Documente Academic

Documente Profesional

Documente Cultură

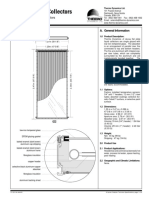

S SERIES Solar Collectors: Glazed Liquid Flat Plate Collectors

Încărcat de

atseucTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

S SERIES Solar Collectors: Glazed Liquid Flat Plate Collectors

Încărcat de

atseucDrepturi de autor:

Formate disponibile

Thermo Dynamics Ltd.

S SERIES Solar Collectors 44 Borden Avenue

Dartmouth, Nova Scotia

Canada, B3B-1C8

Glazed Liquid Flat Plate Collectors Tel: (902) 468-1001 Fax: (902) 468-1002

Technical Specifications Email: solarinfo@thermo-dynamics.com

http://www.thermo-dynamics.com

0.086m A. General Information

(3-3/8")

1.0 Product Description:

Thermo Dynamics S32 flat plate liquid

collectors are single glazed with low-iron

tempered glass. The absorber consists

of a single serpentine aluminum fin with

1.20m (47-3/8") an integral copper tube , which is com-

pletely surrounded by the aluminum and

metallurgically bonded together. The

back and sides are insulated with a 25

mm (1") layer of compressed fiberglass.

The collector frame is extruded alumi-

num with a baked-enamel finish, (dark

brown). Collector mounting is by way of

a sliding bolt-track. Flush and racked

collector mounting formats are easily ac-

commodated.

2.47m (97-3/8")

1.1 Options:

"A" collector with 4 external connections

(inlet, outlet, bypass tube); "B" collector

with 2 external connections (inlet, out-

let); factory installed temperature sen-

sors; absorber coatings: selective An-

odic-Cobalt™ surface, or semi-selective

paint surface.

1.2 Dimensions:

S32: 1.20 m x 2.47 m x 0.086 m

47-3/8 in x 97-3/8 in x 3-3/8 in

Gross area: 2.96 m2 (31.9 ft2 )

Aperture area: 2.78 m 2 (30.0 ft 2)

Absorber area: 2.87 m2 (30.9 ft2 )

Volume: 0.389 liter (0.086 IG)

Connections: 3/8" compression

fittings

S32 1.3 Weight:

Model Net Shipping

S32 45 kg (99 lb) 47 kg (104 lb)

low-iron tempered glass

2.0 Product Use

EPDM glazing gasket

2.1 Product Applications:

baked enamel (dark brown)

Residential domestic hot water, small

aluminum cap stripping

commercial and industrial process hot

baked enamel (dark brown) water.

aluminum frame

2.2 Geographic and Climatic Limitations:

mechanical connection

None.

EPDM grommet and fiber washers

inlet and outlet tubes

aluminum-copper absorber

selective surface

fibreglass insulation

aluminum backing sheet

TC.210.01.SEP/99 S Series Collector Technical Specifications; page 1 of 8

S SERIES Solar Collectors

Glazed Liquid Flat Plate Collectors

Technical Specifications

B. Glazing System

3.0 Manufacturer’s Experience 1.0 General Description: 2.3 Refractive Index:

Glazing is a 3.2 mm (1/8") single sheet of 1.525

3.1 Background: low-iron tempered glass with an EPDM

Thermo Dynamics Ltd. (TDL) is a Cana- rubber seal around the edges. Glazing is 3.0 Structural Performance

dian company engaged in the research, secured by an aluminum capping fas-

development, production, distribution and tened by stainless steel screws around 3.1 Tensile Strength:

installation of solar thermal equipment. the perimeter. Design Pressure is 2.87 kPa (.416 psi)

The company has been involved in the for 1/8 inch glass with a design factor of

solar thermal industry since 1981 and 1.1 Trade Names: 2.5. Tensile strength is 152 MPa (22,000

operates from its head office and factory Solite psi) with a 2.5 safety factor.

in Dartmouth, Nova Scotia, Canada, the

sister city of Halifax situated on the At- 1.2 Chemical Composition: 3.2 Impact Resistance:

lantic coast. The company’s specializa- Iron oxide content of 0.03% Glazing can withstand 542J (400 ft-lb)

tion is the glazed liquid-flat-plate (LFP) soft-body impact, 3 to 5 times stronger

collectors with metal absorbers. TDL is a 1.3 Physical Treatment: than annealed glass.

fully integrated solar thermal company All glazing is tempered with swiped edges

with the ability to convert raw aluminum and has a shallow stipple pattern to re- 3.3 Uniform Load Resistance:

and copper into a high technology solar duce specular reflectance. Uniform load testing was conducted at

water heating system. the National Solar Test Facility in May

1.4 Thickness: 1986 as part of CSA-378.

Thermo Dynamics Ltd., as a world leader S32: 3.18 mm (1/8") Positive load: 1.5 kPa (0.22 psi)

in solar technology, manufactures and Negative load: 1.9 kPa (0.28 psi)

markets solar heating equipment from

1.5 Spacing:

complete systems to basic selective sur- 4.0 Thermal Performance

Glazing to absorber: 20 to 25 mm (3/4"

face components for O.E.M.’s licensees,

to 1")

dealers and distributors through out North

America, Europe, Africa, New Zealand,

4.1 Coefficient of Thermal Expansion:

as well as 10 other countries around the

1.6 Weight: 89.9 x 10-7° 1/°C (49.9 x 10-7° 1/°F)

world. S32: 7.8 kg/m 2 (1.6 lb/ft 2)

4.2 Operating Temperature Range:

3.2 Production: 1.7 Appearance: Min: below -46°C (-51°F); max: 260°C

3000 m 2 (32,300 ft2 ) per year for S32 Translucent; the inner surface is em- (500°F)

collectors bossed with a stipple pattern which pro-

duces a frosted effect. 4.3 Thermal Conductivity:

3.3 Projects: No data available

Bedford, S-2000 2.0 Optical Performance

Bedford, Nova Scotia, Canada 5.0 Fire Behavior:

Collector number and type: 120 - S32 2.1 Spectral Transmittance: Non-combustible. Does not produce toxic

Total collector area: 360 m2 (3875 ft2 ) Visible light 89.8% ASTM E424-71A fumes in a fire situation.

Residential application, with 2 - S32 per Ultra violet light 51% ISO 9050

home. Solar light/energy 89.5% ASTM E424- 6.0 Durability:

71A Glass is chemically inert to most chemi-

Guelph 2000 cal solvents and staining agents, and is

Guelph, Ontario, Canada resistant to surface weathering, ultravio-

Collector number and type: 200 - S32 let and thermal degradation, and mois-

collectors 95 ture damage.

Total collector area: 600 m2 (6460 ft2 ) Solite

Residential application, with 2 - S32 per

Transmittance

%

home 90

Switzerland

To date: 900 S32 solar collectors.

2700 m 2 (29,062 ft 2) 85

400 500 800 1000 1200 1400 1600 1800

Thermo Dynamics Ltd. has installed thou- Wavelength nm

sands of solar residential domestic hot

water systems. 2.2 Energy Transmission:

Solar spectrum (0-3 micrometres)

S32: 89.5%

Infrared spectrum (>3 micrometres)

No data available

TC.210.01.SEP/99 S Series Collector Technical Specifications; page 2 of 8

Thermo Dynamics Ltd.

S SERIES Solar Collectors 44 Borden Avenue

Dartmouth, Nova Scotia

Canada, B3B-1C8

Glazed Liquid Flat Plate Collectors Tel: (902) 468-1001 Fax: (902) 468-1002

Technical Specifications Email: solarinfo@thermo-dynamics.com

http://www.thermo-dynamics.com

C. Absorber System

1.0 General Description: 3.2 Coefficient of Thermal Expansion: 4.0 Mechanical Integrity:

The absorber consists of eight aluminum Fin tubes: 22 x 10 -6 1/°C (12.2 x 10-6 1/ The collector has completed 30-day stag-

fins arranged in a serpentine fashion with °F) nation testing at The National Solar Test

integral copper waterway tubes, which To allow for thermal expansion, the ab- Facility (NSTF), Mississauga, Canada,

are bonded to and completely surrounded sorber is free to float within the collector with no sign of degradation or loss in

by the aluminum by means of a high container. EPDM gaskets prevent con- performance.

pressure cold rolling process. The ab- tact between the copper tubes and the

sorber coating is Anodic-Cobalt™ selec- aluminum container. 5.0 Durability:

tive surface or black paint selective sur- The absorber and the selective surface

face. The absorber is fabricated from a 3.3 Thermal Capacity of Absorber are not affected by normal aqueous solu-

single, continuous fin, with only 2 sol- System: tions. Stagnation testing has shown no

dered joints at the absorber inlet and No data available. thermal degradation.

outlet connections.

3.4 Operating Temperature Range:

1.1 Generic/Trade Names: Absorber: max. 300°C (572°F)

Absorber: "MICRO-FLO®" Tubes: max. 300°C (572°F)

Absorber fins: “Sunstrip™” Solder: min. -50°C (-58°F); max. 400°C

Tubes: copper (752°F)

Headers: None. Coating: max. 300°C (572°F)

Coating: selective Anodic-Cobalt™ or

semi-selective paint

Solder: 95/5 tin antimony

1.2 Chemical Composition:

Absorber fins: aluminum (AA 1350/0

alloy)

Tubes: copper (CDA 1220/0 alloy)

Headers: None

Coating: anodized-cobalt pigmented, or

semi-selective paint

Solder: no data available

1.3 Physical Treatment:

None.

1.4 Dimensions:

Tube diameter: rhombic shape with an

open area of about 25.6 mm 2 (0.039 in2 )

Tube spacing: 143 mm (5.63")

Absorber thickness: 0.5 mm (0.02")

Coating thickness: no data available.

Sunstrip™ solar fin

2.0 Optical Performance Aluminum strip metalurgically

bonded to a copper tube.

2.1 Absorptivity of Solar Radiation:

Painted surface: α = 95% SS146/8:

Anodic-Cobalt™ surface: α = 92% • 143 mm wide Sunstrip™ Fakir:

• 8 mm copper tube Operation punches and bends the

2.2 Emissivity of Infrared Radiation: • selective surface solar fin into a serpentine

m

Painted surface: ε = 29%

5m

R1.4

0.5 mm

1.2 mm

5m

Anodic-Cobalt™ surface: ε = 15%

0. 3

0. 2

aluminum

3.0 Thermal Performance

6.2 mm

3.1 Thermal Transfer: copper

Good thermal transfer due to the high

conductivity of aluminum and the bond

between the aluminum fins and copper

tubes.

8.1 mm

Sunstrip™ solar fin cross section

11.7 mm SS146/8

Scale: 4:1 mm

TC.210.01.SEP/99 S Series Collector Technical Specifications; page 3 of 8

S SERIES Solar Collectors

Glazed Liquid Flat Plate Collectors

Technical Specifications

D. Insulation E. Collector Assembly

1.0 General Description: 2.3 Coefficient of Thermal Expansion: 1.0 General Description:

Collectors are insulated around the sides No data available The collector is assembled in four stages.

and back with fiberglass board. Com- First, the collector frame and backing

plies with ASTM-C-612 Classes 1 and 2. 2.4 Operating Temperature Range: sheet are assembled. Second, the back

Maximum continuous operating tempera- and side insulation are installed, third,

1.1 Trade Names: ture is 232°C (450°F). the tested absorber assembly is inserted,

Sides: Fiberglas AF530 and finally, the glazing, seal and cap are

Back: Fiberglas AF530 3.0 Fire Behavior installed.

1.2 Chemical Composition: 3.1 Surface Burning Characteristics: 1.1 Container:

Fibrous glass bonded by a thermosetting Fiberglas AF530 is inherently fire safe. The container consists of sections of

resin. Inorganic, will not rot. ULC Flame Spread rating of 15. (com- aluminum extrusion assembled into a

pared to untreated Red Oak as 100 - test rectangular frame, with an aluminum

1.3 Density: method ULC S-102) backing sheet fitted into slots and pop-

48 kg/m 3 (3.0 lb/ft 3 ) riveted in place.

4.0 Durability:

1.4 Thickness: No changes should occur to the insula- 1.2 Insulation:

Side: 25 mm (1") tion when subjected to chemicals nor- Insulation is placed on the aluminum back

Back: 25 mm (1") mally encountered in use conditions. No and along the sides.

thermal degradation has been found af-

2.0 Thermal Performance ter prolonged stagnation testing. Mois- 1.3 Absorber Assembly:

ture adsorption is less than 0.2% by vol- The serpentine absorber is fitted into the

2.1 Thermal Conductivity: ume, 96 hours at 49°C (120°F) and 95% inlet and outlet connection fittings pro-

0.036 W/m•°C (0.25 Btu•in/hr•ft 2•°F) at R.H. Inorganic therefore does not breed truding through the side. Mechanical

24°C (75°F) or promote bacteria and fungus. Essen- compression fittings are inserted into

tially odorless. EPDM grommets, locking the absorber in

place and insulating it from the container.

2.2 Thermal Resistance:

The absorber expands and contracts

RSI 0.7 °C•m2 /W (R 4 °F•ft 2•hr/Btu) at

freely within the container.

24°C (75°F)

S32B

S32A

Nova Scotia's EnviroHome,

Bedford, Nova Scotia, Canada

• one S32A solar collector

• one S32B solar collector

S32 solar collectors

• collectors shown as part of the Thermo

Dynamics Ltd Solar Boiler™ system

TC.210.01.SEP/99 S Series Collector Technical Specifications; page 4 of 8

Thermo Dynamics Ltd.

S SERIES Solar Collectors 44 Borden Avenue

Dartmouth, Nova Scotia

Canada, B3B-1C8

Glazed Liquid Flat Plate Collectors Tel: (902) 468-1001 Fax: (902) 468-1002

Technical Specifications Email: solarinfo@thermo-dynamics.com

http://www.thermo-dynamics.com

Sunstrip™ MICRO-FLO® absorber

typical series connection:

• S32 A collector c/w 4 connection

1.4 Glazing Assembly:

(inlet, outlet, bypass tube)

The pre-cut glass is cleaned and fitted

• S32B collector c/w 2 connections

onto the retainer ledge in the collector

(inlet, outlet)

container with a high-temperature con-

tinuous EPDM gasket. A removable alu-

minum cap stripping is then secured to

the container with black oxide coated

stainless steel screws.

2.0 Collector Container:

Collector container sides are fabricated

from aluminum extrusions with an inte-

gral mounting channel. The bottom is an

aluminum sheet which fits into a slot in S32B

the frame and is pop-riveted to the sides.

2.1 Materials:

Extruded framework is aluminum 6061-

T6 alloy. The back sheet is aluminum

utility grade sheet with a thickness of

0.51 mm (.020")

2.2 Finish:

Aluminum frame comes in a standard

dark brown baked enamel finish.

3.0 Moisture Control System:

Four holes in the back sheet allow suffi-

cient air flow through the collector to

remove any condensation or moisture.

4.0 Sealant and Gaskets

4.1 General Description:

Inlet and outlet pipes are sealed with

high-temperature round EPDM gaskets.

The continuous glazing gasket is a U-

shaped EPDM neoprene. Silicone caulk-

ing is used for the container corner seal-

ant.

4.2 Chemical Composition:

Header and glazing gasket: ethylene

propylene diene monomer rubber (EPDM)

Caulking: silicone rubber

4.3 Physical Properties: S32 A

EPDM gasket has a tensile strength of

13800 kPa (2000 psi). Sealants and

gaskets do not corrode other collector

materials.

4.4 Coefficient of Thermal Expansion:

no data available.

4.5 Operating Ranges:

no data available.

• SS146/8 U-bend

• serpentine absorber

• continuous solar fin

• no soldered joints

TC.210.01.SEP/99 S Series Collector Technical Specifications; page 5 of 8

S SERIES Solar Collectors

Glazed Liquid Flat Plate Collectors

Technical Specifications

F. Installation G. Operation

1.0 Handling and Transportation 1.0 Method of operation and Control: 2.1 Testing Information:

Collectors can be used with distilled wa- Agency: National Solar Test Facility

1.1 Packaging: ter or antifreeze solutions. The S Series Date: July 15, 1992

Collectors are shipped individually in collectors operate in a closed-loop drain Fluid: 60% distilled water, 40% propy-

double-strength cardboard boxes. back system. The small diameter ab- lene glycol

sorber tubing allows draining through cap-

1.2 Labour and Equipment: illary action to draw fluid up through re- 3.0 Recommended Flow Rate:

Two people can move and mount collec- versed slope sections of collector and 0.6 L/min ( 0.132 IGPM)

tors. piping.

4.0 Maximum Operating Pressure:

2.0 Mounting Procedure: 2.0 Pressure Drop vs. Collector Flow: Factory tested to 1724 kPa (250 psi).

An aluminum mounting bracket allows ∆P (kPa)

attachment to the bolt-track in the collec- 400 5.0 Recommended Operating Pressure:

tor frame extrusion anywhere along its .828 IGPM = 1 USGPM = .063 kg/s Below 200 kPa (30 psi) for drainback

300

width or length. The mounting bracket systems and 135-270 kPa (20-40 psi) for

allows collector mounting parallel to the closed loop systems.

200

roof surface or tilted up at any angle.

S32, 4' x 8' 6.0 Maximum Operating Temperature:

100

3.0 Collector Interconnection: S40, 4' x 10' 300°C (570°F)

Small insulated copper tubing with me- 0

chanical compression fittings are used to 0.00 0.01 0.02 0.03 0.04 0.05 7.0 Stagnation Temperature:

Flow (kg/s)

interconnect the S Series solar collec- ∆P (kPa) Stagnation temperature of the collector

tors. 150 is approximately 232°C (450°F).

125

4.0 System Connection: 100 8.0 Recommended Heat Transfer Fluids:

Piping connections are made with small Propylene Glycol USP, food grade anti-

75

diameter copper tubing with mechanical freeze solution for closed loop systems

compression or sweated soldered fittings. 50 S32, 4' x 8' where freezing is a concern. Typically

S40, 4' x 10'

25 use 40% propylene glycol mixed with

5.0 Start-up Tests: 0

60% distilled water by volume. In warmer

i) Air or water pressure test at 690 kPa. 0.00 0.01 0.02 0.03 climates the recommended heat transfer

Flow (kg/s)

ii) Visual check for leaks. fluid is distilled water.

"B" collector

"A" collector

Recommended solar collector Typical inter collector mounting procedure

mounting methods

TC.210.01.SEP/99 S Series Collector Technical Specifications; page 6 of 8

Thermo Dynamics Ltd.

S SERIES Solar Collectors 44 Borden Avenue

Dartmouth, Nova Scotia

Canada, B3B-1C8

Glazed Liquid Flat Plate Collectors Tel: (902) 468-1001 Fax: (902) 468-1002

Technical Specifications Email: solarinfo@thermo-dynamics.com

http://www.thermo-dynamics.com

H. Maintenance and Warranty I. Durability

1.0 Cleaning and Maintenance: 4.0 Replacement of Parts: 1.0 Operating Experience:

Glazing should be self-cleaning, depend- The glazing may be replaced in the in- The S32 has been installed worldwide

ing on local conditions. Dirt accumula- stalled system without removing the col- since 1985.

tion on the glass cover will be washed lector from the array by removing the

away by the rain. If cleaning is required, screws holding the glazing cap stripping. 2.0 Accelerated Aging Tests:

use a standard window cleaning agent. Total replacement time is a maximum of The collector has been subjected to 30

The glycol antifreeze solution should be fifteen minutes and requires only a screw day plus high temperature (204°C;400°F)

checked annually and renewed if neces- driver. Sensors are clamped on outlet stagnation tests at the Canadian Na-

sary. No other maintenance is normally piping using screw-type pipe clamps. tional Solar Test Facility with no evi-

required. Replacement time is approximately ten dence of deterioration (CSA F-378). One

minutes. year of stagnation at DSET laboratories

2.0 Manufacturer Servicing: in Arizona were also conducted in 1982

A trouble-shooting guide to help the If the recommended installation proce- with no sign of deterioration.

home-owner maintain and service the dures are followed, one collector may be

equipment is included in the installation replaced in the array without removing

manual. All service and repair is readily another collector. Collectors are con-

available from the manufacturer or dis- nected together with a standard copper

tributor. couplings (mechanical or soldered).

3.0 Availability of Parts: 5.0 Warranty:

All parts are available from the manufac- The solar collector absorber is warranted

turer and distributors. for a period of ten years. Repair allow-

ances may also apply. The manufacturer

may repair or replace the absorber as

required at his discretion.

S32 solar collectors

• one S32A and one S32B

• integrated with Solar Boiler™ module

• total collector area: 6 m2 ( ft2)

• residential domestic hot water

• location: Halifax, Nova Scotia, Canada

S32 solar collectors

• one S32A and one S32B

• integrated with Solar Boiler™ module

• total collector area: 6 m2 ( ft2)

• residential domestic hot water

• location: Nairobi, Kenya, Africa

TC.210.01.SEP/99 S Series Collector Technical Specifications; page 7 of 8

S SERIES Solar Collectors

Glazed Liquid Flat Plate Collectors

Technical Specifications

J. Collector Efficiency

1.0 General Description 3.0 Time Constant: 5.0 Incident Angle Modifier:

115sec± 5 sec at 0.021 kg/s (0.46 lb/s) K(τα) = 1 - 0.239(1/cosθ - 1)

1.1 Test Method:

Tested in accordance with SRCC (Solar 4.0 Efficiency: 6.0 SRCC Standard Day Tests:

Rating and Certification Corporation) Efficiency curve is based on gross col- The following standard day tests were

Standard OG100-81 with reference ANSI/ lector area, and was determined using performed by the Solar Rating & Certifi-

ASHRAE Standard 93-86. Thermal effi- the indoor solar simulator. cation Corporation, (SRCC). Original

ciency is calculated as recommended in certification date, August 1992.

ASHRAE 93-86. First order efficiency equation:

η = 0.642- 4.648(Ti - Ta)/G

1.2 Testing Information:

SRCC Standard Day Tests, (SRCC Standard 100-81)

Agency: National Solar Test Facility

Location: Ontario, Canada Clear Day Mildly Cloudy Cloudy Day Clear Day Mildly Cloudy Cloudy Day

Lat. 43.53 °N

(Ti-Ta) 23 MJ/m2•d 17 MJ/m2•d 11 MJ/m2•d (Ti-Ta) 2000 Btu/ft2•d 1500 Btu/ft2•d 1000 Btu/ft2•d

Long. 79.66 °W

-5°C 40 30 21 -9°F 38 29 19

Elevation: 160 m (525 ft)

5°C 35 25 16 9°F 33 24 15

Date: July 15, 1992

20°C 28 19 10 36°F 27 18 9

1.3 Details of Tested collector: 50°C 16 8 1 90°F 15 7 1

Model: S32 80°C 6 1 – 144°F 6 1 –

Glazing: low-iron tempered Solite Megajoules per Collector per day Thousands of Btu per Collector per day

Absorber material: aluminum fin and

tube 1.2

Absorber coating: Anodic–Cobalt™ 1.1

1.0

Insulation: fiberglass 0.9

Gross area: 2.96 m2 (31.9 ft2 ) 0.8

Aperture area: 2.78 m 2 (30.0 ft 2) 0.7

Incident Angle Modifier 0.6

Absorber area: 2.87 m 2 (30.9 ft 2 ) 0.5

0.4

1.4 Comments: 0.3

0.2

The time constant and thermal efficiency 0.1

test were determined in the solar simula- 0.0

tor. Incident angle modifier was deter- 0 20 40 60

mined from outdoor testing. Angle of Incidence (degrees)

2.0 Test Conditions Collector Thermal Efficiency

2.1 Collector Tilt and Orientation: 1.0

Normal to the direction of irradiation. 0.9

2.2 Heat Transfer Fluid: 0.8

60% water, 40% propylene glycol 0.7

2.3 Liquid Flow Rate: 0.6

0.0214 kg/s (0.0463 lb/s) 0.5

2.4 Range of Ambient Air Temperature: 0.4

19.9°C to 20.7°C (67.8°F to 69.3°F) 0.3

2.5 Wind Velocity: 0.2

3.5 m/sec (11.5 ft/sec) 0.1

2.6 Range of insolation: 0.0

996 to 1007 W/m2

0.00 0.02 0.04 0.06 0.08 0.10

2

316 to 319 Btu/ft2 h (Ti-Ta)/G (°C•m /W)

The S Series Collectors described by this brochure, when properly installed and maintained, meet the minimum standards established by the SRCC, (Solar Rating &

Certification Corporation). This certification does not imply endorsement or warranty of this product by SRCC.

TC.210.01.SEP/99 S Series Collector Technical Specifications; page 8 of 8

S-ar putea să vă placă și

- Anet A8 ManualDocument73 paginiAnet A8 ManualHenry Pablo50% (2)

- SU Gate SealsDocument170 paginiSU Gate SealsHoe TommyÎncă nu există evaluări

- Forming Limit DiagramsDocument7 paginiForming Limit DiagramsatseucÎncă nu există evaluări

- Kairos Thermo GR 2 KWDocument2 paginiKairos Thermo GR 2 KWGreen FilterÎncă nu există evaluări

- Injection Molding AssignmentDocument8 paginiInjection Molding AssignmentaakshusabhÎncă nu există evaluări

- Solar Boiler TechDocument8 paginiSolar Boiler TechatseucÎncă nu există evaluări

- Problems and Solutions To Smith/Hashemi 4/e (Chapter 11)Document34 paginiProblems and Solutions To Smith/Hashemi 4/e (Chapter 11)pagonde8350% (2)

- ZE Twin-Screw ExtrudersDocument30 paginiZE Twin-Screw ExtrudersSimas Servutas100% (1)

- 33kv Cables GTPDocument3 pagini33kv Cables GTPManohar Potnuru100% (1)

- Polymer Pencil Mini PlantDocument4 paginiPolymer Pencil Mini Plantcareindia100% (1)

- Earthing System Design Tool For Low Voltage InstallationsDocument36 paginiEarthing System Design Tool For Low Voltage InstallationsLim BoraÎncă nu există evaluări

- Klucel HPC BookletDocument26 paginiKlucel HPC BookletΜανωλης ΛοιζοςÎncă nu există evaluări

- Fb-Aftermarket-Catalog-Data ANDRITZDocument44 paginiFb-Aftermarket-Catalog-Data ANDRITZgalihÎncă nu există evaluări

- K-84-11 - Series 3300 Addressable - Manual Pull Station PDFDocument2 paginiK-84-11 - Series 3300 Addressable - Manual Pull Station PDFBetoSouzaÎncă nu există evaluări

- Insulation Sheath Xlpe Lead Voltage 127 / 220 / 245 KV Short-CircuitDocument1 paginăInsulation Sheath Xlpe Lead Voltage 127 / 220 / 245 KV Short-CircuitMena KamelÎncă nu există evaluări

- Product Specification Epm38031: Rhz1 19/33Kv 1X630Kcu+H50Document2 paginiProduct Specification Epm38031: Rhz1 19/33Kv 1X630Kcu+H50JFREY1504Încă nu există evaluări

- Sa302318 DatasheetDocument1 paginăSa302318 DatasheetrourouÎncă nu există evaluări

- Datos CableDocument3 paginiDatos CablePablo Briceño NavarroÎncă nu există evaluări

- XHIOLE (Cbe) 1x"S"/35 12/20kV: Product Specification EPM100051Document2 paginiXHIOLE (Cbe) 1x"S"/35 12/20kV: Product Specification EPM100051Fahad UsmanÎncă nu există evaluări

- BT Panel Technical SheetDocument2 paginiBT Panel Technical SheetAngelÎncă nu există evaluări

- Compliance FormDocument4 paginiCompliance FormHello WorldÎncă nu există evaluări

- GTP 240Document2 paginiGTP 240er.manishnhpcÎncă nu există evaluări

- GTP 185Document3 paginiGTP 185er.manishnhpcÎncă nu există evaluări

- Honeywell stt250 Manual de UsuarioDocument6 paginiHoneywell stt250 Manual de UsuarioLuis Angel Sanchez OrtizÎncă nu există evaluări

- Technical Offer-SWE-298-23-V1Document1 paginăTechnical Offer-SWE-298-23-V1Karim RahmaniÎncă nu există evaluări

- 131 - 1.9.1.2-01T - Aluminum WireDocument4 pagini131 - 1.9.1.2-01T - Aluminum WireDiidaii MontañoÎncă nu există evaluări

- Advantages of Aluminum Vacuum NO LogoPDFDocument45 paginiAdvantages of Aluminum Vacuum NO LogoPDFKonstantin MarjanuczÎncă nu există evaluări

- Lucy Zodion Cutout Isolator Catalogue 13 PDFDocument22 paginiLucy Zodion Cutout Isolator Catalogue 13 PDFAlex HowesÎncă nu există evaluări

- Lvis09axsfy23 5c300sa002sDocument1 paginăLvis09axsfy23 5c300sa002sVishal SharmaÎncă nu există evaluări

- Tools - Earthing Design For LV SystemDocument37 paginiTools - Earthing Design For LV Systemosp005Încă nu există evaluări

- Solarizer Elite Data SheetDocument1 paginăSolarizer Elite Data SheetEmmvee SolarÎncă nu există evaluări

- AXCES 3x7025 1830 KVDocument2 paginiAXCES 3x7025 1830 KVZoran DurutovicÎncă nu există evaluări

- Busbar Deisgn GuideDocument9 paginiBusbar Deisgn Guideali ridhoÎncă nu există evaluări

- Te Quick Ref Epp 1984 NZ 9 - 12Document160 paginiTe Quick Ref Epp 1984 NZ 9 - 12Ricky YoungÎncă nu există evaluări

- Li# 1 - 3c X 70 + 35mm2 Swa Fr-3 BahraDocument2 paginiLi# 1 - 3c X 70 + 35mm2 Swa Fr-3 BahraMuhammad ShahidÎncă nu există evaluări

- 5831 - PVC Insulation & SheathDocument6 pagini5831 - PVC Insulation & SheathvurumuuÎncă nu există evaluări

- 54 PNA enDocument2 pagini54 PNA enArmin HajdarovićÎncă nu există evaluări

- MV Power CablesDocument2 paginiMV Power CablesQC ĐNÎncă nu există evaluări

- 1X240 - AL - XLPE - ATA - PVC - 18 - 30 (36) KVDocument1 pagină1X240 - AL - XLPE - ATA - PVC - 18 - 30 (36) KVShadi BadawyÎncă nu există evaluări

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 paginiSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlÎncă nu există evaluări

- Technical Description Tether Cable BWT 2 - 16kN Buoyant Work Class TetherDocument6 paginiTechnical Description Tether Cable BWT 2 - 16kN Buoyant Work Class TetherRich ManÎncă nu există evaluări

- NA2XS (F) 2Y 12-20 KV 1x400Document2 paginiNA2XS (F) 2Y 12-20 KV 1x400plavi10Încă nu există evaluări

- Specification Control Drawing Cat5E Cable, Awg 24: C5E-24C124-C14Document3 paginiSpecification Control Drawing Cat5E Cable, Awg 24: C5E-24C124-C14gbdf onlkklnÎncă nu există evaluări

- Tafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TDocument4 paginiTafa Arc Spray Wire 1.9.1.2-01T - Aluminum Wire 01TIkhsan LyÎncă nu există evaluări

- Crgo Aksteels Tran CorDocument38 paginiCrgo Aksteels Tran CoripraoÎncă nu există evaluări

- List Material ME Dan GroundingDocument2 paginiList Material ME Dan GroundingsandyÎncă nu există evaluări

- TDS, CSD - Iec 60502-2Document4 paginiTDS, CSD - Iec 60502-2Ghiles AOUICHEÎncă nu există evaluări

- XLERATOReco-Tech-Sheet 21 - SecadoresDocument2 paginiXLERATOReco-Tech-Sheet 21 - Secadoresvdíaz_485617Încă nu există evaluări

- TPG NA2XS2Y 1x300 mm2 20KVDocument2 paginiTPG NA2XS2Y 1x300 mm2 20KVtees220510Încă nu există evaluări

- Technology Department Technical Data Sheet Low Voltage Power CableDocument2 paginiTechnology Department Technical Data Sheet Low Voltage Power CableMuhammad ShahidÎncă nu există evaluări

- Climateworx 689Document8 paginiClimateworx 689Ronny Rodriguez SandovalÎncă nu există evaluări

- Captador Sonnenkraft SK500Document2 paginiCaptador Sonnenkraft SK500Abdoullai camaraÎncă nu există evaluări

- GTP 50Document2 paginiGTP 50er.manishnhpcÎncă nu există evaluări

- List Material ME Dan GroundingDocument2 paginiList Material ME Dan GroundingsandyÎncă nu există evaluări

- Bartec CatalogoDocument3 paginiBartec CatalogoManuel PousaÎncă nu există evaluări

- Ariston GR CATALOGUE 200 2 300 2 LITERS BBDocument2 paginiAriston GR CATALOGUE 200 2 300 2 LITERS BBARUL SANKARAN0% (2)

- Summary of Modifications/Changes in This UpdateDocument11 paginiSummary of Modifications/Changes in This UpdateAnonymous vh1f95o8Încă nu există evaluări

- Vitosol 100-FMDocument12 paginiVitosol 100-FMMohamed KhaldiÎncă nu există evaluări

- 2.ARC - ARC Binh Duong ASRS - Quotation For PK2 - Panel and Refrigeration System - Phase 2 - 2020 10 28Document12 pagini2.ARC - ARC Binh Duong ASRS - Quotation For PK2 - Panel and Refrigeration System - Phase 2 - 2020 10 28vu nguyen ngocÎncă nu există evaluări

- System PDF Files - 1. UL and cUL Systems - cwd1033Document3 paginiSystem PDF Files - 1. UL and cUL Systems - cwd1033Emanuel Almeida PastlÎncă nu există evaluări

- 2012 Under Water SpecsDocument2 pagini2012 Under Water SpecsSuresh SubbarayanÎncă nu există evaluări

- Data Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZDocument1 paginăData Sheet For Three-Phase Squirrel-Cage-Motors: MLFB-Ordering Data: 1LE1023-1AA43-4AB4-ZFredericks ACÎncă nu există evaluări

- (N) TMCGEH3S 3x120sqmm Orange TPU JacketDocument3 pagini(N) TMCGEH3S 3x120sqmm Orange TPU JacketAbl Jara MamaniÎncă nu există evaluări

- 782-AL3cond. EN 50182 PR MKM - Xls 1/1 30/05/2016Document1 pagină782-AL3cond. EN 50182 PR MKM - Xls 1/1 30/05/2016Mena KamelÎncă nu există evaluări

- DDK 2011 00005 - Technical Datasheet - 13115-2TDocument6 paginiDDK 2011 00005 - Technical Datasheet - 13115-2TMehedi HasanÎncă nu există evaluări

- TedeutschproductsDocument105 paginiTedeutschproductsTony C.Încă nu există evaluări

- Advefoam 32Document2 paginiAdvefoam 32melsabaeÎncă nu există evaluări

- Universal Cable, AXCES 12/20 (24) KV 3x70/16: Product InformationDocument2 paginiUniversal Cable, AXCES 12/20 (24) KV 3x70/16: Product InformationMiso MisoÎncă nu există evaluări

- QT Iii 7622 S2Document28 paginiQT Iii 7622 S2ING CASTILLOÎncă nu există evaluări

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)De la EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)Încă nu există evaluări

- Geothermal Solutions PDFDocument36 paginiGeothermal Solutions PDFatseucÎncă nu există evaluări

- Evaluation of Sheet Metal Formability by Tensile TestsDocument12 paginiEvaluation of Sheet Metal Formability by Tensile TestsatseucÎncă nu există evaluări

- Microstructural Evolution and Observed Stress Response During Hot Deformation of 5005 and 6022 Al AlloysDocument8 paginiMicrostructural Evolution and Observed Stress Response During Hot Deformation of 5005 and 6022 Al AlloysatseucÎncă nu există evaluări

- Progress in Development of High-Temperature Solar-Selective Coating PDFDocument7 paginiProgress in Development of High-Temperature Solar-Selective Coating PDFatseucÎncă nu există evaluări

- A Study of Ac Reactive Magnetron Sputtering Technique For The Deposition of Compositionally Graded Coating in The Cr-Al-N System PDFDocument8 paginiA Study of Ac Reactive Magnetron Sputtering Technique For The Deposition of Compositionally Graded Coating in The Cr-Al-N System PDFatseucÎncă nu există evaluări

- FEM-Based Design of An Induction Motor's Part Winding To Reduce The Starting Current PDFDocument4 paginiFEM-Based Design of An Induction Motor's Part Winding To Reduce The Starting Current PDFatseucÎncă nu există evaluări

- Infrared Absorption SpectrosDocument25 paginiInfrared Absorption SpectrosatseucÎncă nu există evaluări

- G Series TechDocument8 paginiG Series TechatseucÎncă nu există evaluări

- Sunstrip TechDocument4 paginiSunstrip TechatseucÎncă nu există evaluări

- Spectral Selective Absorbing Surface On Solar Collector ElementsDocument29 paginiSpectral Selective Absorbing Surface On Solar Collector ElementsatseucÎncă nu există evaluări

- A Study of Ac Reactive Magnetron Sputtering Technique For The Deposition of Compositionally Graded Coating in The Cr-Al-N System PDFDocument8 paginiA Study of Ac Reactive Magnetron Sputtering Technique For The Deposition of Compositionally Graded Coating in The Cr-Al-N System PDFatseucÎncă nu există evaluări

- RefrigPipingHandbook SuvaDocument161 paginiRefrigPipingHandbook SuvaDaveB11WhitÎncă nu există evaluări

- PAK Single Screw Extruder SpecsDocument1 paginăPAK Single Screw Extruder Specsfadjar sophianÎncă nu există evaluări

- Create 3D Text in 3DS MaxDocument5 paginiCreate 3D Text in 3DS Maxbrpnaidu2157Încă nu există evaluări

- Phani Gudipati Talks Extrusion in Advanced Materials Processes Magazine 4 - 2021Document4 paginiPhani Gudipati Talks Extrusion in Advanced Materials Processes Magazine 4 - 202118P202 - AJAY SIVARAMAN AÎncă nu există evaluări

- Ergo Engineers: Manufactured byDocument5 paginiErgo Engineers: Manufactured bythanhphuc1011Încă nu există evaluări

- Design, Manufacturing, and Testing of WT DoorsDocument11 paginiDesign, Manufacturing, and Testing of WT DoorsTheyaga GanesanÎncă nu există evaluări

- 11Document26 pagini11Madesh PmadeshÎncă nu există evaluări

- Astm B 491B491M-06 PDFDocument6 paginiAstm B 491B491M-06 PDFRamsi AnkziÎncă nu există evaluări

- Plant Based Meat MaterialsDocument7 paginiPlant Based Meat MaterialsKhampa Ngawang PhuntshoÎncă nu există evaluări

- Additive ManufacturingDocument7 paginiAdditive ManufacturingIslam HelazaÎncă nu există evaluări

- Tiles ProcessDocument7 paginiTiles Processinkera - HRÎncă nu există evaluări

- 11.shineworld Company Profile 20211201Document42 pagini11.shineworld Company Profile 20211201Moutaz IsmailÎncă nu există evaluări

- Principles of Major Manufacturing ProcessesDocument40 paginiPrinciples of Major Manufacturing ProcessesWatyu Dennis PeterÎncă nu există evaluări

- CW October 2012Document62 paginiCW October 2012Clint FosterÎncă nu există evaluări

- Professor Terry Sheppard (Auth.) - Extrusion of Aluminium Alloys-Springer US (1999)Document10 paginiProfessor Terry Sheppard (Auth.) - Extrusion of Aluminium Alloys-Springer US (1999)Enquiry SgÎncă nu există evaluări

- Katalog Welding Machine LengkapDocument25 paginiKatalog Welding Machine LengkapAhmad NajihullahÎncă nu există evaluări

- Comm Off - Renovation of Hatti HoudDocument18 paginiComm Off - Renovation of Hatti HoudthesmileynoobÎncă nu există evaluări

- Desmopan Product RangeDocument26 paginiDesmopan Product RangeDhimas KLSÎncă nu există evaluări

- Poly-Bi Technical Report - v1Document14 paginiPoly-Bi Technical Report - v1Diogo FrancoÎncă nu există evaluări

- E Original BrabenderDocument20 paginiE Original BrabenderErick Emma SánchezÎncă nu există evaluări

- Alluminio TeoriaDocument91 paginiAlluminio TeoriaxypangioÎncă nu există evaluări

- Medium VoltageDocument68 paginiMedium VoltageNesya LaxmithaÎncă nu există evaluări

- Learning SketchupDocument16 paginiLearning Sketchupgerardtt2772Încă nu există evaluări