Documente Academic

Documente Profesional

Documente Cultură

Knauf ASTM Ceiling Manual

Încărcat de

dishkuDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Knauf ASTM Ceiling Manual

Încărcat de

dishkuDrepturi de autor:

Formate disponibile

06 - 2018

GYPSUM BOARD

CEILINGS ASTM

GYPSUM BOARD CEILING SYSTEMS

Manual Ceiling (ASTM)-UB.indd 1 3/29/17 6:24 PM

Contents

Introduction 03

System overview 04

Construction details 05 - 12

General information 13

Installation steps 14

Processing of gypsum boards 15

Joint treatment 16

Cladding of boards 17 - 18

Certifications 19

Manual Ceiling (ASTM)-UB.indd 2 3/29/17 6:25 PM

To our Valued Customers,

Greetings!

Knauf is a family name and a corporate group of global dimensions at the same time synonymous with a type of

corporate culture which has become rare. Knauf is a typical family firm in spite of its size and this is precisely the

reason for its amazing success. It is short and direct decision-making paths, the courage to tackle new ideas,

innovations, investments and the wealth of ideas contributed by all Knauf employees that characterize the company.

From its beginnings in gypsum processing, Knauf has expanded and diversified to become a corporation with

worldwide activities, Knauf UAE has been active in the Middle East for more than a decade.

Knauf shows its commitment not only in the GCC, headquarters in Dubai UAE, but also in the subcontinent.

We have offices based in Saudi, Qatar and India to support the market and dealers.

Knauf provides value-added products and services in the following fields:

• Building materials and systems based on gypsum and gypsum-related products

• ASTM certified products & systems

• Multi- Purpose Joint compounds

• Knauf Aquapanel interior and exterior wall systems

• Knauf Insulations sustainable, high-performance, cost-effective insulation solutions

• Knauf Heradesign’s acoustic designs for Interior and Exterior in ceiling & partition systems

• Knauf Integral’s Knauf GIFA Floor, sheet-panelled access floors

• Thermal and sound insulation materials

• Value engineering and technical consultancy for architects and consultants to meet specified design requirements

• On site hands-on training and supervision for contractors when installing drywall systems

• Knauf systems are approved by Dubai, Abu Dhabi, Ras Al Khaimah and Qatar Civil Defense

Sustainability is central to our vision of doing the right thing for our clients, our people and the communities in which

we work. We maintain and provide certificates for individual products and designs to improve quality and performance.

Knauf systems combine innovative products to realize speed of installation and warranted high performance-based

systems as per ASTM, EN-BS and DIN Standards.

Knauf is not only committed towards it Products and System but also towards it employees. Within the framework of

its four key K-Values; Partnership, Commitment, Entrepreneurship and Menschlichkeit meaning human touch Knauf

looks after its people and drives a sense of passion in all its staff. This is what makes Knauf unique and special!

Safety is something that Knauf does not compromise on whether for its products or people and therefore all our

products are tested and approved by Intertek to make sure that nothing leaves the plant which is not up to the mark.

Amer Bin Ahmed

Managing Director

Knauf GCC & India

Manual Ceiling (ASTM)-UB.indd 3 3/29/17 6:25 PM

System overview

m L - angle

0m

122

mm

Main Channel 600 Access

Perimeter Wall 600 Opening

UD - Channel mm

150

406

406

406

200

100

0m

m Hat Furring Channel

Gypsum Board

Knauf Fire Resistant & Non Fire Resistant, Ceiling Assemblies,

Tested in accordance to ASTM E-119

* Fire Protection to Floor or Roof Cavity above

* Fire Protection to Steel Beams Supporting Concrete Floors

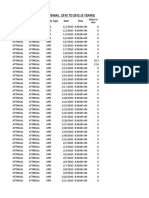

Spacing of Structure

Cladding Fire

Thickness Suspension Upper Furring Resistance

Hangers (mm) Channels (mm) Channels (mm)

1 x 12.7 mm -

1220 mm 1000 mm 406 mm

1 x 15.9 mm -

*2 x 12.7 mm 60 min.

1220 mm 1000 mm 406 mm

*2 x 15.9 mm 120 min.

*Boards types: Knauf Type-X Boards

A) Splicing of Main Channel

B) Splicing of furring Construction

channel details

A)

A)

Splicing of Main

Splicing of Main Channel

Channel B)

B) Splicing of furring channel

Splicing of furring channel

mm

A) Splicing of Main Channel

609 rlap

Ove B) Splicing of furring channel

m

6m

40

m

mm 09 m

609 rlap6 verlap

LN Screw

Ove O Hat Furring Channel

38

m m

6m

Hat Furring Channel

6m

Splicing / End to End Connection

40 40

12.5

LN Screw LN Screw

Hat Furring Channel

Hat Furring Channel

38

38

Hat Furring Channel

Splicing / End to EndHat Furring Channel

Connection

12.5

Splicing / End to End Connection

12.5

Manual Ceiling (ASTM)-UB.indd 4 3/29/17 6:25 PM

Construction details for Fire Rated Systems

Construction details for Non Fire Rated Systems

These details represent some of the most common designs situations relevant to the

Construction details for Non Fire Rated Systems

Knauf KC A001 ceiling systems.

These details represent some of the most common designs situations relevant to the

Knauf KC A001 ceiling systems.

C)These

Abutment to wall,

details represent perpendicular

some todesigns

of the most common primary support

situations relevantchannel

to the

Knauf KC A001 ceiling

C) Abutment systems.

to wall, perpendicular to primary support channel

C) Abutment to wall, perpendicular to primary support channel

Wedge Anchor

Perimeter Wall fixing

L - angle

Hammer Fixings

Main Channel

Wedge Anchor

1000 mm 200Wall

Perimeter mm fixing

L - angle

Hammer Fixings

Main Channel

1000 mm 200 mm

TN Screw Hat Furring Channel UD-Channel

LN Screw

Knauf Gypsum Board

TN Screw Hat Furring Channel UD-Channel

LN Screw

Knauf Gypsum Board

D) Abutment to wall, parallel to primary support channel

D) Abutment to wall, parallel to primary support channel

D) Abutment to wall, parallel to primary support channel

Wedge Anchor

Wire Hanger

Perimeter Wall fixing Main Channel

Hammer Fixings

1220Anchor

Wedge mm c/c L-angle

Wire Hanger

Perimeter Wall fixing Main Channel

Hammer Fixings

1220 mm c/c L-angle

150 mm 406 mm

Hat Furring Channel Knauf Joint Compound

TN Screw

UD-Channel Knauf Gypsum Board

150 mm 406 mm

Hat Furring Channel Knauf Joint Compound

TN Screw

UD-Channel Knauf Gypsum Board

Manual Ceiling (ASTM)-UB.indd 5 3/29/17 6:25 PM

Construction

Constructiondetails

Construction detailsfor

details forFire

for FireRated

Fire RatedSystems

Rated Systems

Systems

Construction details

Constructiondetails

details

Construction

E) Optional

E) Optional

E) Suspension

OptionalSuspension Support

SuspensionSupport

Support

Option

Option-- -111

Option Option

Option---222

Option

L-Angle

L-Angle

Wedge

WedgeAnchor

Anchor

Wire

WireHanger

Hanger

Main

MainChannel

Channel

TNTNScrew

Screw Hat

HatFurring

FurringChannel

Channel

LNLNScrew

Screw

Knauf

Knauf GypsumBoard

Gypsum Board

F)

F) Abutment

F) Abutmentto

Abutment towall,

to wall,parallel

wall, parallelto

parallel toprimary

to primarysupport

primary supportchannel,

support channel,double

channel, doublelayer

double layer

layer

Wedge

WedgeAnchor

Anchor

Perimeter

PerimeterWall

Wallfixing

fixing L L- angle

Hammer - angle

HammerFixings

Fixings Main

MainChannel

Channel

LNLNScrew

Screw 1220

1220mm

mmc/cc/cL-angle

L-angle

150

150mm

mm 406

406mm

mm

Hat

HatFurring

FurringChannel

Channel Knauf

KnaufJoint

JointCompound

Compound

TNTNScrew

Screw

UD-Channel Knauf

KnaufGypsum

GypsumBoard

Board

UD-Channel

Manual Ceiling (ASTM)-UB.indd 6 3/29/17 6:25 PM

Construction details for Fire Rated Systems

Construction details for Fire Rated Systems

G)

G) Change

G) Changeof

Change ofoflevel

leveland

level and

and bulkhead

bulkhead

bulkhead

Wedge

Wedge Anchor

Anchor

UD-Channel

UD-Channel

Hat

Hat Furring

Furring

Channel

Channel LL -- Angle

Angle

Main

Main Channel

Channel

200

200 mm

mm Perimeter Wall

Perimeter Wall fixing

fixing

LN

LN Screw

Screw Hammer Fixings

Hammer Fixings

UD-Channel

UD-Channel

Hat

Hat Furring

Furring Channel

Channel UD-Channel

UD-Channel

TN

TN Screw

Screw Knauf

Knauf Gypsum

Gypsum Board

Board Fire

Fire Sealant

Sealant

H)H) Movement

H) Movementcontrol

Movement control

control joint

joint

joint

Knauf

Knauf Approved

Approved Fixing

Fixing

LL -- angle

angle

LN

LN Screw

Screw

Main Channel

Main Channel

Hat

Hat Furring

Furring Channel

Channel

TN Knauf

Knauf Movement

TN Screw

Screw Movement

Control

Control Joint

Joint

Manual Ceiling (ASTM)-UB.indd 7 3/29/17 6:25 PM

Construction details for Fire Rated Systems

Construction details for Fire Rated Systems

Construction details for Fire Rated Systems

I) Junction with partition

I)I) Junction

Junction with

with partition

partition

Wedge Anchor

Wedge Anchor

Wedge Anchor

Wedge Anchor

L - Angle

L - Angle

50 mm 50 mm

UD-Channel

Main Channel 50 mm 50 mm

UD-Channel

LN Screw

Main Channel

LN Screw

TN Screw Hat Furring Channel

Fire Sealant KnaufHat

Gypsum

TN Screw FurringBoard

Channel

Fire Sealant Knauf Gypsum Board

J)J) Reinforcement

Reinforcementof

ofBoard

BoardJoints

Joints(Square edge only)

J) Reinforcement of Board Joints (Square edge only)

For Fire Resistant System

For Fire Resistant System

Hat Furring Channel

Hat Furring

Main ChannelChannel

Main Channel

TN Screw

Knauf Joint Compound

TN Screw

Knauf Joint Compound Knauf Gypsum Board

Knauf Gypsum Board

Manual Ceiling (ASTM)-UB.indd 8 3/29/17 6:25 PM

Construction details for Non Fire Rated Systems

Construction

Construction details

details for

for Non

Non Fire

Fire Rated

Rated Systems

Systems

Thesedetails

These detailsrepresent

representsome

someofofthe

themost

mostcommon

commondesigns

designssituations

situationsrelevant

relevanttotothe

the

Knauf KC A001 ceiling systems.

Knauf KC A001 ceiling systems.

These details represent some of the most common designs situations relevant to the

Knauf KC A001 ceiling systems.

K) Optional

K) Optional Suspension

Suspension Support

Support

K) Optional Suspension Support

Option

Option--11 Option - 2

Option - 2

Option - 1 Option - 2

Wedge Anchor

L-Angle Wire Hanger

Main Channel

Wedge Anchor

L-Angle Wire Hanger

Main Channel

TN Screw Hat Furring Channel

Knauf Gypsum Board LN Screw

TN Screw Hat Furring Channel

Knauf Gypsum Board LN Screw

L) Abutment to wall, parallel to primary support channel

L)

L) Abutment

Abutment to

to wall,

wall, parallel

parallel to

to primary

primary support

support channel

channel

Wedge Anchor

Perimeter Wall fixing L - angle

Hammer Fixings Main Channel

Wedge Anchor

Perimeter Wall LN Screw

fixing L - angle1220 mm c/c L-angle

Hammer Fixings Main Channel

LN Screw 1220 mm c/c L-angle

150 mm 406 mm

Hat Furring Channel Knauf Joint Compound

TN Screw

150 mm UD-Channel 406 mm Knauf Gypsum Board

Hat Furring Channel Knauf Joint Compound

TN Screw

UD-Channel Knauf Gypsum Board

Manual Ceiling (ASTM)-UB.indd 9 3/29/17 6:25 PM

Constructiondetails

Construction details forNon

Non FireRated

Rated Systems

Construction detailsfor

for NonFire

Fire RatedSystems

Systems

These details represent some of the most common designs situations relevant to the

These

Knaufdetails

KC A001represent

ceiling some of the most common designs situations relevant to the

systems.

These details

Knauf KC A001 represent some of the most common designs situations relevant to the

ceiling systems.

Knauf KC A001 ceiling systems.

M) Abutment to wall, perpendicular to primary support channel

M) Abutment to wall, perpendicular to primary support channel

M) Abutment to wall, perpendicular to primary support channel

Wedge Anchor

Perimeter Wall fixing

WedgeL Anchor

- angle

Hammer

Main LChannel Perimeter WallFixings

fixing

- angle

Hammer Fixings

Main Channel

1000 mm 200 mm

1000 mm 200 mm

TN Screw Hat Furring Channel

UD-Channel

TN Screw

Knauf Gypsum Board Hat Furring Channel

LN Screw UD-Channel

Knauf Gypsum Board LN Screw

N) Abutment to wall, parallel to primary support channel

N)

N) Abutment

Abutmenttotowall,

wall,parallel

parallelto

toprimary

primarysupport

supportchannel

channel

Wedge Anchor

Wire

WedgeHanger

Anchor

Perimeter Wall fixing Main Channel

Hammer Wire Hanger

PerimeterFixings

Wall fixing Main Channel

Hammer Fixings 1220 mm c/c L-angle

1220 mm c/c L-angle

150 mm 406 mm

150 mm Hat Furring Channel 406 mm Knauf Joint Compound

TN Hat

Screw

Furring Channel Knauf Joint Compound

UD-Channel

TN Screw Knauf Gypsum Board

UD-Channel Knauf Gypsum Board

10

Manual Ceiling (ASTM)-UB.indd 10 3/29/17 6:25 PM

Construction details for Non Fire Rated Systems

Construction details for Non Fire Rated Systems

Construction details for Non Fire Rated Systems

O) Change of level and bulkhead

O) Change

O) Changeof

oflevel

leveland

andbulkhead

bulkhead

Wedge Anchor

UD-Channel

Hat Furring Wedge Anchor

UD-Channel

Channel

Hat Furring L - Angle

Channel

L - Angle

Main Channel

200 mm Perimeter Wall fixing

LN Screw

Main Channel Hammer Fixings

UD-Channel

200 mm

LN Screw Perimeter Wall fixing

UD-Channel Hammer Fixings

TN Screw Hat Furring Channel UD-Channel

Knauf Gypsum Board Fire Sealant

TN Screw Hat Furring Channel UD-Channel

Knauf Gypsum Board Fire Sealant

P)P) Movement

Movementcontrol

controljoint

joint

P) Movement control joint

Knauf Approved Fixing

L - angle

Knauf Approved

LN ScrewFixing

L - angle

Main Channel

LN Screw

Main Channel

Hat Furring Channel

Knauf Movement

TN Screw

Hat Furring Channel Control Joint

Knauf Movement

TN Screw

Control Joint

11

Manual Ceiling (ASTM)-UB.indd 11 3/29/17 6:25 PM

Construction details for Non Fire Rated Systems

Construction details for Non Fire Rated Systems

Construction details for Non Fire Rated Systems

Q)Junction

Q) Junctionwith

withPartition

Partition

Q) Junction with Partition

Wedge Anchor

WedgeL Anchor

- angle Knauf UW Runner

L - angle Knauf Drywall

Knauf UW Runner

Screw

50 mm 50 mm

Knauf Drywall

Knauf GypsumScrew

Board

Main Channel

50 mm 50 mm

LN Screw Knauf CW Stud

Main Channel Knauf Gypsum Board

Insulation Material

LN Screw Knauf CW Stud

Insulation Material

Hat Furring Channel Knauf Gypsum Board

UD-Channel Fire Sealant

Hat Furring ChannelTN Screw Knauf Gypsum Board

UD-Channel Fire Sealant

TN Screw

R)

R) Reinforcement

Reinforcementof

ofBoard

BoardJoint

Joint(Square edge Only)

R) Reinforcement of Board Joint (Square edge Only)

Hat Furring Channel

Main Channel

Hat Furring Channel

Main Channel

TN Screw

Knauf Joint Compound Knauf Gypsum Board

TN Screw

Knauf Joint Compound Knauf Gypsum Board

12

Manual Ceiling (ASTM)-UB.indd 12 3/29/17 6:25 PM

General information

General Insulation

Knauf KC A001 Ceiling Systems must be installed in If insulation is required, once the primary support

accordance with Knauf 's recommendations. When and the ceiling channels have been connected and

creating an airtight space, methods for the reduction of before the boarding has started, Knauf insulation

potential “ceiling lift ’’ should be considered. as specified should be inserted above the primary

support channels. Care should be taken to ensure

Perimeter Fixing that the insulation is fitted neatly without gaps at

Mark the position of the ceiling line with a Chalk Line (1). abutments or between different rolls.

Knauf UD channels should be secured to the walls at the

required heights, at maximum 609mm centers and 50mm Movement Control Joints

from the ends of channels. The Knauf UD forming the Create movement control joints where ceiling

perimeter and the Knauf Main C Channels do not need to runs exceed 10m, coinciding where possible with

be mechanically fixed together (2). movement joints in the surrounding structure.

Suspension Boarding

Select the fixing centers suited to the ceiling loading. See All boards should be fixed to the ceiling grid

page 3 for spacing of dowels. with the decorative face of the boards outwards and

Fix Knauf approved fixing to the structural soffit with secured with Knauf Screws at maximum 203 mm

suitable fixings. Use the Knauf L Angle and fix to the centers (6).

approved fixing dowel (3). Boards should be mounted at 90° to the direction of

the ceiling channels (7).

Primary Support Channels – C Second layer should be installer with staggered joints.

Channels as shown in details (J) page 8

The centers of the primary support channels should be

aligned at the required height.

Knauf L Angle should be fixed to the Knauf Main C

Channels with two Knauf LN Wafer Head Screws (4). Board Joint Reinforcement

(Only for Fire Resistant System)

Splicing of the Main C Channels

If straight lengths of Knauf Main C Channels Where the cut end of Gypsum board end’s

need jointing, place the channels back to Reinforcement through the inclusion of additional Hat

back, with a minimum 609 mm overlap, and fix with Furring Channels should be implemented. A piece of

two Knauf LN Wafer Head Screws. Hat Furring channel should be located approx. 1 inch

back from each board edge.

Hat Furring Channels

The Knauf Hat Furring Channels should be

positioned at 406mm centers within the perimeter

channels to coincide with the abutments of the

boards, which will be fixed later. Connect the Knauf Hat

Furring Channels to the Knauf Main C Channel by means

of Knauf LN Wafer Head Screws (5).

13

Manual Ceiling (ASTM)-UB.indd 13 3/29/17 6:25 PM

Installation steps

Mark the position of the ceiling Fix the UD channel on the Predrill the holes for the

1 line (deducting the thickness of 2 perimeter (at 609mm centers 3

the boards) with a Chalk Line. and 50mm from end of channel). the dowel (e.g. Wedge Anchor)

at the recommended spacing.

Knauf Main C Channels should Connect the Knauf Hat Furring Channels to the

4 5 Knauf Main C Channel by means of Knauf LN Wafer Head Screws

Knauf LN Wafer Head Screws

at the desired length.

Fix the boards to the furring channel with

6 max. 203 mm. 7 Knauf screws.

14

Manual Ceiling (ASTM)-UB.indd 14 3/29/17 6:25 PM

Processing of gypsum boards

Score the board by pushing along the

Cut the paper face with a sharp knife

cut side, then cut the other paper side

Cut the board 45 degrees Smooth the cut edge with a beveler

Cutting and processing the boards

n Knauf Boards shall be cut by scoring and breaking or by sawing

n When cutting by scoring, the face paper shall be cut with a utility knife

n Knauf boards shall be broken by snapping boards in the reverse direction, then cutting the

back paper with a utility knife

n Cut edges should be smoothed with Knauf Beveler / Rasp Combo to obtain neat

joints when installed

n Short edges should be chamfered with Knauf Beveler / Rasp Combo

n Holes for pipes or other small openings shall be scored on the back and the face outlined before

removal / cut out with a purposely designed tool

15

Manual Ceiling (ASTM)-UB.indd 15 3/29/17 6:25 PM

Joint treatment

Cutting and processing the boards

n Board surface should be cleaned of materials such as dust, oil etc.

n Filling and covering of joints should only take place after the boards have been allowed to

rest in the given humidity and temperature zones, and no more longitudinal

changes can be expected, i.e. expansion or contraction.

n Firstcoat of Knauf Joint filler should be applied with tools of sufficient width to extend a

minimum 50 mm beyond both sides of the center of the joint (100 mm width).

n Knauf Joint Tape should be embedded into the joint filler to reinforce the joint between two

gypsum boards.

n Once the first coat has dried, a second coat of Knauf Joint filler should be applied with 100 mm

width on both sides of the center of the joint tape (200 mm width).

n A very thin third coat of Knauf Joint filler should be applied with a minimum width no less than

150 mm beyond both sides of the center of the joint tape (300 mm width).

n Once third coat has dried, surface should be sanded and smoothed.

16

Manual Ceiling (ASTM)-UB.indd 16 3/29/17 6:25 PM

Cladding of boards

Boards should be mounted at 90° to the direction of the ceiling channels.

In case of multi layer cladding, apply layers with staggered joints according to application scheme.

.

Spacing of screws Fastening of cladding

Board thickness First layer Second layer

Screw Spacing second layer: 203 mm 12.7 mm TN 3.9X25 mm TN 3.9X35 mm

15.9 mm TN 3.9X25 mm TN 3.9X45 mm

Single / First layer cladding

2436 mm

406 406 406 406 406 406

203 203 203 203

1000

1220

1220

1220

2436

17

Manual Ceiling (ASTM)-UB.indd 17 3/29/17 6:25 PM

Cladding

Cladding of

of boards

boards

Second

Second layer

layer cladding

cladding

Second

Second layer

layer should

should be

be installer

installer with

with staggered

staggered joints.

joints.

2) See Detail (J) page 08 406 406

2436 mm

406 406 406 406

203 203 203 203

1000

1220

1220

1220

ASTM Ceiling Accessories 2436

System’s components

35

38

23

22

22 25

12.5 35 12.5

12

67

Hat Furring Channel (0.5 mm. thk.) Main "C" Channel (1.4 mm. thk.) UD Channel (0.5 mm.thk.) L-Angle (0.5 mm.thk.)

TN Screw

3.9 dia. X 25/35/45 mm Length LN Screw Hammer Fixings Wedge Anchor

18

Manual Ceiling (ASTM)-UB.indd 18 3/29/17 6:25 PM

Certifications

Estidama Requirements

Asbestos content

The boards produced at the Knauf factory in Ras Al Khaimah have been tested on asbetos content. No asbestos

could be traced in the boards’ composition. Complies with the requirements of EN 13964.

Formaldehyde content

The boards produced at the Knauf factory in Ras Al Khaimah have been tested on DIN EN ISO 16009 for

formaldehyde emissions. Maximum concentration levels 16µg/m3(0.016mg/m3) (complies with the requirements

of EN 13964).

Regional Materials

On a range of 500 miles from factory and quarry location, our boards can provide

points for regional materials mentioned in different evaluation criteria (LEED,

Estidama, etc.).

Total VOC content

Our boards have been tested for total Volatile Organic Compounds emissions.

Detected amount: below 0.05 mg/kg.

Certificate of Registration

QUALITY MANAGEMENT SYSTEM - ISO 9001:2008

This is to certify that: Knauf LLC

PO Box 112871

Dubai

United Arab Emirates

Holds Certificate No: FM 577441

and operates a Quality Management System which complies with the requirements of ISO 9001:2008 for the

following scope:

The production of Metal Profiles, Plasters, Plasterboards, Ready Fix and all supporting activities

within the Middle East.

For and on behalf of BSI:

Gary Fenton, Global Assurance Director

Originally registered: 09/11/2011 Latest Issue: 25/09/2014 Expiry Date: 09/11/2017

Environmental certifications

Page: 1 of 2

For outstanding performances in water and energy

This certificate was issued electronically and remains the property of BSI and is bound by the conditions of contract.

An electronic certificate can be authenticated online.

Printed copies can be validated at www.bsi-global.com/ClientDirectory or telephone +971 (4) 3364917.

manangement, our factory has been recently awarded the

Information and Contact: BSI, Kitemark Court, Davy Avenue, Knowlhill, Milton Keynes MK5 8PP. Tel: + 44 845 080 9000

BSI Assurance UK Limited, registered in England under number 7805321 at 389 Chiswick High Road, London W4 4AL, UK.

Environmental Performance Certificate from the Ministry of

Environment & Water.

Quality Management System ISO 9001: 2008

19

Manual Ceiling (ASTM)-UB.indd 19 3/29/17 6:25 PM

Knauf Head Office Knauf Manufacturing Plant Knauf Gypsum India Pvt.Ltd

P.O.Box 50006 No. 8 - C, 8th Floor Commercial Complex

Phone: +971 4 337 7170 Ras Al Khaimah, U.A.E. Doshi Tower, New No. 205, (Old No. 156)

Tel: +971 7 221 5300 Poonamallee High Road, Kilpauk

Fax: +971 4 334 9659 Chennai - 600010.Tamil Nadu, India

Fax: +971 7 221 5301

Tel: +91 44 49580000

PP.O.Box: 112871, Dubai UAE Fax: +91 44 49575300

info@knauf.ae The information provided in this leaflet is only intended to give guidance in selecting and using Knauf products. While we make every effort to ensure its accuracy, neither Knauf LLC and its branches

nor any of tis employees or affiliates warrant or assume any legal liability or responsibility for the completeness or usefullness of any failure in installation or constructing any structure installation or building

or caused by using this leaflet. Readers are adviced to independently verify this information prior to rely on it. In particular, readers must obtain appropriate independent advice on the use of products

in specific structures, insllations or buildings to ensure compliance with all regulations, including health and safety regulations. Knauf reserves the right to amend technical specification without notice.

www. .ae The constructional and structural properties, and characteristic building physics Knauf system can solely be

ensured with the exclusive use Knauf system components, or other product expressly recommended by Knauf.

Manual Ceiling (ASTM)-UB.indd 20 3/29/17 6:25 PM

S-ar putea să vă placă și

- Exxonmobil Interview Questions and AnswersDocument60 paginiExxonmobil Interview Questions and Answersrajkamal eshwar100% (3)

- Lesson Plan On Transport MechanismsDocument5 paginiLesson Plan On Transport Mechanismsjecel taray100% (4)

- Ranjit SinghDocument8 paginiRanjit SinghRANJIT100% (1)

- Exportlayers DWG ISO13567Document5 paginiExportlayers DWG ISO13567majstorÎncă nu există evaluări

- Δ Table 6.1.14.4.1 (a) Required Separation of Occupancies (hours) ,† Part 1Document2 paginiΔ Table 6.1.14.4.1 (a) Required Separation of Occupancies (hours) ,† Part 1JamesÎncă nu există evaluări

- The Woodrise 2019 Quebec CityDocument10 paginiThe Woodrise 2019 Quebec Citygulilero_yoÎncă nu există evaluări

- Drywall Manual Fire ProtectionDocument33 paginiDrywall Manual Fire ProtectionPavaloaie Marian ConstantinÎncă nu există evaluări

- Product Technical Sheet - Saflex Structural 092618 0Document5 paginiProduct Technical Sheet - Saflex Structural 092618 0J RogerÎncă nu există evaluări

- Knauf ASTM Partition ManualDocument60 paginiKnauf ASTM Partition ManualStevan MavrenovicÎncă nu există evaluări

- Xtratherm Thermal Bridging Y Value Calc GuideDocument14 paginiXtratherm Thermal Bridging Y Value Calc Guidekevin smithÎncă nu există evaluări

- Systemline Guide 1Document48 paginiSystemline Guide 1Zamfira OctavianÎncă nu există evaluări

- Construction Document Sheet Numbers and Sheet OrderDocument4 paginiConstruction Document Sheet Numbers and Sheet OrderAnnisa SyahraniÎncă nu există evaluări

- Minimal Interior Design Ideas To Beautify Your HouseDocument3 paginiMinimal Interior Design Ideas To Beautify Your House8 SquareÎncă nu există evaluări

- En 323-1993-EnDocument7 paginiEn 323-1993-EnxyzhynÎncă nu există evaluări

- 10.21307 - Immunohematology 2022 048 PDFDocument6 pagini10.21307 - Immunohematology 2022 048 PDFTanupreetÎncă nu există evaluări

- Exilis Ultra 360 Brochure Face qNaWU5wmOeC0zuWDocument2 paginiExilis Ultra 360 Brochure Face qNaWU5wmOeC0zuWJohn LuÎncă nu există evaluări

- Partition ManualDocument42 paginiPartition ManualAnonymous SblBDN0Încă nu există evaluări

- Academic Mediacal Center DSO Dubai DD AR R 0003 GEN R02 Acoustic ReportDocument23 paginiAcademic Mediacal Center DSO Dubai DD AR R 0003 GEN R02 Acoustic ReportNeeskens D'melloÎncă nu există evaluări

- Kitchens Catalogue 2020Document38 paginiKitchens Catalogue 2020Ghulam MujtabaÎncă nu există evaluări

- Soundproofing Solutions-En 2019 02 PDFDocument182 paginiSoundproofing Solutions-En 2019 02 PDFTanase MariusÎncă nu există evaluări

- Zbornik IA2014Document198 paginiZbornik IA2014Marija StoilovićÎncă nu există evaluări

- Applsci 12 06983 v2Document16 paginiApplsci 12 06983 v2Márquez Rojas UlisesÎncă nu există evaluări

- EC 1 - Actions On StructuresDocument52 paginiEC 1 - Actions On StructuresMarcelo Zapata Muñoz0% (1)

- Executive Design of The Façade SystemsDocument145 paginiExecutive Design of The Façade Systemsgerhard.ueber100% (1)

- TGD Part EDocument88 paginiTGD Part EOlivia SaferÎncă nu există evaluări

- Door Sealing Systems: Product CatalogueDocument184 paginiDoor Sealing Systems: Product CatalogueFábio AndréÎncă nu există evaluări

- Shotcrete TechnologyDocument11 paginiShotcrete TechnologyShubhamKumarÎncă nu există evaluări

- DesignBuilder 2.1 Users-Manual LTRDocument642 paginiDesignBuilder 2.1 Users-Manual LTREsteban Omar Bugueño Lara100% (1)

- LP Solidstart LVL Technical Guide EnglishDocument16 paginiLP Solidstart LVL Technical Guide EnglishAngel LigthÎncă nu există evaluări

- Promaseal ADocument4 paginiPromaseal AKamila JihaneÎncă nu există evaluări

- Seismic Design CLTDocument124 paginiSeismic Design CLTBanuta GabrielÎncă nu există evaluări

- Tips For Daylighting 2013Document137 paginiTips For Daylighting 2013mydearteacherÎncă nu există evaluări

- Rev EN 13830 41 e STF PDFDocument81 paginiRev EN 13830 41 e STF PDFmuhammed_bulanÎncă nu există evaluări

- Introduction To Aeronautical Engineering: Amir TeimourianDocument32 paginiIntroduction To Aeronautical Engineering: Amir TeimourianamirÎncă nu există evaluări

- Creating GDL Objects E-GuideDocument192 paginiCreating GDL Objects E-GuideVali EnciuÎncă nu există evaluări

- Enhanced Use of The Work Breakdown Structure by Application of Unique Activity Coding As A Universal Reference Throughout A Project's Lifecycle.Document94 paginiEnhanced Use of The Work Breakdown Structure by Application of Unique Activity Coding As A Universal Reference Throughout A Project's Lifecycle.Theo MoolmanÎncă nu există evaluări

- High Rise Facades: Design and Installation GuideDocument60 paginiHigh Rise Facades: Design and Installation GuidealfieÎncă nu există evaluări

- Classroom Design GuidelinesDocument46 paginiClassroom Design Guidelinesmkrmalathi963Încă nu există evaluări

- ArchiCAD 12 BrochureDocument8 paginiArchiCAD 12 BrochurePratheesh JaisonÎncă nu există evaluări

- Proekt Za Beton - Most Na Reka Vardar PDFDocument78 paginiProekt Za Beton - Most Na Reka Vardar PDFNenad GajicÎncă nu există evaluări

- Tube Clamps 2015Document48 paginiTube Clamps 2015Peter DavidsonÎncă nu există evaluări

- H11 Roof and Wall Systems ............................................................................ 5Document53 paginiH11 Roof and Wall Systems ............................................................................ 5Anonymous qabSVjzrAÎncă nu există evaluări

- Kalzip Sets StandardsDocument32 paginiKalzip Sets StandardsClef GonadanÎncă nu există evaluări

- Celotex BBA - Cavity WallsDocument12 paginiCelotex BBA - Cavity Wallsfaber1972Încă nu există evaluări

- Technical Manual Whole 09 - BRICKDocument150 paginiTechnical Manual Whole 09 - BRICKMuhamad Zaid Md ZinÎncă nu există evaluări

- Nail-Laminated Timber Design & Construction GuideDocument142 paginiNail-Laminated Timber Design & Construction GuideVer LibertadoresÎncă nu există evaluări

- HSE-Acoustic & Fire DoorsDocument6 paginiHSE-Acoustic & Fire DoorsInterior ProjectsÎncă nu există evaluări

- Airsculpt Tensile DownloadDocument6 paginiAirsculpt Tensile DownloadCristi BudauÎncă nu există evaluări

- Ruukki Sandwich PanelsDocument48 paginiRuukki Sandwich PanelsPrabu RengarajanÎncă nu există evaluări

- Lighting Guide PDFDocument11 paginiLighting Guide PDFSteven HungÎncă nu există evaluări

- Richter Fouad - Guidelines For Thermography in Architecture and Civil Engineering Theory Application Areas Practical Implementation PDFDocument185 paginiRichter Fouad - Guidelines For Thermography in Architecture and Civil Engineering Theory Application Areas Practical Implementation PDFTomi Gánn100% (2)

- BREEAM 2011 Hea 05 Acoustic Performance (Requirements For All Schemes)Document22 paginiBREEAM 2011 Hea 05 Acoustic Performance (Requirements For All Schemes)mikelotingaÎncă nu există evaluări

- Knauf ENBS Partition ManualDocument44 paginiKnauf ENBS Partition ManualB P Raju RajuÎncă nu există evaluări

- 3.BSEEP Passive Design GuidebookDocument194 pagini3.BSEEP Passive Design GuidebookDennis Lai Zhan WenÎncă nu există evaluări

- White Book C04 Partitions Section 3Document180 paginiWhite Book C04 Partitions Section 3Chris FindlayÎncă nu există evaluări

- Voltex CIP Product ManualDocument24 paginiVoltex CIP Product ManualgkutÎncă nu există evaluări

- 2014-04-22 Megaprofil ROM SandExcel OfferDocument1 pagină2014-04-22 Megaprofil ROM SandExcel OfferCibotaru MihaiÎncă nu există evaluări

- Windows Specification - Replacement WindowsDocument13 paginiWindows Specification - Replacement WindowsthaidzungÎncă nu există evaluări

- Detail 2006-01-02 PDFDocument25 paginiDetail 2006-01-02 PDFOrlando de Medici100% (1)

- 7 Building TypesDocument160 pagini7 Building TypesSashwat GhaiÎncă nu există evaluări

- Example Cost ModelDocument3 paginiExample Cost ModelAdam TurnerÎncă nu există evaluări

- PRYDA - Connectors & Tie-Down Guide February 2013Document24 paginiPRYDA - Connectors & Tie-Down Guide February 2013Joshua GibbingsÎncă nu există evaluări

- Rheinzink Roof Covering SystemsDocument16 paginiRheinzink Roof Covering Systemspablo_658Încă nu există evaluări

- ISO 128-3:2020 (E) : © ISO 2020 - All Rights ReservedDocument5 paginiISO 128-3:2020 (E) : © ISO 2020 - All Rights ReservedYair Eduardo Mendoza AguilarÎncă nu există evaluări

- Knauf ASTM Ceiling ManualDocument20 paginiKnauf ASTM Ceiling ManualNoshad ul HaqÎncă nu există evaluări

- CERC Regulations FY 21-22Document224 paginiCERC Regulations FY 21-22dishkuÎncă nu există evaluări

- Meridians Deficient Meridians ExcessiveDocument6 paginiMeridians Deficient Meridians ExcessivedishkuÎncă nu există evaluări

- TCM Acupoint TheoryDocument57 paginiTCM Acupoint Theorydishku100% (2)

- Saddle Support SpacingDocument1 paginăSaddle Support SpacingdishkuÎncă nu există evaluări

- National Health Accounts Estimates Report 2014-15 PDFDocument76 paginiNational Health Accounts Estimates Report 2014-15 PDFdishkuÎncă nu există evaluări

- Human Structure and Function IDocument54 paginiHuman Structure and Function IdishkuÎncă nu există evaluări

- An Introduction To The Human Body: - AnatomyDocument28 paginiAn Introduction To The Human Body: - AnatomydishkuÎncă nu există evaluări

- Acupuncture 5 Element Points and LocationsDocument1 paginăAcupuncture 5 Element Points and Locationsdishku100% (2)

- Extracted Pages From 8. AcumedicoDocument1 paginăExtracted Pages From 8. AcumedicodishkuÎncă nu există evaluări

- Pulse DiagnosisDocument10 paginiPulse DiagnosisdishkuÎncă nu există evaluări

- 10 Beautiful Examples of Symmetry in NatureDocument12 pagini10 Beautiful Examples of Symmetry in Naturedishku100% (2)

- Rainfall DataDocument25 paginiRainfall DatadishkuÎncă nu există evaluări

- Table 12: Painting Schedule For Steel PenstockDocument1 paginăTable 12: Painting Schedule For Steel PenstockdishkuÎncă nu există evaluări

- Hydromechanical - Technical SpecificationsDocument16 paginiHydromechanical - Technical SpecificationsdishkuÎncă nu există evaluări

- CPWD Rain - Water Harvesting ManualDocument7 paginiCPWD Rain - Water Harvesting ManualdishkuÎncă nu există evaluări

- ഇന്ത്യൻ ഭരണഘടന - പാഠപുസ്തകംDocument267 paginiഇന്ത്യൻ ഭരണഘടന - പാഠപുസ്തകംdishkuÎncă nu există evaluări

- Workers Available at SiteDocument8 paginiWorkers Available at SitedishkuÎncă nu există evaluări

- Energy and Buildings: Mohammad-Hossein Shariatkhah, Mahmoud-Reza Haghifam, Mohesn Parsa-Moghaddam, Pierluigi SianoDocument8 paginiEnergy and Buildings: Mohammad-Hossein Shariatkhah, Mahmoud-Reza Haghifam, Mohesn Parsa-Moghaddam, Pierluigi SianodishkuÎncă nu există evaluări

- Element: Metal The Lung MeridianDocument2 paginiElement: Metal The Lung MeridiandishkuÎncă nu există evaluări

- The Gravitational Vortex Water Turbine Puts Small Hydro On The Map - EE PublishersDocument10 paginiThe Gravitational Vortex Water Turbine Puts Small Hydro On The Map - EE Publishersdishku100% (1)

- Design Request Neoloy Geocell Slope Protection SystemDocument4 paginiDesign Request Neoloy Geocell Slope Protection SystemdishkuÎncă nu există evaluări

- Geometry in NatureDocument33 paginiGeometry in NaturedishkuÎncă nu există evaluări

- Expenses Tracker TrialDocument39 paginiExpenses Tracker TrialdishkuÎncă nu există evaluări

- Science Year 5: MicroorganismsDocument8 paginiScience Year 5: MicroorganismscthanifahÎncă nu există evaluări

- Project ManagementDocument6 paginiProject ManagementVarunÎncă nu există evaluări

- Classroom of The Elite Volume 12Document276 paginiClassroom of The Elite Volume 12Kaung Khant100% (1)

- Qualities of Effective Business LettersDocument39 paginiQualities of Effective Business Letterskrystel0% (1)

- TKT Module 1 Task Type 4 Introduction To Odd One Out Tasks PDFDocument9 paginiTKT Module 1 Task Type 4 Introduction To Odd One Out Tasks PDFRachel Maria RibeiroÎncă nu există evaluări

- Employee WelfareDocument64 paginiEmployee WelfareJana DxÎncă nu există evaluări

- EE 421-Digital System Design-Dr. Shahid Masud-Updated PDFDocument4 paginiEE 421-Digital System Design-Dr. Shahid Masud-Updated PDFUbaid UmarÎncă nu există evaluări

- Esr 2653Document9 paginiEsr 2653Uğur ErdoğanÎncă nu există evaluări

- CV - Akhil AgarwalDocument2 paginiCV - Akhil AgarwalIshan SaxenaÎncă nu există evaluări

- Lanco Antifloat D-14, TDSDocument2 paginiLanco Antifloat D-14, TDSZein HayekÎncă nu există evaluări

- Subject-Verb AgreementDocument6 paginiSubject-Verb AgreementCheryl AquinoÎncă nu există evaluări

- David Burlock LamoreauxDocument21 paginiDavid Burlock LamoreauxLeena RogersÎncă nu există evaluări

- DefinitionsDocument7 paginiDefinitionsJazmine ButuhanÎncă nu există evaluări

- Statistical Physics Phy632-Tutorial: Sharifah Hafizah Binti Syed Ab AzizDocument26 paginiStatistical Physics Phy632-Tutorial: Sharifah Hafizah Binti Syed Ab AzizSharifahHafizahAl-jufÎncă nu există evaluări

- God Only Knows Chords UkuleleDocument3 paginiGod Only Knows Chords UkuleleMark0% (1)

- Paul Brunton - WikipediaDocument3 paginiPaul Brunton - WikipediaShabd_MysticÎncă nu există evaluări

- Air ConditionerDocument131 paginiAir ConditionerRahul AnsariÎncă nu există evaluări

- Introduction To Social WorkDocument3 paginiIntroduction To Social WorkSheherbano TariqÎncă nu există evaluări

- Cost Optimisation of Water Tanks Designed According To The Aci and Euro CodesDocument25 paginiCost Optimisation of Water Tanks Designed According To The Aci and Euro CodesandysupaÎncă nu există evaluări

- Week 7Document14 paginiWeek 720331a1212Încă nu există evaluări

- Restful ApiDocument27 paginiRestful ApiBlank UserÎncă nu există evaluări

- Basso - 2001 - Neurobiological Relationships Between Ambient Ligh PDFDocument11 paginiBasso - 2001 - Neurobiological Relationships Between Ambient Ligh PDFVíctor MJÎncă nu există evaluări

- Aadi Amavasya SpecialDocument5 paginiAadi Amavasya SpecialjyoprasadÎncă nu există evaluări

- Simulation of CO2 Capture Using MEA Scrubbing A Flowsheet Decomposition Method PDFDocument13 paginiSimulation of CO2 Capture Using MEA Scrubbing A Flowsheet Decomposition Method PDFSuprio KamalÎncă nu există evaluări

- CSR ReportDocument13 paginiCSR Reportrishabh agarwalÎncă nu există evaluări