fern

The Panasonic World Solar Challenge is a

biennial, friendly competition of solar and

energy-efficient vehicles crossing between

October 21 to 28 the Australian continent

from Darwin to Adelaide in a 3000km trek.

Now in its 20th anniversary year, teams came

from across the globe, having researched,

designed and built their own vehicles. Hall

effect current transducers helped New

Zealand’s challenger for the World Solar

Challenge.

Energy management and conservation are

critical for the performance of solar powered

vehicles. Energy flow is measured by

monitoring voltage and current flow and

Raztec Hall effect current transducers

measure the current flow, as no loss is

induced and readings are not disturbed by

voltage in the current carrying conductor. For

example, the preferred way to control motor

power is to operate under torque mode

control. Depressing the accelerator pedal

demands an increase in torque from the

motor in proportion to the angle of depression. To ensure that this process works consistently, the torque controller

must monitor motor current quickly and accurately, and compare this with the demand from the accelerator - motor

torque being directly proportional to current flow.

current cheaply and can tolerate which concentrates the flux through the the selection of core materials that offer

imprecision. Hall magnetic field sensor. This action sharp saturation with little remanence and

Open-loop Hall devices with magnetic increases the relative precision by a high saturation flux density. This can often

circuit (Figure 5) work on the same factor 5 to 10 and greatly improves result in better than 1% linearity over the

principle as the above sensors but, very immunity to stray magnetic fields. rated current range. The selection of

importantly, include a magnetic circuit Advances in magnetic materials allow thermally stable Hall devices allow a

practical dynamic current range of 2.5

Figure 7: Closed-loop decades, meaning a 100A sensor will be

Hall effect current able to accurately measure down to

sensor 200mA.

In order to measure low currents, the

primary can be passed multiple times

around the magnetic circuit (Figure 6).

Strengths of this technology i.e. are

compactness with very low loss method of

measuring AC and DC currents;

fundamentally simple low cost design;

good immunity to stray magnetic fields;

moderate quiescent current; good linearity;

and temperature stable products. Most

open-loop sensors have a moderate

~25KHz frequency response, but devices

with bandwidths up to 350KHz are

available providing reaction times of

~ 300ns and 90% primary current in

~1µs. These sensors feature a very easy

interface with near rail to output voltage.

Selected products have good signal to

noise ratio and are rated for the automotive

temperature range (-40 to 120°C).

Weaknesses i.e. are thermal drift of the

quiescent voltage, and hysteresis may be a

problem for some high precision

Issue 8 2007 Power Electronics Europe

www.raztec.co.nz CURRENT SENSING 31

applications. In some low current applications, Hall sensors cost more than

shunts or Cts. Some sensors may overheat if subjected to high frequency

currents. Gain can change with temperature. A negative shift with increasing

temperature could cause problems if the sensor was used for overload

protection. Low cost sensors may require in-process calibration as their gain

and offsets are commonly not tightly specified.

Open-loop Hall effect current sensors come in a variety of flavours. It is

important that specifications are carefully reviewed so that the most

appropriate sensor is selected. A reputable supplier can assist with their

implementation.

There is a good chance that there will be an open-loop sensor that fits all

your needs, but there are more options. It is possible to increase the current

range of current sensors by shunting some current away from the sensor.

However, this kills the frequency response as the high frequency component

of the current passes through the shunt, bypassing the Hall sensor.

Closed-loop hall effect current sensors

These sensors work on a principle similar to the open-loop Hall sensors,

but include a feedback winding to null the flux in the core (Figure 7). GMR

sensors may be used in place of the Hall element. Because of the servo

effect, excellent linearity results and gain become very independent of

temperature. The feedback coil and associated amplifier does add some cost

however.

The strong points i.e. are good DC and AC accuracy over a reasonable

dynamic range. Low insertion loss; good frequency response (~100kHz);

reasonable cost if a commitment made to ASICs; good immunity to stray

magnetic fields and electric fields with suitable screening.

Weaknesses, in turn, are dynamic range limited in practice by core hysteresis

and null drift with temperature; physically larger and costlier than open loop

devices. Also, high quiescent current particular when the primary current is

high. This makes for self-heating which, in turn, limits their use to lower

ambient temperatures. These factors make them less attractive for automotive

applications.

The performance of closed-loop sensors has stabilised, while that of open-

loop continues to progress with the introduction of new materials and

components. There are now few instances where closed-loop sensors are

needed rather than their less costly open-loop counterparts.

Closed-loop flux-gate current sensors

If a compensating coil is added to a DCCT, its maximum operating range

is no longer limited by core saturation; the compensating winding being

excited to maintain the mean flux in the core to zero. However, two flux-

gate cores working in opposition are needed to prevent excitation energy

being transferred to the compensating winding (and the primary). If high

frequency performance is needed, a CT can be added and its output added

to the low frequency component from the flux-gate sensor. All this adds

cost and complexity to the sensor, but these sensors may offer the most

accurate current sensing available.

Strong points are i.e. very low hysteresis means that the sensors can

measure very low (~50mA) currents with a single primary turn; with a

closed loop compensating winding, hundreds of amps can be measured;

very linear output over a reasonable dynamic range; very good signal to

noise ratio; and if a high frequency winding is included, their frequency

response is good.

Weaknesses i.e. are cost driven by complex magnetics and electronics;

bulky; high quiescent current, particularly with high primary current, which

makes for high self-heating which limits that applications to lower temperature

environments; the compensating winding carries a lot of copper so it is

expensive.

Conclusion

Selecting appropriate current sensing technology is complex and there are a

great many options. Typical of engineering, most are imperfect. Continual

progress in open-loop Hall effect current sensor technology means that the

possible applications of these versatile devices continues to grow and displace

other more traditional devices.

Power Electronics Europe

S-ar putea să vă placă și

- Current Sensing Techniques-Hall EffectDocument18 paginiCurrent Sensing Techniques-Hall EffectsanilÎncă nu există evaluări

- New Algorithm For Generator Differential Protection: Conference PaperDocument5 paginiNew Algorithm For Generator Differential Protection: Conference PaperSaadTahirÎncă nu există evaluări

- Diagnostic Measurements On Instrument TransformersDocument7 paginiDiagnostic Measurements On Instrument TransformersMauricio AgudeloÎncă nu există evaluări

- PotM 2018 01 Diagnostic Measurem On ITs ENUDocument19 paginiPotM 2018 01 Diagnostic Measurem On ITs ENURencziVera100% (1)

- High Performance Differential Protection, Analog Versus NumericalDocument6 paginiHigh Performance Differential Protection, Analog Versus NumericalratheeshkumardÎncă nu există evaluări

- Schneider Installation Guide Pages N33-N48-N49Document3 paginiSchneider Installation Guide Pages N33-N48-N49josette_hajjarÎncă nu există evaluări

- Solid-State Circuit Breakers and Current LimitersDocument9 paginiSolid-State Circuit Breakers and Current LimitersDeepak GehlotÎncă nu există evaluări

- NOTES 4 Sensors For Vibration MeasurementDocument77 paginiNOTES 4 Sensors For Vibration MeasurementmanishpaliÎncă nu există evaluări

- We Can Classify Test Failure Modes in Power Transformers Accord Ing To Transform Er Com Po NentsDocument8 paginiWe Can Classify Test Failure Modes in Power Transformers Accord Ing To Transform Er Com Po NentsShamil NiftaliyevÎncă nu există evaluări

- Cahier Technique No. 199 Page 7 - 12Document6 paginiCahier Technique No. 199 Page 7 - 12Muklis AhmadÎncă nu există evaluări

- PDF Optical Technology in Current Measurement DDDocument17 paginiPDF Optical Technology in Current Measurement DDNarendra0% (1)

- Underground Cable Fault Detection Using IotDocument5 paginiUnderground Cable Fault Detection Using IotMayank KumarÎncă nu există evaluări

- Some Aspects On Integrated Current Shunts For High Frequency Switching Power Electronic ConvertersDocument6 paginiSome Aspects On Integrated Current Shunts For High Frequency Switching Power Electronic ConvertersElena RamonaÎncă nu există evaluări

- aspublishedonIEEEXplore TIE2349876Document10 paginiaspublishedonIEEEXplore TIE2349876josmelÎncă nu există evaluări

- Fly by Wire Digital Muito Bom Maior Estabilidade Eletrônica Porque Depende Menos Dos Valores de Energia ElétricaDocument1 paginăFly by Wire Digital Muito Bom Maior Estabilidade Eletrônica Porque Depende Menos Dos Valores de Energia ElétricaWagner CondorÎncă nu există evaluări

- Introduction To Power Mosfets: Micronote Series 901Document3 paginiIntroduction To Power Mosfets: Micronote Series 901Engr. Syed Ghulam Mustafa ShahÎncă nu există evaluări

- Ceidp DWGDocument4 paginiCeidp DWGyahyaupsefÎncă nu există evaluări

- Design of High Voltage Filter For Power Transformer TestingDocument6 paginiDesign of High Voltage Filter For Power Transformer TestingmayureshÎncă nu există evaluări

- Caution - Leakage Currents - EN - 06 - 13 - DBDocument4 paginiCaution - Leakage Currents - EN - 06 - 13 - DBDedy Setiawan ستياوانÎncă nu există evaluări

- Tirsu - Energy Quality Welding DeviceDocument4 paginiTirsu - Energy Quality Welding DeviceTirsu MihaiÎncă nu există evaluări

- Cable Fault Detection Using Iot: International Research Journal of Engineering and Technology (Irjet)Document4 paginiCable Fault Detection Using Iot: International Research Journal of Engineering and Technology (Irjet)Ravindra GujarÎncă nu există evaluări

- PQ Surveys FFFDocument15 paginiPQ Surveys FFFsrinathlalÎncă nu există evaluări

- Solid-State Circuit Breakers and Current Limiters For Medium-Voltage Systems Having Distributed Power SystemsDocument8 paginiSolid-State Circuit Breakers and Current Limiters For Medium-Voltage Systems Having Distributed Power Systemsrazila rasheedÎncă nu există evaluări

- Impact of Modern Electronic Equipment On The Assessment of Network Harmonic ImpedanceDocument9 paginiImpact of Modern Electronic Equipment On The Assessment of Network Harmonic ImpedancedougmadasÎncă nu există evaluări

- The Danger of Vibration in Power TransformersDocument7 paginiThe Danger of Vibration in Power TransformersDante FilhoÎncă nu există evaluări

- Peterson Coil PDFDocument6 paginiPeterson Coil PDFDeepika GargÎncă nu există evaluări

- The Optimal Setting of Inverse Time Overcurrent Relay in Distribution Systems Installed With Smart Grounding DeviceDocument6 paginiThe Optimal Setting of Inverse Time Overcurrent Relay in Distribution Systems Installed With Smart Grounding Deviceali didebanÎncă nu există evaluări

- Including Uncertainties From Customer Connections in Calculating Low-Voltage Harmonic ImpedanceDocument10 paginiIncluding Uncertainties From Customer Connections in Calculating Low-Voltage Harmonic ImpedanceNam LêÎncă nu există evaluări

- Event Analysis of Pulse-Reclosers in Distribution Systems Through Sparse RepresentationDocument6 paginiEvent Analysis of Pulse-Reclosers in Distribution Systems Through Sparse RepresentationjagmcinquitosÎncă nu există evaluări

- Review Article: Advances in High-Resolution Microscale Impedance SensorsDocument16 paginiReview Article: Advances in High-Resolution Microscale Impedance SensorsgpaivÎncă nu există evaluări

- Review Article: Advances in High-Resolution Microscale Impedance SensorsDocument16 paginiReview Article: Advances in High-Resolution Microscale Impedance SensorsgpaivÎncă nu există evaluări

- Panda Kov 2018Document8 paginiPanda Kov 2018pouyanÎncă nu există evaluări

- Analysis of Harmonic Mitigation Methods For Building Wiring SystemsDocument8 paginiAnalysis of Harmonic Mitigation Methods For Building Wiring SystemsImranul KarimÎncă nu există evaluări

- Review DC CurrentDocument6 paginiReview DC Currentrajagopal gÎncă nu există evaluări

- Countermeasures of Zero-Missing Phenomenon in (E) HV Cable SystemsDocument10 paginiCountermeasures of Zero-Missing Phenomenon in (E) HV Cable SystemsJonayed Iqbal JoyÎncă nu există evaluări

- Rate of Change of Frequency Under Line ContingenciesDocument7 paginiRate of Change of Frequency Under Line Contingenciesjohn georgeÎncă nu există evaluări

- Control Hardware and Suitable Current Sensors For Fast Switching SiC DC-DC ConvertersDocument5 paginiControl Hardware and Suitable Current Sensors For Fast Switching SiC DC-DC ConvertersSilvestarÎncă nu există evaluări

- A Wavelet Based Transformer DifferentialDocument11 paginiA Wavelet Based Transformer Differentialwaael abdulhassanÎncă nu există evaluări

- Dynamic Contact Resistance Measurements On HV Circuit Breaker IJERTV3IS10680 PDFDocument5 paginiDynamic Contact Resistance Measurements On HV Circuit Breaker IJERTV3IS10680 PDFSourav RanaÎncă nu există evaluări

- Circuit BreakerDocument6 paginiCircuit BreakerSindhuKumarÎncă nu există evaluări

- Nwandu Chidike John SeminarDocument31 paginiNwandu Chidike John SeminarChidike NwanduÎncă nu există evaluări

- More Papers and Presentations Available On Above Site: Santosh Bharadwaj ReddyDocument10 paginiMore Papers and Presentations Available On Above Site: Santosh Bharadwaj ReddyS Bharadwaj ReddyÎncă nu există evaluări

- Mingkai Mu - New Core Loss Measurement Method For High-Frequency Magnetic MaterialsDocument8 paginiMingkai Mu - New Core Loss Measurement Method For High-Frequency Magnetic MaterialsNeha RajputÎncă nu există evaluări

- AC DC Current Measurements Using Indirect Non Contact MethodsDocument4 paginiAC DC Current Measurements Using Indirect Non Contact MethodsInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- Analysis of Electrical Resonance Distortion For inDocument8 paginiAnalysis of Electrical Resonance Distortion For inخالدمحمدÎncă nu există evaluări

- Seminor Report Chandra Shekhar Maurya 16EE13Document14 paginiSeminor Report Chandra Shekhar Maurya 16EE13Shubham SinghÎncă nu există evaluări

- CT Analyzer Coming To The Rescue Paper ITMF 2013 Porrelli ENUDocument5 paginiCT Analyzer Coming To The Rescue Paper ITMF 2013 Porrelli ENUkarim_ouakliÎncă nu există evaluări

- Capacitive Voltage Transformer TestingDocument7 paginiCapacitive Voltage Transformer TestingSaeedAhmedKhan100% (1)

- Power Transformer Under Short-Circuit Fault Conditions: A Multiphysics ApproachDocument8 paginiPower Transformer Under Short-Circuit Fault Conditions: A Multiphysics ApproachJigneshÎncă nu există evaluări

- Subharmonic Oscillations and Chaos in DC-DC Switching ConvertersDocument4 paginiSubharmonic Oscillations and Chaos in DC-DC Switching Convertersjai dÎncă nu există evaluări

- Transients Part 1Document4 paginiTransients Part 1Earl Jenn AbellaÎncă nu există evaluări

- Transients and Protective RelaysDocument7 paginiTransients and Protective Relayssdkarthik123Încă nu există evaluări

- Slvae 37Document9 paginiSlvae 37Toader DenisÎncă nu există evaluări

- Capacitive Sensor Interfacing Using Sigma-Delta TechniquesDocument4 paginiCapacitive Sensor Interfacing Using Sigma-Delta TechniquesAlex WongÎncă nu există evaluări

- Simulation of Resistive Super Conducting Fault Current Limiter and Its Performance Analysis in Three Phase Systems IJERTV2IS110178Document5 paginiSimulation of Resistive Super Conducting Fault Current Limiter and Its Performance Analysis in Three Phase Systems IJERTV2IS110178Äy MênÎncă nu există evaluări

- Current Source Based Converteer SSSCDocument6 paginiCurrent Source Based Converteer SSSCRiddhiÎncă nu există evaluări

- A Discharge Locating Probe For Rotating MachinesDocument3 paginiA Discharge Locating Probe For Rotating MachinesJINEETH JJOSEPHÎncă nu există evaluări

- Troubleshooting On Assembled Printed Circuit Boards Using Analogue Signature AnalysisDocument8 paginiTroubleshooting On Assembled Printed Circuit Boards Using Analogue Signature AnalysisJORGEÎncă nu există evaluări

- A Low Voltage All Digital On Chip Oscillator Using Relative Reference ModelingDocument6 paginiA Low Voltage All Digital On Chip Oscillator Using Relative Reference ModelingShruti KalraÎncă nu există evaluări

- Trilogy of Wireless Power: Basic principles, WPT Systems and ApplicationsDe la EverandTrilogy of Wireless Power: Basic principles, WPT Systems and ApplicationsÎncă nu există evaluări

- Efficacy of Pulsed 405-nm Light-Emitting Diodes For Antimicrobial Photodynamic Inactivation: Effects of Intensity, Frequency, and Duty CycleDocument7 paginiEfficacy of Pulsed 405-nm Light-Emitting Diodes For Antimicrobial Photodynamic Inactivation: Effects of Intensity, Frequency, and Duty CycleTu BeeÎncă nu există evaluări

- Lecture9 - Fixed PointDocument36 paginiLecture9 - Fixed PointTu BeeÎncă nu există evaluări

- An 046Document7 paginiAn 046Tu BeeÎncă nu există evaluări

- Add Charging StatusDocument5 paginiAdd Charging StatusTu BeeÎncă nu există evaluări

- SMPS Battery Charger CC-CVDocument22 paginiSMPS Battery Charger CC-CVTu BeeÎncă nu există evaluări

- Sboa059 PDFDocument6 paginiSboa059 PDFdisse_detiÎncă nu există evaluări

- GD32F103C8T6 CoreBoard (New Version)Document1 paginăGD32F103C8T6 CoreBoard (New Version)Tu BeeÎncă nu există evaluări

- Woot17 Paper ObermaierDocument11 paginiWoot17 Paper ObermaierTu BeeÎncă nu există evaluări

- 21474CDocument26 pagini21474CTu BeeÎncă nu există evaluări

- IB-DU1000 Metal-Enclosed Bus PDFDocument12 paginiIB-DU1000 Metal-Enclosed Bus PDFdestro57Încă nu există evaluări

- DAE Mechanical Y2Document116 paginiDAE Mechanical Y2Faiz Ur RehmanÎncă nu există evaluări

- PSS Power System Solutions CATALOGUEDocument32 paginiPSS Power System Solutions CATALOGUEmahmoudÎncă nu există evaluări

- Transformer Questions: Q1. The Diagram Shows The Apparatus Used by A Student To Investigate A TransformerDocument4 paginiTransformer Questions: Q1. The Diagram Shows The Apparatus Used by A Student To Investigate A TransformerJessicaÎncă nu există evaluări

- Curso WD3 - Rev02.1 PDFDocument60 paginiCurso WD3 - Rev02.1 PDFSunny ElÎncă nu există evaluări

- Informe Simulacion 3Document39 paginiInforme Simulacion 3Carlos SarmientoÎncă nu există evaluări

- A-320 Study Notes PDFDocument158 paginiA-320 Study Notes PDFM DarwishÎncă nu există evaluări

- Types of DC Motors Notes Electric DrivesDocument77 paginiTypes of DC Motors Notes Electric DrivesJyothish VijayÎncă nu există evaluări

- h3dkz TIMER OMRONDocument25 paginih3dkz TIMER OMRONMai Văn BáchÎncă nu există evaluări

- Features: 899 - 1A - F - C EDocument3 paginiFeatures: 899 - 1A - F - C EiskarupÎncă nu există evaluări

- Data Sheet For SINAMICS G120X: Rated Data General Tech. SpecificationsDocument3 paginiData Sheet For SINAMICS G120X: Rated Data General Tech. SpecificationsRenatoHonorioÎncă nu există evaluări

- Procedure - VITEK 2 Systems - Network Configuration Guide - Win10 - REF. 048640-02 - MAR 4259Document72 paginiProcedure - VITEK 2 Systems - Network Configuration Guide - Win10 - REF. 048640-02 - MAR 4259Kevin DiazÎncă nu există evaluări

- BA AC Mini Service GBDocument32 paginiBA AC Mini Service GBLeonel Fernando Rodriguez RodriguezÎncă nu există evaluări

- Grinding Mills With Dual Pinnion DrivesDocument20 paginiGrinding Mills With Dual Pinnion Drivesjazzfan52Încă nu există evaluări

- CP700 Inverter Manual-20190716Document114 paginiCP700 Inverter Manual-20190716Ingeniería AplicacionesÎncă nu există evaluări

- Dewalt d25481Document12 paginiDewalt d25481Vasilic NikolaÎncă nu există evaluări

- LV Genset FDS A19-0444-01-SUEZ-EL-930-RP-XXX RevADocument13 paginiLV Genset FDS A19-0444-01-SUEZ-EL-930-RP-XXX RevAGiangDoÎncă nu există evaluări

- Micom P940 Series Frequency RelaysDocument16 paginiMicom P940 Series Frequency Relaysdave chaudhuryÎncă nu există evaluări

- BSC ProDocument57 paginiBSC ProDawit Adane KebedeÎncă nu există evaluări

- AGC-4 Data Sheet 4921240400 UK - 2014.02.10Document30 paginiAGC-4 Data Sheet 4921240400 UK - 2014.02.10edgarcooÎncă nu există evaluări

- Electricity Merit Badge Class 1 2017Document34 paginiElectricity Merit Badge Class 1 2017RoshanÎncă nu există evaluări

- Smart UPSDocument20 paginiSmart UPSHashimIdreesÎncă nu există evaluări

- Electrical OverviewDocument7 paginiElectrical OverviewJoydipto BoseÎncă nu există evaluări

- Ingeteam NEODocument2 paginiIngeteam NEOAlen ŽarkovićÎncă nu există evaluări

- AC Motors: AC Motors Convert AC Electrical Energy To Mechanical EnergyDocument106 paginiAC Motors: AC Motors Convert AC Electrical Energy To Mechanical Energybhuvana71Încă nu există evaluări

- Tabletop ModelsDocument8 paginiTabletop ModelsChuck_YoungÎncă nu există evaluări

- Electrocardiografo Biocare IE3Document81 paginiElectrocardiografo Biocare IE3brenda ruano100% (3)

- 16M Motor Grader R9H00001-UP (MACHINE) POWERED BY C13 Engine (SEBP6123 - 84) - CaracterísticasDocument22 pagini16M Motor Grader R9H00001-UP (MACHINE) POWERED BY C13 Engine (SEBP6123 - 84) - CaracterísticasDouglas GomesÎncă nu există evaluări

- Electrician: Sector - ElectricalDocument73 paginiElectrician: Sector - ElectricalAbdul AjisÎncă nu există evaluări

- Corrente DC - AcDocument4 paginiCorrente DC - AcMichael Antonio Cruz TrujilloÎncă nu există evaluări