Documente Academic

Documente Profesional

Documente Cultură

WPS Format

Încărcat de

akhilsyam210 evaluări0% au considerat acest document util (0 voturi)

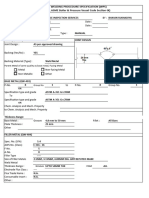

164 vizualizări2 paginiQW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONS (WPS) JOINTS (QW-402) Joint Design Backing (Yes) Backing Material (Type) Metal Nonmetallic (No) where applicable, the root spacing and the details of weld groove may be specified.

Descriere originală:

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentQW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONS (WPS) JOINTS (QW-402) Joint Design Backing (Yes) Backing Material (Type) Metal Nonmetallic (No) where applicable, the root spacing and the details of weld groove may be specified.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

164 vizualizări2 paginiWPS Format

Încărcat de

akhilsyam21QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONS (WPS) JOINTS (QW-402) Joint Design Backing (Yes) Backing Material (Type) Metal Nonmetallic (No) where applicable, the root spacing and the details of weld groove may be specified.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

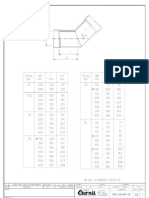

QW-482 SUGGESTED FORMAT FOR WELDING PROCEDURE SPECIFICATIONS (WPS)

(See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)

Company Name By:

Welding Procedure Specification No. Date Supporting PQR No.(s)

Revision No. Date

Welding Process(es) Type(s)

(Automatic, Manual, Machine, or Semi-Auto.)

JOINTS (QW-402) Details

Joint Design

Backing (Yes) (No)

Backing Material (Type)

(Refer to both backing and retainers.)

Metal Nonfusing Metal

Nonmetallic Other

Sketches, Production Drawings, Weld Symbols or Written Description

should show the general arrangement of the parts to be welded. Where

applicable, the root spacing and the details of weld groove may be

specified.

(At the option of the Mfgr., sketches may be attached to illustrate joint

design, weld layers and bead sequence, e.g., for notch toughness proce-

dures, for multiple process procedures, etc.)

*BASE METALS (QW-403)

P-No. Group No. to P-No. Group No.

OR

Specification type and grade

to Specification type and grade

OR

Chem. Analysis and Mech. Prop.

to Chem. Analysis and Mech. Prop.

Thickness Range:

Base Metal: Groove Fillet

Other

*FILLER METALS (QW-404)

Spec. No. (SFA)

AWS No. (Class)

F-No.

A-No.

Size of Filler Metals

Weld Metal

Thickness Range:

Groove

Fillet

Electrode-Flux (Class)

Flux Trade Name

Consumable Insert

Other

*Each base metal-filler metal combination should be recorded individually.

QW-482 (Back)

WPS No. Rev.

POSITIONS (QW-405) POSTWELD HEAT TREATMENT (QW-407)

Position(s) of Groove Temperature Range

Welding Progression: Up Down Time Range

Position(s) of Fillet

GAS (QW-408)

PREHEAT (QW-406) Percent Composition

Preheat Temp. Min. Gas(es) (Mixture) Flow Rate

Interpass Temp. Max.

Preheat Maintenance Shielding

(Continuous or special heating, where applicable, should be recorded) Trailing

Backing

ELECTRICAL CHARACTERISTICS (QW-409)

Current AC or DC Polarity

Amps (Range) Volts (Range)

(Amps and volts range should be recorded for each electrode size,

position, and thickness, etc. This information may be listed in a tab-

ular form similar to that shown below.)

Tungsten Electrode Size and Type

(Pure Tungsten, 2% Thoriated, etc.)

Mode of Metal Transfer for GMAW

(Spray arc, short circuiting arc, etc.)

Electrode Wire feed speed range

TECHNIQUE (QW-410)

String or Weave Bead

Orifice or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding, etc.)

Method of Back Gouging

Oscillation

Contact Tube to Work Distance

Multiple or Single Pass (per side)

Multiple or Single Electrodes

Travel Speed (Range)

Peening

Other

Filler Metal Current

Other

(e.g., Remarks, Com-

Travel ments, Hot Wire

Weld Type Amp Volt Speed Addition, Technique,

Layer(s) Process Class Dia. Polar. Range Range Range Torch Angle, etc.)

S-ar putea să vă placă și

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDe la EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsEvaluare: 4.5 din 5 stele4.5/5 (10)

- Offshore Electrical Engineering ManualDe la EverandOffshore Electrical Engineering ManualEvaluare: 4 din 5 stele4/5 (9)

- Ansi Aga B109 1 2000Document43 paginiAnsi Aga B109 1 2000Ihab El-SaftawiÎncă nu există evaluări

- GE Custom 8000 Horizontal Induction Motor - GEEP-124-I (1998)Document41 paginiGE Custom 8000 Horizontal Induction Motor - GEEP-124-I (1998)Edson França Rodrigues100% (1)

- QW-482 WPS FormatDocument2 paginiQW-482 WPS FormatMardeOpamen100% (1)

- Procedure Qualification RecordDocument2 paginiProcedure Qualification RecordDan ClarkeÎncă nu există evaluări

- WPS1Document10 paginiWPS1bhavin178Încă nu există evaluări

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- IT418 - C# Programming Project: Lottery Number GeneratorDocument41 paginiIT418 - C# Programming Project: Lottery Number GeneratorCarmenLim07100% (5)

- CSS ExercisesDocument8 paginiCSS ExercisesWarnnie MusahÎncă nu există evaluări

- ASME WPS-PQR-WQT CombinedDocument6 paginiASME WPS-PQR-WQT CombinedStan HonÎncă nu există evaluări

- Formas Soldadura ASME IX 2017Document7 paginiFormas Soldadura ASME IX 2017Ulises GómezÎncă nu există evaluări

- Wps FormatDocument2 paginiWps FormatMeghan GhoneÎncă nu există evaluări

- 3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15eDocument6 pagini3 BodyPart Edcb3a5f Eede 445f A423 Ea2f5809c15emayank0738Încă nu există evaluări

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 paginiForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)mohammadÎncă nu există evaluări

- Sample Editable WPSDocument2 paginiSample Editable WPSsbmmlaÎncă nu există evaluări

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Document2 paginiQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Co D E)Vaibhav GuptaÎncă nu există evaluări

- WPS&PQR FormsDocument4 paginiWPS&PQR FormsArab WeldersÎncă nu există evaluări

- Welding Procedure SpecificationDocument12 paginiWelding Procedure Specificationsanjay sharmaÎncă nu există evaluări

- WPS FormatDocument3 paginiWPS Formatvivek bhangaleÎncă nu există evaluări

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 paginiForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad MunadiÎncă nu există evaluări

- WPS & WPQR (Asme Section IX)Document7 paginiWPS & WPQR (Asme Section IX)Rizaldy PhoenksÎncă nu există evaluări

- QW 482Document4 paginiQW 482Jesus Silva HenaoÎncă nu există evaluări

- Welding Procedure Specification (WPS) : JOINTS (QW-402)Document4 paginiWelding Procedure Specification (WPS) : JOINTS (QW-402)Andhira FarizkiÎncă nu există evaluări

- QW 406 Asme CodeDocument3 paginiQW 406 Asme CodeMardeOpamenÎncă nu există evaluări

- FORM QW-482 (Back) : ASME BPVC - IX-2019Document1 paginăFORM QW-482 (Back) : ASME BPVC - IX-2019Balkishan DyavanapellyÎncă nu există evaluări

- Suggested Format PQRDocument2 paginiSuggested Format PQRAngel RebolloÎncă nu există evaluări

- BPVC Ix QW-482Document2 paginiBPVC Ix QW-482ganesh82Încă nu există evaluări

- Form PQR 1 AsmeDocument6 paginiForm PQR 1 AsmeZam Zam NoorÎncă nu există evaluări

- Form Qw-483 Suggested Format For Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code) Record Actual Variables Used To Weld Test CouponDocument2 paginiForm Qw-483 Suggested Format For Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code) Record Actual Variables Used To Weld Test CouponMijanur Rahman100% (1)

- ASME BPVC - IX-2019: FORM QW-482 (Back)Document1 paginăASME BPVC - IX-2019: FORM QW-482 (Back)Pepe PedroÎncă nu există evaluări

- Fillet Inspection SheetDocument2 paginiFillet Inspection SheetShankey JAlanÎncă nu există evaluări

- QW 483Document2 paginiQW 483delta lab sangliÎncă nu există evaluări

- Wps FormatDocument2 paginiWps FormatParminder SinghÎncă nu există evaluări

- SAMPLE FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR) BPVC - Ix - qw-483Document2 paginiSAMPLE FORMAT FOR PROCEDURE QUALIFICATION RECORDS (PQR) BPVC - Ix - qw-483Lovedeep SinghÎncă nu există evaluări

- BPVC Ix qw-483 PDFDocument2 paginiBPVC Ix qw-483 PDFEmma DÎncă nu există evaluări

- BPVC Ix qw-483 PDFDocument2 paginiBPVC Ix qw-483 PDFazizÎncă nu există evaluări

- BPVC Ix qw-483 PDFDocument2 paginiBPVC Ix qw-483 PDFEmma DÎncă nu există evaluări

- BPVC Ix qw-483 PDFDocument2 paginiBPVC Ix qw-483 PDFEmma DÎncă nu există evaluări

- BPVC Ix qw-483 PDFDocument2 paginiBPVC Ix qw-483 PDFedinson castrilloÎncă nu există evaluări

- BPVC Ix qw-483 PDFDocument2 paginiBPVC Ix qw-483 PDFDwi Agus YuliyantoÎncă nu există evaluări

- Qw-483 Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)Document3 paginiQw-483 Procedure Qualification Records (PQR) (See QW-200.2, Section IX, ASME Boiler and Pressure Vessel Code)Zam Zam NoorÎncă nu există evaluări

- Wps PQR FormDocument8 paginiWps PQR Formmayank0738Încă nu există evaluări

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document2 paginiForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)MALABAR TIMESÎncă nu există evaluări

- WPS 1310Document2 paginiWPS 1310paulÎncă nu există evaluări

- Automatic, Manual, Machine, or Semi-Auto.Document10 paginiAutomatic, Manual, Machine, or Semi-Auto.ChE_MattÎncă nu există evaluări

- WPS Format PDFDocument2 paginiWPS Format PDFHimansu Sekhar JenaÎncă nu există evaluări

- WPS-PQR Gr. CF8MDocument9 paginiWPS-PQR Gr. CF8Mansarmulla711Încă nu există evaluări

- WPS-PQR Gr. WCBDocument9 paginiWPS-PQR Gr. WCBansarmulla711Încă nu există evaluări

- Qw-482 Welding Procedure Specification (WPS)Document3 paginiQw-482 Welding Procedure Specification (WPS)Sagar GourÎncă nu există evaluări

- (Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Document6 pagini(Refer To The Both Backing and Retainers) (Metal /non Fusing Metal /Non-Metallic /others)Saifulla CmpÎncă nu există evaluări

- PQR - 007 샘플Document2 paginiPQR - 007 샘플주용환Încă nu există evaluări

- PQR - 007 샘플Document2 paginiPQR - 007 샘플주용환Încă nu există evaluări

- Metals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Document6 paginiMetals Inspection Services, Inc.: QW - 482 Suggested Format For Welding Procedure Specification (WPS)Luis MuñozÎncă nu există evaluări

- Form PQR 2 AsmeDocument6 paginiForm PQR 2 AsmeZam Zam NoorÎncă nu există evaluări

- Joints (Qw-402) DetailsDocument3 paginiJoints (Qw-402) DetailsNaqqash SajidÎncă nu există evaluări

- 653 WPS-PQR PDFDocument4 pagini653 WPS-PQR PDFETSÎncă nu există evaluări

- Wps Magi Tig Exemple PDFDocument6 paginiWps Magi Tig Exemple PDFJaime PatrónÎncă nu există evaluări

- How to prepare Welding Procedures for Oil & Gas PipelinesDe la EverandHow to prepare Welding Procedures for Oil & Gas PipelinesEvaluare: 5 din 5 stele5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADe la EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AÎncă nu există evaluări

- ESAB Electrodes User ManualDocument44 paginiESAB Electrodes User ManualF. Alijani100% (1)

- Hempel's Thinner 0845000000 En-UsDocument10 paginiHempel's Thinner 0845000000 En-UsJose F. MaestreÎncă nu există evaluări

- HealthDocument123 paginiHealthakhilsyam21Încă nu există evaluări

- Prakrithi Enna VismayamDocument159 paginiPrakrithi Enna Vismayamakhilsyam21Încă nu există evaluări

- Qa QC DifferenceDocument1 paginăQa QC Differenceakhilsyam21Încă nu există evaluări

- AFM-Mild Steel Low Hydrogen ElectrodesDocument12 paginiAFM-Mild Steel Low Hydrogen Electrodesakhilsyam21Încă nu există evaluări

- O2 AnalyzerDocument20 paginiO2 Analyzerakhilsyam21Încă nu există evaluări

- 2020 Answe KeyDocument1 pagină2020 Answe KeyParameswaran T.N.Încă nu există evaluări

- Sister Nivedita 1Document116 paginiSister Nivedita 1akhilsyam21Încă nu există evaluări

- Lincguns EngDocument6 paginiLincguns Engakhilsyam21Încă nu există evaluări

- 003 2020 M Set ADocument16 pagini003 2020 M Set AVyshakhanÎncă nu există evaluări

- Weld TestingDocument51 paginiWeld TestingYuki FongÎncă nu există evaluări

- A New Dawn (Eng) PDFDocument16 paginiA New Dawn (Eng) PDFBrijeshÎncă nu există evaluări

- Omi PB 02 0 Eng Plug ValveDocument4 paginiOmi PB 02 0 Eng Plug Valveakhilsyam21Încă nu există evaluări

- HDPE Pipe Installation GuideDocument48 paginiHDPE Pipe Installation GuideAkhil Syamkumar86% (7)

- Torque ValuesDocument1 paginăTorque Valuesakhilsyam21Încă nu există evaluări

- True Rms Clampmeter Fluke 325Document5 paginiTrue Rms Clampmeter Fluke 325akhilsyam21Încă nu există evaluări

- Weld DefectsDocument80 paginiWeld Defectsakhilsyam21100% (1)

- Heat Treatment of SteelDocument35 paginiHeat Treatment of Steelakhilsyam21Încă nu există evaluări

- PipingDocument54 paginiPipingakhilsyam21Încă nu există evaluări

- P NumbersDocument2 paginiP Numbersakhilsyam21Încă nu există evaluări

- S-Curve Module ExamplesDocument7 paginiS-Curve Module Examplesakhilsyam21Încă nu există evaluări

- Instructor GuideDocument4 paginiInstructor Guideakhilsyam21Încă nu există evaluări

- Pipe DataDocument1 paginăPipe Dataakhilsyam21Încă nu există evaluări

- Introduction To CorrosionDocument35 paginiIntroduction To Corrosionakhilsyam21Încă nu există evaluări

- Learning Spoken EnglishDocument54 paginiLearning Spoken EnglishSarah JT93% (87)

- Registration Form Saudi Prometric ExamDocument4 paginiRegistration Form Saudi Prometric Examakhilsyam21100% (1)

- Low Alloy WiresDocument10 paginiLow Alloy WiresRyan KimÎncă nu există evaluări

- Introduction To Nondestructive TestingDocument34 paginiIntroduction To Nondestructive TestingNanditha Mandava ChowdaryÎncă nu există evaluări

- Miter ElbowDocument4 paginiMiter Elbowakhilsyam21Încă nu există evaluări

- Influence of Nano - Sized Powder Content On Physical Properties of Waste Acid Refractory BrickDocument19 paginiInfluence of Nano - Sized Powder Content On Physical Properties of Waste Acid Refractory BrickamnajamÎncă nu există evaluări

- TRIVAL ANTENE - General Catalogue 2015-10-0Document232 paginiTRIVAL ANTENE - General Catalogue 2015-10-0Stanko Recek100% (1)

- Multibio BrochureDocument1 paginăMultibio Brochuree-ComfortUSAÎncă nu există evaluări

- Best Practices Nightlife 2d Ed 2011Document30 paginiBest Practices Nightlife 2d Ed 2011johnd7463Încă nu există evaluări

- Hotel Cleaning Equipment Used byDocument9 paginiHotel Cleaning Equipment Used byLeonardo ViridisÎncă nu există evaluări

- Seipl Profile and CapabilitiesDocument32 paginiSeipl Profile and CapabilitiesAbhishek GuptaÎncă nu există evaluări

- 2 BoilersDocument83 pagini2 BoilersSurasan ThepsiriÎncă nu există evaluări

- Applications of Statistics and Probability in Civil EngineeringDocument9 paginiApplications of Statistics and Probability in Civil EngineeringAlexis CruzÎncă nu există evaluări

- Self - FRIO SLIM - Datesheet - enDocument5 paginiSelf - FRIO SLIM - Datesheet - enJuan Carlos Gomez Lopez-ViotaÎncă nu există evaluări

- 7 Golden Rules of Mobile Testing TemplateDocument36 pagini7 Golden Rules of Mobile Testing Templatestarvit2Încă nu există evaluări

- Windows 10Document28 paginiWindows 10Vibal PasumbalÎncă nu există evaluări

- Buku Program Kopo 18Document20 paginiBuku Program Kopo 18Mieza Binti YusoffÎncă nu există evaluări

- ASOC Exam Study Based On Latest Syllabus IndiaDocument238 paginiASOC Exam Study Based On Latest Syllabus IndiaBiju Gopi ThilakaÎncă nu există evaluări

- Polymer and Web ComponentsDocument26 paginiPolymer and Web ComponentsAdjetey Adjei-laryeaÎncă nu există evaluări

- Fire Risk Assessment ChecklistDocument10 paginiFire Risk Assessment Checklistm. absiyeÎncă nu există evaluări

- Women in LeadershipDocument17 paginiWomen in LeadershipSodfa EttafakshiÎncă nu există evaluări

- A1NM Rev 30 TYPE CERTIFICATE DATA SHEET A1NM 767Document16 paginiA1NM Rev 30 TYPE CERTIFICATE DATA SHEET A1NM 767MuseÎncă nu există evaluări

- Referencing Using The Documentary-Note (Oxford) System, Deakin UniversityDocument9 paginiReferencing Using The Documentary-Note (Oxford) System, Deakin UniversityjengadjÎncă nu există evaluări

- FE107 Experimental ResultsDocument11 paginiFE107 Experimental ResultsEsapermana RiyanÎncă nu există evaluări

- Aa1a32 02Document3 paginiAa1a32 02MramirezÎncă nu există evaluări

- K13 High-Flex Waterproofing SlurryDocument3 paginiK13 High-Flex Waterproofing SlurryAmila SampathÎncă nu există evaluări

- 2014 Rude Customer ServiceDocument3 pagini2014 Rude Customer ServiceCaptain WalkerÎncă nu există evaluări

- An Overview of Load Flow Analysis Methods For Electrical Distribution NetworksDocument3 paginiAn Overview of Load Flow Analysis Methods For Electrical Distribution NetworksSantosh Ramana Kumar JogaÎncă nu există evaluări

- IT Audit Exercise 2Document1 paginăIT Audit Exercise 2wirdinaÎncă nu există evaluări

- 5 Star SynopsisDocument22 pagini5 Star Synopsisabdul wahidÎncă nu există evaluări

- Guide To Port Entry CD: Frequently Asked Questions (FAQ)Document6 paginiGuide To Port Entry CD: Frequently Asked Questions (FAQ)Gonçalo CruzeiroÎncă nu există evaluări