Documente Academic

Documente Profesional

Documente Cultură

Toy Derringer Handgun Firing Mechanism PDF

Încărcat de

yuehan0%(1)0% au considerat acest document util (1 vot)

435 vizualizări5 paginiThis patent describes a handgun firing mechanism with the following key elements:

1) An L-shaped sear carried by the hammer that is engaged with and held in place by the trigger during movement from the ready to tripping position.

2) Means for releasing the sear from engagement with the trigger at the tripping position, allowing the hammer to fire. This means is independent of the hammer and trigger.

3) A spring biasing mechanism that biases the sear into maintaining contact with the trigger.

In summary, this patent introduces an improved double action firing mechanism for a handgun that reliably engages and releases a sear to enable firing with each trigger pull.

Descriere originală:

Titlu original

Toy derringer Handgun firing mechanism.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis patent describes a handgun firing mechanism with the following key elements:

1) An L-shaped sear carried by the hammer that is engaged with and held in place by the trigger during movement from the ready to tripping position.

2) Means for releasing the sear from engagement with the trigger at the tripping position, allowing the hammer to fire. This means is independent of the hammer and trigger.

3) A spring biasing mechanism that biases the sear into maintaining contact with the trigger.

In summary, this patent introduces an improved double action firing mechanism for a handgun that reliably engages and releases a sear to enable firing with each trigger pull.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0%(1)0% au considerat acest document util (1 vot)

435 vizualizări5 paginiToy Derringer Handgun Firing Mechanism PDF

Încărcat de

yuehanThis patent describes a handgun firing mechanism with the following key elements:

1) An L-shaped sear carried by the hammer that is engaged with and held in place by the trigger during movement from the ready to tripping position.

2) Means for releasing the sear from engagement with the trigger at the tripping position, allowing the hammer to fire. This means is independent of the hammer and trigger.

3) A spring biasing mechanism that biases the sear into maintaining contact with the trigger.

In summary, this patent introduces an improved double action firing mechanism for a handgun that reliably engages and releases a sear to enable firing with each trigger pull.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 5

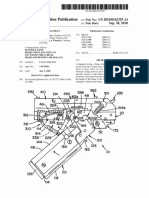

United States Patent [19] [11] 4,407,085

Hillberg et al. [45] Oct. 4, 1983

[54] HANDGUN FIRING MECHANISM FOREIGN PATENT DOCUMENTS

[76] inventors: Robert L. Hillberg, 26 Mount

Sanford Rd.’ Cheshire’ C‘onn. 06410; 1185092 [/1965 Fed. Rep. of Germany ...... .. 89/147

Fr§defi¢k F- Stevens, 177 Brett Rd» Primary Examiner-Charles T. Jordan

Falr?eld, Coml- 06430 Assistant Examiner—Ted L. Parr

[2]] Appl‘ NO‘: 308 427 Attorney, Agent, or Firm—-McCormick, Paulding &

’ Huber

[22] Filed: Oct. 2, 1981 57 ABS Cr

[51] int. Cl.3 ............................................ .. F41C 19/00 [ 1

[52] US. Cl. .................................................. .. 42/69 R A multi-barrd, breach loaded pistol having a double

[58] Field of Search ............. .. 42/8, 69 R, 42 R, 42 B, action ?ring mechanism includes an L-Shaped sear car- >

42/65; 89/147 ried by the hammer and released from engagement with

[56] References Cited the trlgger by engagement of a portlon of the sear with

the gun frame.

U.S. PATENT DOCUMENTS

1,348,035 7/1920 Mossberg ................................ .. 42/8 13 Claims, 5 Drawing Figures

4,407,085 2

1

The illustrated gun 10 has an improved ?ring mecha

HANDGUN FIRING MECHANISM nism of the double action type, indicated generally by

the reference numeral 12, which is capable of moving a

BACKGROUND OF THE INVENTION hammer to and releasing it in a tripping position to ?re

5 the gun in response to a single pull of a trigger. Pressure

This invention relates in general to ?rearms and deals on the trigger must be released after each shot is ?red to

more particularly with a handgun having an improved

enable the ?ring mechanism to engage for the next shot.

double action ?ring mechanism which includes a trig The pistol 10 generally comprises a frame 14 which

ger, a movable hammer, and a sear engageable with the

trigger. In a handgun of this type, drawing back the has a breech portion 16. A barrel assembly 18 is pivot

trigger causes the hammer to move to a tripping posi ally supported at the forward end of the frame by a

tion against the biasing force of a mainspring. At the hinge pin 20 to break upwardly and away from the

tripping position the sear disengages from the trigger breech portion to an open position, such as indicated in

permitting the hammer to move freely to its striking broken lines in FIG. 2, upon rearward movement of a

position in response to the biasing force of the main releasing latch indicated at 22 and associated with the

spring. In a mechanism of the aforedescribed general 15 pistol rear sight. The illustrated barrel assembly 18 has

type coengageable cam surfaces are usually provided on four integral barrels, as shown in FIG. 1. Each barrel .

the trigger and the sear to effect disengagement of the has a bore 24 which includes a chamber 26 at its breech

sear from the trigger at the tripping position. However, end. The chambers are closed by the breech portion 16

play between various parts of the mechanism resulting when the barrel assembly is latched in its closed position

from accumulated manufacturing tolerances and/or relative to the frame, as it appears in FIG. 1. The barrel

wear may cause premature release of the sear from the assembly may also include an extractor mechanism

trigger. This condition results in release of the hammer which operates in a manner well known in the art to

before the mainspring is fully compressed so that poten extract spent cartridges from the chambers 26, 26 when

tial energy stored in the mainspring is seriously reduced. the barrel assembly 18 is broken upwardly to an open

This problem is particularly severe in a small handgun, 25 position relative to the frame 14. However, for clarity

such as a derringer of the so-called “hammerless” type of illustration, the extractor mechanism Fs not shown.

wherein the hammer is concealed within the gun frame The ?ring mechanism 12 is arranged for rim ?re and

and has relatively little room for travel. Premature re includes a hammer assembly indicated generally at 28, a

lease of the hammer in a gun of this type is likely to mainspring assemblydesignated generally .by the nu

result in mis?re. The present invention is concerned meral 30 and a trigger 32. The trigger is slidably sup

with this problem. ported in opposing upper and lower ways formed in the

SUMMARY OF THE INVENTION frame 14 for movement between a ready position shown

in full lines in FIGS. 1 and 2 and a ?ring position indi

In accordance with the invention an improved ?ring cated by broken lines in FIG. 3. The rear upper portion

mechanism is provided for a handgun which has a 35 of the trigger 32 has a rearwardly facing bearing surface

frame, a trigger supported on the frame for movement 34, for a purpose which will be hereinafter further evi

between ready and ?ring positions, and a hammer as dent. A lug 35 depends from the lower rear portion of

sembly supported on the frame and including a hammer the trigger and cooperates with the frame 14 to limit

and a sear carried by the hammer and engageable with forward travel of the trigger 32. A trigger spring assem

the trigger to effect movement of the hammer to a trip bly which includes a trigger spring 36 and a spring

ping position in response to movement of the trigger guide rod 38 is received within a rearwardly opening

from its ready to its ?ring position. In accordance with bore in the trigger and acts between the trigger 32 and

the invention there is provided means for maintaining the frame 14 to normally bias the trigger in a forward

the sear in engagement with the trigger during move direction toward its inactive or ready position. The

ment of the trigger from its inactive to its tripping posi 45 hammer assembly, shown in further detail in FIGS. 4

tion, and means independent of the hammer and the and 5, generally comprises a hammer 40, a ?ring ele

trigger and engageable with the sear for effecting re ment, indicated generally at 42, and a sear 44 carried by

lease of the sear from the trigger at the tripping position. the hammer. In accordance with the invention, the

BRIEF DESCRIPTION OF THE DRAWING 50 ?ring mechanism further includes a spring biasing

FIG. 1 is a perspective view of a handgun embodying mechanism 46 for biasing the sear 44 into and maintain

ing the sear in the path of the trigger and means inde

the present invention. pendent of the trigger and engageable with the sear for

FIG. 2 is a somewhat enlarged side elevational view

of the gun of FIG. 1 shown partially in longitudinal releasing the sear from engagement with the trigger at

55 the tripping position, as will be hereinafter further dis

section.

FIG. 3 is a fragmentary side elevational view similar cussed.

to FIG. 2 but showing the ?ring mechanism in another The hammer 40 comprises an elongated member

pivotally supported at its lower end on a pivot pin 48, as

position. shown in FIGS. 2 and 3, which extends transversely of

FIG. 4 is a somewhat enlarged fragmentary side ele

vational view of the hammer assembly. the gun frames. The hammer has transversely enlarged

FIG. 5 is a fragmentary front elevational view of the upper and lower end portions, respectively indicated at

hammer assembly shown in FIG. 4. 50 and 52, integrally joined by an elongated connecting

portion 54 which extends along one side of the gun

DETAILED DESCRIPTION OF PREFERRED frame. A rearwardly opening slot in the lower portion

EMBODIMENT 65 50 receives the forward end of the mainspring assembly

Referring now to the drawing, a multi-barrel, breech 30 which includes a strut 56 and a mainspring 58 re

loaded handgun or pistol embodying the present inven ceived on the strut. A pin 60 mounted in ?xed position

tion is indicated generally by the reference numeral 10. on the lower part 50 extends transversely of the slot

4,407,085

3 4

therein and is engaged by the upper end of the strut 56, movement of the hammer 40 toward its tripping posi

as best shown in FIGS. 2 and 3. tion causes clockwise movement of the sear 44 against

The ?ring element 42 has a generally cylindrical the opposing biasing force of the biasing mechanism 46.

body portion 62. Four equiangularly spaced ratchet As the hammer assembly 28 attains its tripping position

notches 63, 63 open outwardly through the rear periph the sear 44 pivots out of engagement with the trigger

eral surface of the body portion 62. Another cylindrical allowing the hammer assembly to pivot in counter

portion 64 of somewhat smaller diameter projects for clockwise direction from its broken line position of

wardly from the body portion 62 and carries a radially FIG. 3 to its full line or striking position of FIG. 2

disposed ?ring lug 66. The ?ring element 42 is sup wherein the ?ring lug 66 engages the rim of an associ

ported for rotation on and relative to the hammer 40 by ated chambered round to ?re it. When the trigger is

an integral hub shaft 68 which projects rearwardly from released it is biased forwardly to its ready position by

the body portion 62 and which is received within a bore the trigger spring 36 to reset the ?ring mechanism to

in the hammer upper portion 50. A retaining ring 70 ?re the next round.

engaged within an annular groove in the hub shaft 68 We claim:

retains the ?ring element 42 in assembly with the ham 15 1. In a handgun having a frame and a ?ring mecha

mer. An elongated hand or pawl 72 pivotally supported nism including a trigger supported on the frame for

at its lower end on the frame 14 is spring biased in coun movement between ready and ?ring positions, a ham

terclockwise direction from its positions in FIGS. 2 and mer assembly supported on the frame for movement

3 and has an upper end arranged for sequential engage between striking and tripping positions, and a main

ment with the ratchet notches 63, 63, as will be hereinaf 20 spring normally biasing the hammer toward its striking

ter further discussed. position, the hammer assembly including a hammer and

The sear 44 is a generally L-shaped member which is a sear pivotally supported on the hammer and engage

supported within a downwardly opening slot 74 in the able with another part of the ?ring mechanism for mov

hammer upper portion 50. A pin 76 extends transversely ing the hammer assembly from its striking position to its

of the upper portion 50 and through the slot 74 to sup 25 tripping position and releasing the hammer in its trip

port the sear proximate the junction of its legs for piv ping position in response to movement of the trigger

otal movement on and relative to the hammer 40, as best from its ready position to its ?ring position, the im

shown in FIG. 4. One leg of the sear has a forwardly provement wherein said sear comprises a generally

facing abutment surface 78. The other leg has a rear L-shaped member having two legs, one of said legs

wardly facing abutment surface 80 on its free end for being engageable with said other part, and said handgun

engaging a bearing surface 81 on the gun frame. The includes means independent of said other part and en

spring biasing mechanism 46, which, as shown, com gageable with the other of said legs for releasing said

prises a spring 82 and a spherical ball 84 is received sear from engagement with said other part at said trip

within a bore in the hammer upper portion 50 and acts ping position to allow said hammer to move to its ?ring

between the hub shaft 68 and an associated leg of the 35 position in response to the biasing force of said main

sear 44 to bias the sear in a counterclockwise direction spring, and means for biasing said one'leg toward said

and toward its trigger engaging position, as best shown other part and maintaining it in engagement with said

in FIG. 4. other part until said sear means is released from engage

Further disclosure of a ratchet or ?ring element and ment with said other part by engagement of said other

pawl mechanism, similar to the ?ring element 42 and leg with said independent means.

pawl 72, and a mainspring assembly, similar to the main 2. In a handgun as set forth in claim 1 the further

spring assembly 30, may be found in the copending improvement wherein said independent means com

application of Robert L. Hillberg for MULTI-BAR prises a ?rst abutment in the path of said other leg.

REL PISTOL, Ser. No. 111,870 ?led Jan. 14, 1980. The 3. In a handgun as set forth in either claim 1 or claim

latter application is hereby adopted by reference as part 45 2 wherein said other part comprises said trigger.

of the present disclosure. 4. In a handgun as set forth in either claim 1 or claim

When the trigger is in its ready position, as it appears 2 the further improvement wherein said independent

in FIGS. 1 and 2, the hammer assembly 28 is in its for means is further characterized as an abutment surface

ward position of FIG. 2 and the ?ring element 42 is at on said frame.

rest generally adjacent the breech 16. In the latter posi 5. In a handgun as set forth in claim 4 the further

tion of the trigger, the sear 44 is biased in counterclock improvement wherein said hammer assembly is dis

wise direction by the biasing mechanism 46 to its trigger posed wholly within the con?nes of said frame.

engaging position wherein the abutment 78 is disposed 6. In a handgun as set forth in claim 1 the further

immediately rearwardly of and in alignment with the improvement wherein said L-shaped sear member is

bearing surface 34. Drawing back on the trigger causes 55 supported to pivot proximate the junction of said legs.

the hammer 40 to pivot in clockwise direction about the 7. In a handgun as set forth in claim 6 the further

pivot pin 48, against the biasing force of the mainspring improvement wherein said one leg has a forwardly

58, as viewed in FIGS. 2 and 3. As the hammer pivots facing abutment surface thereon engageable with a

rearwardly toward its tripping position, shown in bro rearwardly facing bearing surface on said other part and

ken lines in FIG. 3, the pawl 72 engages an associated said other leg has a rearwardly facing abutment surface

ratchet notch 63 to index the ?ring element 42 in coun thereon engageable with a forwardly facing bearing

terclockwise direction, as viewed in FIG. 5. The sear 44 surface on said frame.

remains in engagement with the trigger until the abut 8. In a handgun as set forth in claim 7 the further

ment surface 80 on the sear engages the bearing surface improvement wherein said other part comprises said

81 on the gun frame. The abutment surface 80 cooper 65 trigger.

ates with the bearing surface 81 to provide means inde 9. In a handgun having a frame assembly and a ?ring

pendent of the trigger for releasing the sear from en mechanism, the frame assembly including a frame and a

gagement with the trigger. Thereafter, further pivotal barrel assembly having a plurality of bores, each of the

4,407,085

5 6

bores having an associated cartridge chamber, the ?ring 11. In a handgun as set forth in either claim 9 or claim

mechanism including a trigger supported on the frame 10 wherein said L-shaped sear member is supported to

for movement between ready and ?ring positions, a pivot proximate the junction of said legs.

hammer assembly supported on the frame for pivotal 12. In a handgun having a frame and a ?ring mecha

movement between striking and tripping positions, a nism including a trigger supported on the frame for

mainspring normally biasing the hammer assembly movement between ready and ?ring positions, a ham

toward its striking position, the hammer assembly in mer assembly supported on the frame for movement

cluding a hammer, and a ?ring element supported on between striking and tripping positions, and a main

the hammer for sequential rotary indexing movement sprin-g normally biasing the hammer toward its striking

relative to the hammer to positions of ?ring alignment position, the hammer assembly including a hammer and

with each successive one of the cartridge chambers, a sear pivotally supported on the hammer and engage

retaining means for securing the ?ring element in assem able with another part of the ?ring mechanism for mov

bly with the hammer, sear means carried by the hammer ing the hammer assembly from its striking position to its

and engageable with the trigger for moving the hammer tripping position and releasing the hammer in its trip

assembly to and releasing it in its tripping position to ping position in response to movement of the trigger

15

move to its striking position in response to biasing force from its ready position to its ?ring position, the im

of the mainspring, means for biasing said sear means to provement wherein said sear has two legs and is pivot

a position wherein it is engageable with said trigger, and ally supported on said hammer at the junction of said

means for indexing the ?ring element in timed relation legs, one of said legs being engageable with said other

to movement of the hammer assembly between its strik 20 part, said handgun includes means independent of said

ing and tripping positions, the improvement wherein other part and engageable with the other of said legs for

said sear means comprises a generally L-shaped sear releasing said sear from engagement with said other

pivotally supported on said hammer and having two part at said tripping position to allow said hammer to

legs, one of said legs being engageable with said trigger, move to its ?ring position in response to the biasing

and said handgun includes means independent of said 25 force of said mainspring, and means for biasing said one

hammer and said trigger and having an abutment in the leg toward said other part and maintaining it in engage

path of the other of said legs and engageable with said ment with said other part until said sear is released from

other leg for moving said sear out of engagement with engagement with said other part by engagement of said

said trigger as said hammer assembly reaches its trip other leg with said independent means.

ping position. 30 13. In a handgun as set forth in claim 12 the further

10. In a handgun as set forth in claim 9 the further improvement wherein said other part comprises said

improvement wherein said abutment is de?ned by said trigger.

* * * * *

frame.

35

45

50

55

65

S-ar putea să vă placă și

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsDe la EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsÎncă nu există evaluări

- Practical Guide to the Operational Use of the PPS-43 Submachine GunDe la EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunÎncă nu există evaluări

- Post 6 36083 SA Repeating DerringerDocument18 paginiPost 6 36083 SA Repeating Derringerbadlabmouse0% (1)

- Firing Mechanism For A RevolverDocument9 paginiFiring Mechanism For A RevolverjonybravominiÎncă nu există evaluări

- Revolver PatentDocument5 paginiRevolver PatentdududadamikeÎncă nu există evaluări

- Chimera ManualDocument12 paginiChimera ManualticocrazyÎncă nu există evaluări

- V3 ECM Tutorial v1.0Document40 paginiV3 ECM Tutorial v1.0lmkkilo3Încă nu există evaluări

- OBAS-12 Updated v2Document89 paginiOBAS-12 Updated v2Professor100% (2)

- Gun ModifyDocument3 paginiGun ModifyBrotha BlakÎncă nu există evaluări

- Us 3722358Document9 paginiUs 3722358awe234Încă nu există evaluări

- Excalibur Catalog, Cobray, Leinad Derringer, Mac-10, m11 Parts, Kits CatalogDocument16 paginiExcalibur Catalog, Cobray, Leinad Derringer, Mac-10, m11 Parts, Kits CatalogFrancisco Barron20% (5)

- Product Instructions - Flat Bending Jig InstructionsDocument34 paginiProduct Instructions - Flat Bending Jig InstructionsDale WadeÎncă nu există evaluări

- Home N Ew Arrivals C Loseouts Schem Atics Sell Your PartsDocument2 paginiHome N Ew Arrivals C Loseouts Schem Atics Sell Your Partstwinscrewcanoe100% (1)

- Some Detailed Jager Pictures PDFDocument53 paginiSome Detailed Jager Pictures PDFwienslaw580486% (7)

- System For Shooting Using Compressed Gas - US Patent 5909000Document21 paginiSystem For Shooting Using Compressed Gas - US Patent 5909000Aride4everÎncă nu există evaluări

- On Target Shooter NZ - Brun Latrige 8 MM Self-Loading 'Belly Guns'Document3 paginiOn Target Shooter NZ - Brun Latrige 8 MM Self-Loading 'Belly Guns'Roddy PfeifferÎncă nu există evaluări

- Ruger Mark IDocument7 paginiRuger Mark IAdam OrionÎncă nu există evaluări

- Post 3 45540 22 Pocket Pistol Dwgs PDFDocument9 paginiPost 3 45540 22 Pocket Pistol Dwgs PDF41das1100% (1)

- StenDocument13 paginiStendinosauro007100% (2)

- United States Patent (191: SeminianoDocument2 paginiUnited States Patent (191: Seminianoomikami50% (2)

- Ruger MkII Ejector Dimension Ed FlatDocument1 paginăRuger MkII Ejector Dimension Ed FlatMike NichlosÎncă nu există evaluări

- Jaco DerringerDocument4 paginiJaco DerringerFunkpiratÎncă nu există evaluări

- Rechambering ShotgunsDocument6 paginiRechambering ShotgunsZardoz1090Încă nu există evaluări

- Patented June 1, 1901. No. 675,999.: L. HellfritzschDocument4 paginiPatented June 1, 1901. No. 675,999.: L. HellfritzschСлэйтер Строительная компанияÎncă nu există evaluări

- Sent in To TFB Is Another Concept Design For AnDocument5 paginiSent in To TFB Is Another Concept Design For Aneduar laraÎncă nu există evaluări

- 22-Caliber Revolver PDFDocument24 pagini22-Caliber Revolver PDFApril Bishop100% (5)

- 1F7BZ MR Singleshot's Book of Rifle Plans Part5Document12 pagini1F7BZ MR Singleshot's Book of Rifle Plans Part5angelines123100% (6)

- 44 Magnum PDFDocument19 pagini44 Magnum PDFAnderson Perosa100% (1)

- Browning Round Slide PistolDocument9 paginiBrowning Round Slide PistolHarrie Nak100% (2)

- Blowback Firearm Bolt MassesDocument2 paginiBlowback Firearm Bolt MassesEscribir4TPÎncă nu există evaluări

- Mauser Model 45 ENGLISH PDFDocument19 paginiMauser Model 45 ENGLISH PDFIM_JohnnyV100% (1)

- EP2369289A1Document10 paginiEP2369289A1awe234100% (1)

- Chechnya WolfDocument4 paginiChechnya WolfLambourghini100% (1)

- D66C5 MR Singleshot's Book of Rifle Plans Part1 PDFDocument18 paginiD66C5 MR Singleshot's Book of Rifle Plans Part1 PDFMainAvel100% (7)

- Expedient .380 SMG - Impro GunsDocument6 paginiExpedient .380 SMG - Impro GunsВладимир Конев0% (1)

- 级触发自动武器 PDFDocument15 pagini级触发自动武器 PDFJin SongÎncă nu există evaluări

- 1911 Frame TutorialDocument22 pagini1911 Frame Tutorialblackta6100% (6)

- 12 GaugeDocument3 pagini12 GaugeDavid Hoffman100% (1)

- FE Analysis of Firearm Locking Systems: Lorenzo CastiglioniDocument15 paginiFE Analysis of Firearm Locking Systems: Lorenzo CastiglionijkruiseÎncă nu există evaluări

- Front Bolt Action Assault ShotgunDocument7 paginiFront Bolt Action Assault ShotgunJoel WatsonÎncă nu există evaluări

- Carl Gustav SMGDocument18 paginiCarl Gustav SMGJorihood100% (1)

- 48Document20 pagini48UralguyÎncă nu există evaluări

- MAX1045 ManualDocument13 paginiMAX1045 Manualbrowar444100% (1)

- MK 1Document4 paginiMK 1Oscar AchtenveertigÎncă nu există evaluări

- AMT LightningDocument9 paginiAMT LightningJustinÎncă nu există evaluări

- United States "Patents PDFDocument17 paginiUnited States "Patents PDFTien Nguyen VanÎncă nu există evaluări

- CZ-52 PistolDocument6 paginiCZ-52 PistolSerteco Coleccionista Militaria100% (1)

- Blowback Gun DesignDocument5 paginiBlowback Gun DesignLogicIndustriesLLC100% (4)

- 12 Gauge Single-Shot ShotgunDocument1 pagină12 Gauge Single-Shot ShotgunGus Garcia50% (2)

- Darcy Falling Block Study PlansDocument12 paginiDarcy Falling Block Study Plansangelines123100% (19)

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.De la EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Evaluare: 5 din 5 stele5/5 (1)

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationDe la EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationÎncă nu există evaluări

- Building or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsDe la EverandBuilding or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsÎncă nu există evaluări

- Professional Gunsmithing - A Textbook on the Repair and Alteration of Firearms - With Detailed Notes and Suggestions Relative to the Equipment and Operation of a Commercial Gun ShopDe la EverandProfessional Gunsmithing - A Textbook on the Repair and Alteration of Firearms - With Detailed Notes and Suggestions Relative to the Equipment and Operation of a Commercial Gun ShopEvaluare: 5 din 5 stele5/5 (3)

- Trigger Assembly With A Safety Device For A CrossbowDocument11 paginiTrigger Assembly With A Safety Device For A Crossbowyuehan100% (1)

- Schaefer Page 1 - Modern Stock Airgun1Document11 paginiSchaefer Page 1 - Modern Stock Airgun1yuehanÎncă nu există evaluări

- Ukrainian - IMKAS - Suppressors With Floating BafflesDocument20 paginiUkrainian - IMKAS - Suppressors With Floating Bafflesyuehan100% (1)

- A Single ShontgunDocument3 paginiA Single ShontgunyuehanÎncă nu există evaluări

- Serbu RN50 ShortyDocument19 paginiSerbu RN50 ShortyyuehanÎncă nu există evaluări

- Building A Suppressor For Ar-15 5.56Document18 paginiBuilding A Suppressor For Ar-15 5.56yuehan100% (2)

- 1907 Bsa - Manual.eng-CngunDocument28 pagini1907 Bsa - Manual.eng-Cngunyuehan100% (1)

- Compact Foldable HandgunDocument34 paginiCompact Foldable Handgunyuehan100% (1)

- Four Tubes of Concealable FirearmDocument15 paginiFour Tubes of Concealable FirearmyuehanÎncă nu există evaluări

- Pressure Air GunDocument7 paginiPressure Air GunyuehanÎncă nu există evaluări

- The Practical AstronomerDocument258 paginiThe Practical AstronomeryuehanÎncă nu există evaluări

- Lûëîßûäá., Patented July 8, 1913.: C6265 Z1' MEN@ MijnDocument6 paginiLûëîßûäá., Patented July 8, 1913.: C6265 Z1' MEN@ MijnyuehanÎncă nu există evaluări

- ShotGun PlanDocument14 paginiShotGun Planyuehan100% (2)

- Thompson Center Encore Pistol PDFDocument24 paginiThompson Center Encore Pistol PDFyuehanÎncă nu există evaluări

- SRP v1.1.3 - Optional FeaturesDocument7 paginiSRP v1.1.3 - Optional FeaturesIllya FÎncă nu există evaluări

- PelletDocument2 paginiPelletguian domanÎncă nu există evaluări

- Rifle - July 2016Document64 paginiRifle - July 2016Dennis Shongi50% (2)

- Fire and Fury 2.1Document12 paginiFire and Fury 2.1Elodin9Încă nu există evaluări

- Combat 2 ItalyDocument2 paginiCombat 2 ItalyJames LewisÎncă nu există evaluări

- .22 Winchester Magnum Rimfire Cartridge DetailsDocument5 pagini.22 Winchester Magnum Rimfire Cartridge Detailsblowmeasshole1911Încă nu există evaluări

- Jeff Cooper's Commentaries #7Document70 paginiJeff Cooper's Commentaries #7deolexrexÎncă nu există evaluări

- Gun With Green Screen - Recherche GoogleDocument1 paginăGun With Green Screen - Recherche GoogleEnfnÎncă nu există evaluări

- Ruger & His Guns: A History of The Man, The Company & Their FirearmsDocument14 paginiRuger & His Guns: A History of The Man, The Company & Their FirearmsFirearms - Modern, Historic and Collectible Guns50% (4)

- The .50BMG Rifle CalibreDocument9 paginiThe .50BMG Rifle CalibreІгор ШтайєрÎncă nu există evaluări

- Present Arms AR-15 Gunners MountDocument18 paginiPresent Arms AR-15 Gunners MountAmmoLand Shooting Sports NewsÎncă nu există evaluări

- Azp S 60Document8 paginiAzp S 60hartmann10Încă nu există evaluări

- Bergara 2021 Low Res Rev4 2 21Document21 paginiBergara 2021 Low Res Rev4 2 21Jose Luis AcevedoÎncă nu există evaluări

- The American Sharps Shooters-2016-5Document20 paginiThe American Sharps Shooters-2016-5musgrave762100% (1)

- Jurisprudence - Evidence Lecture - VerdoteDocument83 paginiJurisprudence - Evidence Lecture - VerdoteAceAsabu100% (4)

- Tikka T3 Varmint StainlessDocument1 paginăTikka T3 Varmint StainlessAnthony LeonardÎncă nu există evaluări

- Holsters For The Ruger LCRX 3Document3 paginiHolsters For The Ruger LCRX 3Gunner's AlleyÎncă nu există evaluări

- Thesis StatementDocument6 paginiThesis StatementDillan McNishÎncă nu există evaluări

- Ruger FirearmsDocument124 paginiRuger Firearmsinfoconcasa100% (1)

- Silhouette .177 Cal PCP Pistol MODEL 1700P: Exploded View & PartslistDocument5 paginiSilhouette .177 Cal PCP Pistol MODEL 1700P: Exploded View & PartslistTim SmithÎncă nu există evaluări

- At4 886-12Document110 paginiAt4 886-12scotty2hotty28100% (1)

- Beretta 92 Series 2010 ProductsDocument8 paginiBeretta 92 Series 2010 ProductsMaster ChiefÎncă nu există evaluări

- Var TMP TMP Generated HomeGunsmithingDigest3rdEdition/Home+Gunsmithing+Digest+3rd+EditionDocument286 paginiVar TMP TMP Generated HomeGunsmithingDigest3rdEdition/Home+Gunsmithing+Digest+3rd+EditionRafael Luiz FontanaÎncă nu există evaluări

- Mk18 Mod1 SBR RifleDocument21 paginiMk18 Mod1 SBR Riflesjdarkman1930Încă nu există evaluări

- SAS Weapons Anti Materiel Rifles Barret M82Document1 paginăSAS Weapons Anti Materiel Rifles Barret M82Blank086Încă nu există evaluări

- USMC OrdnanceEquipmentDocument160 paginiUSMC OrdnanceEquipmentpogy111100% (2)

- Safir T14Document10 paginiSafir T14drtarkan72100% (1)

- Henry Golden Boy - H004 Series RiflesDocument12 paginiHenry Golden Boy - H004 Series RiflesMaster ChiefÎncă nu există evaluări

- IPSC Handgun RulesDocument75 paginiIPSC Handgun Rulessilv3rw0lf100% (1)

- D20 Modern Weapons LockerDocument192 paginiD20 Modern Weapons Lockersean_ferguson_48100% (7)