Documente Academic

Documente Profesional

Documente Cultură

Pp-In-Ii-001-Instrument Installation Design PDF

Încărcat de

Erick SavrinaldoTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Pp-In-Ii-001-Instrument Installation Design PDF

Încărcat de

Erick SavrinaldoDrepturi de autor:

Formate disponibile

DOCUMENT NO. REV.

PT Caltex Pacific Indonesia PP-IN-II-001 1

DATE : October 1, 2001 SHEET : 1 OF 14

PROCEDURE PREPARED BY Hadi Prijono HPR

CHECKED BY Hadi Prijono HPR

APPROVED BY Shawn SPD

INSTRUMENT INSTALLATION DESIGN

PT. CALTEX PACIFIC INDONESIA

REV DATE PAGES DESCRIPTION PREP’D CHK’D APP’D

0 10/01/01 ALL ISSUED FOR IMPLEMENTATION HPR HPR SPD

1 1/7/02 ALL CPI SPEC REVIEW TEAM ( HP, TJR, IVS) Team Team Team

TABLE OF CONTENT

1. GENERAL .......................................................................................................................... 2

1.1. Scope........................................................................................................................ 2

1.2. References................................................................................................................. 2

1.3. Terminology.............................................................................................................. 3

2. EXECUTION ...................................................................................................................... 4

2.1. Protection ................................................................................................................. 4

2.2. Installation General................................................................................................... 5

2.3. Installation Design .................................................................................................... 6

2.4. Bundled Tubing ....................................................................................................... 13

2.5. Installation Drawings .............................................................................................. 13

2.6. Installation Index..................................................................................................... 14

OPTIONAL ATTACHEMENTS FOR THIS SPECIFICATION:

ADDENDUM 1: “Project Specific Clarifications & Requirements”

PT. CALTEX PACIFIC INDONESIA Instrument Installation Design

PP-IN-II-001 Rev. 1

1. GENERAL

1.1. Scope

1.1.1. This specification covers the design, layout, and drawing procedures for

instrument location, support and piping. No deviation shall be made without

written approval by COMPANY.

1.1.2. Instrument installations include the following:

?? All instrument impulse piping, except the valued connection on pipelines or

equipment.

?? All instrument air and pneumatic lines, except the main instrument air header

and its valued connections.

?? All supports for instruments and impulse or pneumatic tubing.

1.2. References

1.2.1. Related Specifications

Work prescribed by this specification is to be coordinated with Work prescribed

in other specifications in this package, such as :

?? PP-IN-II-002 Instrument Piping System – Field Pressure Testing

?? PP-IN-II-003 Instrumentation Calibration and test Procedure

?? PP-IN-II-004 Control System Loop Check Procedures

?? SP-IN-II-001 General Instrument Specification

?? SP-IN-II-002 Instrument with Package or Mechanical Unit

?? SP-IN-II-003 Tropic Proofing for Instrumentation

?? SP-IN-II-004 Instrument Wiring

?? SP-IN-II-005 Instrument Material

?? Safety in Design COMPANY MANUAL

1.2.2. Code and Standard

The publications listed below form part of this specification. Each publication

shall be the latest revision and addendum in effect on the date this specification is

issued for construction unless noted otherwise. Except as modified by the

requirements specified herein or the details of the drawings, Work included in

this specification shall conform to the applicable provisions of these publications.

1.2.2.1 ANSI (American National Standards Institute)

?? ANSI B31.1 Power Piping

?? ANSI B31.3 Process Piping

1.2.2.2 API (American Petroleum Institute)

July, 2002 Page 2 of 14

PT. CALTEX PACIFIC INDONESIA Instrument Installation Design

PP-IN-II-001 Rev. 1

?? API 550 Part I - Installation of Refinery Instruments

?? API RP500 Hazardous Areas

?? API 550 Part II - Process Stream Analyzers

?? API RP520 Sizing, Selection, and Installation of Pressure-

Relieving Devices in Refineries:

Part II - Installation

?? ANSI/ISA RP 12.6 Wiring Practice for Hazardous Locations

1.2.2.3 ASME (American Society of Mechanical Engineers)

??ASME Section I Boiler and Pressure Vessel – Rules for

Construction of Power Boilers

1.2.2.4 ISA (Instrument Society of America)

?? ISA S5.1 Instrument Symbols and Identification (Also ISA 5.2,

5.3, 5.4, 5.5)

?? ISA S20 Specification Sheets

?? ISA S12.1 Electrical Instruments in Hazardous (Classified)

Locations

?? ISA RP12.4 Instrument Purging for Reduction of Hazardous Area

Classification

1.2.2.5 NFPA (National Fire Protection Association)

?? NFPA 70 National Electrical Code

1.2.2.6 NEMA

1.3. Terminology

In this specification, the following words and terms shall have the meanings hereby

assigned to them, unless noted otherwise.

1.3.1. COMPANY

Refers to PT. CALTEX PACIFIC INDONESIA, as the ultimate user and owner,

the authorized representative of COMPANY or COMPANY third party

inspection.

1.3.2. CONTRACTOR

Refers to company selected by COMPANY, which may be responsible for the

detailed engineering design, material and equipment procurement, and

construction as specified in Contract, Scope of Work, or Work Order.

1.3.3. Vendor

Refers to the company selected by COMPANY or CONTRACTOR, which is

responsible for the purchase agreement or purchase order of the goods/services

specified in this specification.

Note:

July, 2002 Page 3 of 14

PT. CALTEX PACIFIC INDONESIA Instrument Installation Design

PP-IN-II-001 Rev. 1

?? For EPC (Engineering, Procurement and Construction) project purposes:

The terminology shall have the meanings as above.

?? For “ Direct Procurement” by COMPANY purposes:

Vendor shall also be responsible as CONTRACTOR.

1.4. Conflicting Requirements

1.4.1. In case of conflict between this Specification and its associated Specifications

and the above Codes and Standards, the Vendor shall bring the matter to the

COMPANY’s attention for resolution and approval in writing. However, the

most stringent requirement shall apply.

1.4.2. Should conflicts exist between this specification and other documents, the

following order of precedence shall govern:

?? Scope of Work

?? Data Sheets.

?? This Specification

?? Other COMPANY Specifications

?? Other Referenced Publications

?? Approved for Construction Drawings

?? Vendor’s Code

2. EXECUTION

2.1. Protection

2.1.1. Pre -installation

2.1.1.1 Instrument and accessories shall be stored in a dry place, protected from

damage; capped, sealed or covered to prevent the entrance of foreign

material; caps, seals and shipping stop shall remain in place until

equipment is installed.

2.1.1.2 Before installation, instrumentation shall be handled with care preventing

jarring, dropping or straining. If exposed to the weather, cases, covers

and weather seals shall be properly fitted.

2.1.2. Seals and Purges

2.1.2.1 Special precautions, due to the rain and possible condensate formation,

are required to keep the instrument dry and to meet the area electrical

classifications. Refer to API RP500 and ANSI / NFPA 70 , “ National

Electric Code “ , for more information.

2.1.2.2 Seals and purges shall be provided when necessary to prevent corrosive

or solids bearing material from entering instruments and instrument lines.

2.1.2.3 Where diaphragm type seals are most applicable, they shall be given first

consideration.

July, 2002 Page 4 of 14

PT. CALTEX PACIFIC INDONESIA Instrument Installation Design

PP-IN-II-001 Rev. 1

2.1.2.4 In Classified Areas, with prior COMPANY approval, field panels and /

or local control panels containing instruments shall be air purged. The

amount and method of purging shall be per NFPA Standard 496, “

Purged and Pressurized Enclosure for Electrical Equipment “. The

minimum requirement is Type Z purging.

2.1.2.5 Field panel, for junction box use only, don’t require purging.

2.1.2.6 The NEMA 4X rating shall be maintained after all conduit and / or

tubing penetrations have been made into the field or local control panel.

2.1.3. Pressure Testing

2.1.3.1 Field pressure tests shall be made to ensure the integrity of the field

installed instrument piping.

2.1.4. Checkout and Calibration

2.1.4.1 After all instruments have been installed, wired, tubed, and / or piped,

each individual instrument and its associated parts shall be checked out

for correctness of function. All process and instrument tubing shall be

checked for leaks.

2.1.4.2 After the instrument installation has been fully check out, each

instrument will have its calibration checked as installed.

2.1.4.3 No instruments shall be commissioned for service without being checked

and calibrated per two proceeding paragraphs.

2.1.4.4 Documentation of Checkout and Calibration per ISA shall be provided to

COMPANY

2.2. Installation General

2.2.1. During construction and after mounting , instrument faces shall be protected to

prevent damage.

2.2.2. The installation for any type of instrument shall provide independent isolation

valves ( per piping specification ) that permits calibration / maintenance of any

loop without interfering with the normal operation of the adjacent loops, sharing

the same process tap.

2.2.3. When practical, instrument air or power shall be provided as soon as the

instruments are installed to maintain dry internals.

2.2.4. Instruments in vapour or gas service shall be mounted above the sensing point.

2.2.5. Instruments in liquid, steam or condensable vapour service shall be mounted

below the sensing point.

2.2.6. When accessibility, visibility or clearance requirements preclude the normal

mounting, provisions shall be made in the installation assembly configuration to

ensure the proper operation of the instrument.

2.2.7. Close coupled pressure gages are mounted above the sensing point.

July, 2002 Page 5 of 14

PT. CALTEX PACIFIC INDONESIA Instrument Installation Design

PP-IN-II-001 Rev. 1

2.2.8. Installation of all thermocouple elements ( except skin type thermocouple ),

RTDs, and dial thermometer shall be done after completion of main line testing

and flushing.

2.2.9. Mounting principles and details shall be chosen in order to meet the following

requirements :

2.2.9.1 Instruments shall maintain accuracy and repeatability all along their

working life,

2.2.9.2 All mechanical stress exceeding the maximum values given by

instrument vendor shall be avoided by means of appropriate choice of

mounting

2.2.9.3 Easy access to instruments shall be taken into account,

2.2.9.4 The need for self drained systems on wet gas services,

2.2.9.5 The need for avoiding heat tracing, and minimized plugging of impulse

tubing.

2.2.9.6 Two instruments shall never be connected to the same process tapping

point.

2.2.10. All instruments shall be mounted close coupled to the process unless otherwise

specified.

2.2.11. For instrument mounting, the tubing technology shall be used ( according to

ASME B36.10 ), except for level instruments.

2.2.12. All fitting and accessories ( valves, union, tees, reducers ) downstream the piping

block and bleed manifold shall be made of SS316 as a minimum requirement.

2.2.13. Choice between socket welded, flanged or NPT screwed connection to piping

block and bleed integrated manifold shall be done taking into account parameters

such as pressure, temperature and fluid type. Refer to instrument hook up

standard for a proper choice according to piping class.

2.2.14. A particula r attention shall be paid to instruments submitted to vibrations

( compressors and / or heavy instruments with flange connections lower than

300 lbs ). In such cases, instruments shall be suitably supported and process

nozzles for instrument impulse pipe shall be bracketed.

2.2.15. Instruments connected to small size process pipe or pipes made of synthetic

material shall be suitably supported.

2.2.16. Instruments shall be installed on 2” pipe support. If process pipe translation

(vibration, heat) is not expected, supporting of instrument using existing

structural beams is preferred.

2.3. Installation Design

2.3.1. Accessibility

2.3.1.1 Each instrument shall be considered as a normal working location and

therefore shall be located in order to satisfy workers safety conditions as

well as efficiency.

July, 2002 Page 6 of 14

PT. CALTEX PACIFIC INDONESIA Instrument Installation Design

PP-IN-II-001 Rev. 1

2.3.1.2 Instrument accessibility shall be in accordance with the Accessibility

Chart shown in Attachment – 1 and Caltex ‘Safety in Design’ Manual

2.3.1.3 Instrument block valves at piping or equipment shall be accessible from

grade, platform, stairway, permanent or portable ladder.

2.3.1.4 Access from portable ladder shall be limited to 15 feet above grade.

Above 15 feet instrument accessibility shall be from platform or

permanent ladder, except in pipeways where all instrument block valves

are accessible, regardless of elevation. No valve operation regulated with

two hands will be done from a ladder. A platform or chair operator will

be used in accordance with COMPANY Safety in Design Manual.

2.3.1.5 Valve location shall be within regulation called out in Caltex Safety in

Design Manual especially Section 1.3 (Access to Equipment and

Material).

2.3.1.6 Locations accessed by temporary means shall receive approval of

COMPANY.

2.3.2. Indicating Instruments

2.3.2.1 Instruments that must be visible for automatic control adjustment or

manual operation shall be visible from the adjustment or operating point.

If plot arrangement precludes this, other provisions shall be made for

indication at the adjustment or operating point.

2.3.2.2 Indicating instruments that do not have to be visible for automatic

control or manual operation shall be visible from operating aisles or

passageways.

2.3.3. Clearances

2.3.3.1 Instruments shall be located so as to provide the space necessary for

operation and maintenance.

2.3.3.2 Instruments shall be located so as not to encroach into accessways,

equipment maintenance zones or drop areas.

2.3.3.3 Instruments shall be located so as not to interfere with the operation of

valves or equipment.

2.3.4. Location

2.3.4.1 CONTRACTOR to coordinate between all disciplines ( Mechanical,

Electrical, Rotating, Civil and Structural ) to ensure that all instrument

locations meet equipment maintainability and operability guidelines as

well as physical constraints. Special attention for package unit shall be

made.

2.3.4.2 As practical, instrument shall be mounted where they will be free of

vibration, and shielded from direct sunlight and weather where possible.

2.3.4.3 Blind transmitting instruments shall be line mounted, as near to the

sensing point as practical, wherever possible.

July, 2002 Page 7 of 14

PT. CALTEX PACIFIC INDONESIA Instrument Installation Design

PP-IN-II-001 Rev. 1

2.3.4.4 Instruments shall not be line mounted when temperature or vibration

from operating equipment shall affect the operation of the instrument or

cause damage to the instrument piping.

2.3.4.5 Recording or controlling instruments shall be remote mounted at grade or

platforms.

2.3.4.6 Remote mounted instruments shall be grouped together wherever

possible.

2.3.4.7 Flow element shall be mounted on horizontal part of the piping. If not

possible , vertical mounting shall be up for liquids and down flow for

gases. Installation shall follow manuafacturer’s/vendor’s Recommended

Specifications and Instructions for installation.

2.3.4.8 Instrumentation panels shall be mounted such that they do not interfere

with maintenance work on the equipment. Where instrument panels

located on the equipment restrict maintenance access, the panel shall be

located remote from the equipment so that access to both equipment and

instrumentation is free from obstruction.

2.3.4.9 In general, instrument measuring gas, air non-condensable vapours shall

be located above their sensing points. Those measuring steam, liquids, or

condensing vapours shall be located below the sensing points.

2.3.4.10Where instruments are used as a basis for manual control, they shall,

where practicable, be visible from the related controlling device to verify

proper operation.

2.3.4.11All locally mounted instruments shall be mounted as near to the point of

measurement as reasonable and yet still be accessible from the ground or a

platform

2.3.4.12Local flow, pressure, or other variable indicators ( receiver gages or

miliamp meters ) connected to transmitter outputs shall be located near

the control valve that controls the variable. It shall be visible by a person

attempting to manipulate the bypass valve on the control valve during

control valve servicing. All pressure control valves shall have a pressure

gage immediately downstream of the bypass valve.

2.3.4.13Local controller shall not be mounted on a valve yokes. They shall be

located near the valve on a structural support. Only solenoid valve, and

valve positioners and air sets may be mounted on valves.

2.3.4.14Current to pressure transducers ( I/P ) or (P/I), voltage to current ( V/I )

transducers shall be mounted on the control valve, or as specified by

COMPANY.

2.3.5. Supports

2.3.5.1 Instrument piping shall be supported from pipe supports, pipelines or any

permanent structure.

2.3.5.2 Instrument piping shall not be supported at unins ulated pipelines ,whose

temperature more than 125 degrees F (50 degrees C) or less than 40

degrees F (5 degrees C)).

July, 2002 Page 8 of 14

PT. CALTEX PACIFIC INDONESIA Instrument Installation Design

PP-IN-II-001 Rev. 1

2.3.5.3 Instrument piping shall not be supported from pipe supports, or

structures that would be subjected to above normal vibration.

2.3.5.4 Instrument piping supports shall not be welded to stress relieved, alloy

internally lined pipelines.

2.3.5.5 Instrument piping supports shall be sufficient to maintain the piping in a

neat manner.

2.3.5.6 Instruments shall not use instrument piping as support. Multi valve

manifolds for differential pressure instruments may be tubing-supported,

however the design must ensure that adequate support is provided

2.3.5.7 Stanchion-mounting, yoke-mounting and similar are acceptable means of

mounting instruments. Instruments mounted to clips on process piping,

tanks or vessels shall be allowed if the supports are detailed on the

drawings and installed by the vessel or piping fabricator.

2.3.5.8 Handrails shall not be used for supporting instruments or instrument lines.

2.3.5.9 Tubing shall be supported in long runs to prevent sagging. Fluid density

and tube size determine the frequency of support. Generally, unsupported

tubing spans shall be no greater than 36 inches for 3/8-inch and ½-inch

tubing and 18 inches for 1/4-inch tubing

2.3.5.10Surface mounted instruments shall be bolts or screws placed in all

applicable mounting holes.

2.3.6. Instrument Piping and Tubing

2.3.6.1 Instrument piping shall generally be routed within pipe ways and areas

provided for the routing of plant piping.

2.3.6.2 Instrument piping shall be routed in a manner so as to provide for its

protection during plant operation and maintenance.

2.3.6.3 The routing of the instrument piping installation shall be checked by

CONTRACTOR based on standard installation drawing. This standard

installation drawing shall be made by CONTRACTOR for COMPANY

review and approval.

2.3.6.4 Support and routing shall allow for slope on sensing line when needed to

ensure correct reading are measured.

2.3.6.5 All instrument tubing shall be kept plugged after installation until

permanent connections are made. Plugs shall be bar stock with hex heads.

All open vents will include fittings to keep out rain, dust and insects

2.3.6.6 On vertical pipe , impulse pipe to transmitters shall have 15o minimum

slope in order for the condensates to flow back to the process pipe.

2.3.6.7 Instrument tubing carrying process fluids shall be appropriately sloped

downward from the transmitter to allow drainage of fluids in a dry

system , or sloped upward from the transmitter to allow bubbles to rise in

a fluid filled system. No pockets are allowed.

July, 2002 Page 9 of 14

PT. CALTEX PACIFIC INDONESIA Instrument Installation Design

PP-IN-II-001 Rev. 1

2.3.6.8 All piping on steam or hot oil service must be welded , with adequate

unions or flanges for disassembly.

2.3.6.9 Tubing shall be bent when possible to avoid the use of fittings. All

tubing bends shall be made with the correct size tubing bender.

2.3.6.10Tubing shall be cut with a tubing cutter. After cutting, tubing shall be

deburred before connection to fittings.

2.3.6.11The use of short lengths of tubing in long runs shall be avoided, thus

minimizing the use of fittings.

2.3.6.12Tubing shall be arranged so that couplings are accessible and can be

tightened without distorting tubing. Offsets for tubing unions shall be in

the horizontal direction to eliminate moisture traps.

2.3.6.13Tubing shall be routed to prevent mechanical damage and have a neat

appearance.

2.3.6.14Tubing shall not be attached directly to piping, electrical conduit, vessel,

machinery or structural members. They shall be installed in a tubing

raceway, channel or angle support.

2.3.6.15Tubing runs shall be grouped together where possible. Tubing shall be

ganged vertically rather than horizontally to avoid collection of dirt,

corrosives and contamination.

2.3.6.16On tubing-to-pipe connections, teflon paste shall be applied to the male

thread. Teflon tape is not acceptable.

2.3.6.17If extended lengths of multiple tubing are expected, multitube bundles

and junction boxes should be used to the best advantage.

2.3.6.18Multiple instrument tubes to a bulkhead, junction box or control panel

shall be individually identified with stainless steel tags or phenolic

nameplates.

2.3.6.19Bushings shall not be used in instrument piping; neither in transitions

from piping to butting, nor on tubing fittings

2.3.6.20General guidelines for minimum tubing size are

??6.35 mm ( ¼ inch ) : Air supplies to individual transmitters

, positioners, transmitter output,

instrument signal tubing in panels.

??9.53 mm ( 3/8 inch ) : Control valve positioner output.

??12.7 mm ( ½ inch ) : Process input tubing to pressure

transmitter, pressure switches, tubing

on/off piston type valve actuators,

tubing from outlet of boosters to

diaphragm of control valve, analyzer

sample lines, lines to process pressure

gages in local panels. Process input

tubing to flow transmitters, flow

indicators, flow or D/P switches ; All

types of transmitter sealed dead legs.

July, 2002 Page 10 of 14

PT. CALTEX PACIFIC INDONESIA Instrument Installation Design

PP-IN-II-001 Rev. 1

types of transmitter sealed dead legs.

2.3.7. Instrument Wiring

2.3.7.1 Cable Installation

?? Instrument distribution cables may run underground or aboveground.

Corrugated continues armored (MC) cables may run underground or

aboveground in cable trays.

?? All cable entries shall be designed to prevent moisture from entering

instrument termination areas. In field area, cable shall enter through

the bottom of field junction boxes. All cable ends must be sealed

with epoxy to reduce the possibility of gas and vapors passing from

classified areas to non classified areas use proper cable glands.

?? Conduit, flexible conduit or MC Cable installation at the instrument

end shall allow maintenance to remove the wire raceway from the

instrument without breaking the seal on the wire such mean shall

meet NEC (NFPA 70) when reterminated.

?? Cable to well site area shall be routed to avoid working area during

well work-over work and shall be properly protected.

?? Under paved area / process plant cable shall be installed in concrete

trench with removable concrete cover. Concrete trench shall be

designed to prevent entering water, moisture and any unexpected

matter.

?? Direct buried cable shall be protected with protective tiles and

provided with plastic warning tape, cable marker and cable routing

identification. Road crossing requires concrete-encased conduit

(conduit bank).

?? Soil bearing shall be sufficient to support all buried cables and also

to prevent uplifting of the cables.

?? Aboveground cable installation shall be by dedicated trays.

?? Metal boxes shall be grounded in accordance with the provision of

Article 250 of NEC.

?? Electronic and signal wiring shall be adequately segregated from

power wiring and electrical equipment to minimize electromagnetic

interference. The minimum separation between signal cables and

power cables will follow API RP550 section 7.

?? A grounding and bonding system shall be designed and installed to

ensure safety to personnel and equipment and to prevent fires and

damage from lightning

?? Redundant communication cables shall be routed by two different

ways.

?? Instrument cables shall be grouped by service and separated by a 10

cm minimum distance.

July, 2002 Page 11 of 14

PT. CALTEX PACIFIC INDONESIA Instrument Installation Design

PP-IN-II-001 Rev. 1

?? Fiber Optic Cables ( FOC ) can share the same routing and cable

trays used for other instrument cables with the exception of I.S

cables, which have dedicated routing. A 10 cm minimum distance

shall separate FOC from other instrument cables.

?? Telecommunication cables shall be routed on dedicated cable trays.

?? Crossing between instrument cable and power cable runs shall be

made at right angles (90 degrees) at 0.3 m minimum distance.

?? All cores shall be connected on terminal block including spare cores

and unused cores.

?? More than one core connected within one terminal is forbidden.

?? All spare cores shall be identified.

?? External cables shall be installed on aluminum or galvanized steel

cable trays with corrosion proof support and bolting.

?? Inside rooms and buildings, cable shall run on aluminum or

galvanized steel cable trays.

?? Cable trays dimensions shall be adequate to accommodate 30 % of

spare cables.

?? All wires shall be properly labeled at both ends and at junction

boxes.

2.3.7.2 Junction Box

?? Junction boxes shall be made of stainless steel or UV resistant and

flame retardant glass fibre reinforced polyester. The glass fibre

reinforced polyester shall be made to avoid static electricity build up.

?? Only one multicore cable shall be connected to each junction boxes.

?? All cables shall enter the bottom part of JB’s only. No side or top

entry is allowed for outdoor cable boxes.

?? Copper gland plate shall be provided for cable gland earthing of non-

metallic junction box. The gland plate shall be positively earthed.

Gland plate is not required for metallic junction box.

?? Junction box shall be fitted with an extension earth terminal.

?? An insulated earth bus bar shall be used for overall cable shield

termination inside the junction box.

?? No soldered connection shall be allowed.

2.3.7.3 Cable Glands

?? Glands shall be explosion proof certified, acceptable for outdoor use

and installation in Class I Div 1 or Div 2 hazardous area, according

to the classification of the area.

?? Glands shall be double seal compression type, to provide sealing of

inner and outer sheaths and clamping of cables braided armour by a

July, 2002 Page 12 of 14

PT. CALTEX PACIFIC INDONESIA Instrument Installation Design

PP-IN-II-001 Rev. 1

special ring. They shall be disconnectable / reconnectable without

degrading the tightness.

?? Glands shall be NPT threaded.

?? For explosion proof enclosure, cable glands shall not be metric type

and shall enter the enclosure through a clearance hole with a sealing

washer to achieve NEMA 7 or IP 55 protection.

?? Each gland shall be supplied with a flame retardant heat shrink PVC

protective sleeve.

?? Gland grounding of the cable armour shall be in accordance with the

applicable code for the connected equipment.

?? Cable gland plate arrangement shall allow the removal of one cable

gland without removing any other gland fitted on the same gland

plate.

2.4. Bundled Tubing

2.4.1. Aboveground Installation

The bundles shall generally be routed from the field junction boxes to the control

room, through pipeways, and the areas provided for the routing of plant piping.

2.4.2. Belowground Installation

The bundles shall generally be routed from the field junction boxes to the control

room in the most practical direct route.

2.4.3. Tube Bending Requirements

Use minimum tube bend radius in place of fittings wherever possible. Bends

shall be made with a hand or production type bender. Minimum tube bend radius

is as follows:

?? 1/4" OD tubing 9/16" radius

?? 3/8" OD tubing 15/16" radius

?? 1/2" OD tubing 1-1/2" radius

2.5. Installation Drawings

2.5.1. Instrument installation drawings shall be sufficient in detail to indicate the

instrument location, orientation, support, piping arrangement and components

and include:

?? Sequence Diagram

?? Timing Diagram

?? Cause & Effect Diagram

?? Installation Detail

?? Control Schematic

July, 2002 Page 13 of 14

PT. CALTEX PACIFIC INDONESIA Instrument Installation Design

PP-IN-II-001 Rev. 1

?? Control Panel Schematic

?? Cable Schedule

?? Logic Diagrams

?? Vendor Dcumentation

?? Interlock Diagra,

?? PLC/DCS Logic Printout

?? Loop Diagrams

?? Instrument Data Sheets

?? P&ID

2.5.2. Instrument locations shall also be shown on the instrument location plan

drawings.

2.5.3. All instruments, except minor components of a control system, are shown on the

location plan drawings.

2.5.4. Separate instrument installation assemblies shall be prepared for process piping,

pneumatic piping, instrument air supply piping and mounting.

2.5.5. The quantity of assembly drawings required in each of the categories listed in

Section 2.5(4) of this specification, shall be determined by instrument

make/brand, model, and material requirements.

2.5.6. Typical assembly drawings shall be prepared and used for as many installations

as practical.

2.5.7. Assembly drawings may be diagrammatic, orthographic or isometric.

2.5.8. Bill of material shall be included in the installation drawing.

2.6. Installation Index

Field installation instrument index is used to correlate the assembly drawings required for

each field installation.

July, 2002 Page 14 of 14

S-ar putea să vă placă și

- Distributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979De la EverandDistributed Computer Control System: Proceedings of the IFAC Workshop, Tampa, Florida, U.S.A., 2-4 October 1979T. J. HarrisonÎncă nu există evaluări

- SECTION VI Inst Installation General SpecsDocument29 paginiSECTION VI Inst Installation General SpecsgulavÎncă nu există evaluări

- PH Analyser Manual PH-13-SDocument22 paginiPH Analyser Manual PH-13-SSunil Chouhan100% (1)

- 02 - DCS - Introduction To DCSDocument27 pagini02 - DCS - Introduction To DCSSyahir ZufayriÎncă nu există evaluări

- Distributed Control Systems (DCS)Document13 paginiDistributed Control Systems (DCS)Aparna GirishÎncă nu există evaluări

- Appendix M4 - Nigerian Scope Topside Instrumentation Integration MTODocument9 paginiAppendix M4 - Nigerian Scope Topside Instrumentation Integration MTOChukwuma Emmanuel OnwufujuÎncă nu există evaluări

- Opc TestDocument25 paginiOpc TestmarklmendozaÎncă nu există evaluări

- PlantPAx Distributed Control System - The Modern DCSDocument20 paginiPlantPAx Distributed Control System - The Modern DCSVÕ QUỐC HIỆUÎncă nu există evaluări

- FactoryTalk AssetCentre From Rockwell SoftwareDocument28 paginiFactoryTalk AssetCentre From Rockwell SoftwarericardorobsonÎncă nu există evaluări

- Tube Fitting Installation SeminarDocument74 paginiTube Fitting Installation SeminarEscarabÎncă nu există evaluări

- F O U N D A T I O N: OPC Unified Architecture Release Candidate Specification Part 1: Concepts September 28, 2005Document25 paginiF O U N D A T I O N: OPC Unified Architecture Release Candidate Specification Part 1: Concepts September 28, 2005Mário SantosÎncă nu există evaluări

- Danat Al Irfan Ghala Project Electrical Metering Panel Mas Rev01Document55 paginiDanat Al Irfan Ghala Project Electrical Metering Panel Mas Rev01Ansal KhanÎncă nu există evaluări

- DCS Configuration, Hardware & SofwareDocument37 paginiDCS Configuration, Hardware & SofwareEngineer Naeem AkhtarÎncă nu există evaluări

- Junction Box Requirements For Foundation FieldbusDocument3 paginiJunction Box Requirements For Foundation FieldbuszhangyiliÎncă nu există evaluări

- Instrument Technician Position Written Exam No PDFDocument1 paginăInstrument Technician Position Written Exam No PDFDo naÎncă nu există evaluări

- CV For The Post of Computer Operator PDFDocument1 paginăCV For The Post of Computer Operator PDFSyed Adnan Hussain ZaidiÎncă nu există evaluări

- PUB060-001-00 - 1110 RCL NetworksDocument8 paginiPUB060-001-00 - 1110 RCL NetworksapisituÎncă nu există evaluări

- Smart Plant Instrumentation TutorialDocument3 paginiSmart Plant Instrumentation TutorialrodrigopttÎncă nu există evaluări

- 01 Installation of Ratio Flow ControllersDocument1 pagină01 Installation of Ratio Flow ControllersBrandon TrocÎncă nu există evaluări

- SPLMV9Install ChecklistDocument3 paginiSPLMV9Install Checklistanon_908554203Încă nu există evaluări

- CENTUM VP Documents - Yokogawa Electric CorporationDocument1 paginăCENTUM VP Documents - Yokogawa Electric CorporationDhirender DagarÎncă nu există evaluări

- 04 Instrument IndexDocument52 pagini04 Instrument IndexAnanthan SrijithÎncă nu există evaluări

- ID900 Density MeterDocument2 paginiID900 Density Metersaid_rahmansyah4750Încă nu există evaluări

- Process Industry Practices P&Id: Pip Pic001 Piping and Instrumentation Diagram Documentation CriteriaDocument30 paginiProcess Industry Practices P&Id: Pip Pic001 Piping and Instrumentation Diagram Documentation Criterialimulsa78Încă nu există evaluări

- Instrumentation CoursesDocument2 paginiInstrumentation CoursesAbdul LateefÎncă nu există evaluări

- Distributed Control System Slide Group 8 FinalDocument20 paginiDistributed Control System Slide Group 8 FinalTakudzwa MatangiraÎncă nu există evaluări

- BeginnersGuide PPE EnUSDocument76 paginiBeginnersGuide PPE EnUSIvan ČarijaÎncă nu există evaluări

- 6month (Idins) - Control Valve Function Test and Positioner CalibrationDocument3 pagini6month (Idins) - Control Valve Function Test and Positioner CalibrationJAGDEV PANESARÎncă nu există evaluări

- 16 20R300 1 Other Tools For C200Document22 pagini16 20R300 1 Other Tools For C200Avandetq AtenaÎncă nu există evaluări

- Silworx First Steps - Katalog4438Document222 paginiSilworx First Steps - Katalog4438Jorge LuisÎncă nu există evaluări

- Magnetic Level Indication and Bridle Measurements WEBDocument12 paginiMagnetic Level Indication and Bridle Measurements WEBMochamad Irvan MaulanaÎncă nu există evaluări

- Instrumentation EngineeringDocument19 paginiInstrumentation EngineeringKuldeepsingh ChandelÎncă nu există evaluări

- Catalog Foxboro Pneumatic Instruments 03-11Document88 paginiCatalog Foxboro Pneumatic Instruments 03-11Chu Tùng100% (1)

- Adani Power PG 17 Control Design Criteria BTGDocument17 paginiAdani Power PG 17 Control Design Criteria BTGManikanda PrabhuÎncă nu există evaluări

- Instrumentation - Control Design BasisDocument40 paginiInstrumentation - Control Design BasisRajesh Barkur100% (2)

- 05.datasheet InstrumentationDocument47 pagini05.datasheet InstrumentationVikas DwivediÎncă nu există evaluări

- Dcs OperationDocument14 paginiDcs OperationJanaka 76Încă nu există evaluări

- Converting PLC-5 or SLC 500 Logic To Logix-Based LogicDocument82 paginiConverting PLC-5 or SLC 500 Logic To Logix-Based LogicSoy JahÎncă nu există evaluări

- 123, SPECS-GAS-123, Mini QGM Floating Gas Trap, Rev 2Document2 pagini123, SPECS-GAS-123, Mini QGM Floating Gas Trap, Rev 2fahrain2012Încă nu există evaluări

- Distributed Control System (DCS)Document96 paginiDistributed Control System (DCS)Abdul RawoofÎncă nu există evaluări

- Write Protected BlockDocument1 paginăWrite Protected BlockMILOÎncă nu există evaluări

- Small Scale Wastewater Treatment For Single HousesDocument16 paginiSmall Scale Wastewater Treatment For Single HousesvalerieÎncă nu există evaluări

- Job Plan TT Calibration FFDocument2 paginiJob Plan TT Calibration FFKram Alim VillonÎncă nu există evaluări

- How To Do GroundingDocument12 paginiHow To Do Groundingnch1225Încă nu există evaluări

- E2T SCADA Roadmap Functional May 2013 CJS 2013.5.1 Opsmanage13Document27 paginiE2T SCADA Roadmap Functional May 2013 CJS 2013.5.1 Opsmanage13rosy_vereniceÎncă nu există evaluări

- Centrifugal Compressor Surge Control Methods PDFDocument1 paginăCentrifugal Compressor Surge Control Methods PDFBalaji KrishnanÎncă nu există evaluări

- Fisher Fieldvue Dvc6200F Digital Valve Controller PST Calibration and Testing Using Valvelink SoftwareDocument24 paginiFisher Fieldvue Dvc6200F Digital Valve Controller PST Calibration and Testing Using Valvelink SoftwareKram Alim VillonÎncă nu există evaluări

- ABB - AMD220 Pressure GaugeDocument26 paginiABB - AMD220 Pressure GaugeVikas JainÎncă nu există evaluări

- Leak Detection in Pipeline-JijoDocument17 paginiLeak Detection in Pipeline-Jijoamulbaby31Încă nu există evaluări

- Rule of Thumb: Distillation and Gas AdsorptionDocument2 paginiRule of Thumb: Distillation and Gas AdsorptionChristina Joana GuzmanÎncă nu există evaluări

- Training Kit PEK 408 EngDocument38 paginiTraining Kit PEK 408 EngSyed Mohammad NaveedÎncă nu există evaluări

- PlantPAx HMI Security ConfigurationDocument1 paginăPlantPAx HMI Security ConfigurationjaysonlkhÎncă nu există evaluări

- Making and Importance of Process P & ID (Piping & Instrumentation Diagram)Document7 paginiMaking and Importance of Process P & ID (Piping & Instrumentation Diagram)yasirÎncă nu există evaluări

- AICPL Presentation PharmaDocument19 paginiAICPL Presentation Pharmaatul waghÎncă nu există evaluări

- Instrument Setpoint Calculation MethodologyDocument213 paginiInstrument Setpoint Calculation MethodologymyklÎncă nu există evaluări

- PP in Ii 001Document15 paginiPP in Ii 001Dav EipÎncă nu există evaluări

- Piping Cleaning ProcedureDocument13 paginiPiping Cleaning ProcedureKandang SawanganÎncă nu există evaluări

- MQ SP I 7022Document78 paginiMQ SP I 7022jaseel kÎncă nu există evaluări

- A 1 Gen in PH 0004Document49 paginiA 1 Gen in PH 0004api-19762124100% (1)

- PENAWARAN HARGA PT. ............. Proyek PLTMH Semendo - Muara Enim (2X4,5) 9 MW Mini Hydro Power Plant (MHPP) ProjectDocument10 paginiPENAWARAN HARGA PT. ............. Proyek PLTMH Semendo - Muara Enim (2X4,5) 9 MW Mini Hydro Power Plant (MHPP) ProjectErick Savrinaldo100% (1)

- Pipe Laying - HCL Line Storage AreaDocument1 paginăPipe Laying - HCL Line Storage AreaErick SavrinaldoÎncă nu există evaluări

- Wvplhu: Eticket ItineraryDocument3 paginiWvplhu: Eticket ItineraryErick SavrinaldoÎncă nu există evaluări

- Cangkang From Big Hopper To Boiler Use Scrapper Conveyor 600mm PDFDocument1 paginăCangkang From Big Hopper To Boiler Use Scrapper Conveyor 600mm PDFErick SavrinaldoÎncă nu există evaluări

- Summary Project Cost: A. Direct Cost No. Description Grand AmountDocument1 paginăSummary Project Cost: A. Direct Cost No. Description Grand AmountErick SavrinaldoÎncă nu există evaluări

- Boq Pekerjaan Pondasi 500 KV Lot 1.: Foundation For 500 KV Two Circuit TowersDocument8 paginiBoq Pekerjaan Pondasi 500 KV Lot 1.: Foundation For 500 KV Two Circuit TowersErick SavrinaldoÎncă nu există evaluări

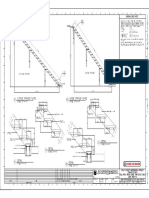

- Duri Otpf10gs000 Civ DTL Ibu 0104 01Document1 paginăDuri Otpf10gs000 Civ DTL Ibu 0104 01Erick SavrinaldoÎncă nu există evaluări

- Head PondDocument1 paginăHead PondErick SavrinaldoÎncă nu există evaluări

- AC Panasonic 1 PK CS YN9SKJ: Section V. Work PreparationDocument1 paginăAC Panasonic 1 PK CS YN9SKJ: Section V. Work PreparationErick SavrinaldoÎncă nu există evaluări

- Distributor Besi & Baja - PTDocument2 paginiDistributor Besi & Baja - PTErick SavrinaldoÎncă nu există evaluări

- Distributor Besi & Baja - PTDocument2 paginiDistributor Besi & Baja - PTErick SavrinaldoÎncă nu există evaluări

- MONTHLY SALES (Des 2019)Document4 paginiMONTHLY SALES (Des 2019)Erick SavrinaldoÎncă nu există evaluări

- Power Station PDFDocument1 paginăPower Station PDFErick SavrinaldoÎncă nu există evaluări

- Herman Tanjung Tool BoxDocument20 paginiHerman Tanjung Tool BoxErick SavrinaldoÎncă nu există evaluări

- Cangkang From PKS Use Belting 600mm and Use Screw Conveyor 800mm To Hopper Mini (6x3x2)Document1 paginăCangkang From PKS Use Belting 600mm and Use Screw Conveyor 800mm To Hopper Mini (6x3x2)Erick SavrinaldoÎncă nu există evaluări

- QuestionerDocument1 paginăQuestionerErick SavrinaldoÎncă nu există evaluări

- Roll PlateDocument1 paginăRoll PlateErick SavrinaldoÎncă nu există evaluări

- Change Working Time in The Ms ProjectDocument1 paginăChange Working Time in The Ms ProjectErick SavrinaldoÎncă nu există evaluări

- ALLOWCATION CREW PERIODE 22 JAN 2014Document8 paginiALLOWCATION CREW PERIODE 22 JAN 2014Erick SavrinaldoÎncă nu există evaluări

- Creating Half-Step Schedules Using P6Document14 paginiCreating Half-Step Schedules Using P6jcdaouÎncă nu există evaluări

- Cangkang From Hopper Mini (6x3x2) Use Screw Conveyor To Hopper Cap.1000m3Document1 paginăCangkang From Hopper Mini (6x3x2) Use Screw Conveyor To Hopper Cap.1000m3Erick SavrinaldoÎncă nu există evaluări

- Cangkang From Big Hopper To Boiler Use Scrapper Conveyor 600mm PDFDocument1 paginăCangkang From Big Hopper To Boiler Use Scrapper Conveyor 600mm PDFErick SavrinaldoÎncă nu există evaluări

- Cangkang From Big Hopper To Boiler Use Scrapper Conveyor 600mmDocument1 paginăCangkang From Big Hopper To Boiler Use Scrapper Conveyor 600mmErick SavrinaldoÎncă nu există evaluări

- Construction Productivity Improvements 03Document130 paginiConstruction Productivity Improvements 03Erick Savrinaldo100% (5)

- Computer ShortcutsDocument4 paginiComputer ShortcutsErick SavrinaldoÎncă nu există evaluări

- Real CostttDocument20 paginiReal CostttErick SavrinaldoÎncă nu există evaluări

- MONTHLY SALES (Des 2019)Document1 paginăMONTHLY SALES (Des 2019)Erick SavrinaldoÎncă nu există evaluări

- MONTHLY SALES (Nop 2019) PDFDocument1 paginăMONTHLY SALES (Nop 2019) PDFErick SavrinaldoÎncă nu există evaluări

- Presentase JKT CS WUR MDDocument25 paginiPresentase JKT CS WUR MDErick Savrinaldo100% (1)

- Q-000 - CPI (Checklist - SMO CS WUR MD C1668423)Document27 paginiQ-000 - CPI (Checklist - SMO CS WUR MD C1668423)Erick Savrinaldo100% (2)

- Whirlpool Water Heater Manual 121802Document16 paginiWhirlpool Water Heater Manual 121802jrhst36Încă nu există evaluări

- Civil Engineering Reviewer - Soil and FoundationDocument8 paginiCivil Engineering Reviewer - Soil and Foundationmark_torreon100% (4)

- HVAC Split Unit Installation Procedure - Method Statement HQDocument7 paginiHVAC Split Unit Installation Procedure - Method Statement HQEngineer ZiaÎncă nu există evaluări

- SECTION 16726 Installation of Telecommunication Facilities Rev 0Document49 paginiSECTION 16726 Installation of Telecommunication Facilities Rev 0Ahmed HashimÎncă nu există evaluări

- BP 220 Revised Rules and Standards For eDocument37 paginiBP 220 Revised Rules and Standards For eJerico NamucoÎncă nu există evaluări

- Steel: StructuresDocument29 paginiSteel: StructuresBa Thanh DinhÎncă nu există evaluări

- Ass 1Document1 paginăAss 1Itefa AnisaÎncă nu există evaluări

- Feasibility Study On The Production of Eco Blocks and Paver in The Municipality of SurallahDocument13 paginiFeasibility Study On The Production of Eco Blocks and Paver in The Municipality of SurallahJeniffer NarcisoÎncă nu există evaluări

- Mantencion de Chimeneas PDFDocument33 paginiMantencion de Chimeneas PDFAndres CortezÎncă nu există evaluări

- Analisa Struktur 4 Tugas 1 Linpro 2.7Document10 paginiAnalisa Struktur 4 Tugas 1 Linpro 2.7Mohamad Taufiqul HakimÎncă nu există evaluări

- District Rate, Sunsari 078-79 12Document51 paginiDistrict Rate, Sunsari 078-79 12APEX ENGINEERING CONSULTANCYÎncă nu există evaluări

- Assignment 4 Weatherproofing - 2021Document4 paginiAssignment 4 Weatherproofing - 2021Nisha PrakashÎncă nu există evaluări

- Antisol®-WB: Product Data SheetDocument2 paginiAntisol®-WB: Product Data Sheetkamran abbasiÎncă nu există evaluări

- Is 4591 1968 PDFDocument17 paginiIs 4591 1968 PDFBharani Kumar Srinivas SurampudiÎncă nu există evaluări

- Acoplamentos Sitex PDFDocument4 paginiAcoplamentos Sitex PDF3DLAB CAD/CAMÎncă nu există evaluări

- 8B GrammarDocument1 pagină8B GrammarCalicatro TeatroÎncă nu există evaluări

- Mechanical Services Particular SpecificationDocument12 paginiMechanical Services Particular SpecificationAhmed Mohamed AliÎncă nu există evaluări

- RDT - Drill Pipe Specs PDFDocument8 paginiRDT - Drill Pipe Specs PDFEder VargasÎncă nu există evaluări

- AOSCA80000Document60 paginiAOSCA80000Rafael Echano AcederaÎncă nu există evaluări

- Vol-I - Main Report - PKG 2 - 9.13 KMDocument357 paginiVol-I - Main Report - PKG 2 - 9.13 KMKARAN TRIVEDI100% (1)

- Valve PDFDocument20 paginiValve PDFRamalingam Prabhakaran100% (1)

- 1 Strand Jack Arrangement For Casing's Lifting 23 March PDFDocument13 pagini1 Strand Jack Arrangement For Casing's Lifting 23 March PDFHaGun GantryÎncă nu există evaluări

- 06 Structural ElementsceDocument40 pagini06 Structural ElementsceJoe PanzerÎncă nu există evaluări

- ASME B16.5 - 3 InchDocument1 paginăASME B16.5 - 3 InchRanjan KumarÎncă nu există evaluări

- bt cad cơ bảnDocument21 paginibt cad cơ bảnVõ Huỳnh Hữu NghịÎncă nu există evaluări

- NL Master Specification Guide For Public Funded Buildings: Issued 2008/03/18Document7 paginiNL Master Specification Guide For Public Funded Buildings: Issued 2008/03/18KevinÎncă nu există evaluări

- Codex Tapered Roller BearingsDocument4 paginiCodex Tapered Roller BearingsAnonymous Cpe6vcÎncă nu există evaluări

- PB-1 Extrusion ManualDocument51 paginiPB-1 Extrusion ManualLubomirBenicek50% (2)

- Pipelaying and InstallationDocument31 paginiPipelaying and InstallationDaniel Inemugha100% (6)

- DWG RegisterDocument7 paginiDWG RegisterPrasadÎncă nu există evaluări