Documente Academic

Documente Profesional

Documente Cultură

Atm3 4 01 Matko 177 188

Încărcat de

Saa D ShamimTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Atm3 4 01 Matko 177 188

Încărcat de

Saa D ShamimDrepturi de autor:

Formate disponibile

ISSN 0005−1144

ATKAAF 42(3−4), 177−188 (2001)

Drago Matko, Gerhard Geiger, Thomas Werner

Modelling of the Pipeline as a Lumped Parameter System

UDK 681.518.3

IFAC IA 5.3.1;2.8.1

Original scientific paper

The paper deals with the simplification of pipeline models. A nonlinear distributed parameters model is line-

arised and its transfer function given. The pipeline is represented as a two-port system. Two causal representations

– the hybrid ones which are used in practice – are studied further. They involve three different transcendent trans-

fer functions which are then approximated by rational transfer functions using a Taylor series expansion. The de-

rived models are valid for low frequencies and are used to discuss how to obtain better approximation. They

equalise the high frequency gain of the transcendent and rational transfer functions and employ a Padé approxi-

mation. Due to the approximation of the high frequency gain, the derived models are only valid for a class of

models – namely – well damped pipelines. The derived models which describe the pipeline as a lumped parame-

ter system were verified on a real pipeline using experiment data.

Key words: modelling, model approximation, distributed-parameter system, lumped-parameter system, pipelines

1 INTRODUCTION are given. They include three different transcendent

Models of pipelines are used for different pur- transfer functions which are approximated by ratio-

poses, such as controller design, leakage monitoring nal transfer functions in Section 3. In Section 5, the

etc. Observer-based leak detection and localisation verification of the simplified models by real experi-

schemes for example require a pipeline model to ment data is presented.

compute the states of a pipeline without leak [1, 2].

The first industrial applications demonstrate the 2 MATHEMATICAL MODELS OF THE PIPELINE

performance of observer-based methods [3].

In these schemes, the observer is derived using a The analytical solution for unsteady flow prob-

mathematical model of the pipeline. The one-di- lems is obtained by using the equations for conti-

mensional compressible fluid flow through pipelines nuity, momentum and energy. These equations cor-

is governed by nonlinear partial differential equa- respond to the physical principles of mass conserva-

tions [4]. Pipelines are therefore distributed para- tion, Newton's second law F = ma and energy con-

meter systems. To date, there is no general closed- servation. Applying these equations leads to a cou-

-form solution. Numerical approaches like the Met- pled non-linear set of partial differential equations.

hod of Characteristics are used instead [5] yielding Further problems arise in the case of turbulent

the computational background for the observer algo- flow, which introduces stochastic flow behaviour.

rithms. Therefore, the mathematical derivation for the flow

through a pipeline is a mixture of both theoretical

However, sometimes simple models of the and empirical approaches.

pipeline in the form of a lumped parameter system

are use-ful: the classical system theory for Multi- The following assumptions for the derivation of a

Input Multi-Output (MIMO) systems can be used mathematical model of the flow through pipelines

e.g. for controller design and system identification. are made: Fluid is compressible, viscous, adiabatic

The re-sulting algorithms are less time-consuming and homogenous. The resulting nonlinear distribu-

and hen-ce better suited for critical real time appli- ted parameters model is described by the following

cations. Additionally, the analysis of fluid transients two partial differential equations:

caused by leaks is much easier.

A ¶p ¶q

⋅ =− , (1)

The paper is organised as follows: in Section 2 2

a ¶t ¶x

the nonlinear distributed parameter model of the

pipeline is linearised and represented as a two-port 1 ¶q

⋅ + ρg sin α +

λq bg

q2 = −

¶p

, (2)

system. Two representations of the pipeline's model A ¶t 2 DA 2 ρ ¶x

AUTOMATIKA 42(2001) 3−4, 177−188 177

Modelling of the Pipeline ... D. Matko, G. Geiger, T. Werner

where A, D and α are the profile, the diameter and LM 1

the inclination of the pipeline respectively, p the

LM OP = M coshc nL h

PL

c hOP L P O

− Z K tanh nL p

pressure, q the mass flow rate, λ the friction coeffi- p

PP MQ P 0

(10)

cient, ρ the density of the fluid, g the gravity con-

stant and a the velocity of sound.

NQ Q MM Z1 tanhc nL h

0 p

1

cosh c nL h PQ

N Q L

N K p

Nonlinear equations (2, 1) are linearised and writ- 3. Impedance representation: Inputs Q0 , QL , outputs

ten in a form using notations common in the analy- P0 , PL:

sis of electrical transmission lines. Also, the gravity

L 1 O

LM P OP = MM Z cothc nL h −ZK

effect is neglected – included into the working

point. The corresponding system of linear partial 0

K p

c h PP LMQ OP (11)

sinh nL p L

differential equations is

N P Q MM− Z sinh 1nL

L K −ZK coth c nL h P N Q Q

p

PQ 0

¶q ¶p N c h p

L + Rq = − (3)

¶t ¶x 4. Admittance representation: Inputs P0 , PL , outputs

¶p ¶q Q0 , QL:

C =− (4)

¶t ¶x

L 1 − 1 ⋅ 1 O

where L = 1 , R = 2

λ( q ) q −

( q is the flow at the wor-

LM Q OP = MM Z cothc nL h Z sinhc nL h PP LM P OP (12)

0 K

p

K p 0

A A ρD NQ Q MM Z1 ⋅ sinh 1nL − Z1 cothc nL h PP N P Q

L p L

king point) and C = A2 are the inertance (inductivi- N K c h p Q K

a

ty), resistance and capacitance per unit length, res- It should be noted that the forms 1 to 4 repre-

pectively. sent causal models, whilst Equations (5, 6) repre-

sent a noncausal model with inputs P0, Q0 and out-

The next step in the derivation of a simple mo- puts PL, QL. This completes the derivation of the

del of the pipeline is the analytical solution of linear transfer functions of the linearised pipeline. The re-

quations (3, 4). The Laplace transformation of them sulting transfer functions are transcendent. In the

yields the linear non-causal model next section, their approximations by rational trans-

fer functions will be given.

af af c h af c h

PL s = Z K Q0 s sinh nL p + P0 s cosh nL p (5)

3 LINEAR PIPELINE MODEL WITH LUMPED

Q a sf = Q a s f cosh c nL h − 1 P a s f sinh a nLpf

L 0 p 0 (6) PARAMETERS

Z K

In this section, the rational transfer functions of

where Lp is the length of the pipeline and

the pipeline will be derived. There are seven diffe-

n= a Ls + Rf ⋅ Cs rent transcendent transfer functions in the four pi-

(7)

peline forms of the previous section:

Z K = Ls + R = Ls + R .

(8) 1 , 1 tanh nL ,

c h c h

Z K tanh nL p ,

n Cs p

c h

cosh nL p ZK

Finally, the linearised model of the pipeline can Zk coth c nL h , ZK ⋅ 1 ,

p

be written in one of the following four forms which

differ from each other with respect to the model in-

c h

sinh nL p

1 ⋅ coth nL 1 ⋅ 1

puts (independent quantities) and outputs (depen-

dent quantities) ZK p c h and c h

Z K sinh nL p

.

1. Hybrid representation: Inputs Q0 , PL , outputs QL , First, simple models will be derived. These models

P0 : are only valid for low frequencies. On the basis of

a discussion of simple models, better models, which

LM 1

c h OP

Z K tanh nL p approximate the transcendent transfer functions in

LM OP M

P0

=

cosh nL p c h P LM P OP L

(9)

a broad frequency range, will be derived in subsec-

− 1 tanh nL p tion 4.

N Q MM

QL

ZK

c h coshc1nL h PP NQ Q 0

N Q p

3.1 Models for low frequencies

2. Hybrid representation: Inputs QL , P0 , outputs Q0 , Simple models are obtained by expanding the

PL: transcendent transfer function into a Taylor series.

178 AUTOMATIKA 42(2001) 3−4, 177−188

D. Matko, G. Geiger, T. Werner Modelling of the Pipeline ...

They are as follows: at the other end of the pipeline are kept constant)

1 the shock wave originating at one end of the pipe-

1. Hybrid representation: = line returns after reflection at the other end of the

c h

cosh nL p

pipeline with the opposite phase. The half-period of

Reverse pressure gain at upstream dead end: the oscillations is consequently equal to the time

P0 needed by the shock wave to travel along the pipe-

PL Q0 = 0 line and back. This gives the radial eigen-frequency

Flow gain at downstream reservoir: ω0 = 2p = p ⋅ 1 (16)

QL 4 LC L p 2 LC L p

PL = 0

Q0

which is only 10 % different from ω′0 . The static gain

Pressure gain at downstream dead end: of the treated transfer function is 1, meaning that the

PL step change of the flow at one end of the pipeline

QL = 0 results in the same steady state change of the flow

P0

at the other end (if the pressure at the first end re-

Reverse flow gain at upstream reservoir :

mains unchanged). Similarly, the step change of the

Q0 pressure at one end results in the same steady state

P0 = 0

QL change of the pressure at the other end (if the stea-

dy state flow remains unchanged).

1 = 1 ≈ 1

c h

cosh nL p cosh ea f

Ls + R ⋅ Cs L p j 2. Hybrid representation:

ZK

d i

tanh nL p =

≈ 1 . (13) Negative output admittance at upstream

FH 21 L LC + 241 L R C IK s

2

p

4

p

2 2 2

+ 1 L2p RCs + 1

2

QL

dead end: Q =0

PL 0

This transfer function describes a change of one Input admittance at downstream dead end:

quantity (flow, pressure) at one end of the pipeline, Q

if the same quantity is changing at the other end, − 0 QL = 0

whilst the other quantity remains constant, e.g. the P0

change of the flow at the pipeline's output, if the

1 tanh nL = Cs ⋅ tanh

flow changes at the input of the pipeline whilst the

pressure at the output of the pipeline remains con- ZK p c h Ls + R e a Ls + RfCs L j ≈

p

stant. The transfer function (13) can be interpreted 1 L3 RC 2 s 2 + L Cs

as a second order system with the eigen-frequency 6 p p

≈ .

1 2 ⋅ 1

FH

2 p

24 p

IK

1 L2 LC + 1 L4 R 2 C 2 s 2 + 1 L2 RCs + 1

2 p

ω 0′ = ≈ (14)

1 L2 LC + 1 L4 R 2 C 2 LC L p (17)

2 p 24 p This transfer function describes a change of the

and damping flow at one end of the pipeline, if the pressure is

changing at the same end whilst the flow at the

ζ≈ C ⋅ R⋅ L (15) other end of the pipeline remains constant. It has a

p

2L zero in the origin of the s plane which causes its

static gain to be 0. This is obvious since the flow at

where the second term in the square root of equa- both ends of the pipeline must be the same in the

tion (14) was neglected for small R. The eigen-fre- steady state.

quency can be interpreted as follows: with hybrid

boundary conditions (pressure at one end and flow A higher order Taylor extension of the transcen-

dent transfer function would result in:

1 tanh nL = Cs ⋅ tanh

ZK

c h

p

Ls + R e a Ls + RfCs L j ≈

p

60 6

FH 120

IK

1 C L p 5 RLs 4 + 1 C 2 Lp 3 L + 1 C 3 Lp 5 R 2 s 3 + 1 L3 RC 2 s 2 + L Cs

6 p p

≈ . (18 )

24 12

FH 24 p 2 p

IK

1 L2 C 2 Lp 4 s 4 + 1 RLC 2 Lp 4 s 3 + 1 L2 LC + 1 L4 R 2 C 2 s 2 + 1 L2 RCs + 1

2 p

AUTOMATIKA 42(2001) 3−4, 177−188 179

Modelling of the Pipeline ... D. Matko, G. Geiger, T. Werner

For R→0 this transfer function has two complex Negative output impedance at upstream

conjugate zeros at the radial frequency PL

dead end: − Q0 = 0

6 ⋅ 1 QL

ω= (19)

LC L p

Ls + R coth

which is close to the twice eigen-frequency of the

Z K coth nL p = c h Cs e a Ls + RfCs L j ≈ p

pipeline with hybrid boundary conditions. FH 21 L LC + 241 L R C IK s + 21 L RCs + 1

2

p

4

p

2 2 2 2

p

≈

3. Hybrid representation: Z K tanh nL p = c h FH 16 C Lp L + 1201 C Lp R IK s + 16 L RC s + L Cs .

2 3 3 5 2 3 3

p

2 2

p

Input impedance at downstream reservoir : (23)

P0

Q0 PL = 0 This transfer function describes the change of

the pressure at one end of the pipeline if the flow

Negative output impedance at upstream is changing at the same end while the flow at the

PL other end remains constant. It has a pole in the

reservoir : − P0 = 0 origin of the s plane and has on infinite static gain.

QL

This is obvious since different steady state flows on

Ls + R tanh both ends of the pipeline cause a constant increase

c h

Z K tanh nL p =

Cs e a Ls + RfCs L j ≈ p of the pressure. The remaining dynamics of the

transfer function for small R is a second order sys-

1 L PLCs + F L L + 1 L R CI s + L R

3 2 3 2 tem with the eigen-frequency

≈

3 p H 6 p K p p

FH 21 L LC + 241 L R C IK s + 21 L RCs + 1 . (20)

2

p

4

p

2 2 2 2

p ω= 6 ⋅ 1 (24)

LC L p

This transfer function describes a change of the

pressure at one end of the pipeline, if the flow is which is close to the twice eigen-frequency of the

changing at the same end whilst the pressure at the pipeline with hybrid boundary conditions and the

other end remains constant. Its static gain is LpR damping

which corresponds to the static change of the pres- 3C ⋅ R ⋅ L .

sure due to changing flow. ζ≈ p (25)

2L

A higher order Taylor extension of the transcen- This is the inverse of the case 2.

dent transfer function would result in:

Ls + R ⋅ tanh

e a Ls + RfCs L j ≈

Z K tanh nL p = c h Cs p

1 RL Lp C s + F 1 L Lp C + 1 R LLp C I s + 1 L RLCs + F L L + 1 L R CI s + L Cs

2 5 2 4 2 3 2 5 2 3 3 2 3 2

≈

40 H6 40 K 3 H 6 K .

p p p p

(21)

1 L C Lp s + 1 RLC Lp s + F 1 L LC + 1 L R C I s + 1 L RCs + 1

2 2 4 4 2 4 3 2 4 2 2 2 2

24 12 H2 24 K 2 p p p

For R→0 this transfer function has two complex

conjugate zeros at the radial frequency

ω= 6 ⋅ 1 (22)

LC L p 5. Impedance representation: Z K 1 =

which is close to the twice eigen-frequency of the

sinh nL p c h

pipeline with hybrid boundary conditions. Negative reverse transimpedance at upstream

P0

dead end: − Q0 = 0

4. Impedance representation: Z K coth nL p = c h QL

Input impedance at downstream dead end: Negative transimpedance at downstream

P0 PL

dead end: − QL = 0

QL = 0 Q0

Q0

180 AUTOMATIKA 42(2001) 3−4, 177−188

D. Matko, G. Geiger, T. Werner Modelling of the Pipeline ...

1 Ls + R ◊ 1 This transfer function describes the change of

ZK = ª the flow at one end of the pipeline if the pressure

sinh nL p c h Cs sinh ea f

Ls + R Cs L p j is changing at the same end while the pressure at

1 the other end remains constant. This is an inverse

ª

FH 16 C Lp L + 1201 C Lp R IK s + 16 L RC s + L Cs .

2 3 3 5 2 3 3

p

2 2

p

of the case 3, so a higher order Taylor extension of

the transcendent transfer function would result in:

(26)

1 coth nL = Cs coth

e a Ls + RfCs L j ª

ZK p c h Ls + R p

1 L C Lp s + 1 RLC Lp s + F 1 L LC + 1 L R C I s + 1 L RCs + 1

2 2 4 4 2 4 3 2 4 2 2 2 2

ª

24 12 H2 24 K 2 .

p p p

(28)

1 RL Lp C s + F 1 L Lp C + 1 R LLp C I s + 1 L RLCs + F L L + 1 L R CI s + L R

2 5 2 4 2 3 2 5 2 3 3 2 3 2

40 H6 40 K 3 H 6 K p p p p

This transfer function describes the change of

the pressure at one end of the pipeline, if the flow

is changing at the other end while the flow at the For R ª 0 this transfer function has a pole at the

same end remains constant. It has a pole at the ori- origin of the s plane, i.e. the integral character. The

gin of the s plane, causing its integral character. remaining dynamics of the transfer function is a

The remaining dynamics of the transfer function for second order system with the eigen-frequency

small R is again a second order system with the

same eigen-frequency and damping as in the previ- 6 ◊ 1

ous case. ω= (29)

LC L p

1 coth nL =

6. Admittance representation:

ZK p c h which is close to the twice eigen-frequency of the

pipeline with hybrid boundary conditions and the

Input admittance at downstream reservoir : damping

Q0

P0 PL = 0

ζª 3C ◊ R ◊ L . (30)

p

2L

Negative output admittance at upstream

QL

reservoir : - P0 = 0 7. Admittance representation: 1 =

PL

Z K sinh nL p c h

1 coth nL = Cs coth Negative reverse transadmittance at upstream

ZK p c h Ls + R e a Ls + RfCs L j ª p

Q0

reservoir : - P0 = 0

FH

1 L2 LC + 1 L4 R 2 C 2 s 2 + 1 L2 RCs + 1 IK PL

2 p 24 p 2 p Transadmittance at downstream reservoir:

ª .

3 p

6

FH

1 L3 RLCs 2 + L L + 1 L3 R 2 C s + L R

p p p

IK QL

(27) PL = 0

P0

1 = Cs ◊ 1 ª

Z K sinh nL p c h Ls + R sinh

e a Ls + Rf Cs L j p

ª 1 . (31)

40 6

FH

40 3 6 p

IK

1 RL2 Lp 5 C 2 s 4 + 1 L2 Lp 3 C + 1 R 2 LLp 5 C 2 s 3 + 1 L3 RLCs 2 + L L + 1 L3 R 2 C s + L R

P p p

FH IK

This transfer function describes the change of

the flow at one end of the pipeline if the pressure

is changing at the other end while the pressure at

AUTOMATIKA 42(2001) 3-4, 177-188 181

Modelling of the Pipeline ... D. Matko, G. Geiger, T. Werner

the same end remains constant. It has a static gain The eigen frequency ω0 (Equation 16) determi-

1 which corresponds to the static change of the nes the coefficient

Lp R

flow due to changing pressure. For R ª 0 this trans- a2 = 12 = 42 L2p LC . (36)

fer function has a pole at the origin of the s plane, ω0 p

i.e. the integral character. The remaining dynamics

of the transfer function is a second order system The high frequency gain is determined by

with the eigen-frequency and damping as in the

previous case. 1

a f

lim G0 jω = lim (37)

ωÆ∞ ωÆ∞

cosh e a Ljω + Rf Cjω L j p

4 MODELS FOR WELL-DAMPED PIPELINES

which does not exist. However,

In this section, the pipeline will be presented as

a second order lumped parameter system in the C RL p

± e ( Ljω + R ) C j ω L p j ± ◊

form lim e =e L 2 (38)

ωÆ∞

2

b2 s + b1 s + b0 - sTd

af

G s =

a2 s 2 + a1 s + a0

e (32) does exist and in the case

C ◊ RL p >> 1

where Td is the dead time. The transcendent trans- (39)

L 2

fer functions will be approximated by a rational

transfer function with dead time however only for a the high frequency gain (37) can be approxima-

class of pipelines, as shown later. The procedure of ted by

the approximation is as follows: as the simple mo- C ◊ RL p

b2 -

dels are valid for low frequencies, their static gain is

exact and will be applied to the derived models.

lim G s =

ωÆ∞

af a2

ª 2e L 2 (40)

Also, the eigen-frequency as discussed in the earlier yielding

subsection (Equation 16) will be used. Next, the high

C ◊ RL p

frequency gain will be approximated from transcen- -

dent function and known dead time will be applied. b2 = 82 LCL2p e L 2 . (41)

p

In this way, four coefficients of the transfer func-

tion (32) are determined. The remaining two are The condition (39) can also be written as

obtained using a Padé approximation of the trans-

cendent transfer function. Since the high frequency ζ >> 1 ,

2

gain approximation is valid only under certain con-

ditions, the derived models are only valid for one so the derived models are valid for well damped

class of pipelines. The derived models are as fol- pipelines only.

lows The remaining coefficients b1 and a1 are de-

termined using a Padé approximation of (33) i.e.

1. Hybrid representation: Reverse pressure gain at up- by comparing the corresponding terms of the

stream dead end, Flow gain at downstream reser- following two series expansions:

voir, Pressure gain at downstream dead end and

Reverse flow gain at upstream reservoir a2 s 2 + a1 s + 1

=

1 1 b2 s 2 + b1 s + 1

af

G0 s =

c h =

c h

cosh nL p e - sTd

e - sTd . (33)

cosh nL p a f b

= 1 + a1 - b1 s + a2 - b2 - b a1 - b1 s 2 +K a fg (42)

Since this transfer function connects quantities at and

different ends of the pipeline, the dead time for

- LCs L p

(33) is known – it is the time needed for the

shock wave to travel along the pipeline.

cosh e b Ls + Rg Cs L j e = p

F1

= 1 + G L RC - L LC J s +

2 I

Td = LC L p . (34) H2 p

K p

F

+ G L LC +

2 1 1

L R C - L RC 4 2 2 3 IJ

LC s 2 + K

The static gain of (33) is 1, so the coefficients H p

24 2

p p

K

a0 = 1 The result is (taking into account Equations 36

(35)

b0 = 1 and 41)

182 AUTOMATIKA 42(2001) 3-4, 177-188

D. Matko, G. Geiger, T. Werner Modelling of the Pipeline ...

F - C◊

RL p

- 24 p2 L - p2 L2p R 2 C + 12 p2 L p R LC

I

GH

L p C 96 L - 192 Le L 2

JK

b1 = (43)

d

12 p2 L p RC - 2 LC i

F - C◊

RL p

+ 5p2 L2p R 2 C - 12 p2 L p R LC

I

GH

L p C 96 L - 192 Le L 2

JK

a1 = . (44)

d

12 p2 L p RC - 2 LC i

2. Hybrid representation: Negative output admittance Cs tanh

at upstream dead end and Input admittance at Ls + R e a Ls + Rf Cs L j = p

downstream dead end

= L p Cs - 1 L3p RC 2 + K (52)

3

G0 s = 1 tanh nL p .

af c h (45)

yields

ZK

b1 = L p ◊ C (53)

The dead time of the treated transfer function is

zero since it connects a change of the flow at

one end of the pipeline if the pressure changes a1 = 1 2 L p 12 LC + p2 L p RC .

d i (54)

3p

at the same end:

Td = 0. (46) 3. Hybrid representation: Input impedance at down-

stream reservoir and Output impedance at up-

The static gain of G0(s) is zero, so the coeffici- stream reservoir

ents

a0 = 1 (47) af c h

G0 s = Z k tanh nL p . (55)

b0 = 0.

The dead time of the treated transfer function is

The eigen frequency ω0 is the same as in the zero, since it connects a change of the pressure

previous case: at one end of the pipeline if the flow changes at

the same end, so

a2 = 12 = 42 L2p LC . (48) Td = 0. (56)

ω0 p

The static gain of G0(s) is LpR, yielding

The high frequency gain is determined by

a0 = 1 (57)

b2

= lim 1 tanh nL p = c h b0 = Lp R .

a2 ωÆ∞ Z K

The eigen-frequency is the same as in the previ-

Cjω

= lim tanh e - LCω 2 + RCjω L p = j ous two cases:

ωÆ∞ Ljω + R

C a2 = 12 = 42 L2p LC . (58)

= (49) ω0 p

L

yielding The high frequency gain is determined by

b2

b2 = 42 L2p C LC .

p

(50) = lim Z tanh nL p =

a2 ωÆ∞ k

c h

Ljω + R

The remaining coefficients b1 and a1 are deter- = lim tanh e - LCω 2 + RCjω L p = j

ωÆ∞ Cjω

mined by the same procedure as in the previous

case. A comparison of L

= (59)

C

b2 s 2 + b1 s

a2 s 2 + a1 s + 1

a f

= b1 s + b2 - b1 a1 s 2 + K (51) yielding

b2 = 42 L2p L LC . (60)

and p

AUTOMATIKA 42(2001) 3-4, 177-188 183

Modelling of the Pipeline ... D. Matko, G. Geiger, T. Werner

The remaining coefficients b1 and a1 are deter- The resulting transfer function has an integral

mined by the same procedure as in the two pre- character. Since the models are valid for well

vious cases. A comparison of damped pipelines only, a second order transfer

function is sufficient and the eigen-frequency of

b2 s 2 + b1 s + b0 the pipeline with impedance boundary condi-

= tions which is close to the twice eigen-frequency

a2 s 2 + a1 s + 1

of the pipeline with hybrid boundary conditions

a f b a

= b0 + b1 - b0 a1 s + b2 - b0 a2 + - b1 + b0 a1 a1 s 2 + K f g can not be recognised.

(61)

and

Cs e a Ls + RfCs L j = L R + FH L L - 13 L R CIK s +

Ls + R tanh

p p p

3

p

2

+ L 1 L RLC - L RFH 1 L LC + 1 L R C IK + 1 L RC FH 1 L R C - L LIK O s

3 2 4 2 2 2 3 2 2

+K (62)

NM 3 p

2 p

24 p

2 3 p PQ p p p

yields

b1 =

d

L p 288 L2p R 2 LC + p2 L4p R 4 C 2 - 288 L p RL LC - 72 p2 L2 i (63)

24 p 2

d L2p R 2 C - 3 L i

and

a1 =

d

L p 96 L p RLC - 96 L LC - 16 p2 L p RLC + 3p2 L3p R 3 C 2 i. (64)

8p 2

d L2p R 2 C - 3 L i

5. Impedance representation: Negative reverse trans-

4. Impedance representation: Input impedance at impedance at upstream dead end and negative

downstream dead end and negative output impe- transimpedance at downstream dead end

dance at upstream dead end

af 1 (68)

af

G0 s = Z K coth nL p c h (65) G0 s = Z K

c h

sinh nL p

.

The dead time of the treated transfer function is Since this transfer function connects change of

zero, since it connects a change of the pressure the pressure at one end of the pipeline if the

at one end of the pipeline if the flow changes at flow changes at the other end of the pipeline,

the same end, so the dead time for (68) is known – it is the time

Td = 0 (66) needed for the shock wave to travel along the

pipeline.

Transfer function (65) is the inverse of the

transfer function (45) so the coefficients are: Td = LC L p . (69)

a0 = 0 If the pipeline is approximated with the second

a1 = L p ◊ C order system, what is sufficient for well damped

pipelines, the known eigen-frequency can not be

a2 = 42 L2p C LC used. A determination of all coefficients of the

p second order transfer function by the Padé ap-

b0 = 1 (67) proximation results in a unsolvable system of equ-

ations. So an other procedure should be used.

b1 = 1 2 L p 12 LC + p2 L p RC

d i By this procedure it is supposed that the dyna-

3p mics (i.e. the denominator of the corresponding

b2 = 42 L2p LC . transfer function) of all hybrid representations

p of the pipeline is the same.

184 AUTOMATIKA 42(2001) 3-4, 177-188

D. Matko, G. Geiger, T. Werner Modelling of the Pipeline ...

Equation (68) can be written as: 7. Admittance representation: Reverse transadmittance

at upstream reservoir and admittance at down-

1 1

ZK

sinh nL p c h c h

= Z K coth nL p

cosh nL p c h (70) stream reservoir

af

G0 s = 1 = 1 e - sTd .

and is the product of transfer functions (65) and c h

Z K sinh nL p c h

Z K sinh nL p e - sTd

(33). The dead time is a part of the transfer

function (33). The denominator of the Padé ap- (74)

proximation of this transfer function cancels out Since this transfer function connects change of

the numerator of the Padé approximation of the the flow at one end of the pipeline if the pres-

transfer function (65), so the coefficients of the sure changes at the other end of the pipeline,

resulting transfer functions are: the dead time for (74) is known – it is the time

a0 = 0

a1 = L p ◊ C

a2 = 42 L2p C LC

p

b0 = 1

F RL p

I (71)

- C◊ 2 2

L C G 96 L - 192 Le

p

L 2 - 24p L - p L2p R 2 C + 12 p2 L p R LC J

b1 =

H K

d

12 p2 L p RC - 2 LC i

C RL p

b2 = 8 LCL2 e - L ◊ 2

2 p

p

6. Admittance representation: Input admittance at needed for the shock wave to travel along the

downstream reservoir and output admittance at pipeline.

upstream reservoir Td = LC L p . (75)

G0 s = 1 coth nL p

af c h (72) If the pipeline is approximated with the second

ZK

order system, what is sufficient for well damped

The dead time of the treated transfer function is pipelines, the known eigen-frequency can not be

zero, since it connects a change of the flow at used. A determination of all coefficients of the

one end of the pipeline if the pressure changes second order transfer function by the Padé ap-

at the same end, so proximation results in a unsolvable system of

equations. So again the procedure will be used

Td = 0 (73)

which supposes that the dynamics of all hybrid

Transfer function (72) is the inverse of the trans- representations of the pipeline is the same.

fer function (55) so the coefficients are: Equation (74) can be written as:

a0 = L p R

a1 =

d

L p 288 L2p R 2 LC + p2 L4p R 4 C 2 - 288 L p RL LC - 72 p2 L2 i

24p 2

d L2p R 2 C - 3 L i

a2 = 42 L2p L LC

p

b0 = 1

b1 =

d

L p 96 L p RLC - 96 L LC - 16p2 L p RLC + 3p2 L3p R 3 C 2 i

8p 2

d L2p R 2 C - 3 L i

b2 = 12 = 42 L2p LC .

ω0 p

AUTOMATIKA 42(2001) 3-4, 177-188 185

Modelling of the Pipeline ... D. Matko, G. Geiger, T. Werner

der lag with the time constant of 15 s as the flow

1 transducer dynamics.

= 1 coth nL p 1

c h (76)

Z K sinh nL pc h

ZK cosh nL p c h Accordingly these dynamics were taken into ac-

count in the verification of the lumped parameter

and is the product of transfer functions (72) and model. If the measured flow was used as the input

(33). The dead time is a part of the transfer to a model, the applied input was obtained by

function (33). The denominator of the Padé ap- an approximate deconvolution (filtering by the

proximation of this transfer function cancels out

the numerator of the Padé approximation of the Gs-1 ª 15 s + 1 ) where ε should be small, but was ta-

εs + 1

transfer function (72), so the coefficients of the ken to be 3 so as not to magnify the measurement

resulting transfer functions are: noise. The simulated output flow was first filtered

a0 = L p R

a1 =

d

L p 288 L2p R 2 LC + p2 L4p R 4 C 2 - 288 L p RL LC - 72 p2 L2 i

24p 2

d i

L2p R 2 C - 3 L

a2 = 42 L2p L LC

p

b0 = 1 (77)

F - C◊

RL p

- 24p2 L - p2 L2p R 2 C + 12 p2 L p R LC

I

GH

L p C 96 L - 192 Le L 2

JK

b1 =

d

12 p2 L p RC - 2 LC i

- C ◊ RL p

b2 = 82 LCL2p e L 2 .

p

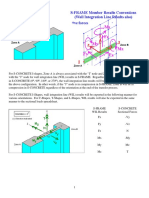

5 VERIFICATION OF THE MODELS

by Gs = 1 and then compared with the mea-

15 s + 1

The models were verified on a real pipeline with sured flow.

the following data: Length of the pipeline Lp =

= 31 146 m, diameter D = 0.143 m, relative rough- Model forms 1 and 2 as described in section 2

ness kc = 0.0291 mm, inclination α = 0 and the fluid were evaluated with the following results:

data: Density ρ = 752 kg/m3, kinematic viscosity v = 1. Hybrid representation: Inputs Q0, PL, outputs QL,

= 7.18 ¥ 10-7 m2/s and velocity of sound a = 1110 m/s. P0

Fluid transients were generated for experimental

verification by closing a shunt valve at the begin-

ning of the pipeline. This leads to a quick drop in

pressure causing fluid transients. There were no

controllers for flow rate or pump pressure.

The excitation was quite high (more than 50 % of

the steady state values of the signals). For this rea-

son, the model was linearised at 75 % of the steady

state flow (18 kg/s) yielding the parameters L = 62.3,

R = 10.6 and C = 1.3 ¥ 10-8. The damping factor for

this case is ζ = 3.37. The experimental data were

first evaluated by the solving the nonlinear partial

differential equations. The evaluation gave unsatis-

factory results due to the dynamics of the transdu-

cers. Since all the data – both input and output –

are measured, only the relative dynamics of the

pressure and flow transducers is significant. A good Fig. 1 The simulated (solid line) and the measured (dashed line)

coincidence was obtained by including the first or- flows at the end of the pipeline

186 AUTOMATIKA 42(2001) 3-4, 177-188

D. Matko, G. Geiger, T. Werner Modelling of the Pipeline ...

In Figure 1 comparison of the simulated (solid

line) and measured (dashed line) flows at the

end of the pipeline is shown.

Figure 2 depicts the simulated and the measured

pressure at the beginning of the pipeline.

Fig. 3 The simulated (solid line) and the measured (dashed line)

flows at the beginning of the pipeline

In the treated case, both terms have a magnitu-

de of about 25 bars, while their difference sho-

uld have a magnitude of 0.6 bars. The numerical

problems arising due to nonlinearities and mea-

Fig. 2 The simulated (solid line) and the measured (dashed line) surement noise magnified by the deconvolution

pressures at the beginning of the pipeline caused the failure of the validation.

6 CONCLUSION

In both figures an acceptable coincidence can be

observed. The error between the outputs of the Three transcendent transfer functions which are

model and the real plant is caused by nonlineari- parts of the linear model of the pipeline as a distri-

ties due to high excitation and, of course, by the buted parameter system are approximated by ratio-

approximation of the pipeline using a lumped pa- nal transfer functions with time delay. The approxi-

rameter model. The »noise« in the simulated sig- mations were verified on a real pipeline by using

nals (especially in Figure 2) is due to the decon- real experiment data. The approximations are only

volution of the model input signal (flow at the valid for one class of models – well damped pipe-

beginning of the pipeline) which increased the lines. Simple models for pipelines which are able to

measurement noise. oscillate are being investigated.

2. Hybrid representation: Inputs QL , P0 , outputs Q0 ,

PL REFERENCES

[1] L. Billmann, Methoden zur Lecküberwachung und Regelung

In Figure 3 the comparison of the simulated and von Gasfernleitungen. TH Darmstadt, 1985.

measured flows at the beginning of the pipeline [2] H. Siebert, Untersuchung verschiedener Methoden zur Leck-

is shown. überwachung bei Pipelines. TH Darmstadt, 1981.

Acceptable coincidence can again be observed. [3] G. Geiger, Application of a Model-Based Method for Leak

Detection and Localization. GMA-Kongress Meß- und Auto-

The verification of the fourth model (output matisierungstechnik 18./19. Juni 1988, VDI Berichte Nr.

pressure as the function of the output flow and 1397, 1998.

input pressure) failed. The reason for that failu- [4] V. L. Streeter, E. B. Wylie, Fluid Transients. McGraw-Hill,

re is as follows: according to Equation (10) the New York, 1978.

resulting output pressure is the difference of two [5] C. V. Rao, K. Eswaran, On the Analysis of Pressure Transi-

terms (pressure changes due to the change of ents in Pipelines Carrying Compressible Fluids. Int. J. Pres.

the output flow and input pressure, respectively). Ves. and Piping, 56:107–129, 1993.

AUTOMATIKA 42(2001) 3-4, 177-188 187

Modelling of the Pipeline ... D. Matko, G. Geiger, T. Werner

Modeliranje cjevovoda kao sustava s usredoto~enim parametrima. U ~lanku se opisuje postupak pojednostav-

ljenja matemati~kih modela cjevovoda. Lineariziran je nelinearni matemati~ki model s raspodijeljenim parametrima

iz ~ega je dobivena prijenosna funkcija. Cjevovod je prikazan kao dvoulazni sustav. Analizirana su dva me|usobno

povezana prikaza triju razli~itih transcedentnih prijenosnih funkcija koje se potom nadomje{taju racionalnim pri-

jenosnim funkcijama uporabom Taylorovog razvoja u red. Izvedeni modeli valjani su za niske frekvencije i koriste

se kako bi se do{lo do boljih aproksimacija. Uspore|uje se visokofrekvencijsko poja~anje transcedentnih i racional-

nih prijenosnih funkcija. Zbog aproksimacije visokofrekvencijskog poja~anja izvedeni su modeli valjani samo za

dobro prigu{ene cjevovode. Izvedeni modeli, koji opisuju cjevovod kao sustav s usredoto~enim parametrima, pro-

vjereni su na realnom cjevovodu.

Klju~ne rije~i: modeliranje, aproksimacija modela, sustav s raspodijeljenim parametrima, sustav s usredoto~enim

parametrima, cjevovod

AUTHORS’ ADDRESSES:

Drago Matko,

Faculty of Electrical Engineering

University of Ljubljana

Tr`a{ka 25, 1000 Ljubljana Slovenia

e-mail: drago.matko@@fe.uni-lj.si

Gerhard Geiger, Thomas Werner

Fachhochschule Gelsenkirchen, Germany

@fh-gelsenkirchen.de

e-mail: gerhard.geiger@

thomas.werner@@fh-gelsenkirchen.de

Received: 2001-07-12

188 AUTOMATIKA 42(2001) 3-4, 177-188

S-ar putea să vă placă și

- Analysis of Modified Isochronal Tests To Predict The Stabilized Deliverability Potential of Gas Wells Without Using Stabilized Flow DataDocument19 paginiAnalysis of Modified Isochronal Tests To Predict The Stabilized Deliverability Potential of Gas Wells Without Using Stabilized Flow DataAndreco 210198Încă nu există evaluări

- Pipe Network AnalysisDocument32 paginiPipe Network AnalysisRANJINI02VÎncă nu există evaluări

- Pge 362 Exam1Document6 paginiPge 362 Exam1Saa D ShamimÎncă nu există evaluări

- ANSI-SMACNA 2006 HvacDuctStandardsDocument64 paginiANSI-SMACNA 2006 HvacDuctStandardsErica MorrisonÎncă nu există evaluări

- Fundamentals of Thermodynamics (6th Edition) SONNTAG, BORGNAKKE VAN WYLENDocument814 paginiFundamentals of Thermodynamics (6th Edition) SONNTAG, BORGNAKKE VAN WYLENDarwinQuin63% (8)

- Extracted Geotechnical Sample ProblemDocument12 paginiExtracted Geotechnical Sample ProblemFrancesca DaisyJaneÎncă nu există evaluări

- CAPE Physics Unit 2 Paper 2 2008Document18 paginiCAPE Physics Unit 2 Paper 2 2008migo1010% (1)

- Astm F1877 PDFDocument14 paginiAstm F1877 PDFMohdhafizFaiz MdAliÎncă nu există evaluări

- The TurbochargerDocument19 paginiThe TurbochargerAbdallah MansourÎncă nu există evaluări

- Analysis of Dynamic Characteristics of Selected Pneumatic SystemsDocument9 paginiAnalysis of Dynamic Characteristics of Selected Pneumatic SystemshamzaÎncă nu există evaluări

- Flow Pressure Analysis of Pipe Networks With Linear Theory MethodDocument5 paginiFlow Pressure Analysis of Pipe Networks With Linear Theory MethodmihretuÎncă nu există evaluări

- Transient Analysis of Isothermal Gas Flow in Pipeline NetworkDocument9 paginiTransient Analysis of Isothermal Gas Flow in Pipeline NetworkBakhytzhan AssilbekovÎncă nu există evaluări

- The Numerical Modelling of Flows in Complex Pipe NetworksDocument6 paginiThe Numerical Modelling of Flows in Complex Pipe NetworksEmmanuelEkhaizorÎncă nu există evaluări

- Design of Natural Circulation BoilerDocument12 paginiDesign of Natural Circulation BoilerALIyilmazÎncă nu există evaluări

- Modeling, Simulation and Control of High Speed Nonlinear Hydraulic ServoDocument13 paginiModeling, Simulation and Control of High Speed Nonlinear Hydraulic ServoJoseph JoseÎncă nu există evaluări

- Flow Reactor Models For Fluid-Fluid Systems, Based On The Two-Film TheoryDocument6 paginiFlow Reactor Models For Fluid-Fluid Systems, Based On The Two-Film TheoryFadwah MokhtarÎncă nu există evaluări

- 1 s2.0 S0307904X08000607 Main PDFDocument17 pagini1 s2.0 S0307904X08000607 Main PDFalorenzo66Încă nu există evaluări

- Mathematical Modeling of Two Tank System Ijariie4840Document8 paginiMathematical Modeling of Two Tank System Ijariie4840Abeng YogtaÎncă nu există evaluări

- Numerical Simulation of Gasification Process On Rib-Tube of Open Rack VaporizerDocument7 paginiNumerical Simulation of Gasification Process On Rib-Tube of Open Rack VaporizerabdoÎncă nu există evaluări

- Optimal Numerical Method For Simulating Dynamic Flow of Gas in PipelinesDocument11 paginiOptimal Numerical Method For Simulating Dynamic Flow of Gas in PipelinesBakhytzhan AssilbekovÎncă nu există evaluări

- Theory Important 2Document9 paginiTheory Important 2Anik MondalÎncă nu există evaluări

- T.R.Fietz. STEADY FLOW IN SMALL PIPE NETWORKS USING LINEAR THEORY.1973Document29 paginiT.R.Fietz. STEADY FLOW IN SMALL PIPE NETWORKS USING LINEAR THEORY.1973Вася ПупкинÎncă nu există evaluări

- Verification of Transient Gas Flow Simulation Model: PSIG 1010Document10 paginiVerification of Transient Gas Flow Simulation Model: PSIG 1010Yogesh JagdaleÎncă nu există evaluări

- Articulo 8-5 PDFDocument10 paginiArticulo 8-5 PDFMiguel OrtegaÎncă nu există evaluări

- Fast Decoupled Load Flow: Hypothesis, Derivations, and TestingDocument7 paginiFast Decoupled Load Flow: Hypothesis, Derivations, and TestingjasonkinÎncă nu există evaluări

- Gas Line Pulse AnalysisDocument6 paginiGas Line Pulse AnalysisSerguÎncă nu există evaluări

- CFD Simulation of The Turbulent Flow of Pulp Fibre SuspensionsDocument11 paginiCFD Simulation of The Turbulent Flow of Pulp Fibre SuspensionsAntonio HazmanÎncă nu există evaluări

- Generalized Averaging Method For Power Conversion Circuits: Seth R. Sanders, Z. Liu, and George C - VergheseDocument9 paginiGeneralized Averaging Method For Power Conversion Circuits: Seth R. Sanders, Z. Liu, and George C - VergheseLazaro S. EscalanteÎncă nu există evaluări

- EasyChair Preprint 1660Document9 paginiEasyChair Preprint 1660HendraMasvikaÎncă nu există evaluări

- SCS & CFD PDFDocument10 paginiSCS & CFD PDFAvinash ParmarÎncă nu există evaluări

- UntitledDocument14 paginiUntitledMed MaxÎncă nu există evaluări

- Advanced Transformer Control Modeling in An Optimal Power Flow Using Newton's MethodDocument9 paginiAdvanced Transformer Control Modeling in An Optimal Power Flow Using Newton's MethodHoracio Manuel Ayala DazaÎncă nu există evaluări

- ISA Transactions: Farshad Merrikh-Bayat, Masoud Karimi-GhartemaniDocument6 paginiISA Transactions: Farshad Merrikh-Bayat, Masoud Karimi-Ghartemaniapi-19660864Încă nu există evaluări

- Simulation of Transients in Unerground Cables With Frequency Dependent ModalDocument12 paginiSimulation of Transients in Unerground Cables With Frequency Dependent ModalMadhusudhan Srinivasan100% (1)

- MITRES 6 007S11 Lec17Document14 paginiMITRES 6 007S11 Lec17Henry Lois Davila AndradeÎncă nu există evaluări

- Markov Channel WirelessDocument28 paginiMarkov Channel WirelessJoão RamosÎncă nu există evaluări

- Difference Between Variable & Fixed Speed Machined in Hydro Power ProjectsDocument14 paginiDifference Between Variable & Fixed Speed Machined in Hydro Power ProjectsHema KumarÎncă nu există evaluări

- Moment Models of General Transmission Lines With Application To Interconnect Analysis and OptimizationDocument37 paginiMoment Models of General Transmission Lines With Application To Interconnect Analysis and Optimizationavishek2byÎncă nu există evaluări

- Modeling of A DC Plasma Torch in Laminar and Turbulent FlowDocument24 paginiModeling of A DC Plasma Torch in Laminar and Turbulent FlowVerayoot1357Încă nu există evaluări

- Commun Nonlinear Sci Numer SimulatDocument9 paginiCommun Nonlinear Sci Numer SimulatAhmed S. El DenÎncă nu există evaluări

- System-Level Analysis of Chilled Water Systems Aboard Naval ShipsDocument6 paginiSystem-Level Analysis of Chilled Water Systems Aboard Naval ShipsAlin NanuÎncă nu există evaluări

- Behavior of Current Transformers (CTS) Under Severe Saturation ConditionDocument5 paginiBehavior of Current Transformers (CTS) Under Severe Saturation ConditionAdianto Ari PurwanaÎncă nu există evaluări

- Two Way Finite Automata With Quantum and Classi - 2002 - Theoretical Computer SCDocument13 paginiTwo Way Finite Automata With Quantum and Classi - 2002 - Theoretical Computer SCwassimÎncă nu există evaluări

- The Flow of Power-Law Fluids in Axisymmetric Corrugated TubesDocument16 paginiThe Flow of Power-Law Fluids in Axisymmetric Corrugated Tubesabcdefg43212004Încă nu există evaluări

- Inversor de Fuente de Corriente Trifásico de Una Etapa para Sistema Fotovoltaico Conectado A La RedDocument9 paginiInversor de Fuente de Corriente Trifásico de Una Etapa para Sistema Fotovoltaico Conectado A La RedeliasÎncă nu există evaluări

- IAHR WG1 2006 Nicolet FinalDocument16 paginiIAHR WG1 2006 Nicolet FinalFolpoÎncă nu există evaluări

- Shanthi PavanDocument12 paginiShanthi PavanAasif HameedÎncă nu există evaluări

- A Computer Model For Three-Dimensional Flow in FurnacesDocument10 paginiA Computer Model For Three-Dimensional Flow in FurnacesGunvir SinghÎncă nu există evaluări

- Basic Integrated Modelling: A Case Study: Mario E. Salgado and Diego R. OyarzúnDocument15 paginiBasic Integrated Modelling: A Case Study: Mario E. Salgado and Diego R. Oyarzúnñ=?!2Încă nu există evaluări

- The Influence of The Lorenz System Fractionality oDocument5 paginiThe Influence of The Lorenz System Fractionality oJulexy AntonellaÎncă nu există evaluări

- Non-Newtonian Tangential Flow in Cylindrical Annuli: TadmorDocument10 paginiNon-Newtonian Tangential Flow in Cylindrical Annuli: TadmorAlejandro Serrano ChavezÎncă nu există evaluări

- Calculating SpectraDocument16 paginiCalculating Spectraziggie_lenzÎncă nu există evaluări

- A Numerical Method For Identifying The Location of A Fluid Leak in A PipelineDocument6 paginiA Numerical Method For Identifying The Location of A Fluid Leak in A PipelinerealÎncă nu există evaluări

- Fast Linear Parameter Varying Model Predictive Control of Buck DC-DC Converters Based On FPGADocument13 paginiFast Linear Parameter Varying Model Predictive Control of Buck DC-DC Converters Based On FPGAnhatvpÎncă nu există evaluări

- Part B - System of Equations For Pipe NetworkDocument137 paginiPart B - System of Equations For Pipe Networksamadony100% (2)

- Model of The Coupled Transmission Lines With A Non-Uniform DielectricDocument6 paginiModel of The Coupled Transmission Lines With A Non-Uniform DielectricGrant HeilemanÎncă nu există evaluări

- Phase Domain Modelling of Frequency Dependent Transmission Lines by Means of An Arma ModelDocument11 paginiPhase Domain Modelling of Frequency Dependent Transmission Lines by Means of An Arma ModelMadhusudhan SrinivasanÎncă nu există evaluări

- Letter: Resolving The Energy Levels of A Nanomechanical OscillatorDocument11 paginiLetter: Resolving The Energy Levels of A Nanomechanical OscillatorFausto CésarÎncă nu există evaluări

- Tutorial On Computer-Aided Analysis Switched-Capacitor CircuitsDocument19 paginiTutorial On Computer-Aided Analysis Switched-Capacitor CircuitsnidhalÎncă nu există evaluări

- Technology: Schweppe CambridgeDocument6 paginiTechnology: Schweppe CambridgeAnonymous eOLCLhÎncă nu există evaluări

- Mercado 2001 Modeling Flow and Heat Transfer in Tubes Using A Fast CFD FormulationDocument10 paginiMercado 2001 Modeling Flow and Heat Transfer in Tubes Using A Fast CFD FormulationeliastorcaÎncă nu există evaluări

- MOCDocument7 paginiMOCAKHILESH PASWANÎncă nu există evaluări

- New Model For Transformer Saturation Characteristics by Including HysteresisDocument7 paginiNew Model For Transformer Saturation Characteristics by Including HysteresisNohelia CruzÎncă nu există evaluări

- Effects of Air Entrainment On Fluid Transients in Pumping SystemsDocument7 paginiEffects of Air Entrainment On Fluid Transients in Pumping SystemsIjaz FazilÎncă nu există evaluări

- Modeling Szymczyk Transactions 130 2015Document10 paginiModeling Szymczyk Transactions 130 2015Jack CavaluzziÎncă nu există evaluări

- Reviews in Computational Chemistry, Volume 31De la EverandReviews in Computational Chemistry, Volume 31Abby L. ParrillÎncă nu există evaluări

- Calculus on Heisenberg Manifolds. (AM-119), Volume 119De la EverandCalculus on Heisenberg Manifolds. (AM-119), Volume 119Încă nu există evaluări

- Quiz Python Effective Programming Week 1Document2 paginiQuiz Python Effective Programming Week 1Saa D ShamimÎncă nu există evaluări

- RARBGDocument1 paginăRARBGSaa D ShamimÎncă nu există evaluări

- West Nile Delta Nooros Atoll: Flow Regimes Size of Each Compartment Material-Balance AnalysisDocument2 paginiWest Nile Delta Nooros Atoll: Flow Regimes Size of Each Compartment Material-Balance AnalysisSaa D ShamimÎncă nu există evaluări

- Quiz#2Document3 paginiQuiz#2Saa D Shamim100% (1)

- Eng. Mohsin Naeem: Career ObjectiveDocument2 paginiEng. Mohsin Naeem: Career ObjectiveSaa D ShamimÎncă nu există evaluări

- Quiz Python Effective Programming Week 2Document2 paginiQuiz Python Effective Programming Week 2Saa D ShamimÎncă nu există evaluări

- DFDGFHGDocument101 paginiDFDGFHGSaa D ShamimÎncă nu există evaluări

- CyberGhost - Login DataDocument1 paginăCyberGhost - Login DataSaa D ShamimÎncă nu există evaluări

- Median ModeDocument3 paginiMedian Modekhelanmm6085Încă nu există evaluări

- RRDocument1 paginăRRSaa D ShamimÎncă nu există evaluări

- MCAT Uhs Past Paper (2008-2016)Document180 paginiMCAT Uhs Past Paper (2008-2016)Rocky Dood Lolz83% (6)

- Acidizing Oil Natural Gas Briefing Paper v2Document5 paginiAcidizing Oil Natural Gas Briefing Paper v2Radu Teodor GoranÎncă nu există evaluări

- DehydrationDocument13 paginiDehydrationSaa D ShamimÎncă nu există evaluări

- Measurement of Flow of A Gas (Repaired)Document30 paginiMeasurement of Flow of A Gas (Repaired)Saa D ShamimÎncă nu există evaluări

- Wcms 110199Document344 paginiWcms 110199jkÎncă nu există evaluări

- Hosts UmbrellaDocument1 paginăHosts UmbrellaFabsor SoralÎncă nu există evaluări

- Mdcat PDFDocument47 paginiMdcat PDFsajidÎncă nu există evaluări

- Numerical Analysis - MTH603 Handouts Lecture 21Document5 paginiNumerical Analysis - MTH603 Handouts Lecture 21roshanpateliaÎncă nu există evaluări

- Project Management and PlanningDocument31 paginiProject Management and PlanningSaa D ShamimÎncă nu există evaluări

- Welltest Cptoauthor PDFDocument6 paginiWelltest Cptoauthor PDFsdc rizkiÎncă nu există evaluări

- Saturation Monitoring With The RST Reservoir Saturation ToolDocument11 paginiSaturation Monitoring With The RST Reservoir Saturation ToolMohamed SadekÎncă nu există evaluări

- Drill Stem TestingDocument16 paginiDrill Stem TestingpothirajkalyanÎncă nu există evaluări

- Gasifier W: SyngasDocument8 paginiGasifier W: SyngascristopuloÎncă nu există evaluări

- 2 Classification Additives CalculationsDocument32 pagini2 Classification Additives CalculationsSaa D ShamimÎncă nu există evaluări

- IODocument61 paginiIOSaa D ShamimÎncă nu există evaluări

- Gasifier W: SyngasDocument8 paginiGasifier W: SyngascristopuloÎncă nu există evaluări

- PGE 361 Lecture 8 Rock Permeability Average (Compatibility Mode)Document20 paginiPGE 361 Lecture 8 Rock Permeability Average (Compatibility Mode)adsadas100% (1)

- 2007 Characteristics of Bio-Oil-Syngas and Its Utilization in FT SynthesisDocument12 pagini2007 Characteristics of Bio-Oil-Syngas and Its Utilization in FT SynthesisSaa D ShamimÎncă nu există evaluări

- Analysis and Design of Suspension Cable BridgeDocument5 paginiAnalysis and Design of Suspension Cable BridgeNhel AlbrechtÎncă nu există evaluări

- PHY3QMO - Computational AssignmentDocument4 paginiPHY3QMO - Computational AssignmentReally SexyÎncă nu există evaluări

- Evaluation of LS-DYNA Concrete Material Model 159Document209 paginiEvaluation of LS-DYNA Concrete Material Model 159SudathipTangwongchaiÎncă nu există evaluări

- Comparacion Ansys CFX y TelemacDocument8 paginiComparacion Ansys CFX y TelemacOscar Choque JaqquehuaÎncă nu există evaluări

- Oceanic Anoxic Events (O.a.e) Organic Rocks Deposition CretaceousDocument6 paginiOceanic Anoxic Events (O.a.e) Organic Rocks Deposition CretaceousJulian De Bedout OrdoñezÎncă nu există evaluări

- Buffer SelectionDocument3 paginiBuffer SelectionSandeep KumarÎncă nu există evaluări

- 8.6C PosttestDocument2 pagini8.6C PosttestYohanes RatnodiyantoÎncă nu există evaluări

- RRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRDocument14 paginiRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRRPranay GoswamiÎncă nu există evaluări

- Promaspray® F5 PDFDocument4 paginiPromaspray® F5 PDFhero6600Încă nu există evaluări

- An Efficient Algorithm For The Calculation of A Constant Q TransformDocument4 paginiAn Efficient Algorithm For The Calculation of A Constant Q TransformKarlAschnikowÎncă nu există evaluări

- Quiz 6 EnergyDocument2 paginiQuiz 6 Energyeloizamay100% (1)

- Analog Vs Digital DataDocument3 paginiAnalog Vs Digital Datanmuhunthan100% (1)

- Denver, H., 1985 - Settlement Calculation For Footings On SandDocument8 paginiDenver, H., 1985 - Settlement Calculation For Footings On SandbusyspiderÎncă nu există evaluări

- Experiment No. 1Document12 paginiExperiment No. 1KennethÎncă nu există evaluări

- Prof. (Retd.) M. G. Gadgil Prof. (DR.) Yogendra Singh: 4.00PM To 6.30PMDocument2 paginiProf. (Retd.) M. G. Gadgil Prof. (DR.) Yogendra Singh: 4.00PM To 6.30PMMohammed Junaid ShaikhÎncă nu există evaluări

- Maxwell-Boltzmann DistributionDocument8 paginiMaxwell-Boltzmann DistributionlamyantingÎncă nu există evaluări

- O3 Final ReportDocument109 paginiO3 Final ReportFaizan MirÎncă nu există evaluări

- Chapter 4Document49 paginiChapter 4Jakir HossainÎncă nu există evaluări

- Thermodynamics MST 2011Document3 paginiThermodynamics MST 2011greenhoochyÎncă nu există evaluări

- Wall Integration Conventions S-CONCRETE R11 S-FRAMEDocument3 paginiWall Integration Conventions S-CONCRETE R11 S-FRAMESyed RaziuddinÎncă nu există evaluări

- Math 112Document3 paginiMath 112janinasuzetteÎncă nu există evaluări

- The Zeeman EffectDocument11 paginiThe Zeeman EffectAlex TarrÎncă nu există evaluări

- 1.1 General: Means So Much Affected As Those Whose Foundations Did Not Reach The Bottom of The Soil"Document54 pagini1.1 General: Means So Much Affected As Those Whose Foundations Did Not Reach The Bottom of The Soil"Sai GnanadeepÎncă nu există evaluări